Three-dimesnional visual camera measuring device with large scene based on calibrating technology

A technology of stereo vision and photogrammetry, applied in the directions of measuring devices, photogrammetry/video metrology, surveying and navigation, etc., to achieve the effect of easy realization, good shooting effect and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

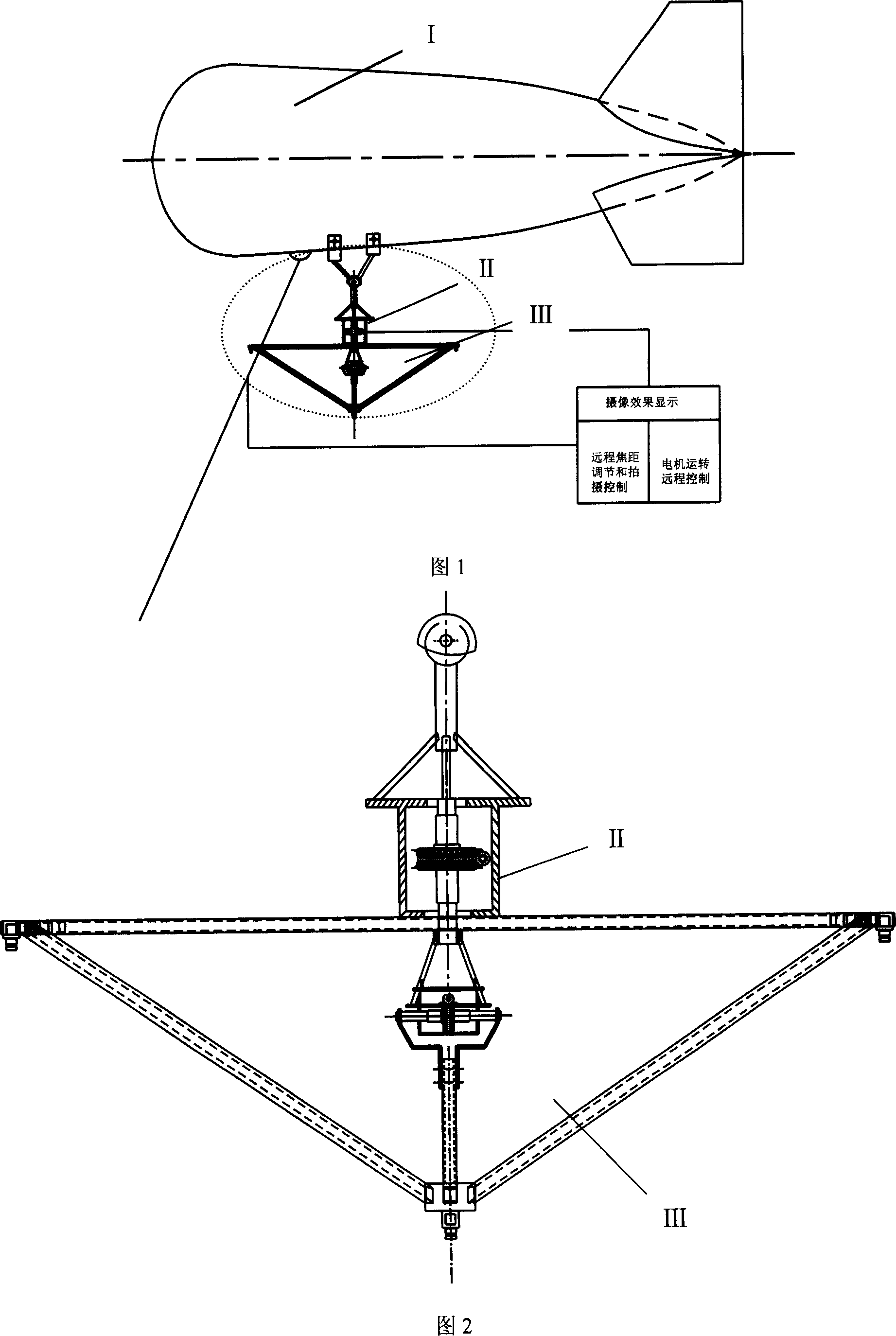

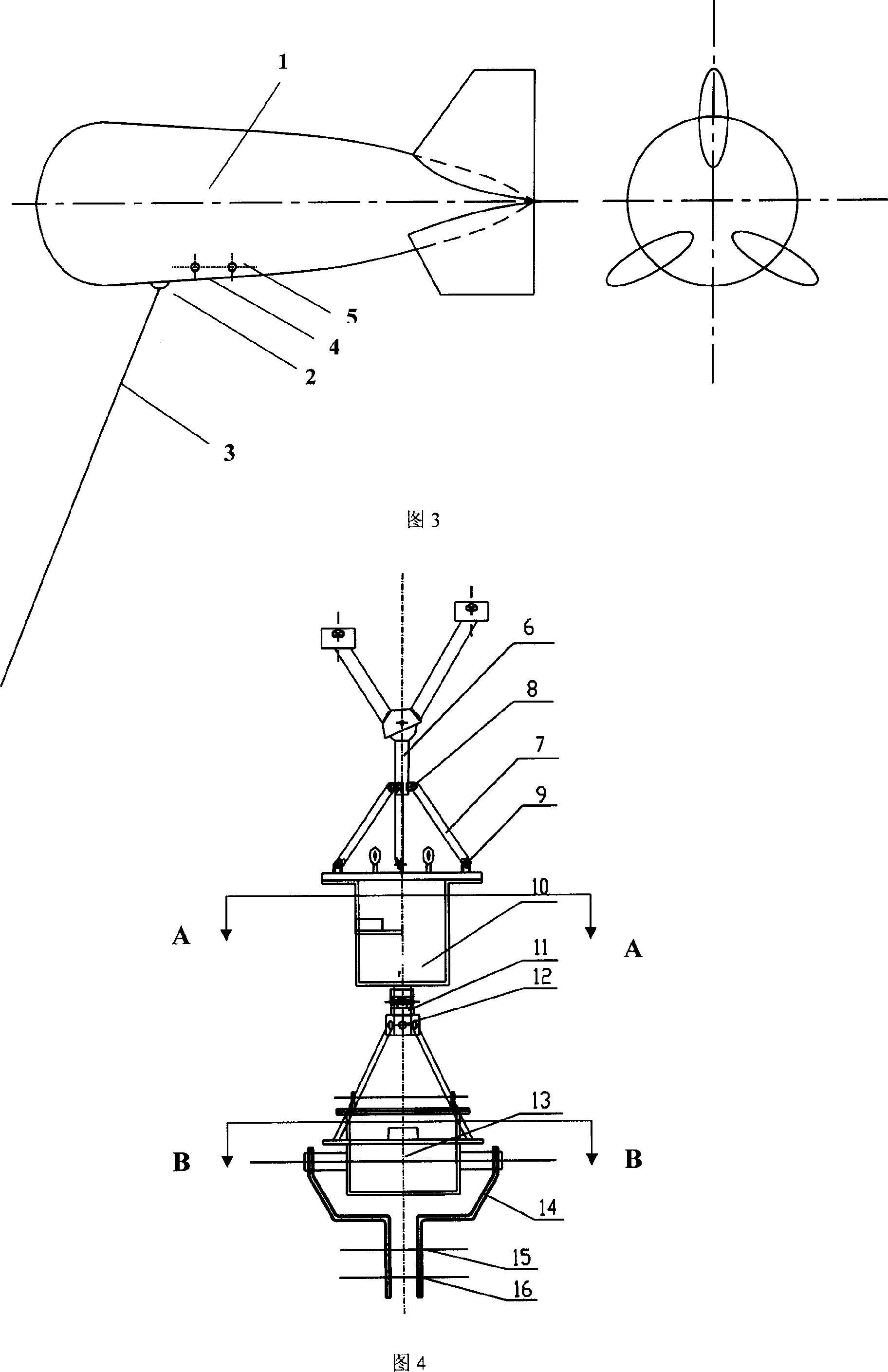

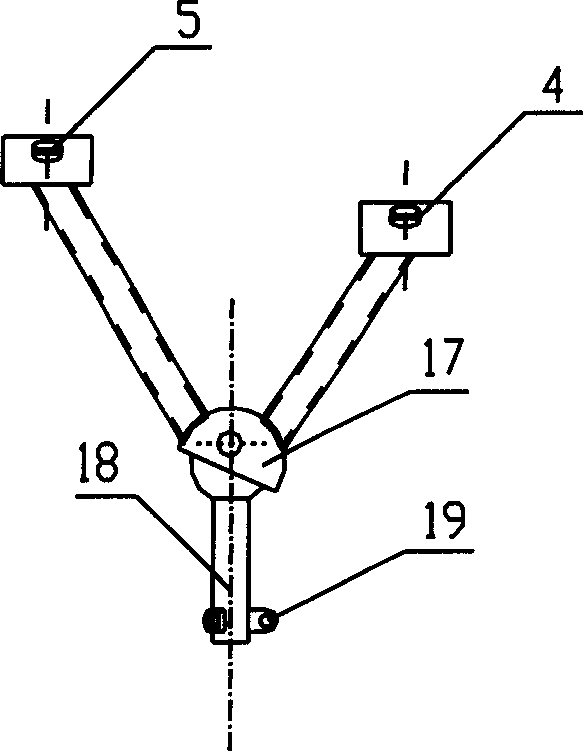

[0037] Figure 1 and Figure 2 are schematic diagrams of the overall structure of the photogrammetry device. It can be seen from the figure that the device includes a power part I for launching a balloon, a photographing orientation control part II and a stereo vision photographing part III. The air balloon power part I is the power source of the entire photogrammetry device; the photographic orientation control part II is a functional component that adjusts the camera orientation in three-dimensional space; the stereo vision photography part III is the photographic image combined with the self-calibration principle of the stereo vision camera Collection features.

[0038] The composition and functions of each part are as follows:

[0039] 1) Lift-off balloon power part I (Fig. 3)

[0040] The power part of the air balloon is composed of a balloon 1, a tether shackle 2 and a tether 3.

[0041] The balloon filled with light gas is the lift-off power source of the photogrammetr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com