Block for construction, panel for construction using the block, and method of molding panel for construction

A technology for construction and building blocks, which is applied in the direction of construction, building materials, building components, etc., can solve the problems of weak strength of connecting blocks, deterioration of adhesives, lack of durability, etc., to improve strength and durability, improve insulation Heat resistance, effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

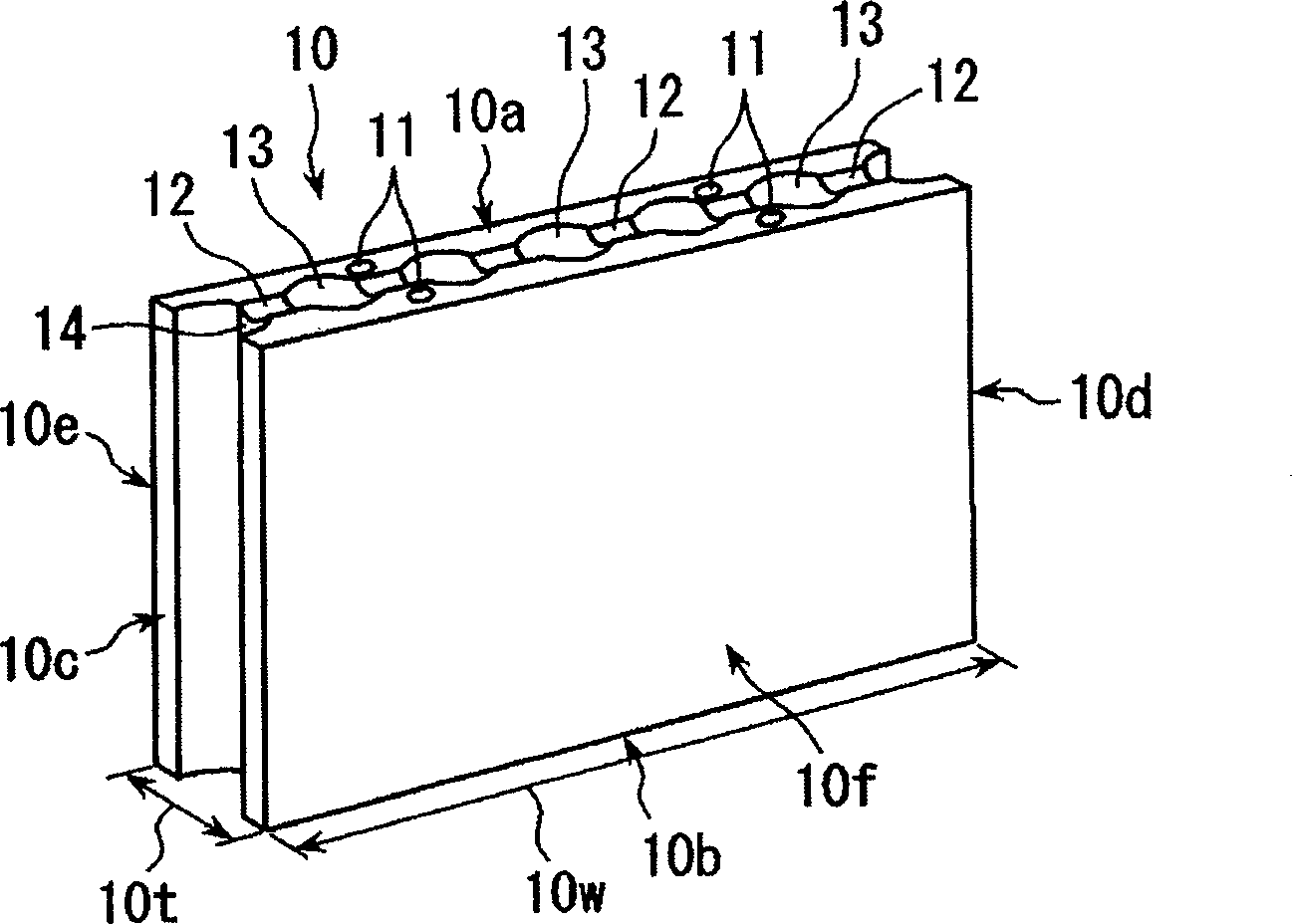

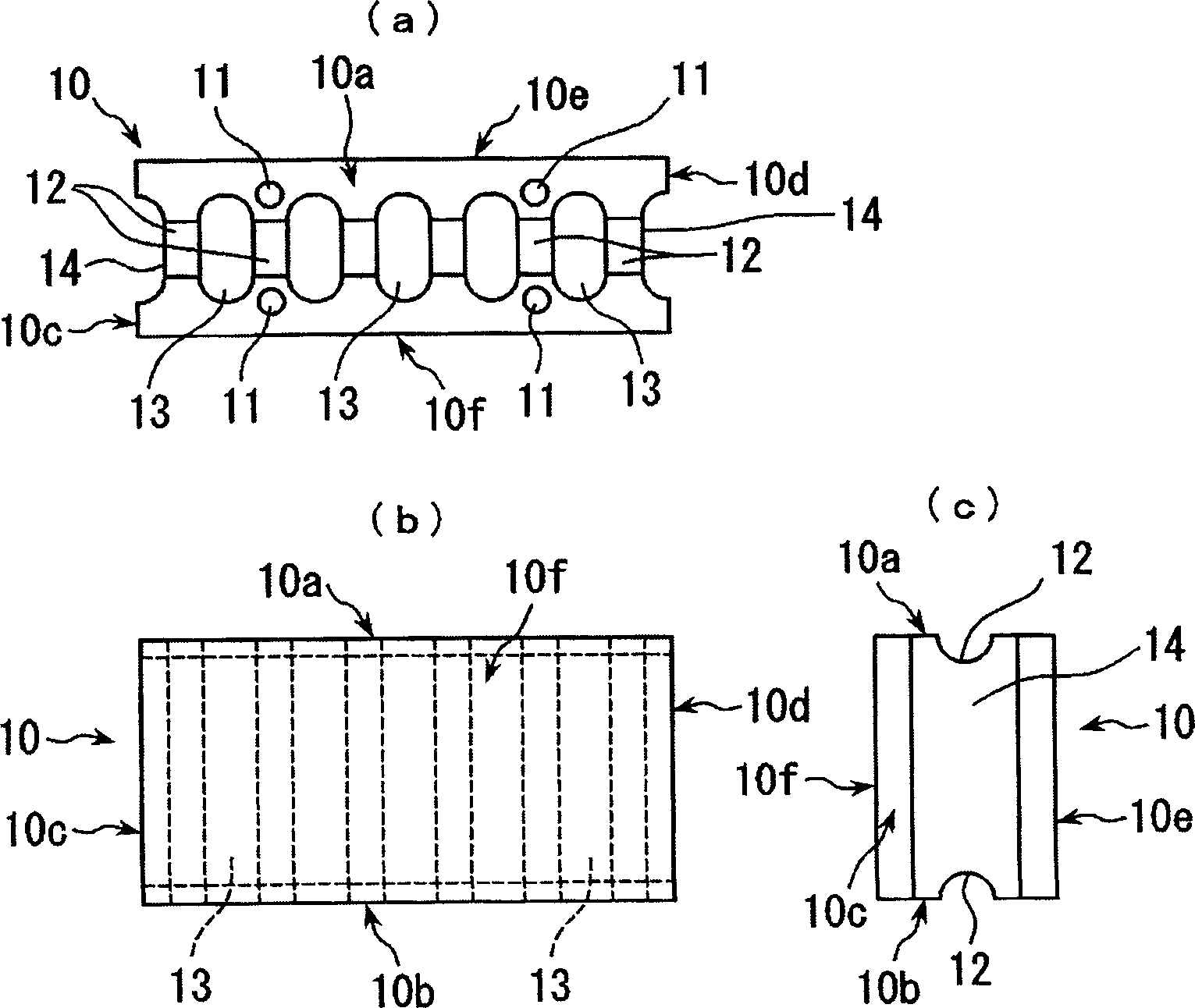

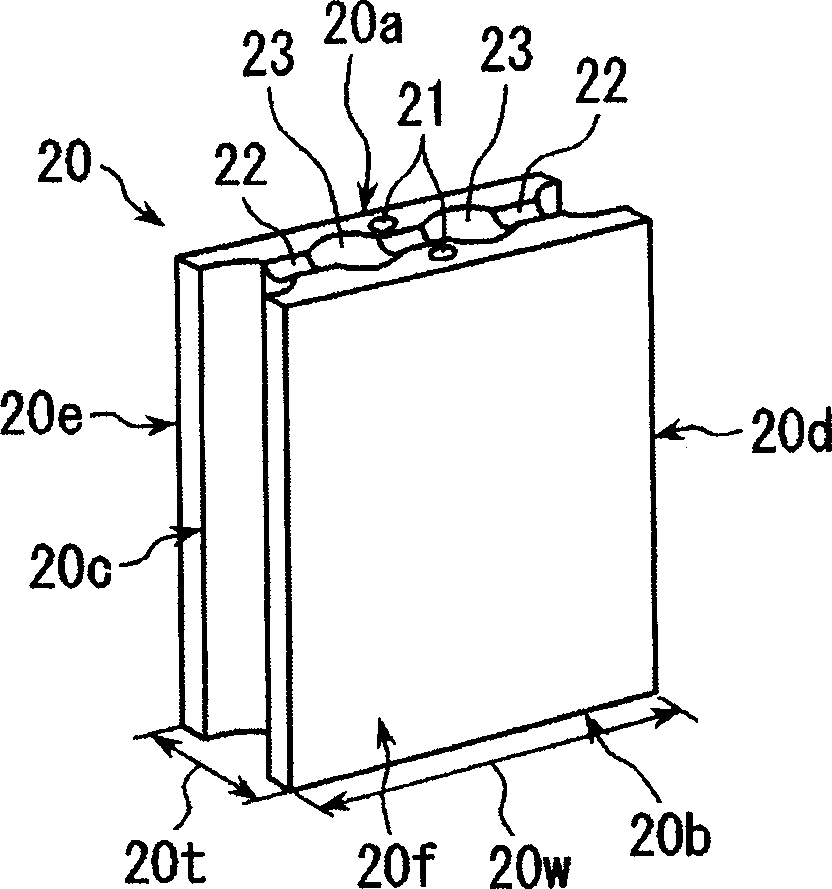

[0073] refer to Figure 1 to Figure 10 , The construction blocks and the construction slabs formed by applying the construction blocks according to the first and second embodiments of the present invention will be described.

[0074] Such as figure 1 , figure 2 As shown, the construction blocks 10 of the first embodiment are arranged in a plurality of planes by making the four outer peripheral surfaces of the upper surface 10a, the lower surface 10b, the left side 10c, and the right side 10d contact each other as will be described later. Blocks that can build planar structures. On building block 10, be formed with its front 10f and back 10e parallel to a plurality of through-holes 11 that are used to insert the rod-shaped tightening parts that will be described later. The other tensioning members are arranged in the direction of the through hole 11, so that the upper surface 10a and the lower surface 10b of the outer peripheral surface intersecting the axial direction of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com