Method of forming powder metallurgy tool steel

A technology of powder metallurgy and forming method, which is applied in the field of metal material forming, can solve the problems of low strength, toughness and other mechanical properties, low production efficiency, and limited use, and achieve low material utilization, high production cost, and uniform structure small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

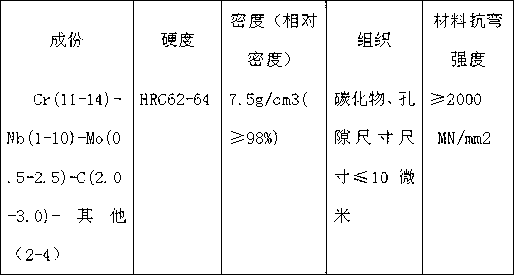

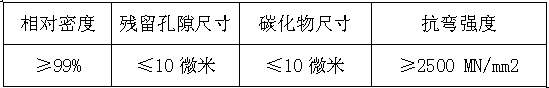

Image

Examples

Embodiment 1

[0027] The forming method of powder metallurgy tool steel comprises the following steps:

[0028] Step 1. Carry out carbon reduction on water atomized tool steel (high-speed steel) Cr12Nb4MO1 powder at a vacuum degree of 5Pa and a temperature of 900°C, and then heat-preserve and anneal at a temperature of 780-820°C;

[0029] Step 2, add graphite lubricant in the tool steel (high speed steel) powder through reduction annealing, graphite lubricant selects DAG154 of Henkel Company, the carbon in graphite lubricant accounts for 2.3% (weight) of total weight, mix uniformly, vacuum Dry and sieve, so that the surface of the powder is evenly coated with a layer of graphite lubricant to aid in sintering, and then evenly mixed with paraffin molding agent to obtain a mixture;

[0030] Step 3. Mold the mixture in step 2 into a material blank or a part blank with a traditional powder metallurgy process. The relative density of the compact is 85%, and then pre-burn and dewax it at a tempera...

Embodiment 2

[0042] The forming method of powder metallurgy tool steel comprises the following steps:

[0043] Step 1. Carry out carbon reduction of water atomized tool steel (high-speed steel) Cr12Ni1MO0.5C2.0 powder at a vacuum degree of 10Pa and a temperature of 900°C, and then heat-preserve and anneal at a temperature of 780°C;

[0044] Step 2. Add graphite lubricant to the reduced annealed tool steel (high-speed steel) powder. The graphite lubricant is DAG154 from Henkel Company. The carbon in the graphite lubricant accounts for 0.5% (weight) of the total weight. Mix evenly and vacuum Dry and sieve, so that the surface of the powder is evenly coated with a layer of graphite lubricant to aid in sintering, and then evenly mixed with paraffin molding agent to obtain a mixture;

[0045] Step 3. The mixture in step 2 is molded into a material blank or a part blank by traditional powder metallurgy technology. The relative density of the compact is 70%. Temperature pre-burning dewaxing;

...

Embodiment 3

[0057] The forming method of powder metallurgy tool steel comprises the following steps:

[0058] Step 1. Carry out carbon reduction of water-atomized tool steel (high-speed steel) Cr12Nb6MO1.5 powder at a vacuum degree of 3Pa and a temperature of 950°C, and then heat-preserve and anneal at a temperature of 820°C;

[0059]Step 2. Add graphite lubricant to the tool steel (high-speed steel) powder through reduction annealing. The graphite lubricant is DAG154 from Henkel Company. The carbon in the graphite lubricant accounts for 3.0% (weight) of the total weight. Mix evenly and vacuum Dry and sieve, so that the surface of the powder is evenly coated with a layer of graphite lubricant to aid in sintering, and then evenly mixed with paraffin molding agent to obtain a mixture;

[0060] Step 3. Mold the mixture of step 2 into a material blank or a part blank with a traditional powder metallurgy process. The relative density of the compact is 85%, and then pre-burn and dewax it at a t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com