Patents

Literature

55results about How to "No cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength and soluble metal-based composite material and preparation method thereof

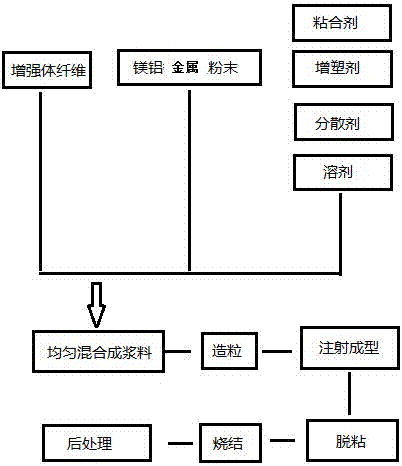

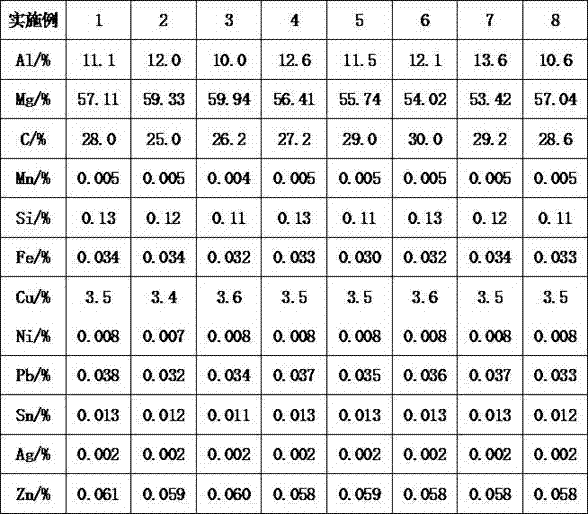

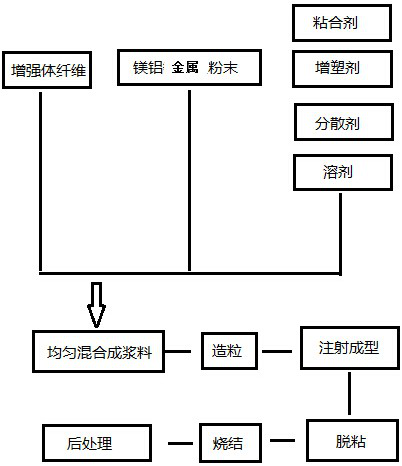

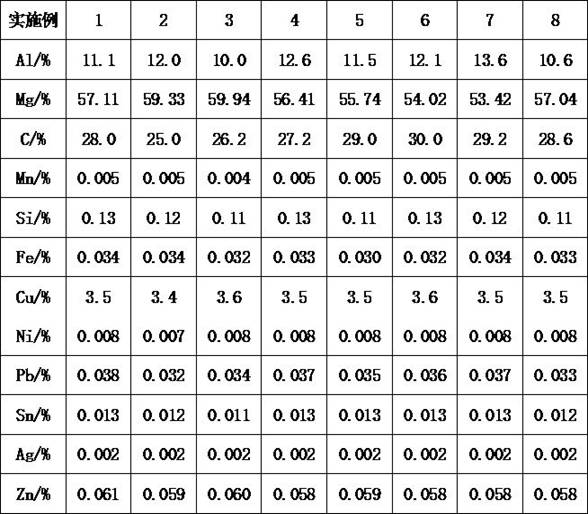

The invention discloses a high-strength and soluble metal-based composite material at first. The high-strength and soluble metal-based composite material comprises the following elemental components in percentage by weight of 10-15% of Al, 50-60% of Mg, 25-30% of C and other trace elements and impurities. Meanwhile, the invention further discloses a method for preparing the high-strength and soluble metal-based composite material. The method comprises the steps of preparing materials in a mass ratio of (10 to 15): (50 to 60): (20 to 30): (10 to 20) of an aluminium metal powder to a magnesium metal powder to carbon fibers to additives; mixing the raw materials according to different preparation flows to prepare a slurry; carrying out injection molding on the slurry to obtain a sintered precursor; carrying out liquid medium removal treatment on the sintered precursor; and carrying out sintering molding on the dried sintered precursor to obtain the metal-based magnesium-aluminium composite material. The high-strength and soluble metal-based composite metal material provided by the invention is high in strength and soluble under a specific condition, and has the characteristics of being excellent in comprehensive mechanical performance and the like.

Owner:CHINA PETROCHEMICAL CORP +3

Preparation method of fastening bolt for automobile wheel

ActiveCN103088268AModerate hardnessImprove the lubrication effectThread cutting machinesBoltsChemical compositionFatigue fractures

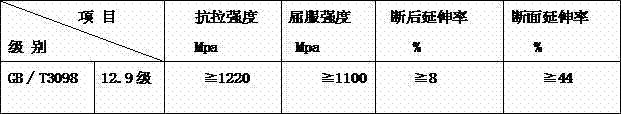

The invention discloses a preparation method of a fastening bolt for an automobile wheel. The preparation method comprises the following processing steps: a, casting a raw material, wherein the raw material comprises the following chemical components in percentage by weight: 0.4 to 0.8% of C, 0.02 to 0.05% of Si, 0.18 to 0.21% of Mn, 0.16 to 0.18% of P, 0.05 to 0.07% of S, 0.05 to 0.15% of Cr, 0.05 to 0.12% of Ti, 0.11 to 0.13% of Cu, 0.01 to 0.02% of Al, 0.02 to 0.03% of Mg, and the balance of iron; and b, scouring the casted and formed rod material; carrying out line drawing on the rod material according to the requirement of the line diameter of the bolt, so that the rod material shrinks to the line diameter required by the bolt; cutting the rod material which is shrunk to the required line diameter to the length required by the bolt; placing the cut rod material into a die cavity at normal temperature; and using upsetting force to enable the dimensions of a head part and a rod part of the rod material to reach the requirements of the bolt. According to the preparation method of the fastening bolt for the automobile wheel, the bolt is processed by cold extruding process, so that the strength of the bolt is improved, the hardness value and the strength value required by the 12.9 high-strength bolt can be realized, and the delayed fracture and the fatigue fracture of the bolt at high strength can be solved; the fastening bolt is reliable in connection and hardly broken during use, prolongs the service life, and meets the usage demand of various industries in the society to high-strength bolts.

Owner:湖北友谦汽车零部件有限公司

Preparation method for high-strength foundation bolt

InactiveCN103205641AModerate hardnessImprove the lubrication effectMetal-working apparatusSolid state diffusion coatingFatigue fracturesHigh stress

The invention discloses a preparation method for a high-strength foundation bolt. Processing steps comprise a step of casting of a rod material, wherein chemical components of a rod material blank comprise, by weight, 0.27 to 0.36% of C, 0.25 to 0.33% of Mn, 0.05 to 0.08% of V, 0.25 to 0.35% of Si, 0.01 to 0.04% of W, no more than 0.025% of P, no more than 0.035% of S, 0.45 to 0.60% of Ni, 0.20 to 0.30% of Sn and 0.45 to 0.65% of Cu, with the balance being Fe. According to the invention, a cold extruding process is used for processing of the bolt, so strength of the bolt is improved, a hardness number and a strength value required by a 12.9 high-strength bolt are reached, the problems of delayed fracture and fatigue fracture of the bolt under high stress are overcome, and the bolt has reliable connection and hardly breaks during usage, has a prolonged service life and meets usage demands for high strength bolts by a variety of industries in society.

Owner:繁昌县琪鑫铸造有限公司

Method for machining T-shaped bolt

The invention discloses a method for machining a T-shaped bolt. The method comprises the following steps of: a) casting a T-shaped rod material blank and controlling the weight percentage of all chemical components of the rod material blank to ensure that the rod material blank comprises 0.28 to 0.35 percent of C, 0.25 to 0.35 percent of Mn, 0.05 to 0.09 percent of V, 0.15 to 0.35 percent of Si, 0.01 to 0.04 percent of W, less than or equal to 0.025 percent of P, less than or equal to 0.035 percent of S, 0.55 to 1.20 percent of Ni, 0.35 to 0.45 percent of Co, 0.20 to 0.30 percent of Sb and less than or equal to 0.20 percent of Cu; according to the method for machining the T-shaped bolt, the bolt is machined by a cold extruding process, so that the intensity of the bolt is improved, the hardness value and the intensity value required by a 12.9 high-intensity bolt can be acquired, and the delayed fracture and the fatigue crack of the bolt under high intensity can be avoided; and during use, the bolt is reliable in connection, is not prone to break, and meets the using requirements of all industries in society on the high-intensity bolt; and the service life of the bolt is prolonged.

