Dual-purpose wheel-skidding shoes

A roller skate and dual-purpose technology, which is applied to roller skates, ice skating, and skateboards, etc., can solve the problems of large sole cavity, material consumption, and waste of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

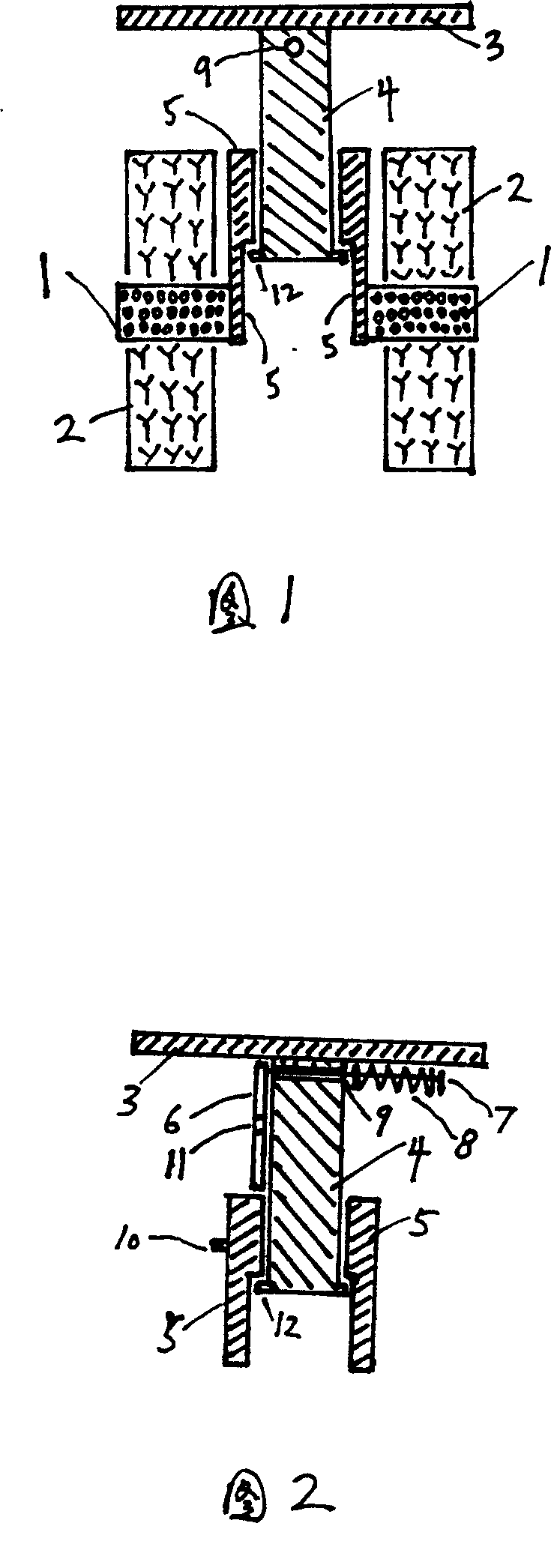

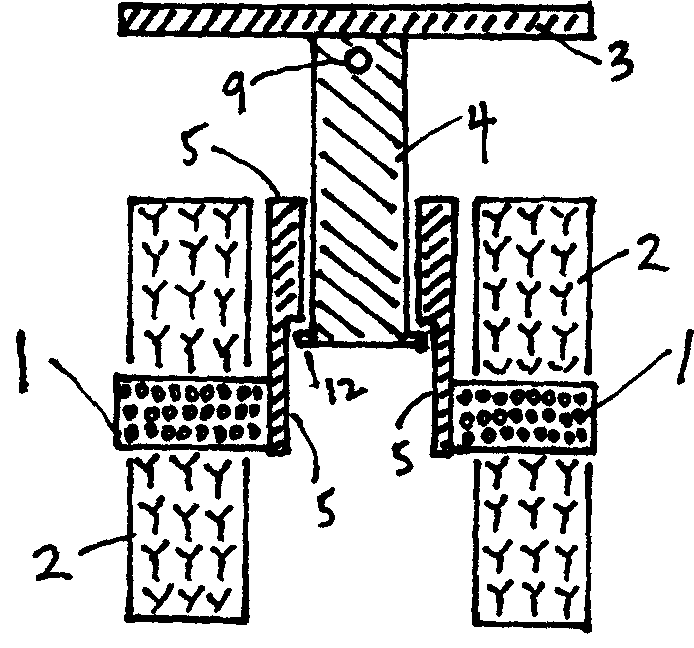

[0012] The invention is composed of a wheel shaft part, a supporting part, a guide support part and an upper and lower lock position part, and the innovation is in the guide support part and the upper and lower lock position part. The wheel shaft part is composed of rollers (2) sleeved at both ends of the shaft core (1), the top part is composed of a supporting plate (3) against the cavity of the sole, and the guide support part is composed of a guide column fixed on the supporting plate (3). (4) is formed with the guide cylinder (5) that is fixed on the shaft core (1), and the upper and lower locking part is made up of lock plate (6), guide push pin (7) and reset stage clip (8).

[0013] The supporting plate (3) is fixed on the top of the sole cavity, the upper end of the guide post (4) is fixed under the supporting plate (3), and the guide post (4) is covered with a guide cylinder ( 5), the two sides of the lower section of the guide cylinder (5) are connected to the shaft c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com