Vapor deposition source and vapor deposition apparatus having the same

An evaporation source and evaporation technology, which is applied in the direction of vacuum evaporation coating, coin-operated equipment for distributing discrete items, sputtering coating, etc., can solve the problems of increasing the evaporation source and the installation cost of heat insulation materials, etc. To achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, the evaporation source and the evaporation apparatus using the evaporation source of the present invention will be described in detail with reference to the drawings.

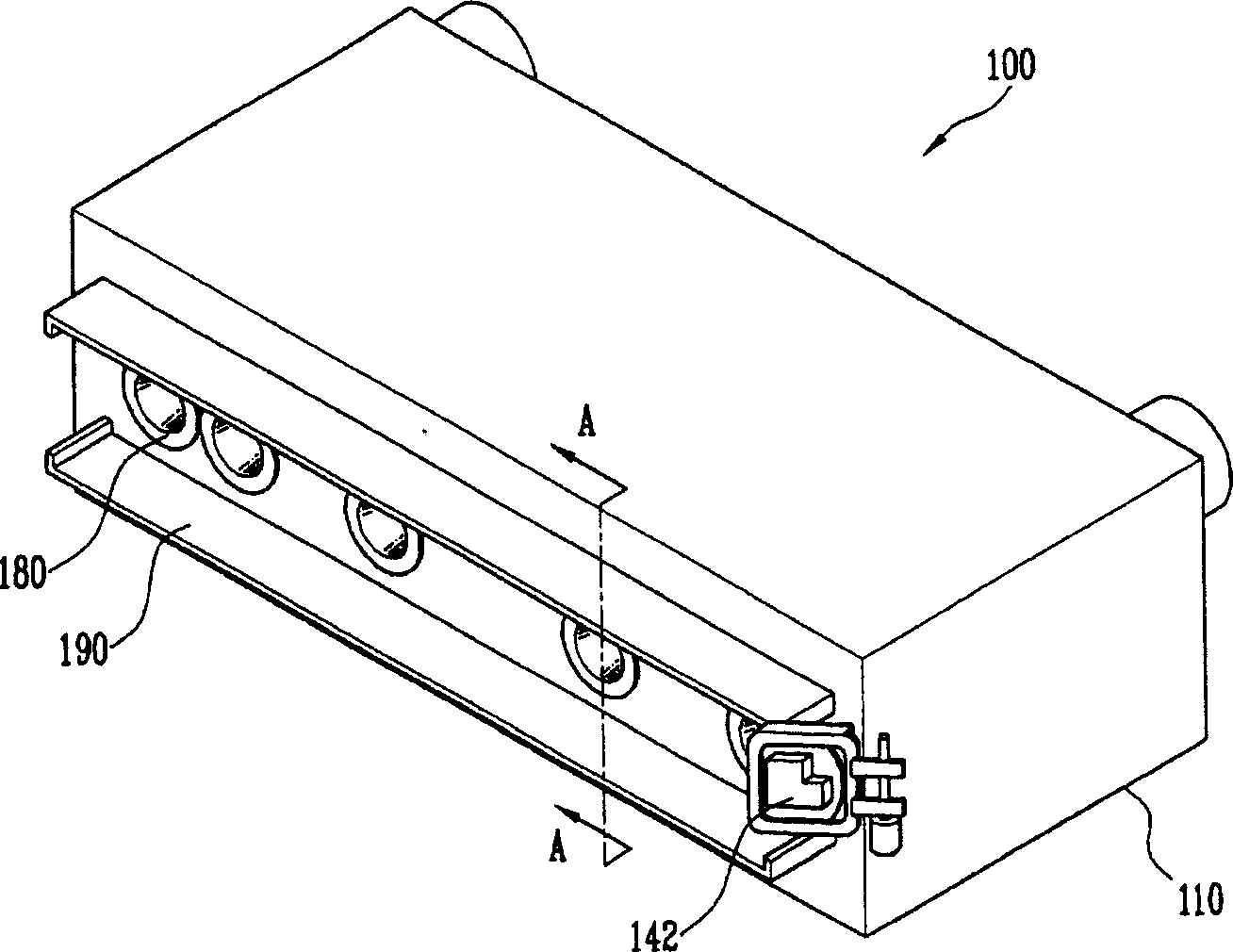

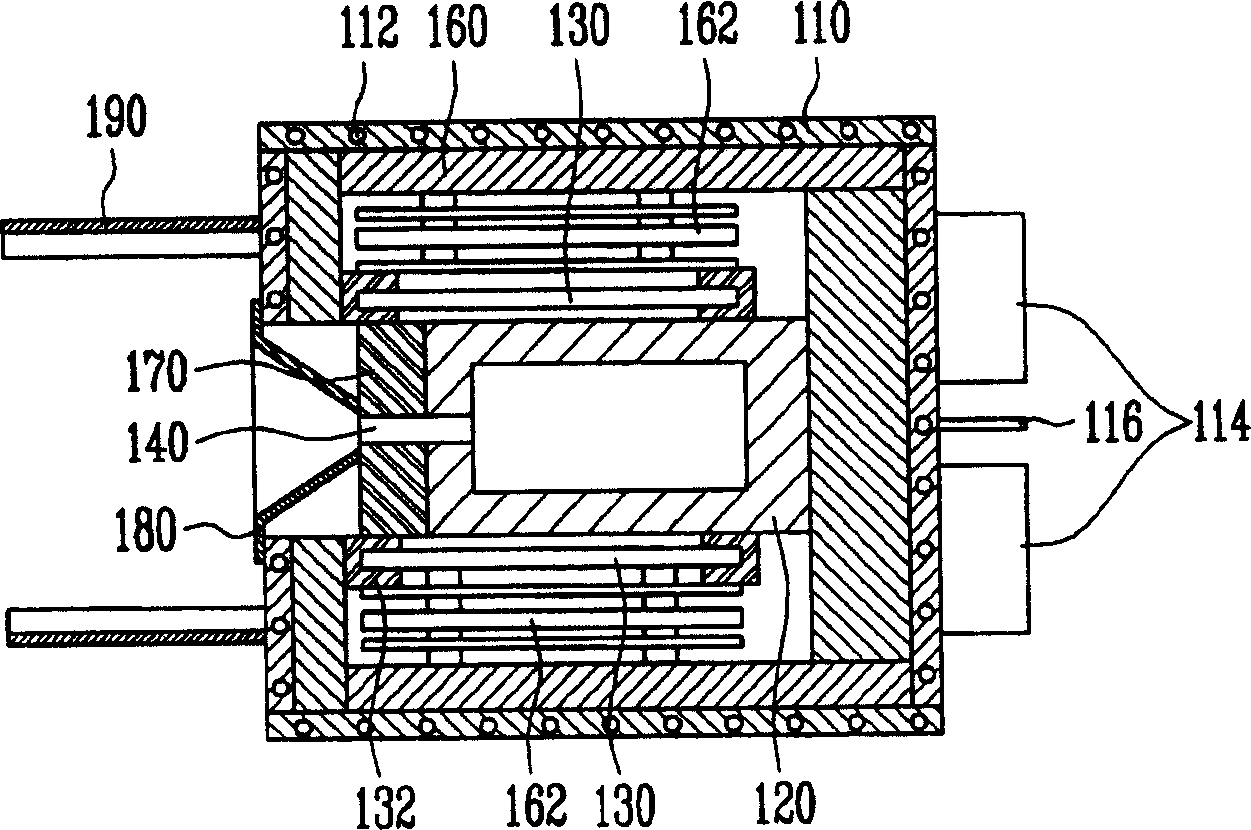

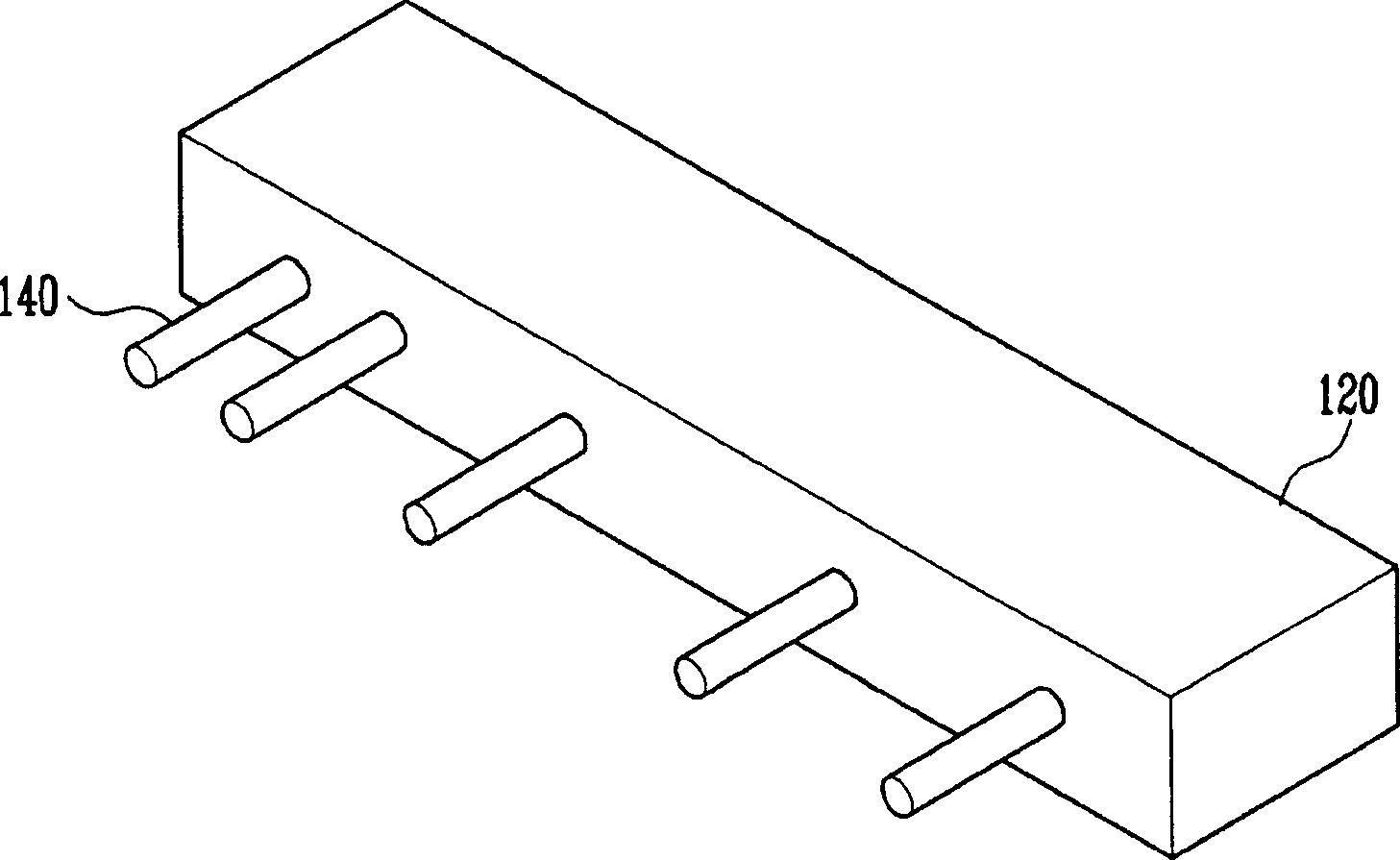

[0038] figure 1 It is a perspective view schematically showing an evaporation source of an ideal embodiment of the present invention; figure 2 is along figure 1 Sectional view of line A-A. Referring to the accompanying drawings, the evaporation source 100 of the present invention includes a crucible 120 disposed inside the housing 110, a heating portion having a heater 130 for heating the crucible 120, a heat insulating material having a plurality of heat insulating materials covering the heating portion. part and a nozzle part communicating with the crucible 120 and having a spray nozzle 140 for spraying the vapor deposition material to the outside.

[0039] The crucible 120 accommodates vapor deposition substances, and in order to heat the crucible 120, a heater 130 is arranged around ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com