Owner:ANHUI LIUFANG ZHONGLIAN MECHANICAL SHARE

Preparation method of high-strength T-shaped bolt

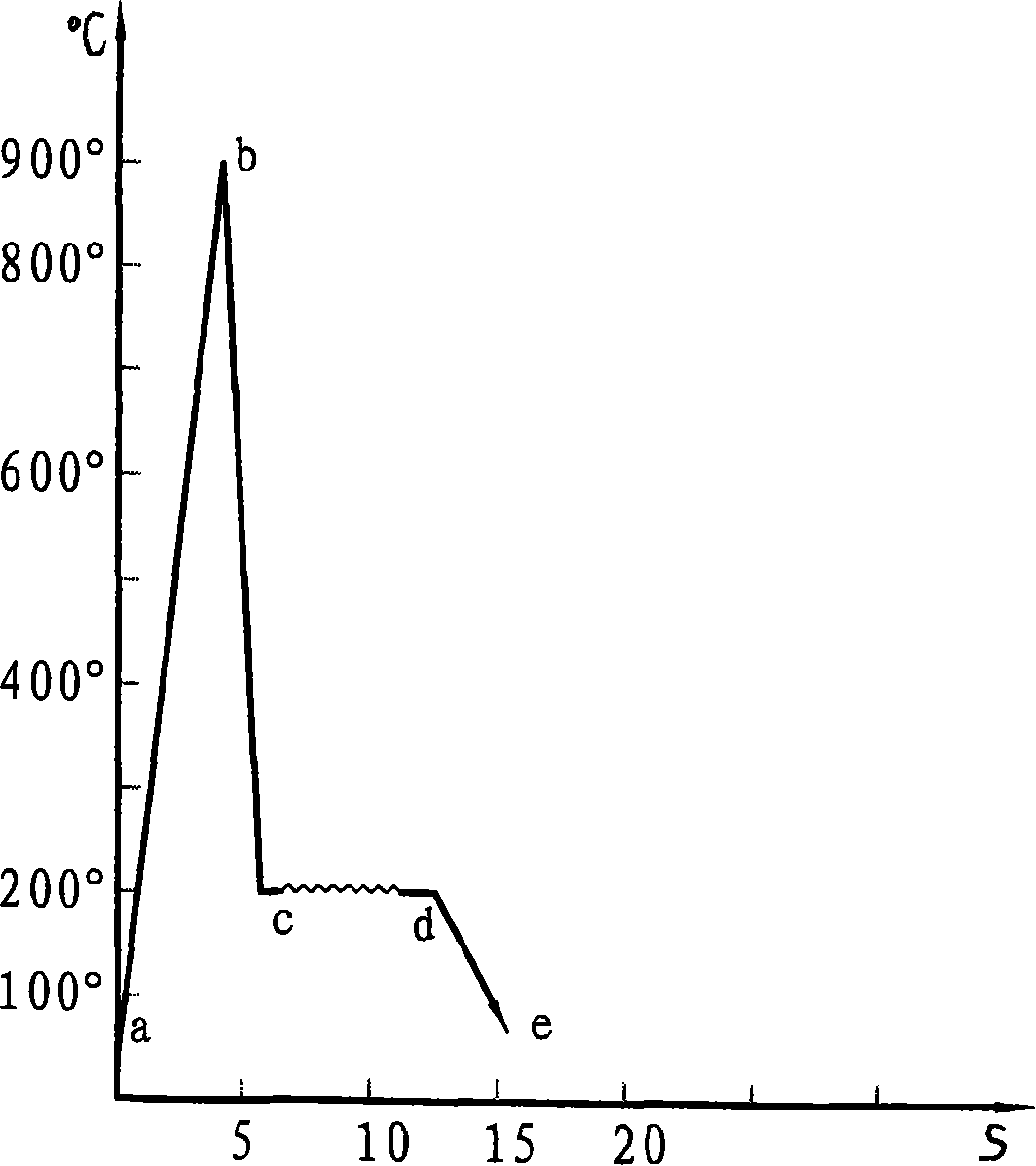

InactiveCN103131948AModerate hardnessImprove the lubrication effectBoltsMedium frequencyHigh intensity

The invention discloses a preparation method of a high-strength T-shaped bolt. The preparation method is mainly characterized in that machining steps comprise T-shaped rod material casting and the like. The T-shaped rod material casting comprises that 12-14 parts by weight of waste iron are first fed into a medium frequency furnace to be melted into molten iron, when temperature inside the medium frequency furnace rises to 1000-1200 DEG C, 30-35 parts by weight of steel ingot, 30-35 parts by weight of cast iron and 12-16 parts by weight of foundry returns are then fed into the molten iron, and at the same time, a layer of warm-keeping covering agent is sprinkled on the surface of the solution for covering, then slagging is conducted, and when temperature inside the medium frequency furnace rises to 1400 DEG C for discharging, pouring is conducted. According to the preparation method of the high-strength T-shaped bolt, cold extruding technology bolt machining is adopted, so that the strength of the bolt is improved, a hardness value and a strength value needed by the high-strength bolt are achieved, and the problems of delayed fracture and fatigue fracture of the bolt under high strength are solved, and in the use process, connection is reliable, the bolt is not prone to fracture, service life of the bolt is prolonged, and use demands to the high-strength bolt in all industries in the society are satisfied.

