Full-automatic bottled coal sample storing, searching, caching and slowly taking management system

A management system and fully automatic technology, which is applied in the field of coal sample testing, can solve problems such as easy tilting of sample bottles, easy drop of bottles, and difficulty in identifying which set of sample storage cabinets the sample bottles are stored in.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

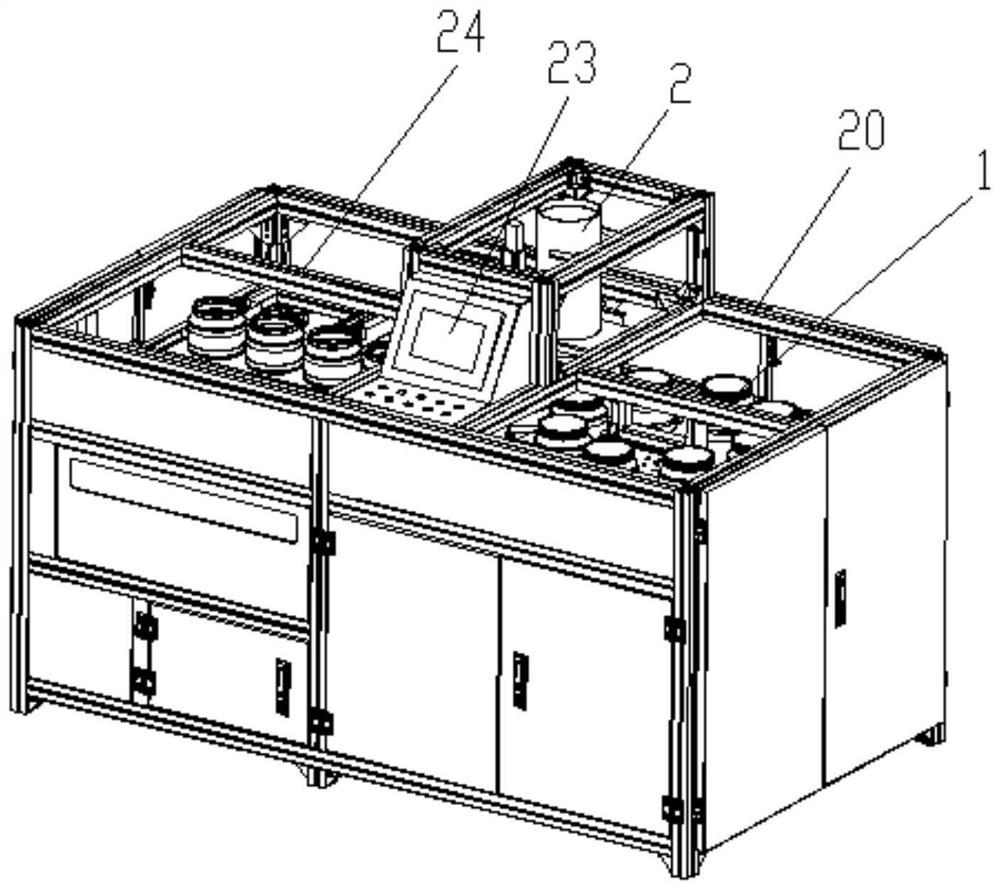

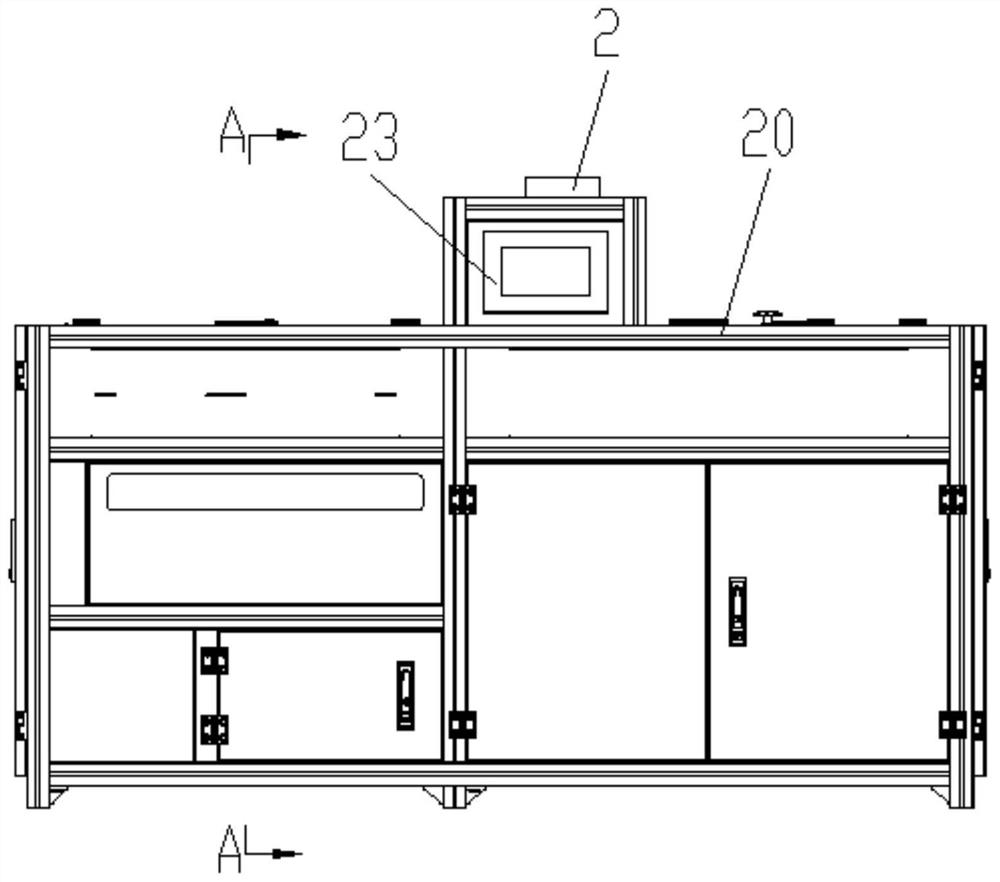

[0052] like Figure 1 to Figure 8 As shown, the present invention provides a fully automatic bottled coal sample storage and retrieval management system, including a cache unit, a cache unit, a transceiver unit and at least one storage and inspection cabinet 25, the cache unit and the cache unit are arranged at intervals, and the storage and inspection cabinet 25 is located on the same side of the cache unit and the cache unit; the transceiver unit is located between the cache unit and the cache unit, and is used to send the sample bottle 1 sent by the cache unit to the storage and inspection cabinet 25 for sample storage, and store the sample bottle 1 in the storage and inspection cabinet. The sample vials 1 in 25 are sent to the slow taking unit for sampling.

[0053] During use, when the sample vials 1 are buffered, at first, a plurality of sample vials 1 are placed on the buffer unit in a manner conceivable by those skilled in the art, and are sent to the transceiver unit ...

