Improved dorsiflexion shoe

A dorsiflexion and insole technology, applied in the field of casual shoes and sports shoes, can solve the problems of restricting marketability and clumsy appearance, and achieve the effect of avoiding morphological problems, great flexibility, and improving the ability of feet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

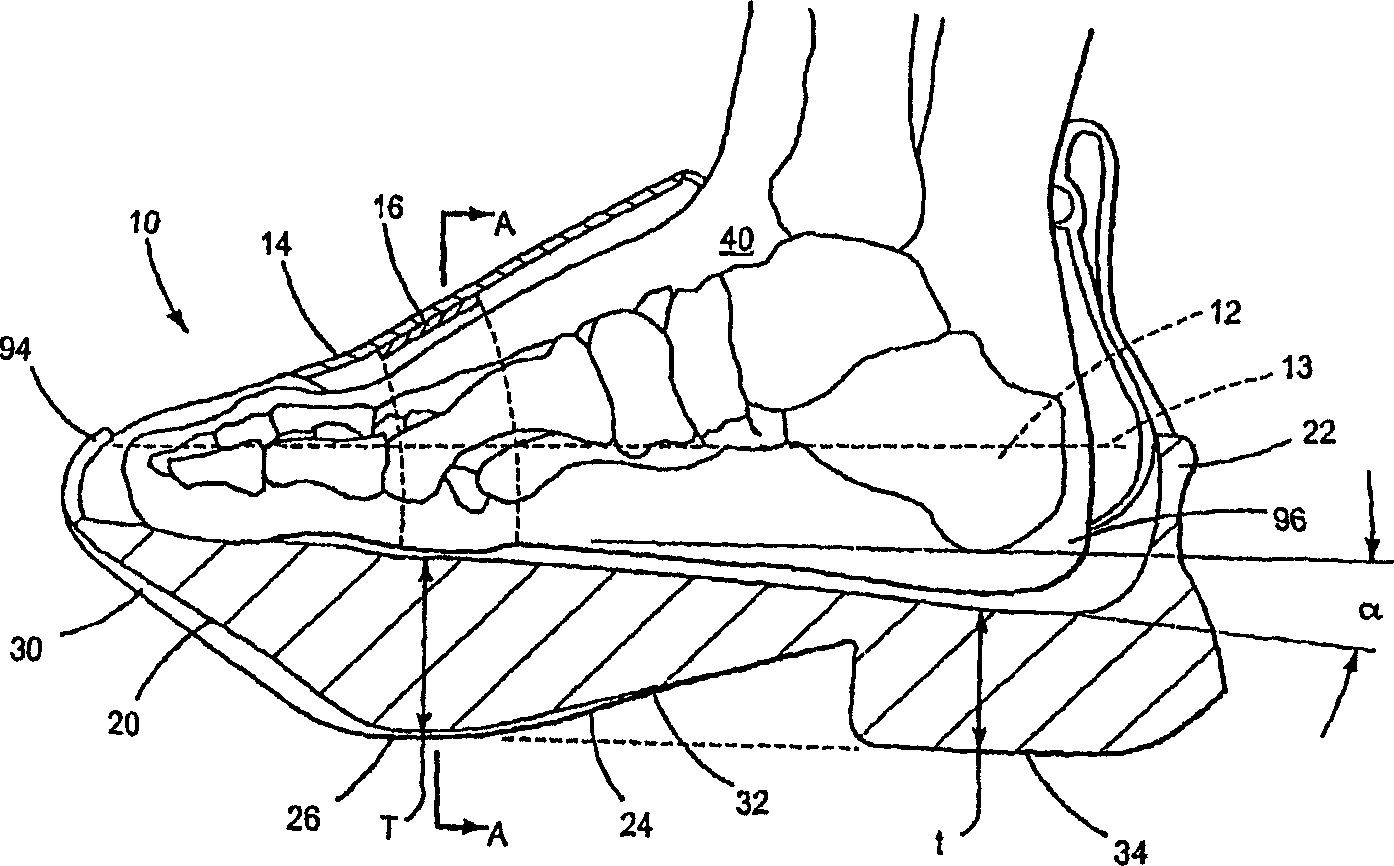

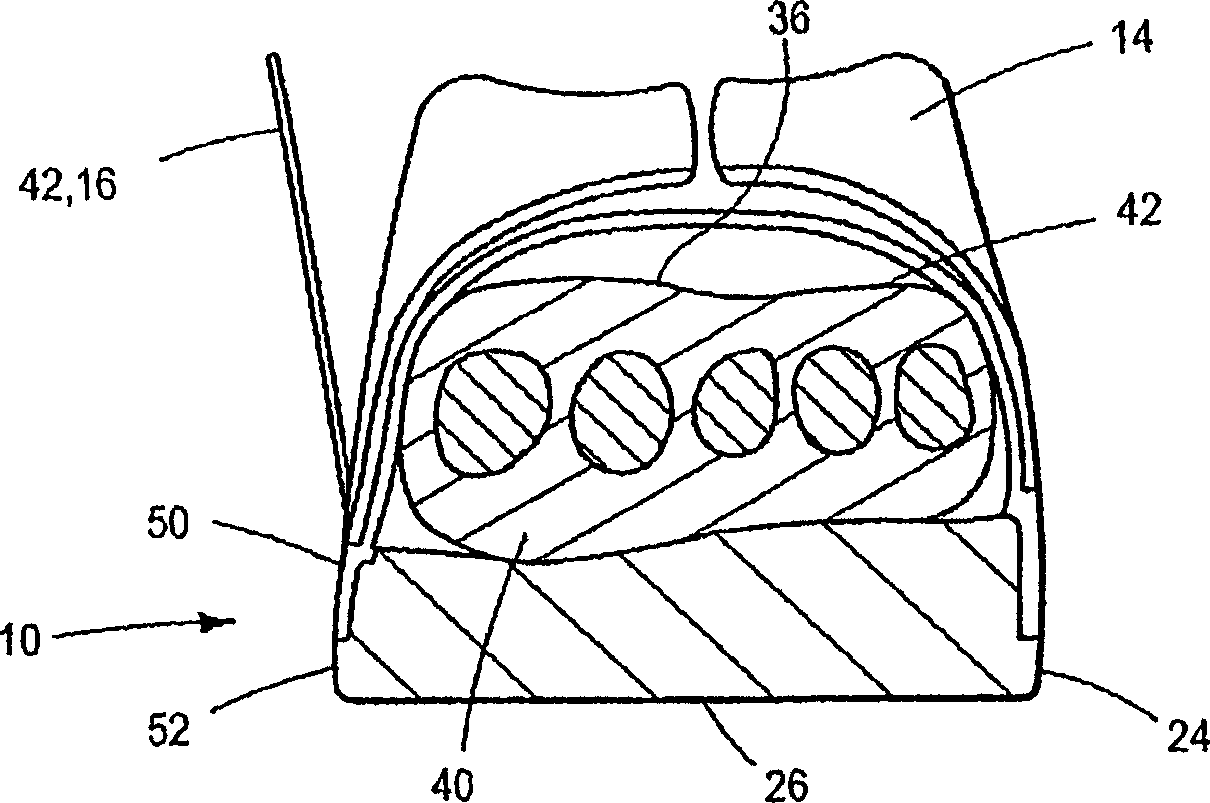

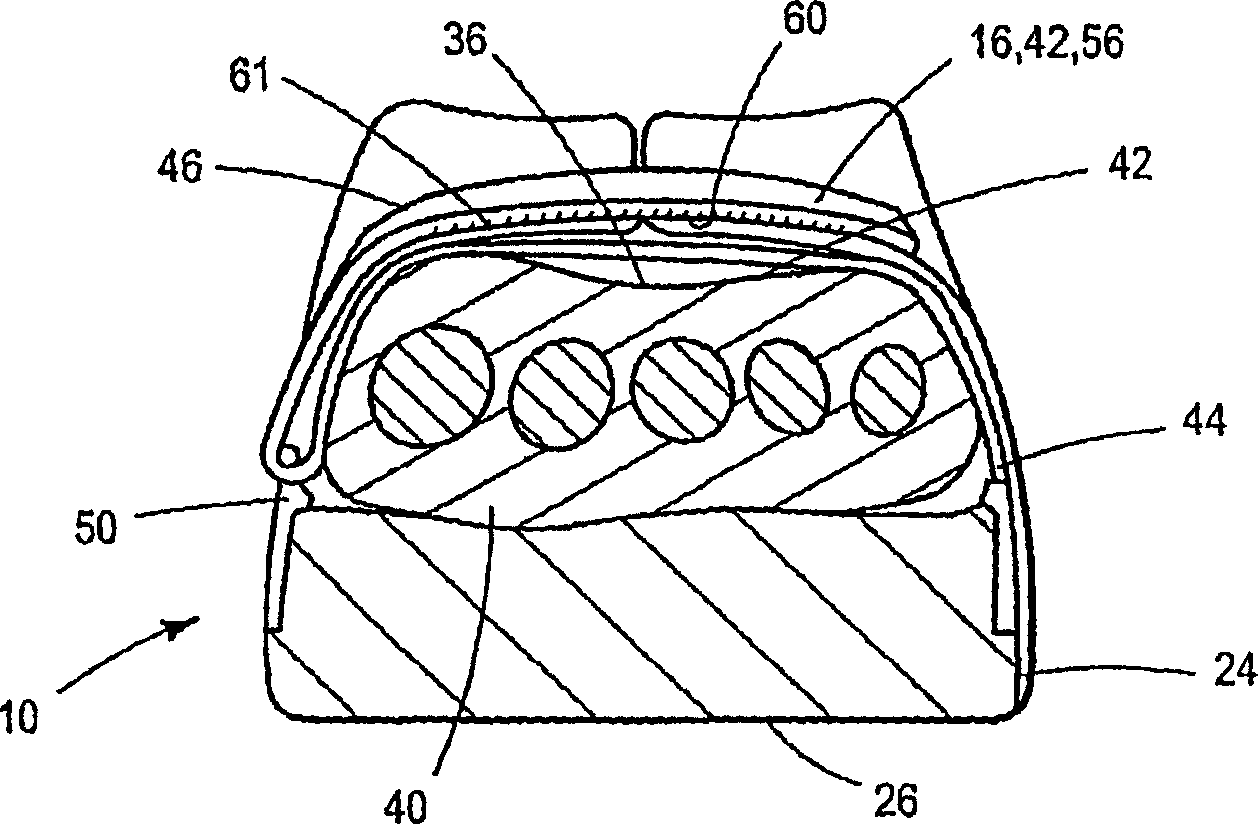

[0036] in such as figure 1 In the preferred embodiment shown, a high performance dorsiflexion shoe 10 has a shoe cover 12 , an upper 14 and a restraint 16 positioned over a metatarsal-phalangeal joint 20 . The shoe cover 12 has a side wall portion 22 with an upper edge 13 . The side wall portion 22 is connected to a sole portion 24 . The sole portion 24 has a ground contacting surface 26 , a forefoot region 30 , a midfoot region 32 and a heel region 34 . The forefoot region 30 is made of a high-density material and has a thickness T measured in a direction perpendicular to the ground-contacting surface 26 of the sole portion 24 that is higher than the thickness t of the heel portion 34, thereby forming a gap from the forefoot region to the heel. Downslope of the characteristic angle α of the zone. The restraint device 16 substantially restrains movement of the wearer's metatarsophalangeal joint 20 during exercise. The forefoot region 30 has a flex zone 28 that is defined t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com