Owner:繁昌县琪鑫铸造有限公司

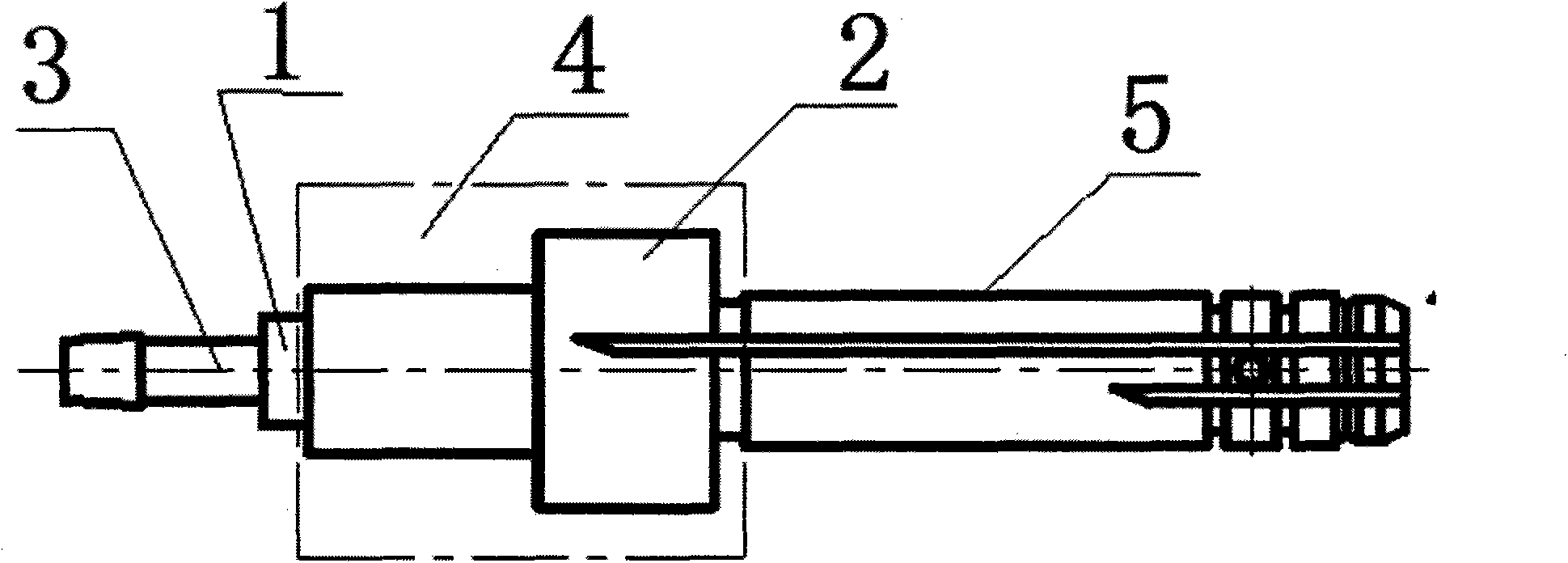

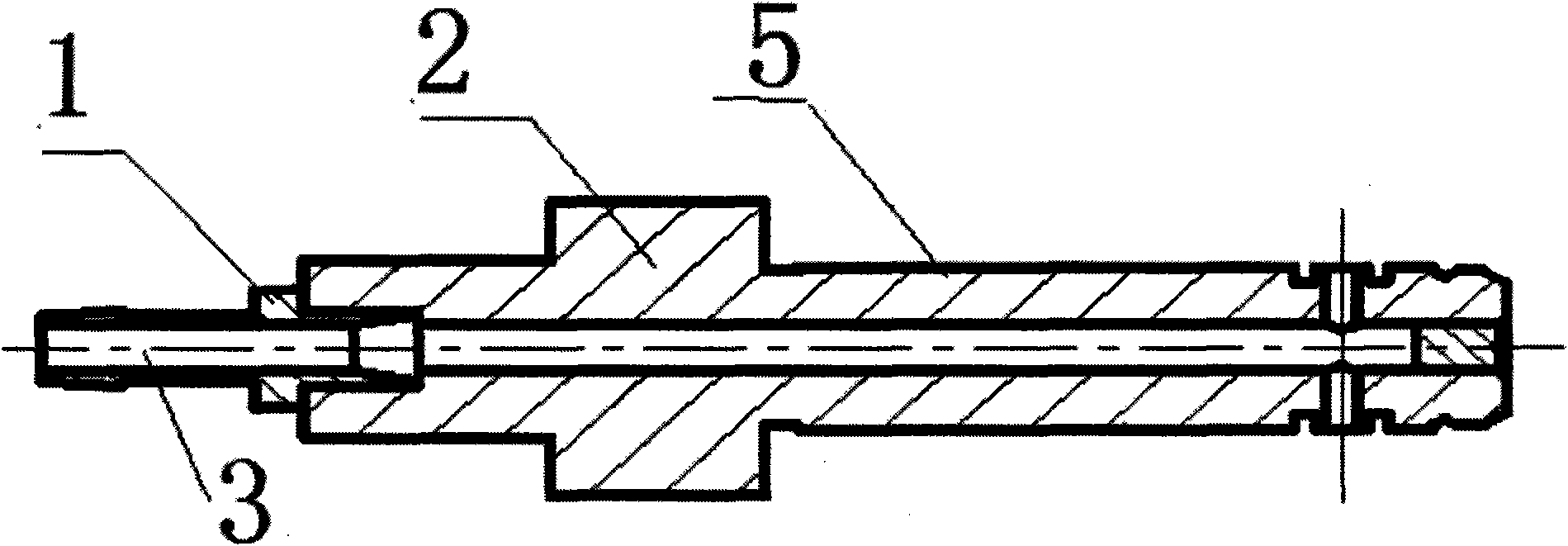

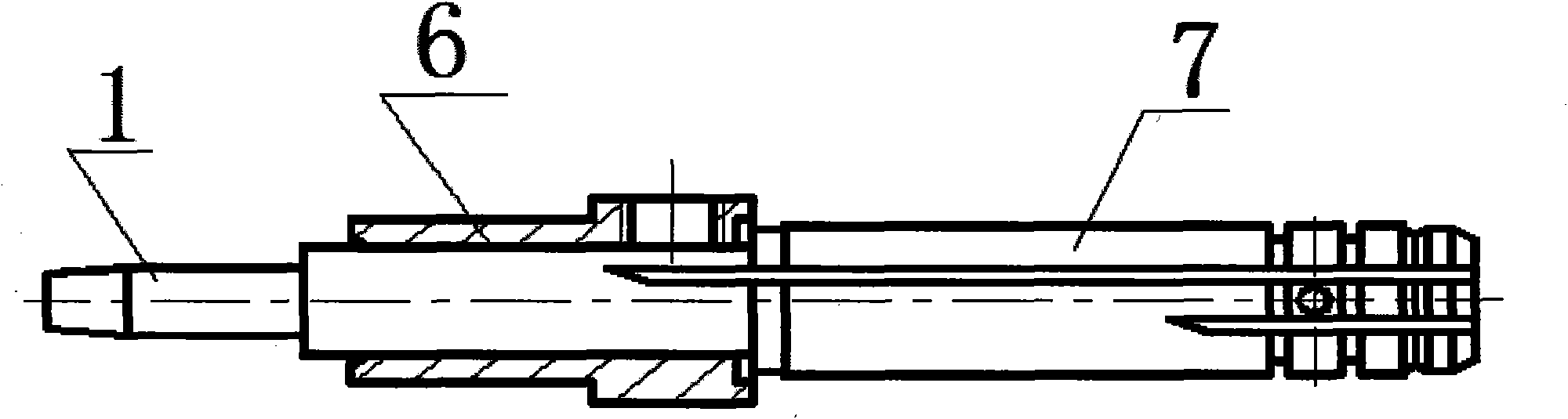

Inner-diameter measuring head of plunger sleeve

The invention relates to an inner-diameter measuring head of a plunger sleeve, belonging to the technical field of pneumatic measuring. The split-type inner-diameter measuring head of the plunger sleeve is characterized in that the inner-diameter measuring head comprises a measuring head used as a measuring part and a positioning sleeve arranged at the periphery of the measuring head; the positioning sleeve is used for positioning and clamping, the measuring head and the positioning sleeve are two independent parts, the measuring head and an air inlet joint are connected into a whole, and the air inlet joint is connected with a float-type pneumatic gauge. As common materials are selected as far as possible on the basis that the functional requirements are met, the split-type inner diameter measuring head of the plunger sleeve is economical and needs no cutting or little cutting. With simple structure, light weight, easy manufacturing, convenient using, good safety, high reliability, good manufacturability, beautiful appearance, high production efficiency and low manufacturing cost, the split-type inner diameter measuring head manufactures parts meeting the using requirements with the least workload and the lowest processing cost,. Moreover, the material cost of the inner-diameter measuring head is greatly reduced.

Owner:王晓英

Method for machining high-strength double end bolt

The invention discloses a method for machining a high-strength double end bolt. The method comprises the following steps of: a, manufacturing a rod blank, and controlling the weight percentage of each chemical component of the rod blank to meet the following requirements: 0.28 to 0.35 percent of C, 0.25 to 0.35 percent of Mn, 0.05 to 0.09 percent of V, 0.15 to 0.35 percent of Si, 0.01 to 0.04 percent of W, less than or equal to 0.025 percent of P, less than or equal to 0.035 percent of S, 0.55 to 1.20 percent of Ni, 0.35 to 0.45 percent of Co, 0.20 to 0.30 percent of Sb and less than or equal to 0.20 percent of Cu; and b, forging a cast rod at the temperature of between 850 and 800 DEG C for not more than 20 times, wherein a thin layer of fly ash is coated on the inner wall of an impression of a forging die; and turning an external thread at each of two ends of the bolt by using a precision lathe after forging. According to the method for machining the high-strength double end bolt, the bolt is machined by adopting a cold extrusion process, so that the strength of the bolt is improved, the hardness value and the strength value required by the 12.9 high-strength bolt are achieved, the problems of delayed fracture and fatigue fracture of the bolt under high strength are solved, the bolt is reliable in connection during use and difficult to break, the service life of the bolt is prolonged, and the using requirement of each industry in the society for the high-strength bolt is met.

Owner:ANHUI LIUFANG ZHONGLIAN MECHANICAL SHARE

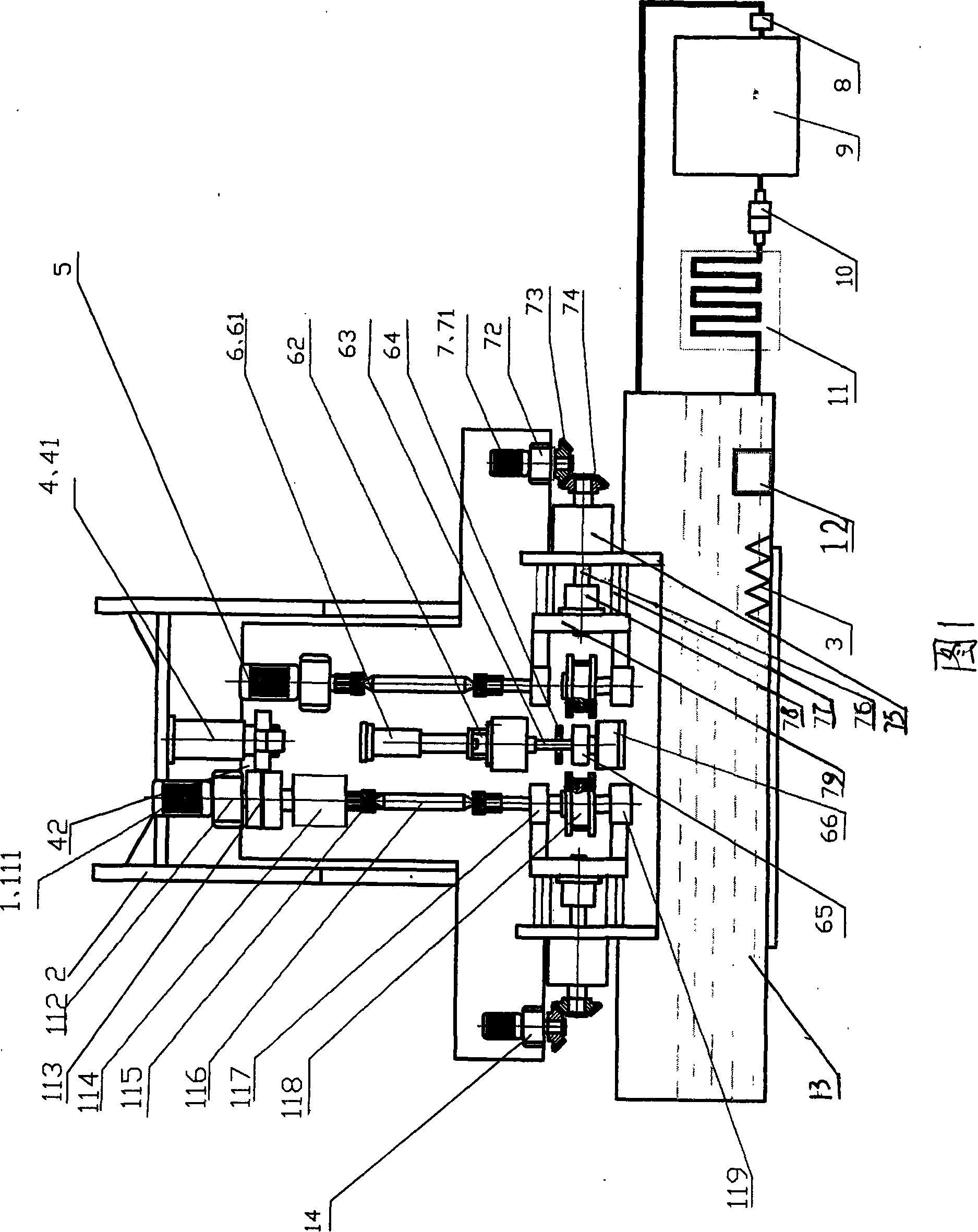

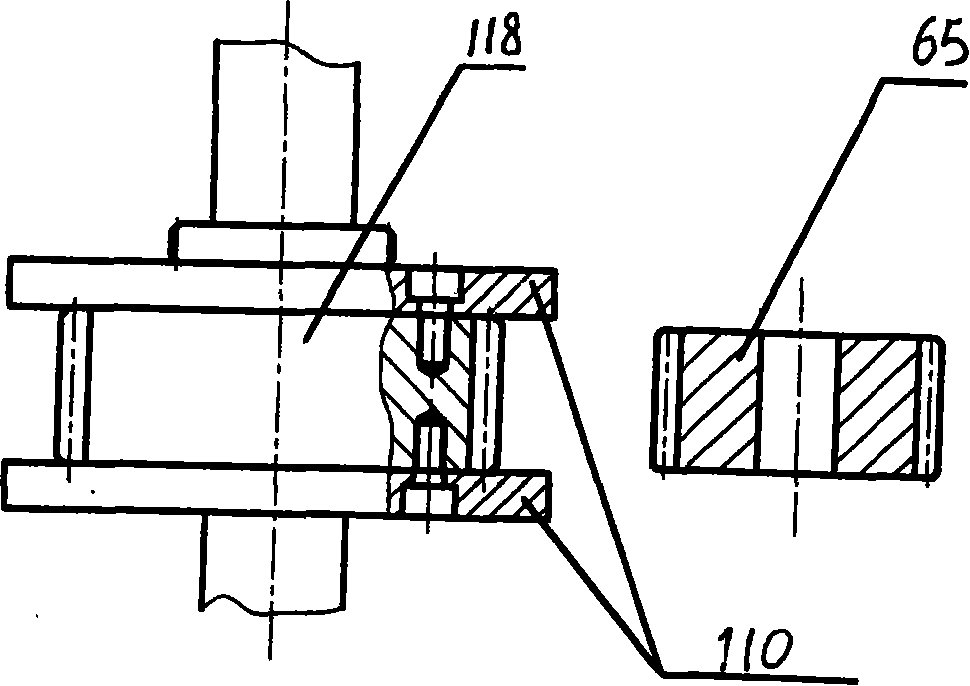

Gear wheel precision hot rolling extruding and grinding machine and processing method thereof

ActiveCN101168183AReduce the impact of stabilizationReduce in quantityGear wheelsHigh volume manufacturingHobbing

A pinion precision hot rolled squeezing and milling device and a method for processing belong to the field of precision-machined machinery devices and craft technology. The purpose of the invention is to provide the pinion precision hot rolled squeezing and milling device, and the method for processing which are economical, practical and have low inaccuracy and high accuracy and are applicable to be in mass production. The technical points are that a framework is straddled and arranged on the two lateral sides of an oil tank, and a slider controlled by a hydraulic oil tank is arranged on the framework, wherein a first gear hobbing die actuating mechanism, a work-piece handing hold-down mechanism, and a second gear hobbing die actuating mechanism are hung vertically and consecutively from left to right, the two lateral sides of the lower portion are correspondingly arranged with pushing shelves of a first screw mandrel pushing mechanism and a second screw mandrel pushing mechanism which are respectively connected with an upper bearing block and a lower bearing block of the first gear hobbing die actuating mechanism and the second gear hobbing die actuating mechanism. Compared with prior crafts and devices, the invention is a finishing tooth processing device and craft which is more advanced, reasonable and scientific, economical, practical, lowly inaccurate, and further has the advantages of high efficiency and high accuracy, and is adaptable for mass production without cutting.