Embodiment 2

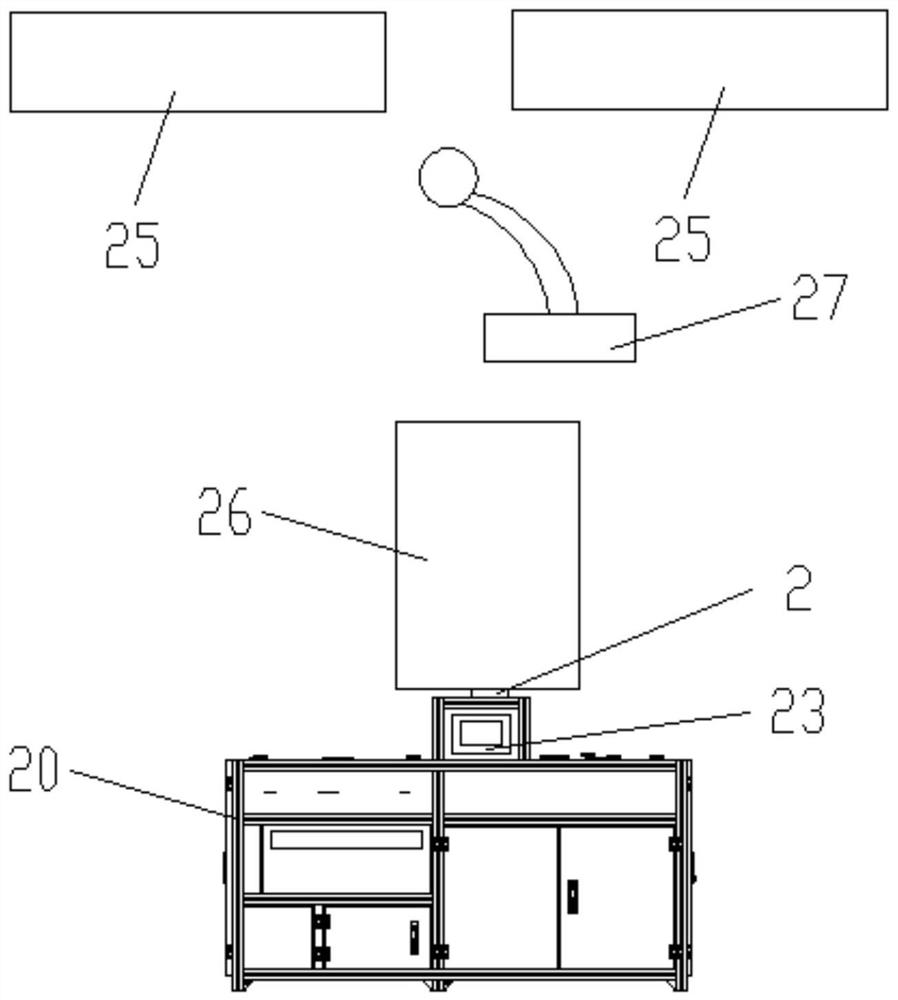

[0066] On the basis of embodiment 1, in the present embodiment, the quantity of storage and inspection sample cabinet 25 is multiple, and a plurality of storage and inspection sample cabinets 25 are distributed on the same side of the cache unit and the cache unit; also include a controller and a pipeline commutator 26, the pipeline commutator 26 is located between the transceiver unit and a plurality of storage and inspection sample cabinets 25, and the cache unit, caching unit, transceiver unit and pipeline commutator 26 are respectively connected to the controller by communication; the pipeline commutator 26 is close to the transceiver unit One end of one end is provided with inlet, and it is provided with a plurality of outlets near one end of storage and inspection sample cabinet 25, and inlet is communicated with any one of them outlet; Connected, the other end of a plurality of feed pipes extends to a plurality of storage and inspection sample cabinets 25 respectively. ...

Embodiment 3

[0071] On the basis of Embodiment 2, this embodiment also includes a robot 27, which is located between the transceiver unit and a plurality of storage and inspection sample cabinets 25, and is connected to the controller by communication, and is used to send the sample bottle 1 sent by the transceiver unit. To a plurality of storage and inspection sample cabinets 25. During the caching process of the sample bottle 1, the controller controls the robot 27 to send the sample bottle 1 in the corresponding storage sample cabinet 25 to the sending and receiving unit according to the information of the sample bottle 1 to be accessed, or send the sample bottle sent by the sending and receiving unit. 1 is sent to the corresponding storage and inspection sample cabinet 25 to realize automatic storage and sampling bottle 1, and the efficiency is greatly improved.

[0072] In Embodiment 2, after the sample bottles 1 are sent to the storage and inspection cabinet 25, the sample bottles 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com