Active matrix display

An active matrix and display technology, applied to static indicators, cathode ray tube indicators, instruments, etc., can solve the problems of increased impedance, visual sensory artifacts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

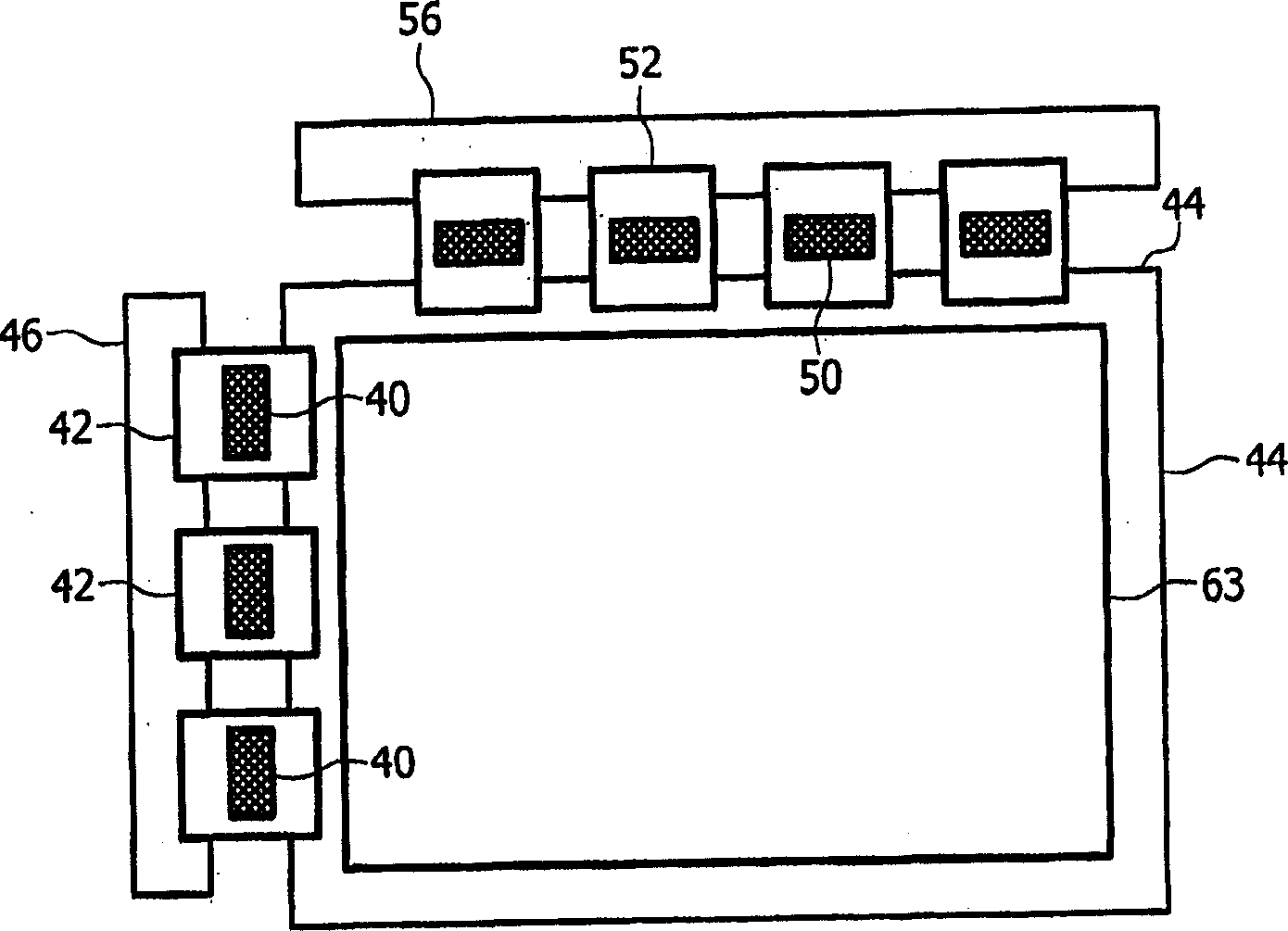

[0033] figure 1 A conventional pixel configuration for an active matrix liquid crystal display is shown. The display is arranged as an array of pixels in rows and columns. Each row of pixels shares a common row conductor 10 and each column of pixels shares a common column conductor 12 . Each pixel includes a thin film transistor 14 and a liquid crystal cell 16 arranged in series between a column conductor 12 and a common electrode 18 . Transistor 14 is switched on and off according to the signal provided on row conductor 10 . In this way, the row conductor 10 is connected to the gate 14a of each transistor 14 of the associated pixel row. Each pixel additionally includes a storage capacitor 20 connected at one end 22 to a next row electrode, a previous row electrode, or a separate capacitor electrode. This capacitor 20 stores the drive voltage, so that the signal is maintained across the liquid crystal cell 16 even after the transistor 14 has been switched off.

[0034] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com