Non-reversible circuit component and sending/receiving module using the same

A technology of circuit components and electrode bodies, which is applied in the direction of electrical components, circuits, waveguide devices, etc., can solve the problems of large cost, complicated wiring pattern 57 winding, and insufficient freedom of wiring patterns, etc., and achieves easy installation operations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

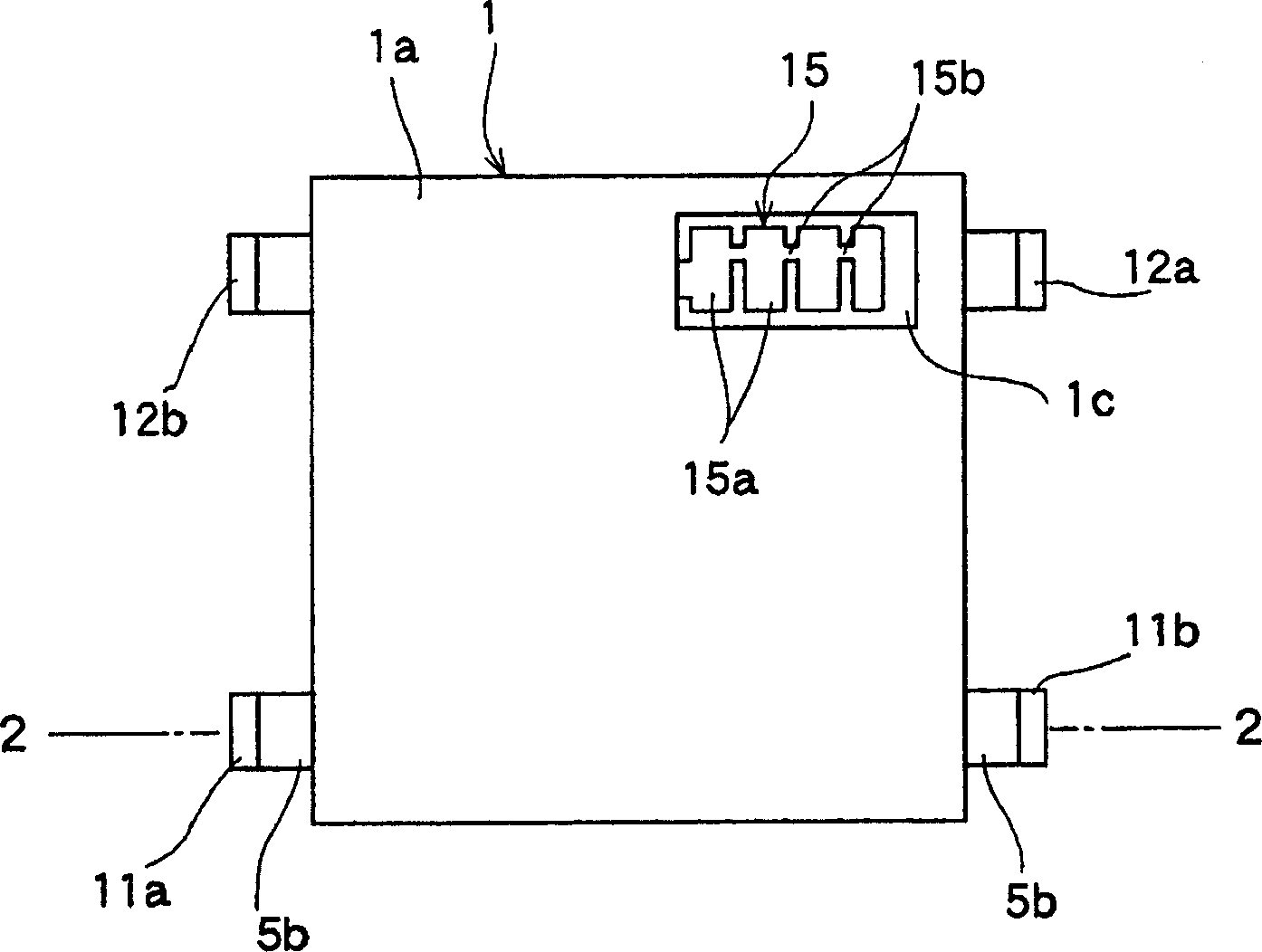

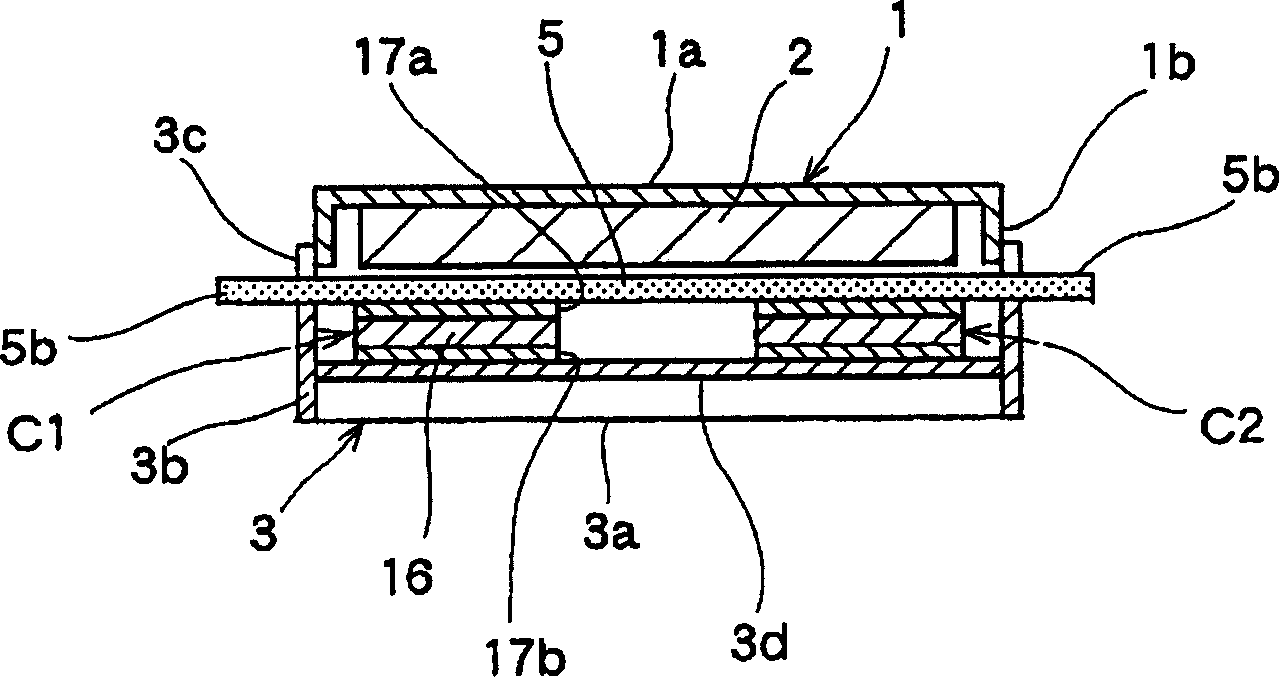

