Circuit arrangement for cooling charge air and method for operating a circuit arrangement of this type

A supercharged air and circuit technology, which is applied in the direction of engine cooling, coolant flow control, and liquid cooling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

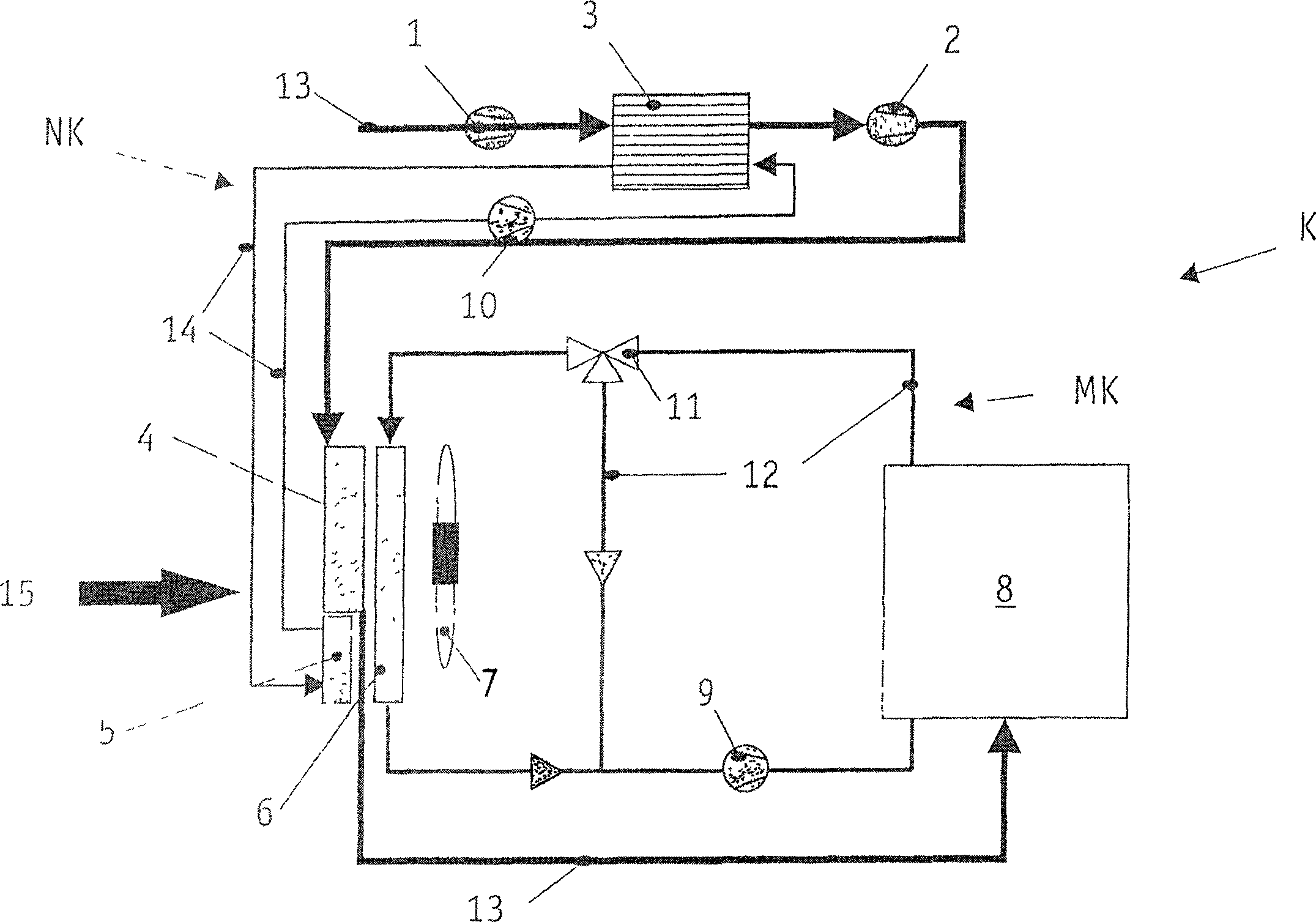

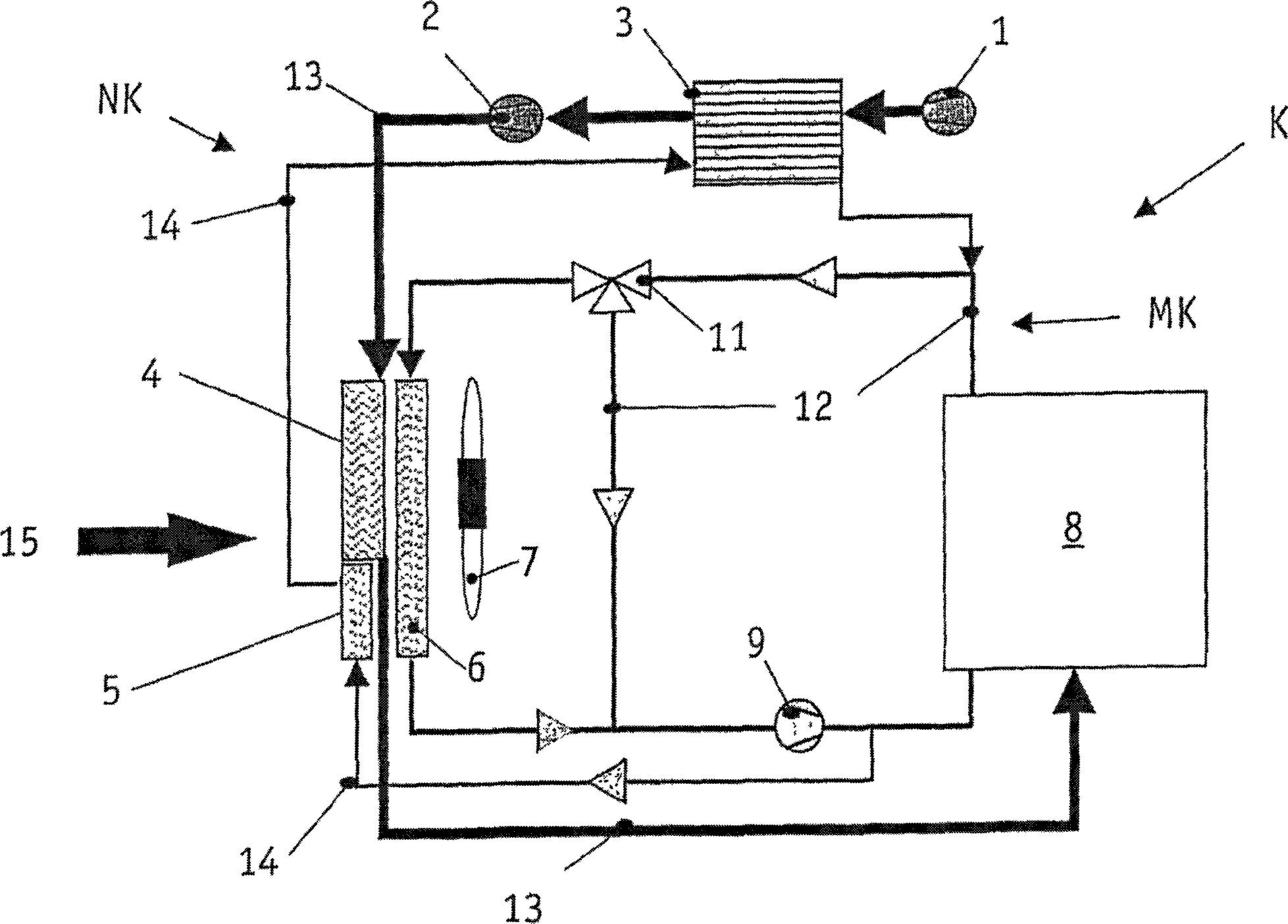

[0017] figure 1 In is a circuit arrangement for cooling two turbochargers connected in series, namely a low-pressure turbocharger 1 and a high-pressure turbocharger 2 . Reference numeral 13 refers to charge air, which is sucked in from the surrounding environment and compressed in the first stage in the low-pressure turbocharger 1 . During this process, the temperature of the charge air 13 increases. In order to continue the compression and at the same time avoid the overheating of the components that are in direct or indirect contact with the charge air 13 and cause the life to be affected Cooling in a low-pressure charge air / coolant cooler 3 which is part of the low-temperature circuit NK. The low temperature circuit NK will be described in detail later.

[0018] After being cooled by the low-pressure-charge air / coolant-cooler 3, the charge air 13 enters the high-pressure-turbocharger 2, where it is further compressed to its final pressure, during which The air is heated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com