Owner:安徽省小小科技股份有限公司

Preparation method of fracture-resistant steel rope bolt

InactiveCN103131954AModerate hardnessImprove the lubrication effectMetal-working apparatusSolid state diffusion coatingChemical compositionFatigue fractures

The invention discloses a preparation method of a fracture-resistant steel rope bolt. The process includes following steps: a. casting rod material, wherein a blank of the rod material comprises, in terms of chemical component, by weight, 0.132%-0.260% of C, 0.62%-1.30% of Si, 0.25%-0.35% of Mn, 0.010%-0.030% of P, 0.010%-0.030% of S, 1.10%-1.50% of Cr, trace quantity-0.0018% of B, 0.012%-0.030% of Cu, and the balances are Fe and inevitable impurities; b. washing the rod material after casting molding in acid, conducting thread drawing for the rod material according to the requirement of thread diameter of the bolt to enable the rod material to shrink to the required thread diameter, cutting the rod material after thread diameter shrinks to the required length of the bolt, placing the cutting-off rod material into a mould shaped cavity which is covered by plant ashes at normal temperature, enabling the rod material to form a required head part and required size of a rod part of the bolt by applying upset forging force, and making screw threads on the periphery face of the rod part of the rod material through turning by using a precision lathe. According to the preparation method of the fracture-resistant steel rope bolt, cold extrusion process is applied to process the bolt, so that the strength of the bolt is improved, required hardness and strength of a high-strength bolt are reached, and the problem that delayed fracture and fatigue fracture of the bolt under high strength is solved. The bolt is reliable to use in connection, not easy to break, and the service life of the bolt is prolonged.

Owner:繁昌县琪鑫铸造有限公司

Preparation method of high-strength steel cable bolt

The invention discloses a preparation method of a high-strength steel cable bolt. The method includes the following steps: casting a rod material, throwing 10-14 parts by weight of waste steel into a medium frequency furnace, enabling the steel to be melted into liquid steel, adding a carbon addition agent, throwing 30-35 parts by weight of steel ingot, 30-35 parts by weight of cast iron and 12-16 parts by weight of returns into the medium frequency furnace after temperature in the medium frequency furnace is increased to 1120-1220 DEG C, conducting slagging and adding 0.4-0.6 part by weight of copper and liquid iron into a ladle to conduct pouring when temperature in the medium frequency furnace increases to 1450 DEG C and the iron is discharged. The preparation method of the high-strength steel cable bolt adopts the cold extrusion process to process the bolt, improves bolt strength, achieves the hardness and the strength required by 12.9 high-strength bolt, resolves the problems of delaying breaking and fatigue breaking of the bolt under high strength, prolongs service life of the bolt due to the fact that the bolt is reliable in connection and not easy to break in use, and meets using requirements of social industries for the high-strength bolt.

Owner:青龙船务工程(南通)有限公司

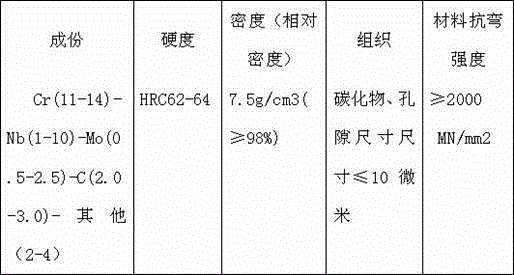

Method of forming powder metallurgy tool steel

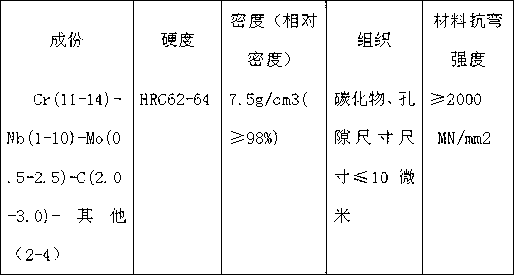

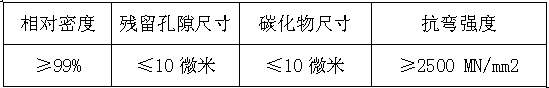

InactiveCN103157796ASmall and uniform tissueImprove performanceVacuum pressureHigh volume manufacturing

The invention discloses a method of forming powder metallurgy tool steel. The method includes a first step of conducting carbon-reduction and anneal on water atomization tool steel powder under the vacuum condition, a second step of evenly coating the surface of the powder with a layer of graphitic lubricant assisting in sintering, and obtaining mixed material after paraffins forming agent is mixed in, a third step of manufacturing material blank or part blank by compression moulding forming of the mixed material and dewaxing, and a fourth step of sintering the material blank or the part blank by a vacuum-pressure furnace. The powder metallurgy tool steel (high-speed steel) produced by the method is even and fine in formation, relative density of the tool steel reaches 99.5% and the density is close to be fully compact. Material performance is excellent, the powder metallurgy tool steel is close to isostatic pressing tool steel (high-speed steel) material in physical and mechanical properties, and the method of forming the powder metallurgy tool steel has the advantage of being low in cost, free from cutting, high in efficiency and capable of massively producing parts the same with powder metallurgy.

Owner:HUNAN HUANYU POWDER METALLURGY CO LTD

Method for machining high-strength U-shaped bolt

ActiveCN103084523AModerate hardnessImprove the lubrication effectMetal-working apparatusBoltsChemical compositionGranularity

The invention discloses a method for machining a high-strength U-shaped bolt. The method comprises the following steps of: a, casting a U-shaped rod blank, and controlling the weight percentage of each chemical component of the rod blank to meet the following requirements: 0.28 to 0.35 percent of C, 0.25 to 0.35 percent of Mn, 0.05 to 0.09 percent of V, 0.15 to 0.35 percent of Si, 0.01 to 0.04 percent of W, less than or equal to 0.025 percent of P, less than or equal to 0.035 percent of S, 0.55 to 1.20 percent of Ni, 0.35 to 0.45 percent of Co, 0.20 to 0.30 percent of Sn, less than or equal to 0.20 percent of Al and the balance of iron; and b, forging a cast U-shaped rod at the temperature of between 650 and 700 DEG C for not more than 25 times, wherein a thin layer of graphite powder is coated on the inner wall of an impression of a forging die, and the granularity of the graphite powder is controlled to be 200 to 300 meshes; and turning an external thread of the bolt by using a precision lathe after forging. According to the method for machining the high-strength U-shaped bolt, the bolt is machined by adopting a cold extrusion process, so that the strength of the bolt is improved, the hardness value and the strength value required by the 12.9 high-strength bolt are achieved, the problems of delayed fracture and fatigue fracture of the bolt under high strength are solved, the bolt is reliable in connection during use and difficult to break, the service life of the bolt is prolonged, and the using requirement of each industry in the society for the high-strength bolt is met.

Owner:舟山德玛吉实业有限公司

Preparation method of high-strength aluminum alloy flange bolt

The invention discloses a preparation method of a high-strength aluminum alloy flange bolt. Machining steps comprise rod material casting and the like. The rod material casting comprises that 11-14 parts by weight of waste aluminum sectional materials are first fed into a medium frequency furnace to be melted into molten steel, carbon adding agents are then added into the molten steel, when temperature inside the medium frequency furnace rises to 650-700 DEG C, 32-42 parts by weight of A356 aluminium ingot, 30-35 parts by weight of cast iron and 12-16 parts by weight of foundry returns are then fed and at the same time, a layer of warm-keeping covering agent is sprinkled on the surface of the solution for covering, then slagging is conducted, after the slagging, alloy is added, and when temperature inside the medium frequency furnace rises to 1400 DEG C for discharging, pouring is conducted. According to the preparation method of the high-strength aluminum alloy flange bolt, cold extruding technology is adopted to machine the bolt, so that the strength of the bolt is improved, a hardness value and a strength value needed by the high-strength bolt are satisfied, and the problems of delayed fracture and fatigue fracture of the bolt under high strength are solved, and in the use process, connection is reliable, the bolt is not prone to fracture, service life of the bolt is prolonged, and use demands to the high-strength bolt in all industries in the society are satisfied.

Owner:繁昌县琪鑫铸造有限公司

Non-machine millstone floor

The invention discloses a non-machine millstone floor, and relates to the field of terrazzo floors. The non-machine millstone floor is mainly prepared in parts by mass: 5 parts of magnesium oxide, 2 parts of magnesium chloride, 50 parts of aggregates and 6 parts of water, and thus the functions of seamless surface, stain resistance, and easy cleaning and maintenance are achieved.

