Copper-nickel-iron loose inner flange and preparation thereof

An inner flange, copper-nickel technology, applied in the field of copper-nickel-iron loose inner flange and its preparation, can solve the problems of difficult to achieve flange air tightness, safety accidents, gas or liquid leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] Below in conjunction with accompanying drawing, take the loose sleeve inner flange of the D400mm of copper-nickel-iron alloy as an example, the present invention will be further described:

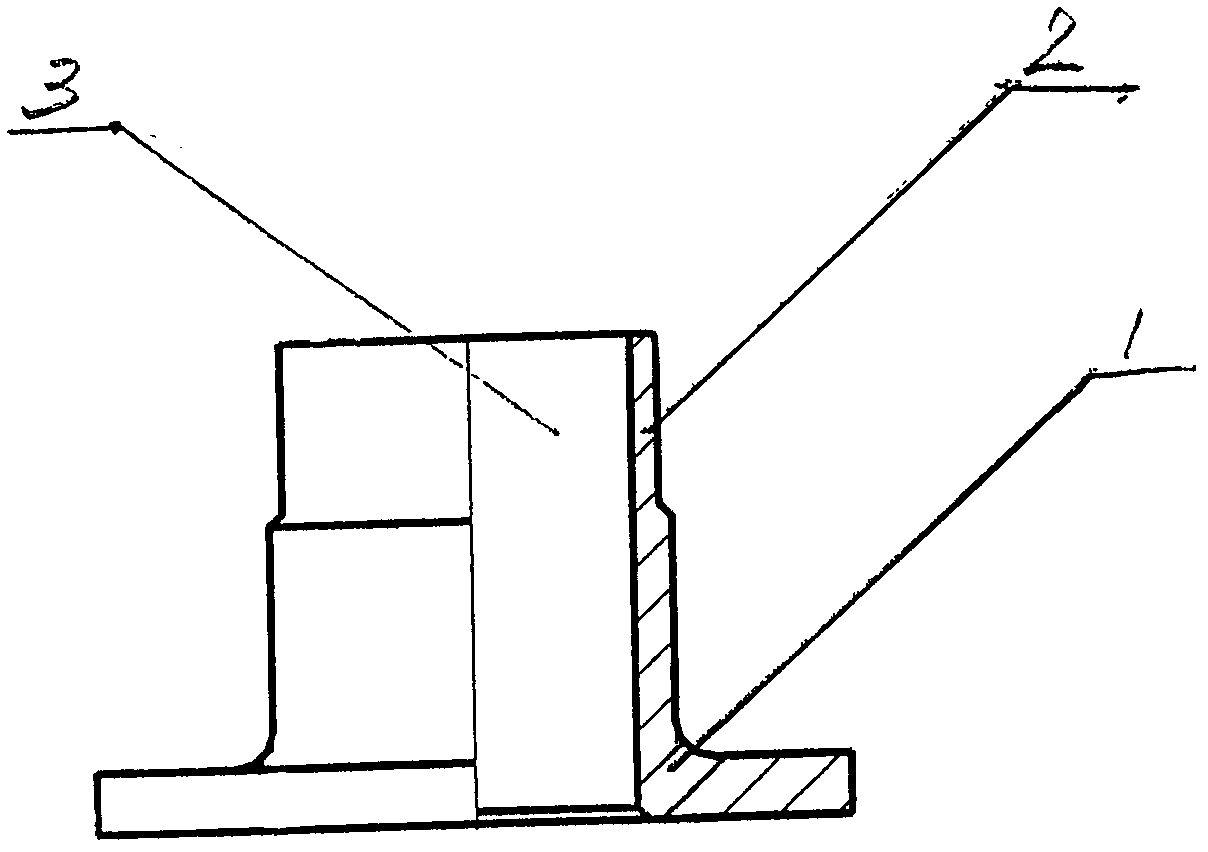

[0007] See attached figure 1 , using copper-nickel-iron alloy, the bottom is a flange ring 1, and the upper opening is a thin-walled opening 2 with an inner hole 3 in the middle.

[0008] See attached figure 1 , when casting, use copper-nickel-iron alloy to add refractory nickel to the bottom, add copper, add old materials and covering agent to melt, take samples and analyze, adjust the content of metal elements to meet the composition requirements of copper-nickel alloy, and carry out deoxidation refining , when the furnace temperature rises to the range of 1350-1450°C, remove the slag, add Cu-Mg alloy for deoxidation, and remove oxygen in the copper liquid; the molten liquid is poured into the mold separately, and the bottom is cast as a flange ring 1, catch It is a blank with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com