Seal for an antifriction bearing

A technology of rolling bearings and seals, which is applied in the field of elastic sealing discs, can solve problems such as the influence of the service life of rolling bearings, increase the heating of rolling bearings, and the loss of lubricating oil, and achieve the effect of simple and damage-free assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

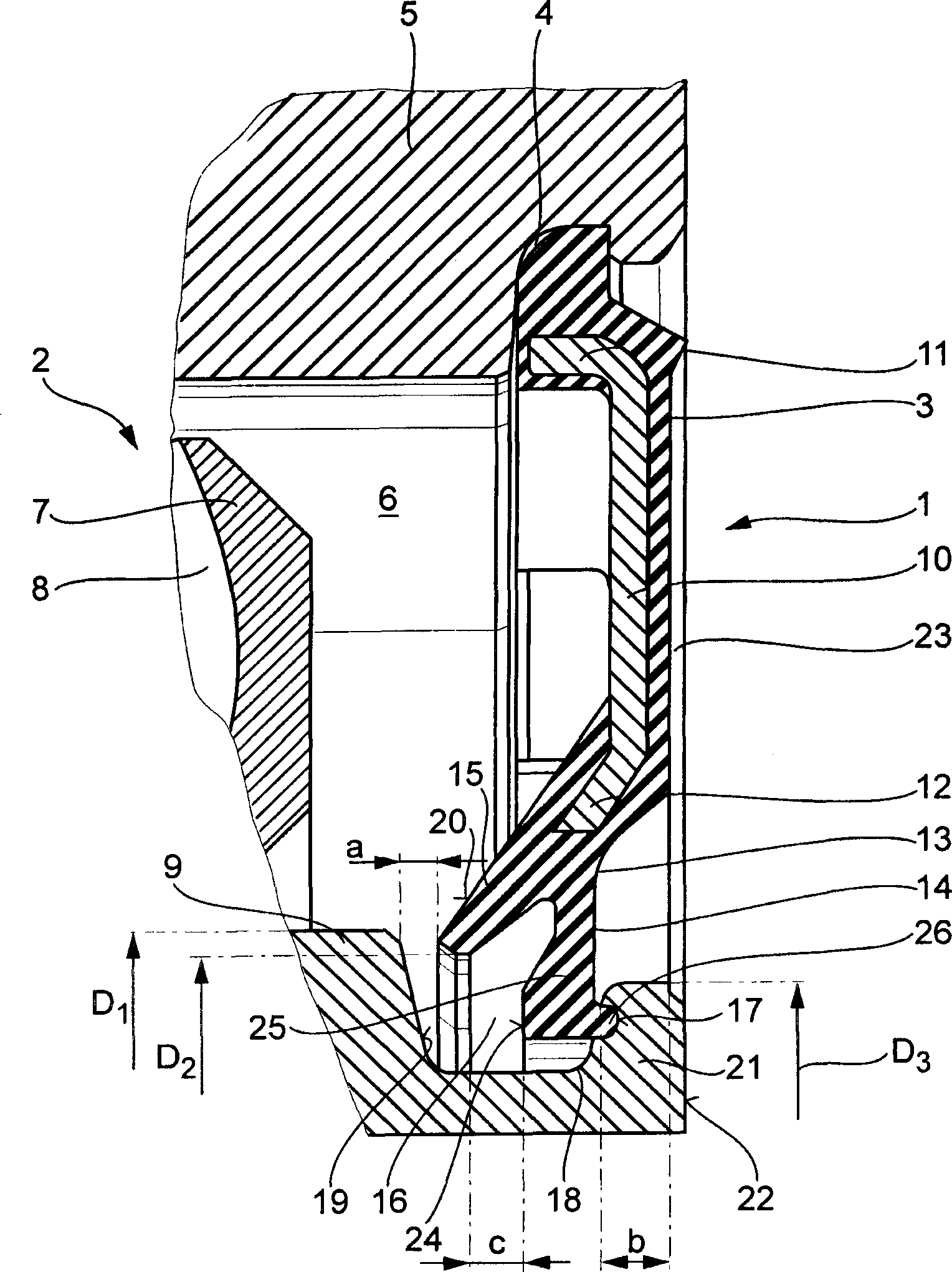

[0021] The single figure shows the structure of a seal 1 according to the invention for a rolling bearing 2 in the assembled state. The seal 1 comprises a sealing disk 3 , which is fastened on the outer circumference in an elastic form-fitting manner in an annular groove 4 of an outer circumferential bearing ring 5 . The sealing disk 3 surrounded by the bearing ring 5 closes the annular installation space 6 of the rolling bearing 2 , into which the rolling elements 8 guided in the rolling element cage 7 are inserted, which are guided between the outer bearing ring 5 and the inner bearing ring 9 in orbit. For increased strength, the sealing disc 3 made of elastic sealing material is provided with a core bone 10 which is designed in the form of a disc. In the direction of the outer bearing ring 5 , the core rib 10 forms a right-angled chamfered rib 11 . In the direction of the inner bearing ring 9 the core bar 10 comprises inwardly inclined legs 12 .

[0022] Consistently, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com