Owner:深圳市鼎顺鑫装饰工程有限公司重庆分公司

Processing method for high-class bolt

ActiveCN103028685AModerate hardnessImprove the lubrication effectMetal-working apparatusBoltsChemical compositionHigh intensity

The invention discloses a processing method for a high-class bolt. The processing method comprises the following steps: a) casting a rod blank and controlling the weight percent of all chemical components of the rod blank as follows: 0.27-0.34% of C, 0.45-0.65% of Mn, 0.05-0.15% of V, 0.15-0.35% of Si, 0.01-0.04% of W, less than or equal to 0.025% of P, less than or equal to 0.025% of S, 1.55-2.00% of Ni, 0.65-0.95% of Co, 0.20-0.30% of Sn and less than or equal to 0.20% of Cu. According to the processing method for the high-class bolt provided by the invention, a cold extrusion process is adopted for processing the bolt, so that the strength of the bolt is increased, the hardness value and strength value required by the bolt with the strength being 12.9 are achieved, the problems of delay breakage and fatigue breakage of the bolt under high strength are solved, the connection is reliable during a use process, the bolt is difficult to break, the service life of the bolt is prolonged and the use requirement for the high-strength bolt in various industries is met.

Owner:ANHUI LIUFANG ZHONGLIAN MECHANICAL SHARE

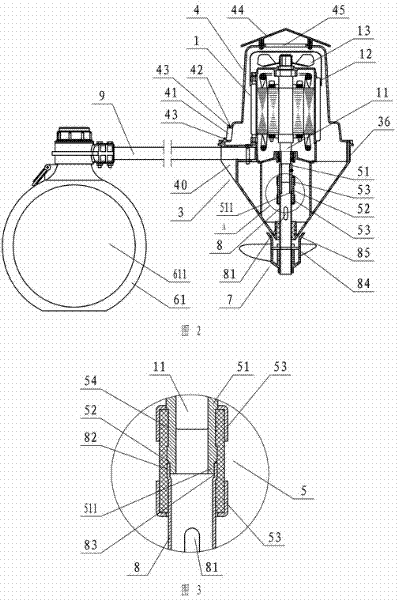

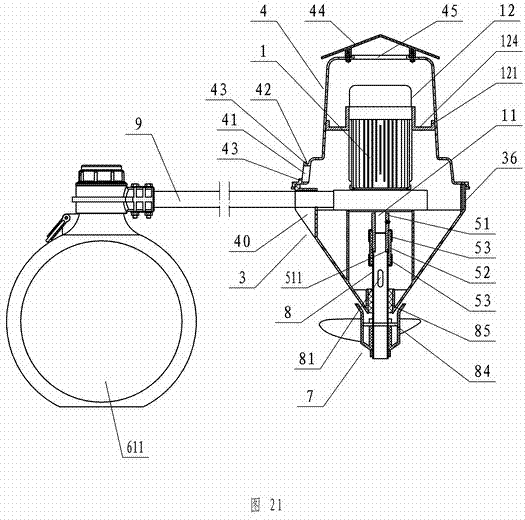

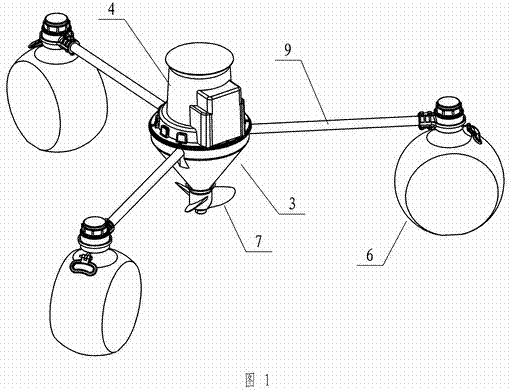

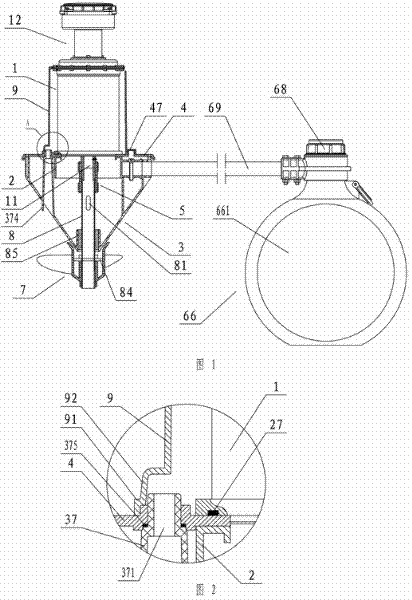

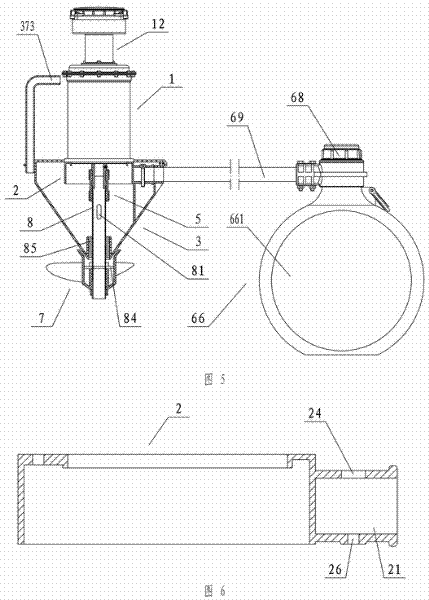

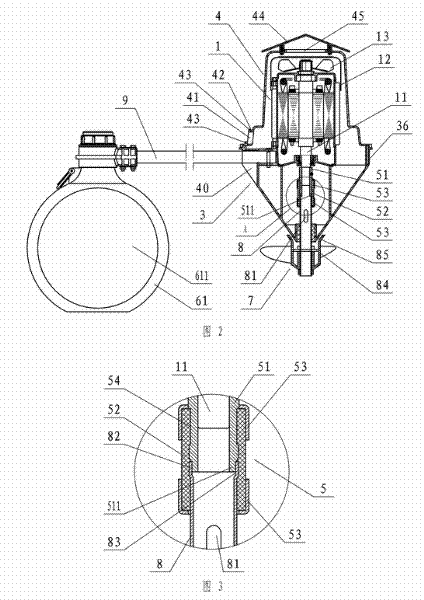

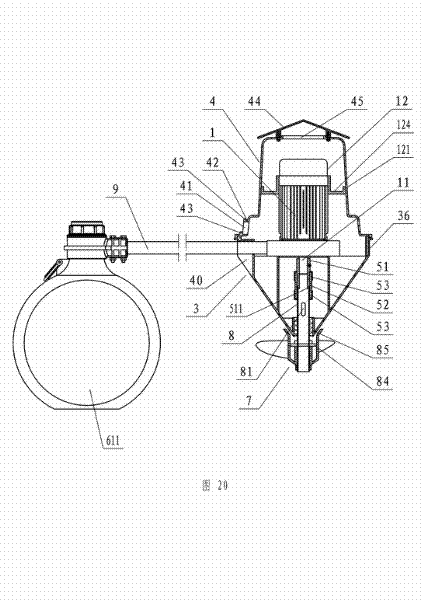

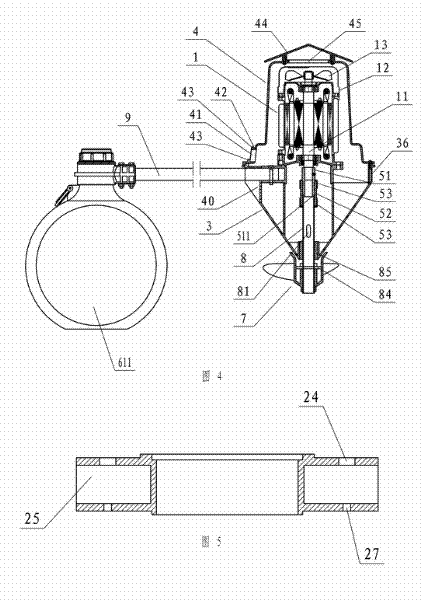

Device for preventing hot air from flowing back in water shield of aerator and impeller aerator

InactiveCN102334461AReduce the temperatureLow costWater aerationPisciculture and aquariaImpellerElectric machine

The invention belongs to the technical field of aerators, and relates to an impeller aerator provided with a device for preventing hot air from flowing back in a water shield. A motor is arranged in a shell consisting of a conical body and the water shield; a supporting base of the motor is connected with the shell; a motor shaft is connected with an impeller shaft and vertically extends into water downward; a motor body is positioned over the horizontal pane; an isolation device for preventing the hot air of the motor from upward flowing back and entering a fan guard of the motor is arranged between the water shield and the motor so as to ensure that the hot air formed after the heat exchange of a cooling fan and radiating fins is not returned to the fan guard of the motor and the temperature of the motor is greatly reduced; the supporting base is connected with supporting rods; and the other end of each of the supporting rods is provided with a floating body respectively. The complete machine floats on the water surface to work through the floating bodies, and a water body lifted by an impeller is guided to various directions by using the conical body so as to ensure that lower-layer water fills a vacancy, so that the aim of oxygen increase is fulfilled through the convection of the water body. Structures such as gears, reduction gearboxes and the like which are required in the prior art are abandoned, lubricating oil is not required to be filled, the oil leakage is effectively prevented from polluting fishing ponds, and the production cost is reduced.

Owner:吴为国

Preparation method of lengthened bolt

ActiveCN103088267AHigh strengthResolving Delayed FracturesThread cutting machinesBoltsChemical compositionFatigue fractures

The invention discloses a preparation method of a lengthened bolt. The preparation method is characterized by comprising the following processing steps of: a, preparing a rod blank through a casting technology, wherein the rod blank comprises the following chemical components in percentage by weight: 0.25%-0.35% of C, 0.08%-0.15% of Mn, 0.05%-0.15% of Si, 0.01%-0.04% of W, no less than 0.015% and no more than 0.025% of P, no less than 0.015% and no more than 0.035% of S, 0.15%-0.20% of Ni, 0.025%-0.045% of Zn, 0.02%-0.03% of Sn, no more than 0.02% of Cr, and the balance of iron. The preparation method of the lengthened bolt disclosed by the invention has the beneficial effect of improving the strength of the bolt by processing the bolt through a cold extrusion process, the hardness value and the strength value required for a 12.9 high-strength bolt are achieved, the problems of delayed fracture and fatigue fracture of the bolt under high strength are solved, the bolt is reliable for connection and less prone to breaking in use, the service life of the bolt is prolonged, and the use requirement on the high-strength bolt in various industries in society is satisfied.

