Marking type plastic junction box

A junction box and plastic technology, which is applied in the direction of weapon accessories, fuzes, offensive equipment, etc., can solve the problems of low reading automation, low reliability and stability of stuck wire terminals, and generation of electronic detonator identification information, etc., to achieve The effect of controlling product yield, convenient and fast circuit detection, and easy automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below with reference to the accompanying drawings and examples.

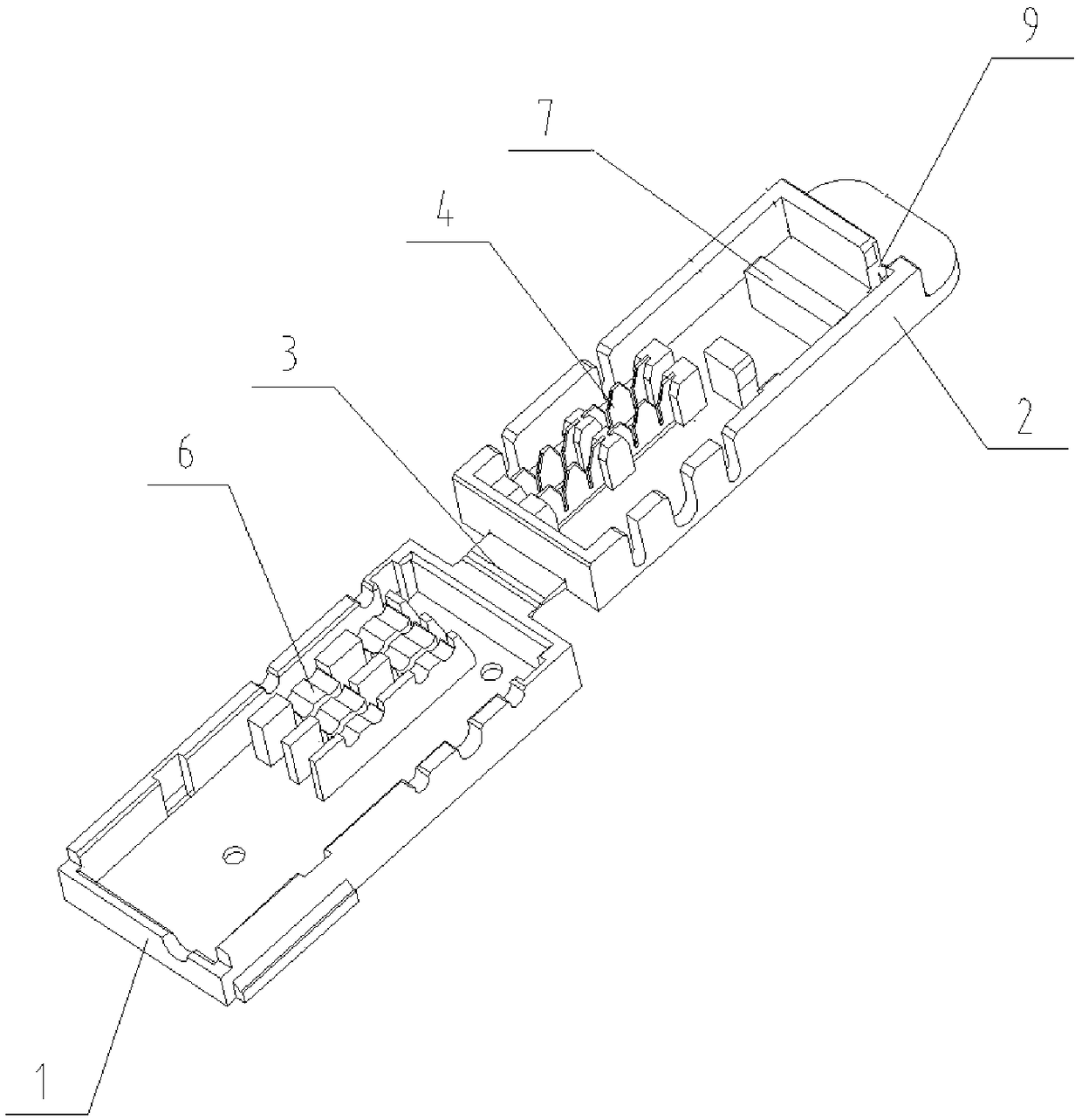

[0032] This embodiment provides a markable plastic junction box, see attached figure 1 , including: upper cover 1, base 2, opening and closing hinge 3, clamping terminal 4, crimping block 6 and closing latch 10;

[0033] The base 2 is a rectangular shell with an opening on the upper surface, and the upper cover 1 is a rectangular shell with an opening on the lower surface, and the sides of the base 2 and the upper cover 1 are connected by an opening and closing hinge 3, and the upper cover 1 can bypass the opening and closing hinge 3 Rotate relative to the base 2, so that the upper cover 1 can be buckled on the base 2, and the inner surface of the side wall of the upper cover 1 after the buckling is in contact with the outer surface of the side wall of the base 2, and the buckled base 2 and the upper The cover 1 relatively forms a closed rectangular housi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com