Hollow pipe for concrete

一种空心管、管体的技术,应用在模壳/模板/工作架、建筑构件、建筑构件在现场的制备等方向,能够解决无法形成井字肋等效双向板、刚度大等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

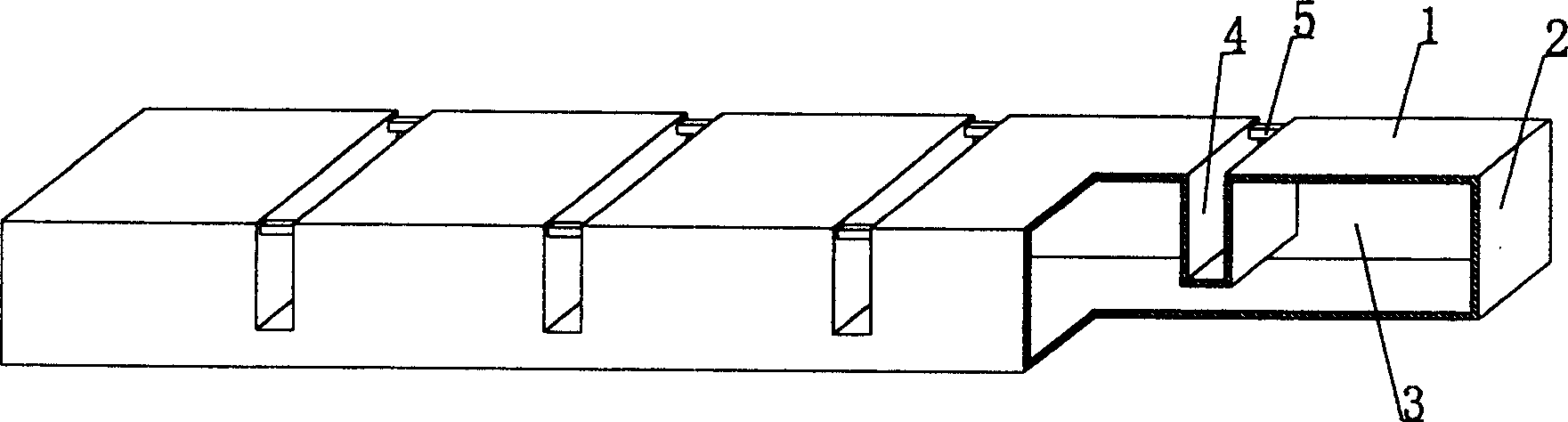

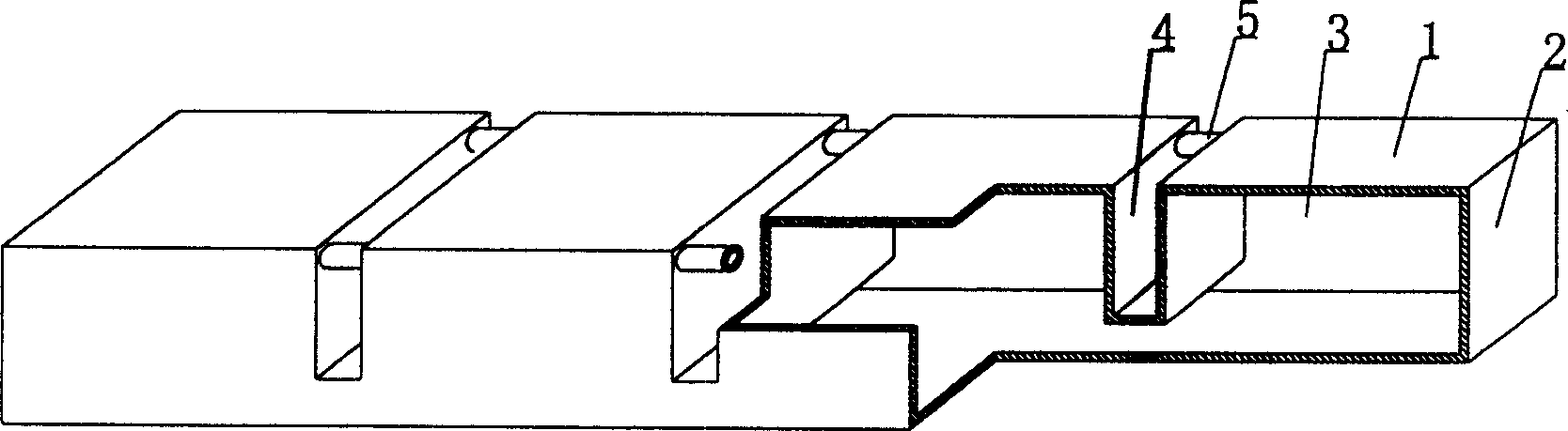

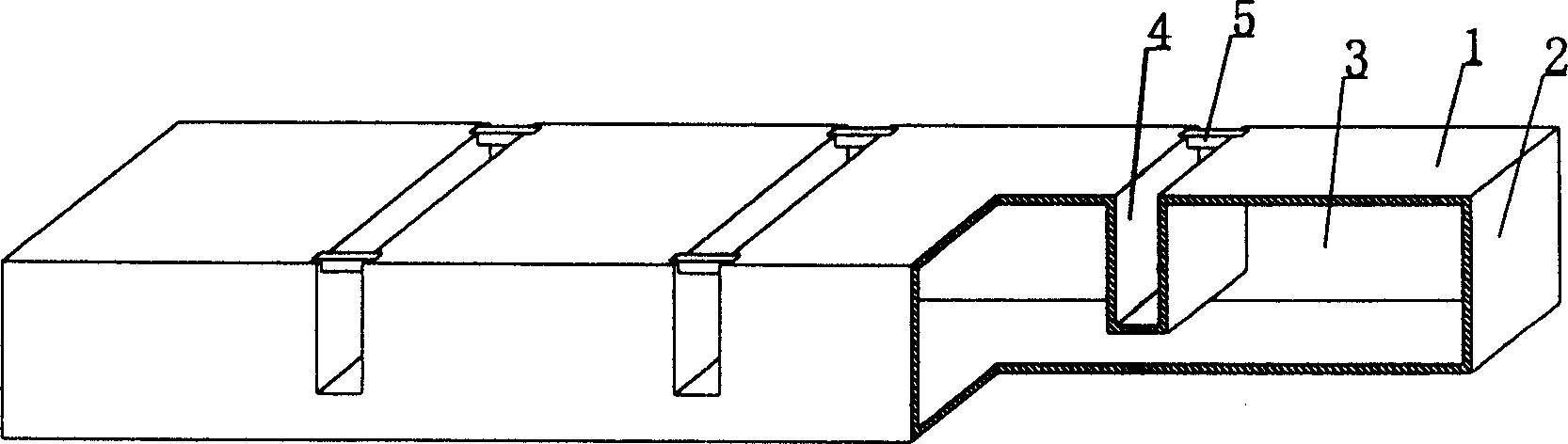

[0057] As shown in the accompanying drawings, the present invention includes a pipe body 1 and a pipe end cap 2. The two pipe end caps 2 seal off both ends of the pipe body 1 to form a closed cavity 3. It is characterized in that the pipe body 1 is provided with at least One groove 4, at least three grooves 4 are provided with at least one brace 5, the grooves 4 are arranged in parallel, at least one of the pipe body 1 or the pipe end head 2 is wrapped with a reinforcement 9, and the reinforcement 9 is At least one of steel bar, steel wire, steel mesh, steel wire mesh, steel mesh, fiber, fiber mesh or cloth, thin metal strip, thin strip with holes, thin strip with convex nails, braided tape or packing tape. figure 1 It is a structural schematic diagram of Embodiment 1 of the present invention. In the accompanying drawings, 1 is a pipe body, 2 is a pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com