Carrying device

A conveying device and conveyor technology, applied in the direction of conveyors, vibrating conveyors, conveyor objects, etc., can solve problems such as problems that cannot be completely eliminated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

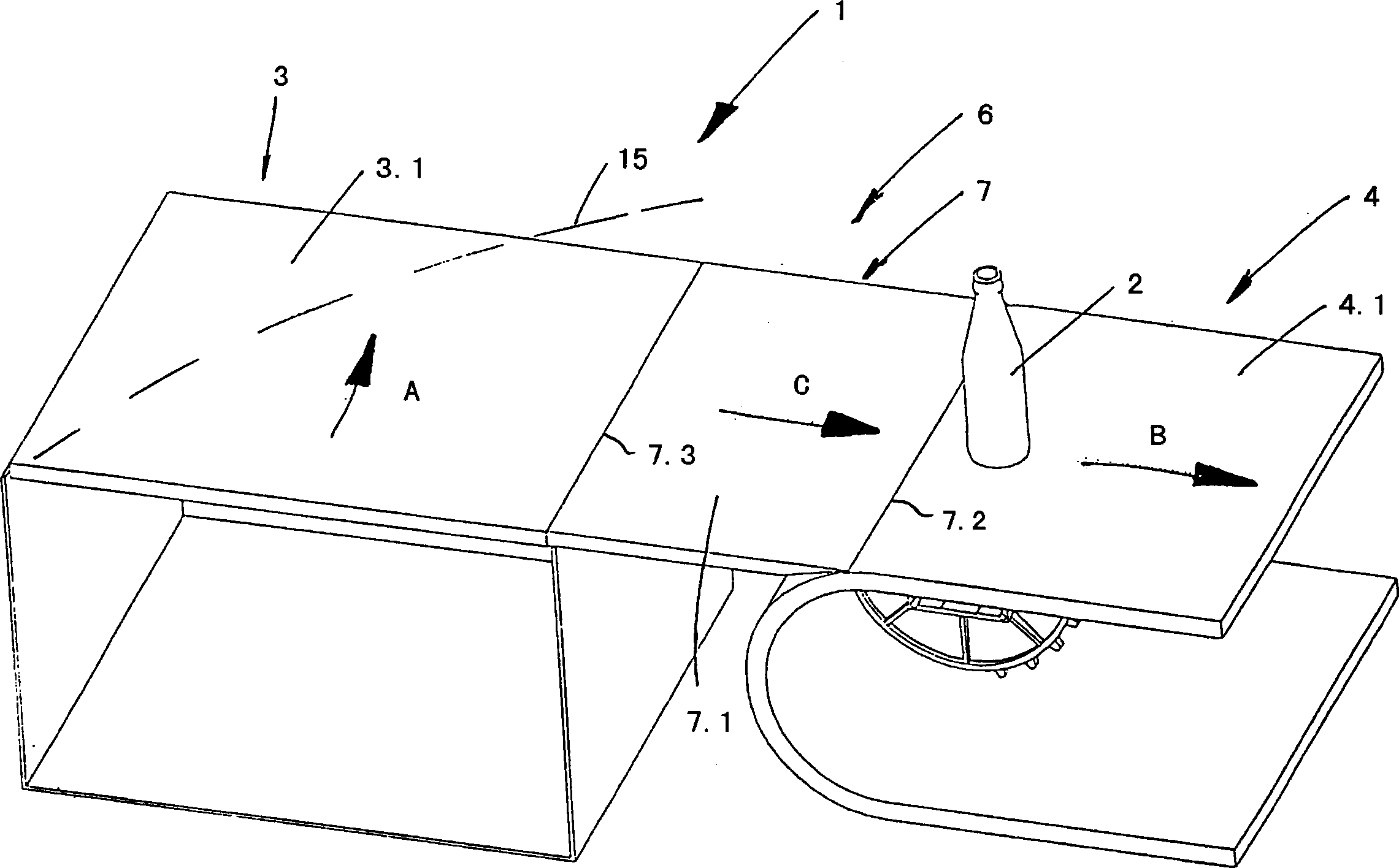

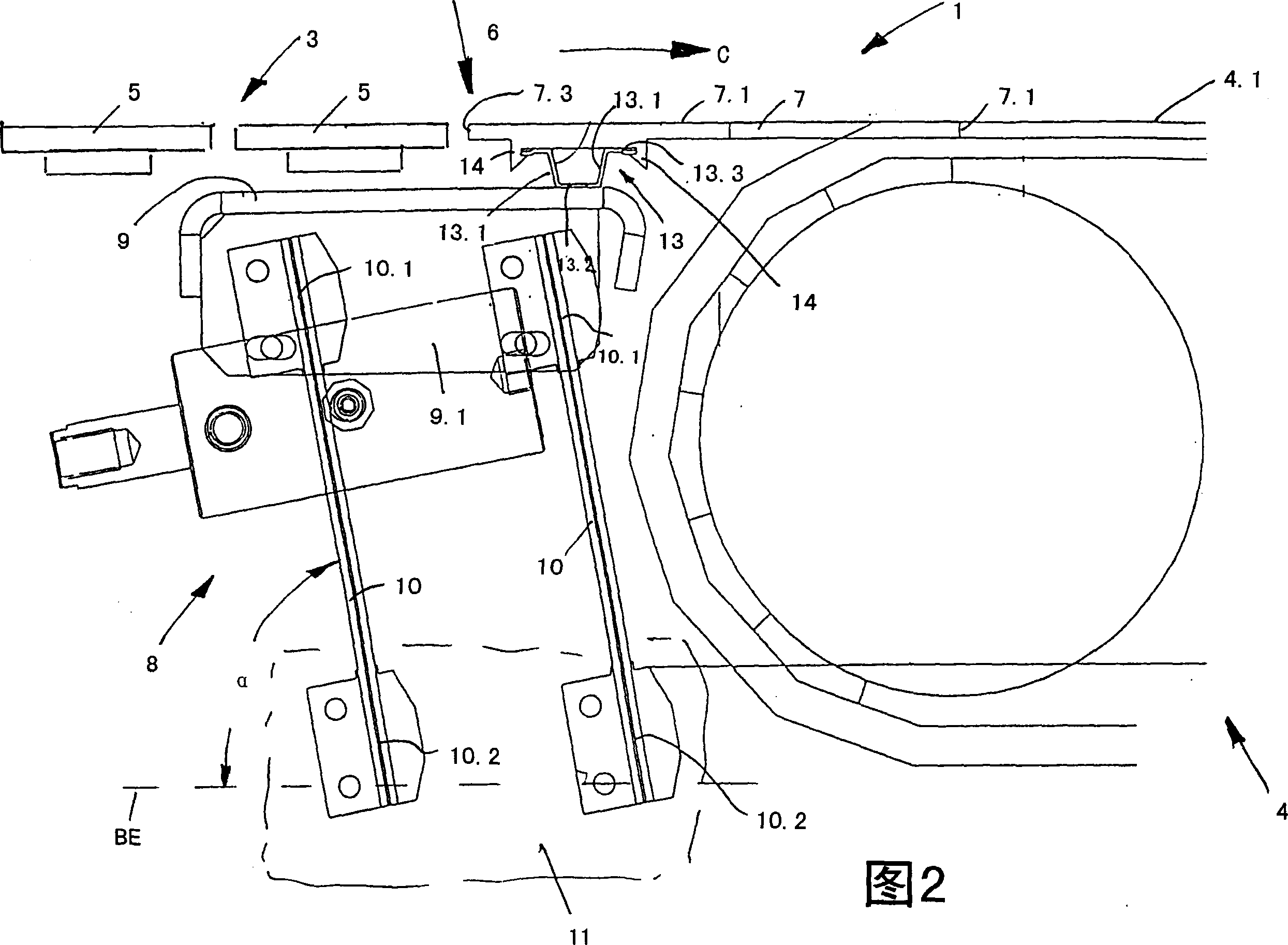

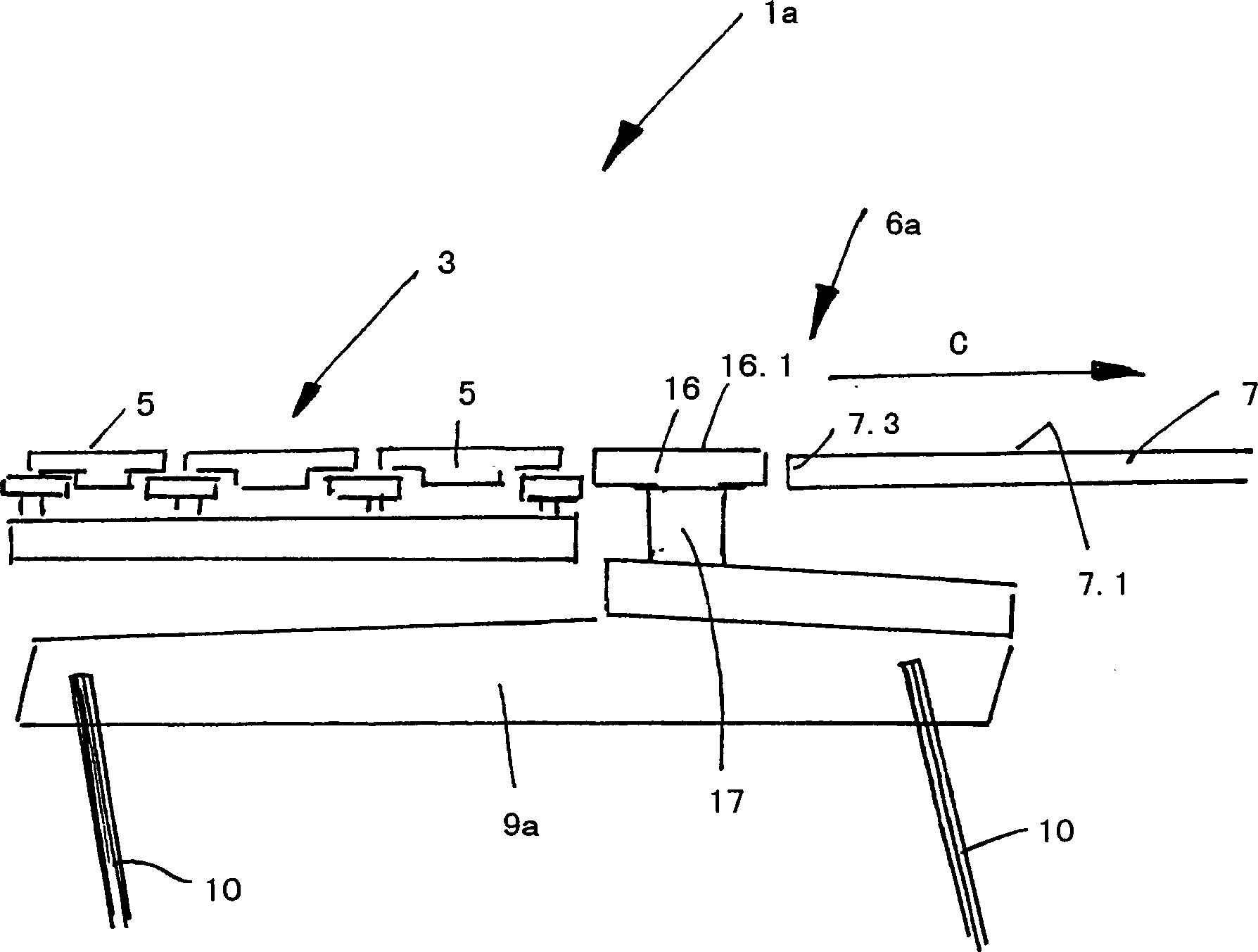

[0027] The conveying device generally indicated with 1 in the drawings for conveying bottles 2 or similar containers mainly comprises two conveyors 3 and 4, wherein the conveyor 4 is used, for example, to guide away bottles 2 from a processing machine, for example from A sterilizer (Pasteur) guides away the filled and closed bottles 2, and the conveyor 3 constitutes the transfer or conveying section of the processing machine, for example the sterilizer, on which the bottles 2 are guided to Sent through a processing machine, for example through a tunnel furnace of the sterilizer.

[0028] On the conveyors 3 and 4 or on the conveying surfaces 3.1 or 4.1 of these conveyors, the bottles 2 are respectively placed upright, that is to say with their bottle axes oriented in the vertical direction. Conveyor belts or hinged belt chains (Scharnierbandketten) connected to each other laterally (Fig. 2 and image 3 ), which are driven circumferentially by means of corresponding drives, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com