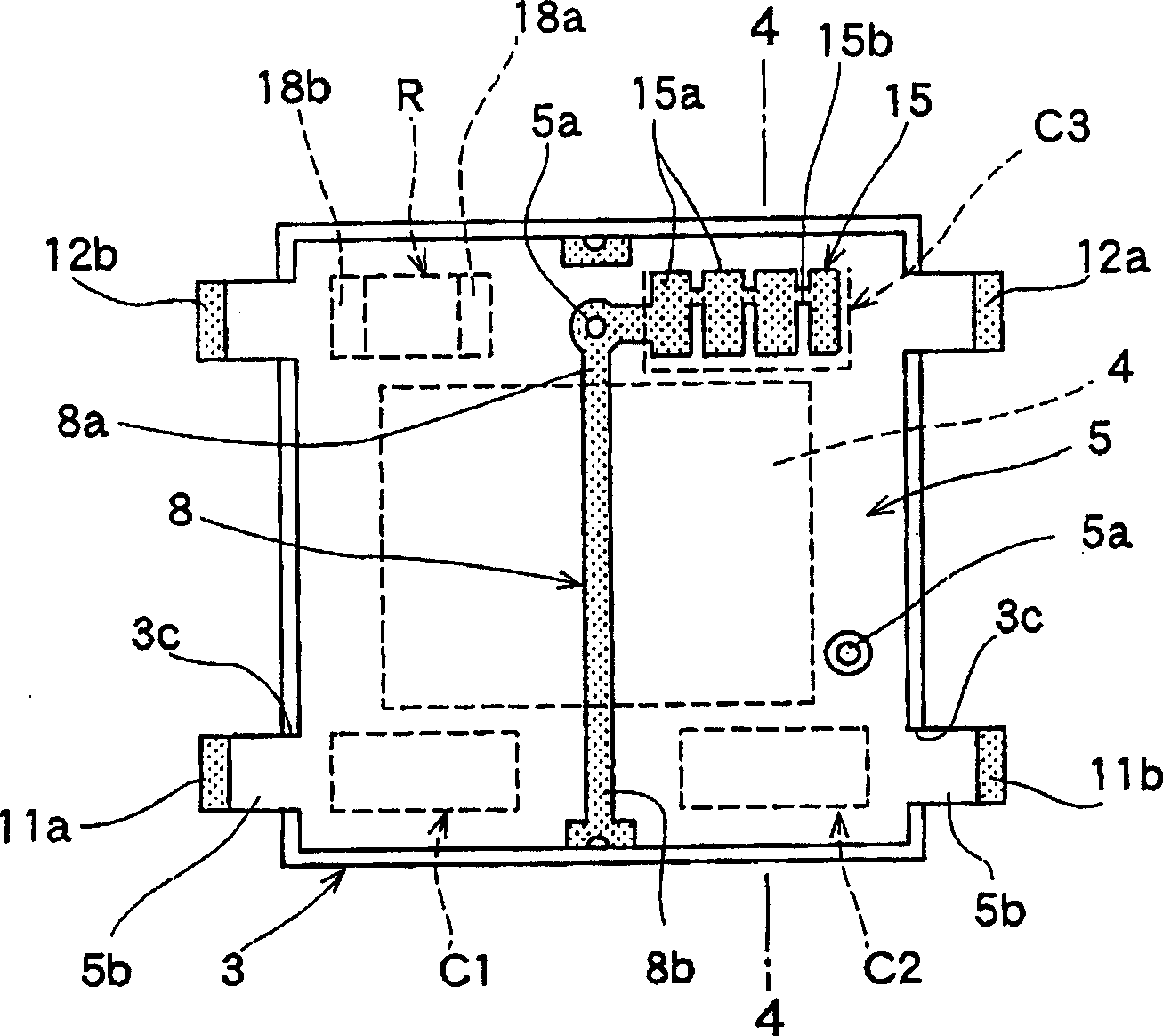

[0048] Describe the drawings of the non-reciprocal circuit element of the present invention and the transceiver module using the non-reciprocal circuit element, then figure 1 Is a plan view showing the first embodiment of the non-reciprocal circuit element of the present invention, figure 2 Yes means figure 1 The cross-sectional view in line 2-2, image 3 It is a plan view showing the state of the first embodiment of the non-reciprocal circuit element of the present invention with the first yoke and magnet removed, Figure 4 Yes means image 3 The section view in the 4-4 line, Figure 5 It is a bottom view showing the first embodiment of the non-reciprocal circuit element of the present invention with the bottom plate of the second yoke removed.

[0049] In addition, Figure 6 Is a bottom view of the multilayer substrate showing the first embodiment of the non-reciprocal circuit element of the present invention, Figure 7 It is a bottom view of the multilayer substrate of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com