Owner:重庆冠鹏机车部件有限公司

Method for machining connection rod bolt of diesel engine

InactiveCN103084525AHigh strengthResolving Delayed FracturesMetal-working apparatusBoltsChemical compositionHardness

The invention discloses a method for machining a connection rod bolt of a diesel engine. The method comprises the following steps of: manufacturing a rod material blank, and controlling the weight percentage of all chemical components of the rod material blank to ensure that the rod material blank comprises 0.28 to 0.32 percent of C, 0.35 to 0.45 percent of Mn, 0.05 to 0.15 percent of V, 0.15 to 0.35 percent of Si, 0.01 to 0.04 percent of W, less than or equal to 0.025 percent of P, less than or equal to 0.035 percent of S, 0.55 to 1.20 percent of Ni, 0.35 to 0.45 percent of Co, 0.20 to 0.30 percent of Sn and less than or equal to 0.20 percent of Cu. According to the method for machining the connection rod bolt of the diesel engine, the bolt is machined by a cold extruding process, so that the intensity of the bolt is improved, the hardness value and the intensity value which are required by a 12.9 high-intensity bolt can be acquired, and the delayed fracture and fatigue crack of the bolt under high intensity can be overcome; the bolt is reliable in connection during use, and is not prone to break and crack; the service life of the bolt is prolonged; and the using requirements of all industries in society on the high-intensity bolt can be met.

Owner:佛山顺恒鑫科技实业有限公司

Method for manufacturing abrasion-resistant foundation bolt

The invention discloses a method for manufacturing an abrasion-resistant foundation bolt. Machining steps include: casting a rod, by weight, adding 12-14 parts of scrap iron into a medium frequency furnace to melt to form molten iron, adding carburant, when the temperature in the medium frequency furnace rises to 1000-1220 DEG C, adding 0.1-0.2 part of molybdenum, 30-35 parts of steel ingot, 30-35 parts of scrap steel and 12-16 parts of foundry returns, simultaneously scattering a layer of heat preservation covering agent on the surface of the melt and covering, slagging, after slagging, adding 0.5-0.8 part of ferro-nickel alloy and 1-2 parts of ferrosilicon alloy, when the temperature in the medium frequency furnace rises to 1450 DEG C, withdrawing, adding 0.4-0.6 part of magnesium powder along with molten iron into a ladle, and casting. The method adopts cold extrusion process to machine the bolt, the strength of the bolt is improved, hardness and strength required by the 12.9 high-strength bolt are met, and delayed fracture and fatigue fracture of the bolt under high strength are avoided. The bolt is reliable in connection and not prone to break, prolongs service life, and meets use requirements of various industries in society for the high-strength bolt.

Owner:浙江同力重型机械制造有限公司

Preparation method of anti-fracture engine crankshaft

InactiveCN105420609AHigh strengthExtend your lifeSolid state diffusion coatingFurnace typesChemical compositionMetallurgy

The invention discloses a preparation method of an anti-fracture engine crankshaft. The preparation method comprises the steps that a rod blank is cast; and chemical components of the rod blank are made to meet the requirement that the rod blank is composed of, by weight, 0.28-0.35% of C, 0.25-0.35% of Mn, 0.15-0.35% of Si, 0.01-0.04% of W, 0-0.025% of P, 0-0.035% of S, 0.55-1.20% of Ni, 0.35-0.45% of Co, 0.20-0.30% of Sn, and 0-0.20 of Al. By means of the preparation method, the strength of the engine crankshaft is improved, the hardness value and the strength value which are required by a high-strength engine crankshaft are reached, the problems of delayed fracture and fatigue fracture of the engine crankshaft under high strength are solved, connection is reliable when the engine crankshaft is in use, fracture is unlikely to occur, the service life of the engine crankshaft is prolonged, and using requirements of various industries in the society for the high-strength engine crankshaft are met.

