Pumping-up type aerator of water-cooled machine

A water-cooled motor and aeration machine technology, which is applied in water/sludge/sewage treatment, water aeration, sustainable biological treatment, etc., can solve the problems of poor heat dissipation and falling on the motor, and increase photosynthesis effect, cost reduction, and large water volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

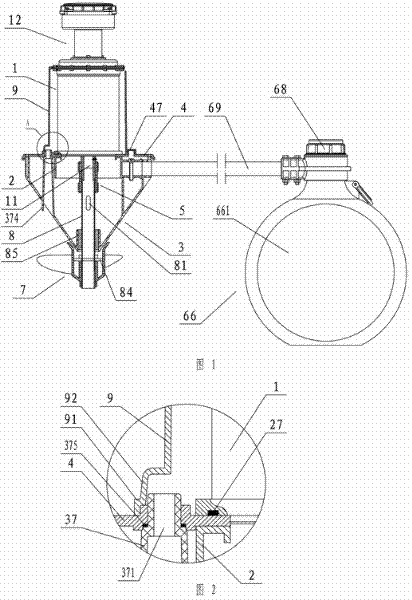

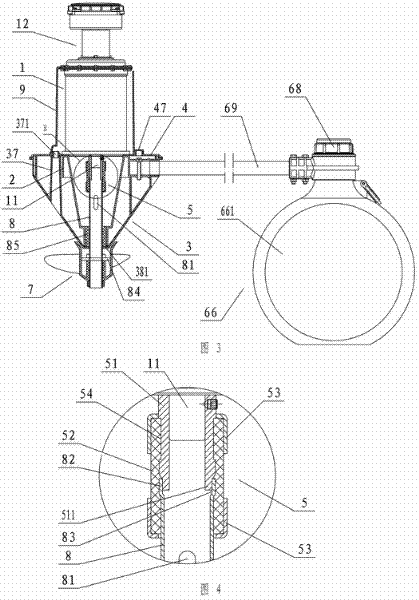

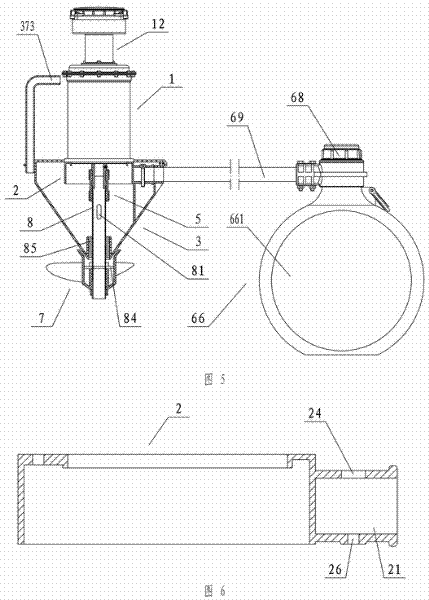

[0056] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-23 :

[0057] The water-cooled motor pumping type aerator includes a floating body, a motor 1, an impeller shaft 8, an impeller 7, and a conical body 3. The motor is connected to the floating body assembly by a support seat 2, and works together on the water surface. The motor 1 is installed vertically, and the motor shaft 11 is vertical. Extend downwards into the water, or the motor shaft is connected to the impeller shaft 8 through the coupling 5, the impeller shaft 8 extends vertically downwards into the water, the lower end of the impeller shaft is equipped with the impeller 7, the body of the motor 1 is above the horizontal plane, the motor housing It has a waterproof sealing structure, and the power wiring device of the motor is on the top of the motor. The wiring device can be composed of a sealed junction box 12 and the wiring t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com