Inner-diameter measuring head of plunger sleeve

A technology of measuring head and plunger sleeve, which is applied in the field of plunger sleeve inner diameter measuring head and split type plunger sleeve inner diameter measuring head, can solve the problems of low production efficiency, high material cost, high production cost, etc., and achieve high production efficiency, The effect of reducing material cost and small processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

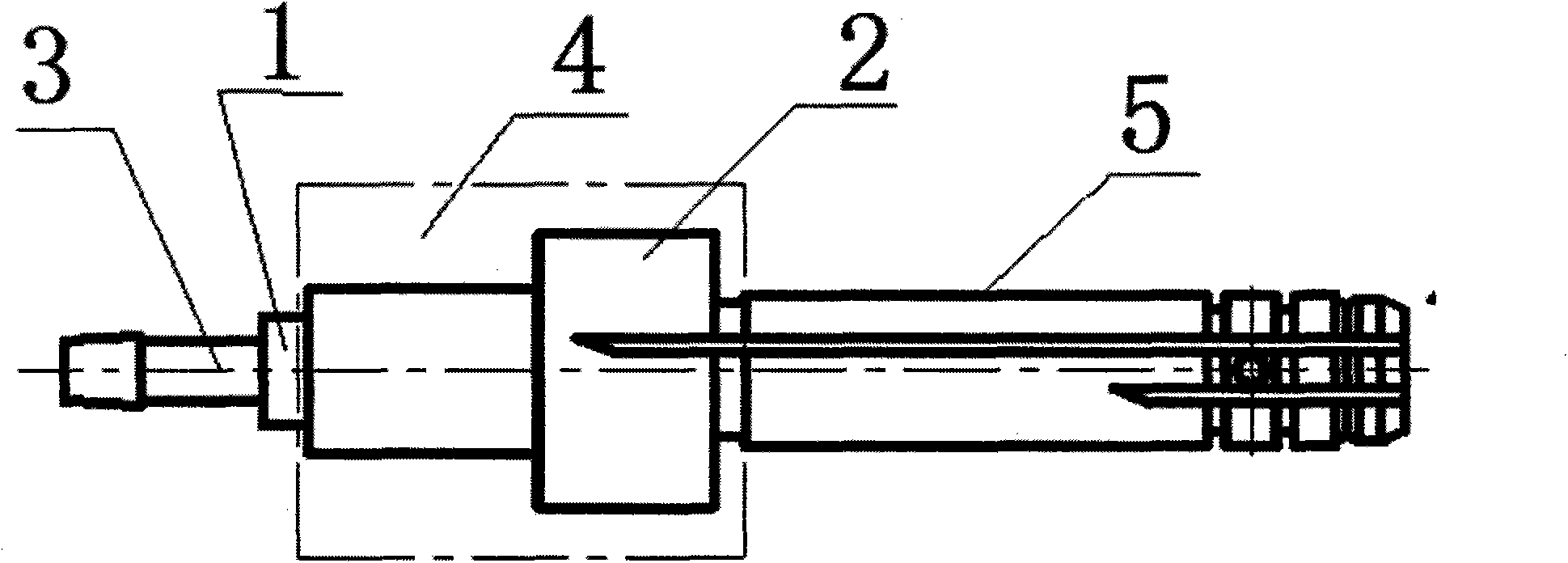

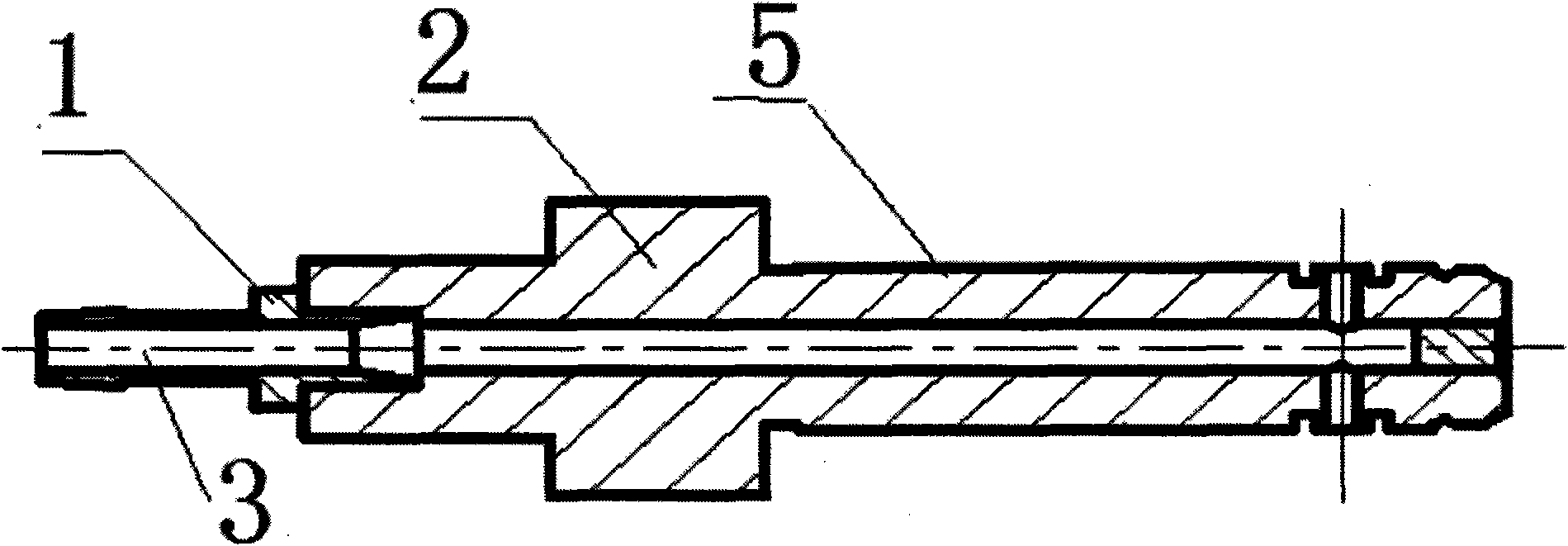

[0021] Measure the inner diameter of the plunger sleeve (integral type) ( figure 1 ) For example:

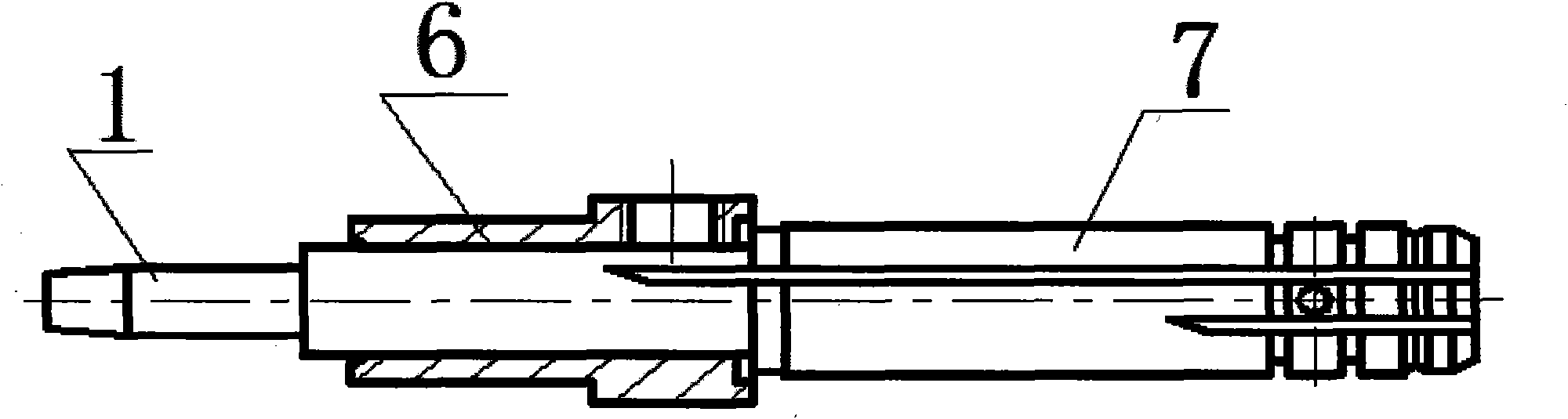

[0022] The plunger sleeve inner diameter measuring head (split type) of this embodiment ( image 3 ) is the original plunger sleeve inner diameter measuring head (integral) ( figure 1 ) The measuring part 5 and the positioning clamping part 4 are separately designed into two parts: the measuring head 7 and the positioning sleeve 6.

[0023] Measuring head 7 is the measuring part of the inner diameter measuring head of the plunger sleeve. Due to its special working environment and performance requirements, the selected material requires small heat treatment deformation, good wear resistance, and good dimensional stability after heat treatment and aging, so GCr15 is still selected. Manufactured from bearing steel. GCr15 bearing steel will obtain a stable metallographic structure after repeated internal stress elimination, multiple tempering and ice-cooling treatments during p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com