Owner:HEFEI HAIYUAN MACHINERY

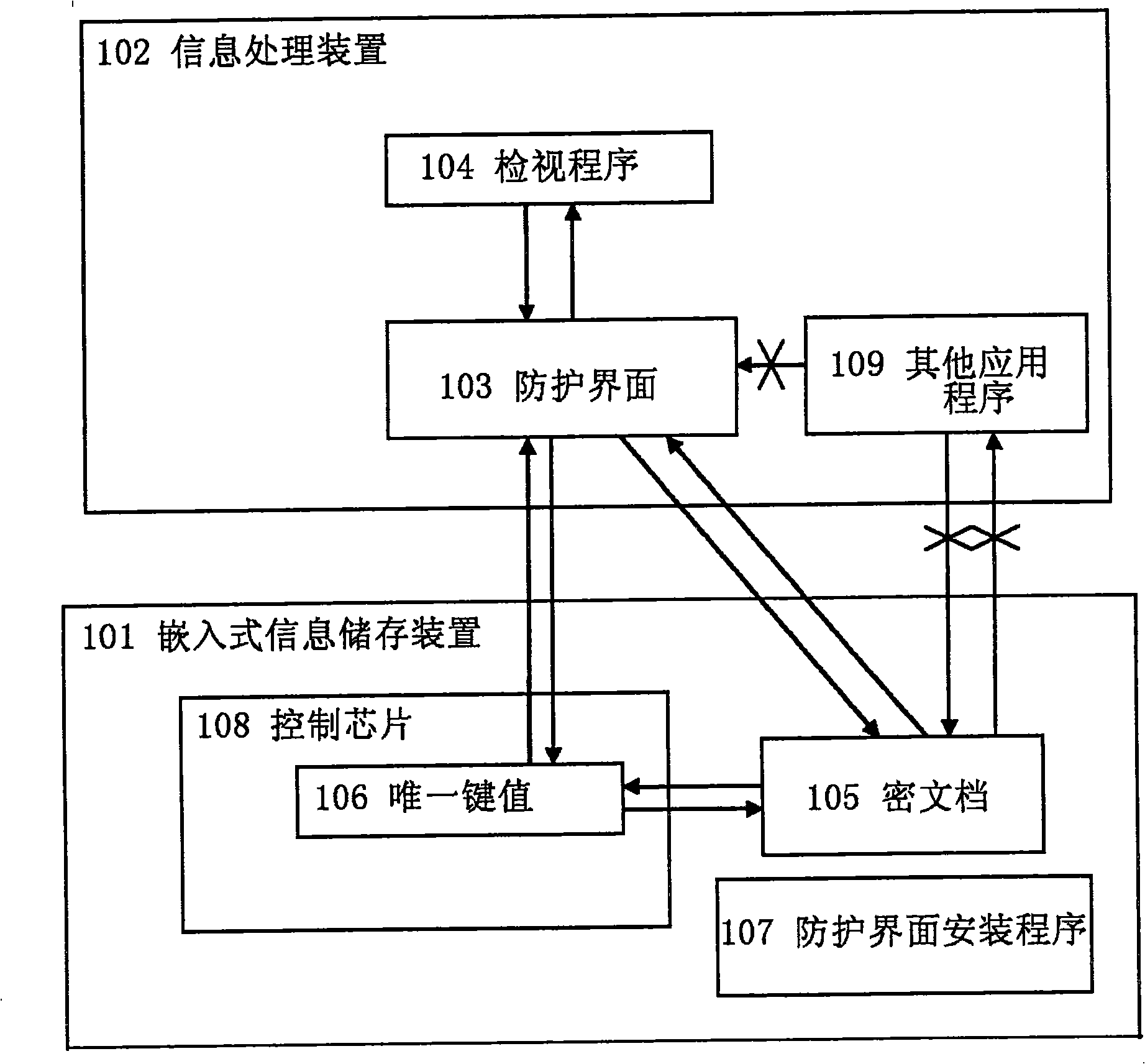

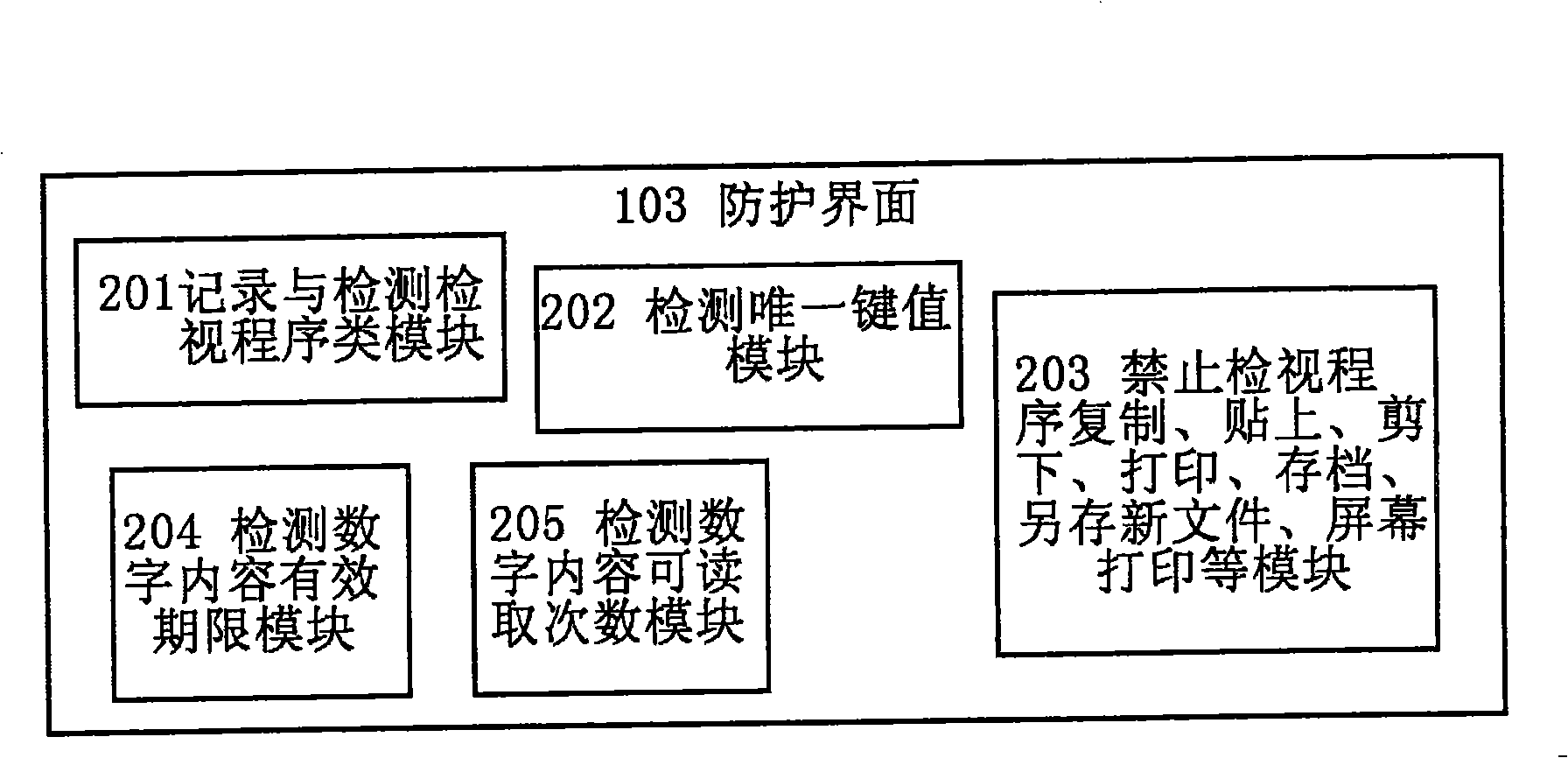

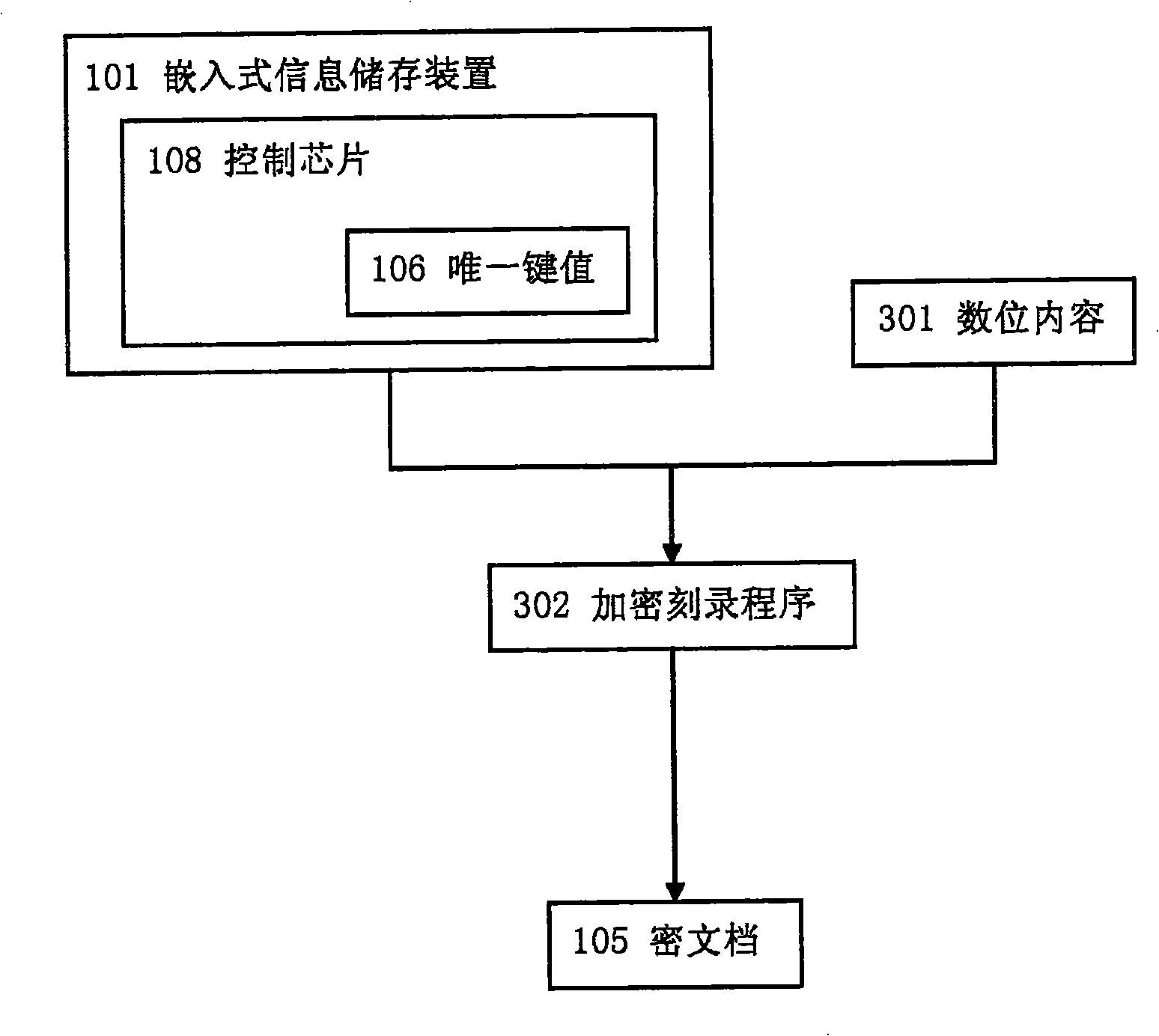

Embedded type information memory device and method for preloading digital assets management

InactiveCN101324865AAvoid misuseNo copyingUnauthorized memory use protectionProgram/content distribution protectionDigital rights managementEmbedded system

The invention discloses an embedded type information storage device with encryption and decryption functions, and a method for preloading digital asset management (Preload DRM). The preloading of the digital rights management can be customized according to the demands of clients. The device for preloading the digital rights management comprises encryption content and a protection interface which are pre-stored in the embedded type information storage device.

Owner:FINEART TECH CO LTD

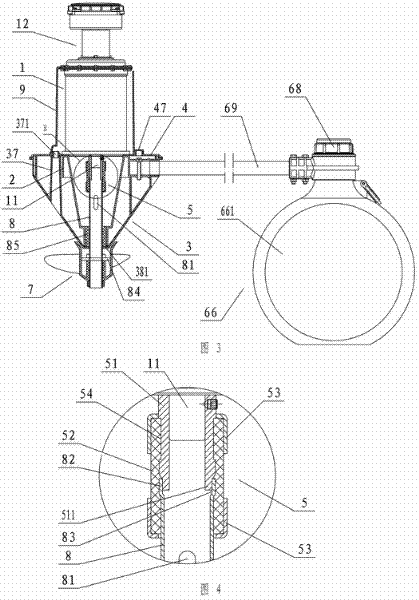

Pumping-up type aerator of water-cooled machine

InactiveCN102396429AOutstanding FeaturesHighlight significant progressWater aerationPisciculture and aquariaMicroorganismImpeller

The invention relates to a pumping-up type aerator of a water-cooled machine, belonging to the technical field of aerators. The pumping-up type aerator comprises a floating body, a motor, an impeller shaft, an impeller and a conical body, wherein the motor is connected with a floating body assembly through a supporting seat and works together with the supporting seat in a way of floating on the water, a motor shaft vertically and downwards extends into water, the impeller is arranged at the lower end of the motor shaft, a motor body is arranged on a position above the water, and the conical body is arranged at the lower part of the supporting seat so that water pumped up by the impeller disperses; and the periphery of the conical body or the conical body is provided with a water guiding device enabling the motor to be cooled, the water guiding device guides a part of water pumped up by the impeller to the surface of a motor housing so that the motor is better cooled. The impeller pumps up water during forwarding; the impeller jets flow downwards during reversing to generate negative pressure, absorb air and fill gas into water so as to aerate; and a diffusion wheel diffuses water pumped up by the impeller during pumping up water to the periphery so that aeration by pumping up water in the daytime to increase photosynthesis of microorganisms in water and aeration by jetting flow at night are realized.

