Automatic detecting device and method for TV set

An automatic detection device, TV technology, applied in the direction of TV, electrical components, image communication, etc., can solve the problems of inability to realize fully automatic debugging and inspection, low efficiency, etc., to improve operational efficiency and accuracy, and realize full automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

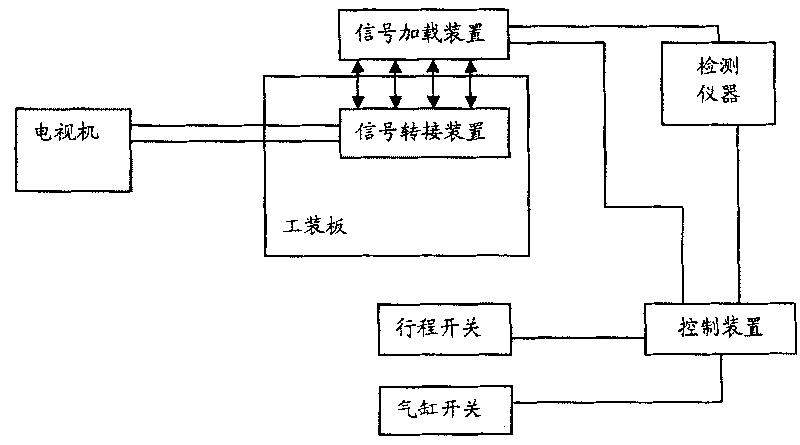

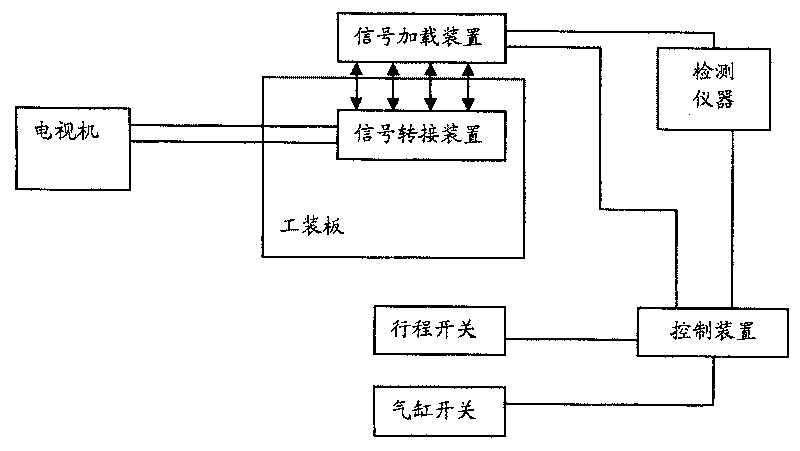

[0035] A TV automatic detection device, combined with figure 1 , including assembly line (not shown in the figure), tooling board, signal transfer device, signal loading device, control device, station start-stop device, and testing instrument.

[0036] The tooling board is a carrying device placed on the assembly line, which is driven by the assembly line to flow and can carry the TV set; the signal transfer device is fixed on the tooling board;

[0037] The assembly line is a transmission mechanism for directional movement, and is equipped with several detection stations, and each detection station is equipped with a signal loading device and a station start-stop device;

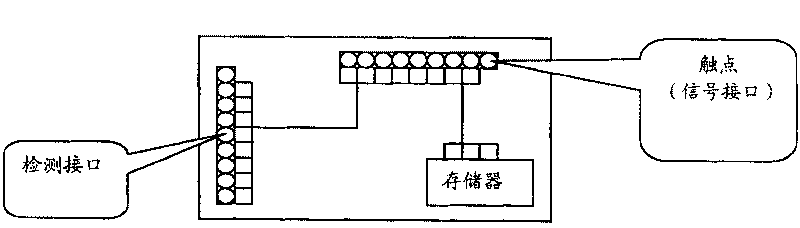

[0038] Signal switching devices such as figure 2 As shown, it includes a detection interface, a signal interface and a memory; the detection interface can be connected to the detection interface line on the TV, and generally adopts a jack structure corresponding to the detection line pin of the TV; the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com