Anti-flood water blocking plate

The technology of a water retaining plate and a stainless steel plate is applied in the direction of anti-war damage and sealing device, which can solve the problems of falling off, loss of wood, time-consuming and labor-consuming, etc., and achieves the effect of novel structure, good sealing performance and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

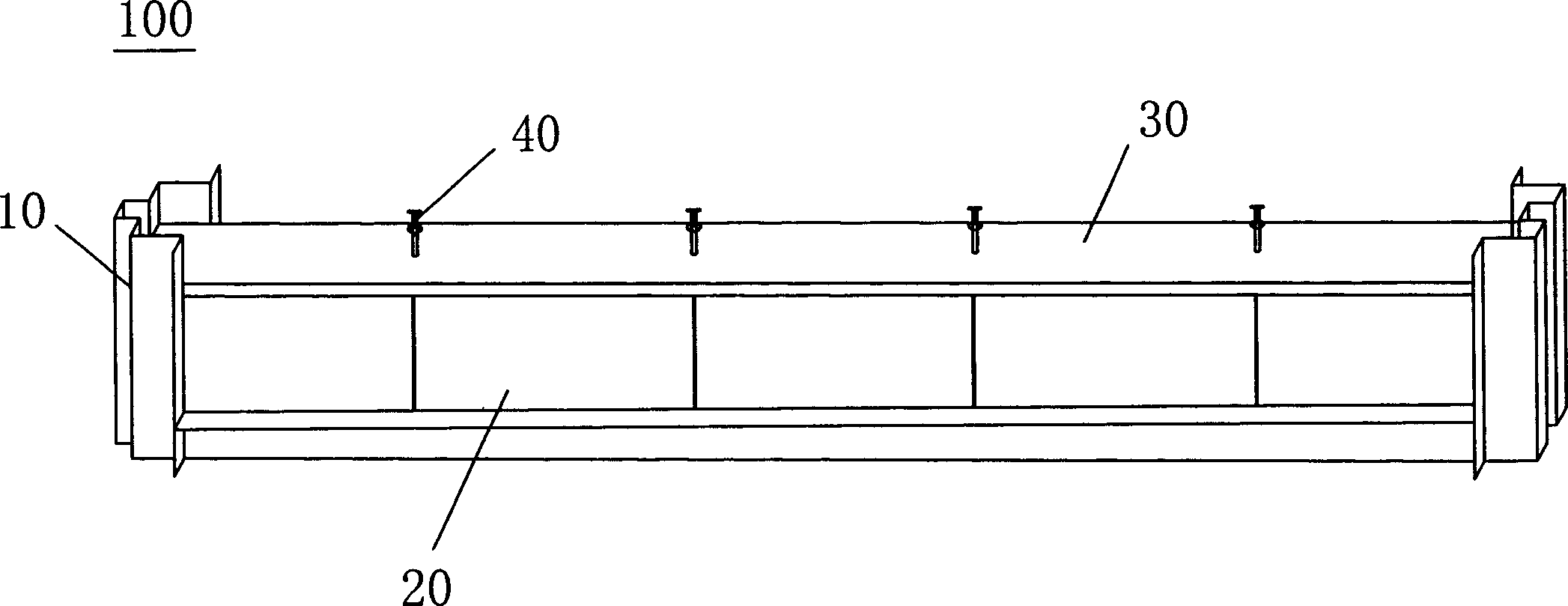

[0027] see figure 1 As shown, the embodiment of the flood control baffle 100 of the present invention includes a sealing frame 10 , a plurality of single panels 20 , a gland 30 and a tightening screw 40 . Among them, the ""-shaped sealing frame 10 is fixed on the door frame that needs to be protected against floods, and a plurality of single panels 20 are combined and installed on the sealing frame. 40 passes through the gland 30 and the single plate 20, the lower end of the lifting screw 40 is fixed on the sealing frame, and the upper end locks the gland tightly, so that the whole flood control baffle is integrated as a whole.