Owner:吴为国

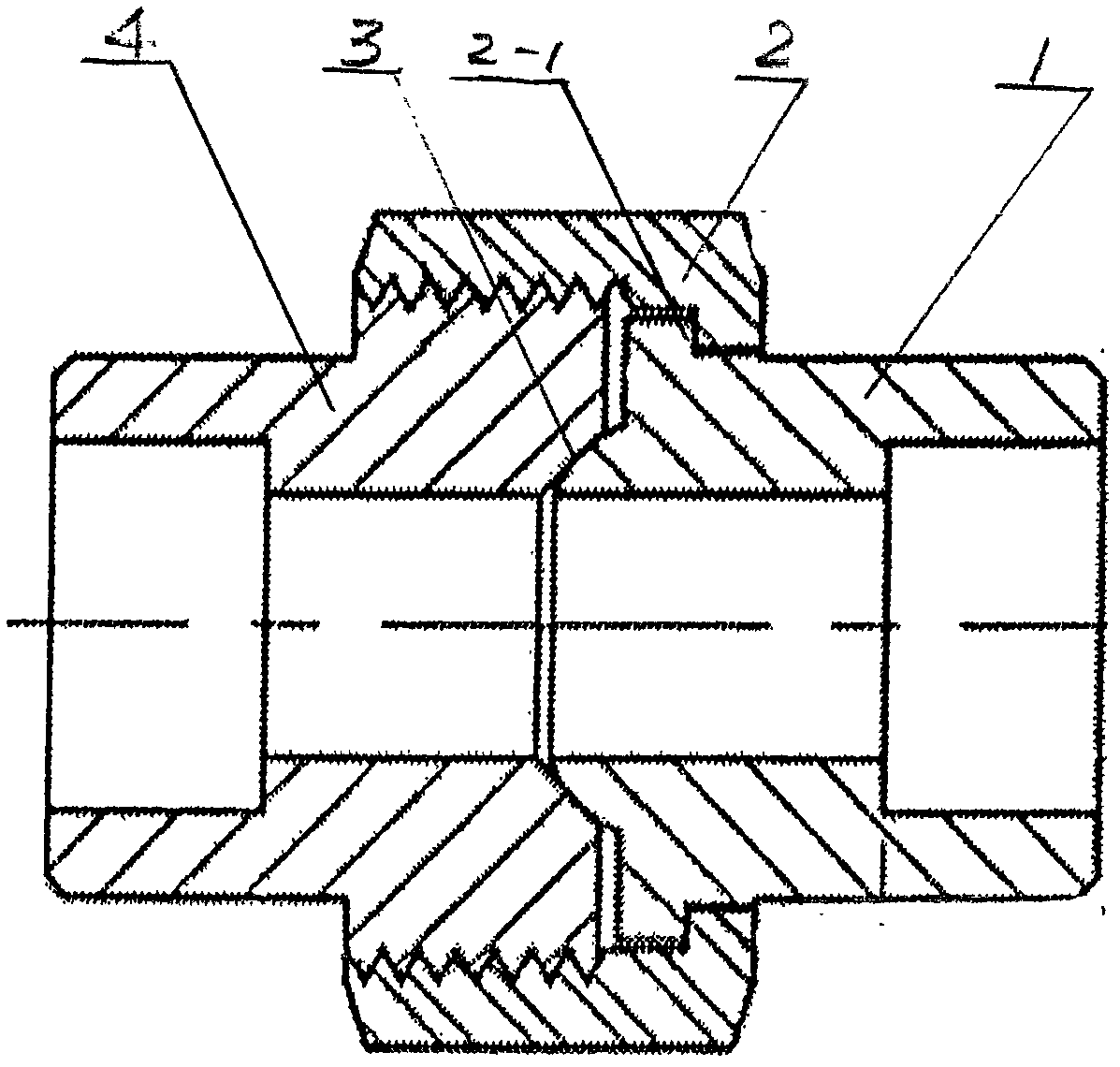

Copper-nickel-iron pipeline connection pipe fitting and preparation thereof

The invention provides a copper-nickel-iron pipeline connection pipe fitting and preparation thereof. The copper-nickel-iron pipeline connection pipe fitting comprises an outwards protruded surface joint, an inwards concave surface joint and a locking nut. The copper-nickel-iron pipeline connection pipe fitting is characterized in that the meshed positions of the outwards protruded surface joint and the inwards concave surface joint are provided with meshed arc surfaces. The preparation includes shove charging, smelting, sampling, analyzing, deoxidizing, refining, casting, forging and pressing, and finish machining. Compared with the prior art, a rubber pad is removed, cost is relatively saved, and the copper-nickel-iron pipeline connection pipe fitting is completely adapted to pipeline connection on the condition of high pressure or high temperature. Meanwhile, as the forging and pressing process is utilized, mechanical performance is improved, non-cutting or little cutting is achieved, alloy material is saved, and production cost is reduced. The copper-nickel-iron pipeline connection pipe fitting has the advantages of being convenient to connect, firm to connect, and high in seal degree, and pipeline connection is safe.

Owner:上海世航铜镍管件有限公司

Method for manufacturing abrasion-resistant U-shaped bolt

The invention discloses a method for manufacturing an abrasion-resistant U-shaped bolt. Machining steps include: casting a U-shaped rod, by weight, adding 11-14 parts of scrap steel into a medium frequency furnace to melt to form molten steel, adding carburant, when the temperature in the medium frequency furnace rises to 1120-1220 DEG C, adding 0.1-0.2 part of molybdenum, 0.2-0.3 part of magnesium ingot, 5-7 parts of scrap aluminum, 32-34 parts of steel ingot, 30-35 parts of pig iron and 12-16 parts of foundry returns, simultaneously scattering a layer of heat preservation covering agent on the surface of the melt and covering, slagging, after slagging, adding 0.6-0.9 part of ferromanganese and 2-3 parts of ferrosilicon alloy, when the temperature in the medium frequency furnace rises to 1400 DEG C, withdrawing, adding 0.4-0.6 part of copper along with molten iron into a ladle, and casting. The method adopts cold extrusion process to machine the bolt, the strength of the bolt is improved, hardness and strength required by the 12.9 high-strength bolt are met, and delayed fracture and fatigue fracture of the bolt under high strength are avoided. The bolt is reliable in connection and not prone to break, prolongs service life, and meets use requirements of various industries in society for the high-strength bolt.

Owner:浙江艾信汽车零部件股份有限公司

Speed reducing impeller-free aerator

The invention belongs to the technical field of aerators, and relates to a speed reducing impeller-free aerator. A motor is arranged in a shell consisting of a cone and a waterproof cover; the motor is connected with the shell by a supporting seat; a motor shaft is connected with an impeller shaft and vertically downwards extends to the water; a motor body is positioned above the horizontal plane; an isolating device for preventing hot air of the motor from refluxing to a motor fan cover is arranged between the waterproof cover and the motor, so that the hot air formed after heat exchange of a cooling fan and radiating fins does not reflux to the motor fan cover, and the temperature of the motor is greatly reduced; the supporting seat is connected with supporting rods, and the other ends of the supporting rods are respectively provided with a floating body; and the whole aerator works by means of the floating bodies which float on the water surface, the water stirred up by the impeller is guided around by the cone, so that the water of the lower layer is complemented and the aeration purpose is fulfilled by water convection. According to the aerator, structures such as a gear, a reduction box and the like in the prior art are abandoned, lubricating oil is not needed, a fish pond is effectively prevented from being polluted by leaked oil, and the production cost is reduced.

Owner:吴为国

Copper-nickel-iron loose inner flange and preparation thereof

The invention provides a copper-nickel-iron loose inner flange and preparation thereof. The preparation is characterized by being composed of shove charging, smelting, sampling, analyzing, deoxidizing, refining, casting, drawing, and finish machining. Compared with the prior art, the copper-nickel-iron loose inner flange is completely adapted to the pipeline connection on the condition of high pressure or high temperature. Meanwhile, the drawing process is utilized, mechanical performance of the copper-nickel-iron loose inner flange is improved, non-cutting or little cutting is achieved, alloy material and resources are saved, and production cost is lowered. The copper-nickel-iron loose inner flange has the advantages of being good in gas tightness, and pipeline connection is safe.

Owner:上海世航铜镍管件有限公司

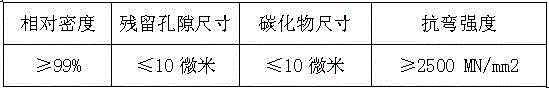

Method of forming powder metallurgy tool steel

InactiveCN103157796BSmall and uniform tissueImprove performanceVacuum pressureHigh volume manufacturing

The invention discloses a method of forming powder metallurgy tool steel. The method includes a first step of conducting carbon-reduction and anneal on water atomization tool steel powder under the vacuum condition, a second step of evenly coating the surface of the powder with a layer of graphitic lubricant assisting in sintering, and obtaining mixed material after paraffins forming agent is mixed in, a third step of manufacturing material blank or part blank by compression moulding forming of the mixed material and dewaxing, and a fourth step of sintering the material blank or the part blank by a vacuum-pressure furnace. The powder metallurgy tool steel (high-speed steel) produced by the method is even and fine in formation, relative density of the tool steel reaches 99.5% and the density is close to be fully compact. Material performance is excellent, the powder metallurgy tool steel is close to isostatic pressing tool steel (high-speed steel) material in physical and mechanical properties, and the method of forming the powder metallurgy tool steel has the advantage of being low in cost, free from cutting, high in efficiency and capable of massively producing parts the same with powder metallurgy.

Owner:HUNAN HUANYU POWDER METALLURGY CO LTD

Method for machining T-shaped bolt

ActiveCN103084532BModerate hardnessImprove the lubrication effectBoltsChemical compositionHigh intensity

Owner:ANHUI LIUFANG ZHONGLIAN MECHANICAL SHARE

Method for machining high-strength double end bolt

The invention discloses a method for machining a high-strength double end bolt. The method comprises the following steps of: a, manufacturing a rod blank, and controlling the weight percentage of each chemical component of the rod blank to meet the following requirements: 0.28 to 0.35 percent of C, 0.25 to 0.35 percent of Mn, 0.05 to 0.09 percent of V, 0.15 to 0.35 percent of Si, 0.01 to 0.04 percent of W, less than or equal to 0.025 percent of P, less than or equal to 0.035 percent of S, 0.55 to 1.20 percent of Ni, 0.35 to 0.45 percent of Co, 0.20 to 0.30 percent of Sb and less than or equal to 0.20 percent of Cu; and b, forging a cast rod at the temperature of between 850 and 800 DEG C for not more than 20 times, wherein a thin layer of fly ash is coated on the inner wall of an impression of a forging die; and turning an external thread at each of two ends of the bolt by using a precision lathe after forging. According to the method for machining the high-strength double end bolt, the bolt is machined by adopting a cold extrusion process, so that the strength of the bolt is improved, the hardness value and the strength value required by the 12.9 high-strength bolt are achieved, the problems of delayed fracture and fatigue fracture of the bolt under high strength are solved, the bolt is reliable in connection during use and difficult to break, the service life of the bolt is prolonged, and the using requirement of each industry in the society for the high-strength bolt is met.

Owner:ANHUI LIUFANG ZHONGLIAN MECHANICAL SHARE

A kind of high-strength, soluble metal matrix composite material and its preparation method

The invention discloses a high-strength and soluble metal-based composite material at first. The high-strength and soluble metal-based composite material comprises the following elemental components in percentage by weight of 10-15% of Al, 50-60% of Mg, 25-30% of C and other trace elements and impurities. Meanwhile, the invention further discloses a method for preparing the high-strength and soluble metal-based composite material. The method comprises the steps of preparing materials in a mass ratio of (10 to 15): (50 to 60): (20 to 30): (10 to 20) of an aluminium metal powder to a magnesium metal powder to carbon fibers to additives; mixing the raw materials according to different preparation flows to prepare a slurry; carrying out injection molding on the slurry to obtain a sintered precursor; carrying out liquid medium removal treatment on the sintered precursor; and carrying out sintering molding on the dried sintered precursor to obtain the metal-based magnesium-aluminium composite material. The high-strength and soluble metal-based composite metal material provided by the invention is high in strength and soluble under a specific condition, and has the characteristics of being excellent in comprehensive mechanical performance and the like.

Owner:CHINA PETROCHEMICAL CORP +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com