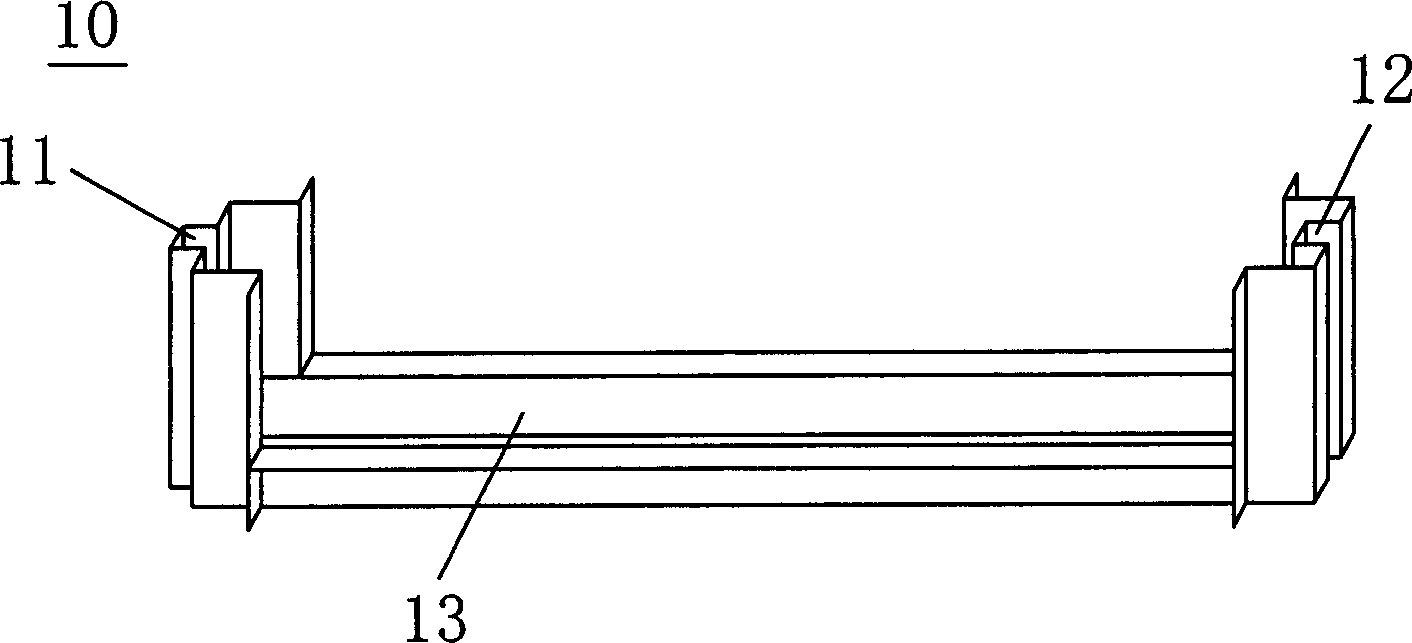

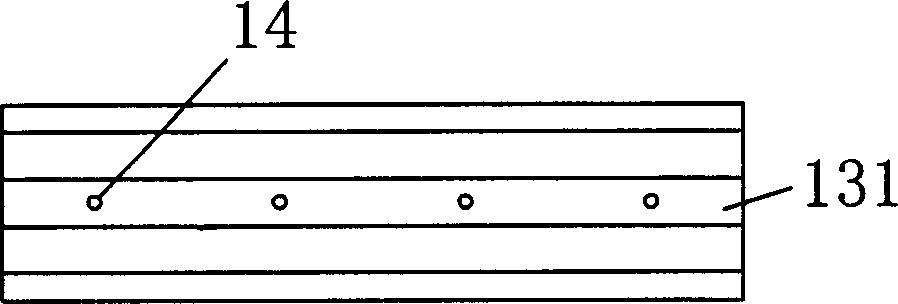

[0028] The following combination Figure 2 ~ Figure 6 Describe the structure of each part.

[0029] figure 2 yes figure 1 Schematic diagram of the sealing frame structure of the illustrated embodiment. see figure 2 , the sealing frame 10 is in the shape of "", fixed on the door frame with expansion screws, and then sealed with cement mortar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com