Double-drive walking type chassis crane

A dual-power drive, crane technology, applied to cranes and other directions, can solve the problems of large site restrictions, difficult movement, waste, etc., and achieve the effect of enhanced stability and good mobile flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

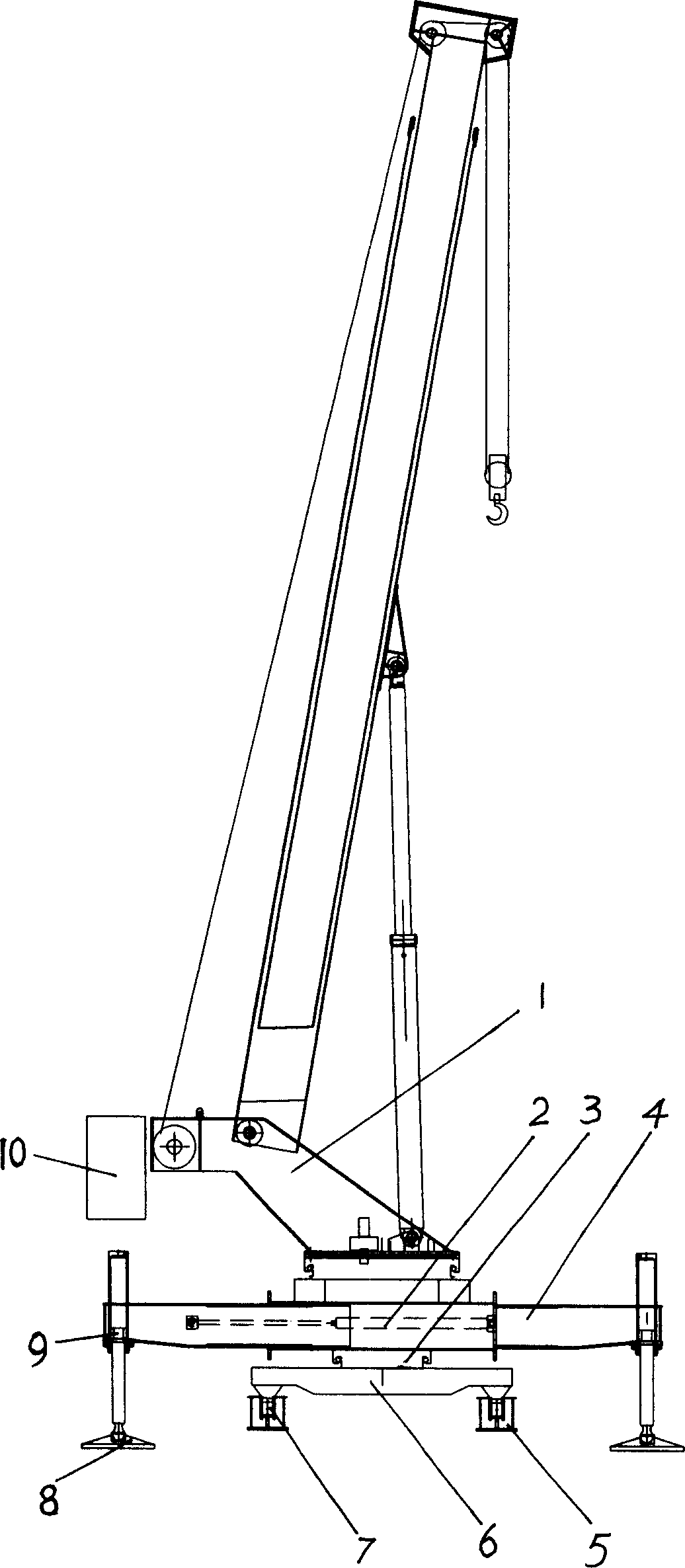

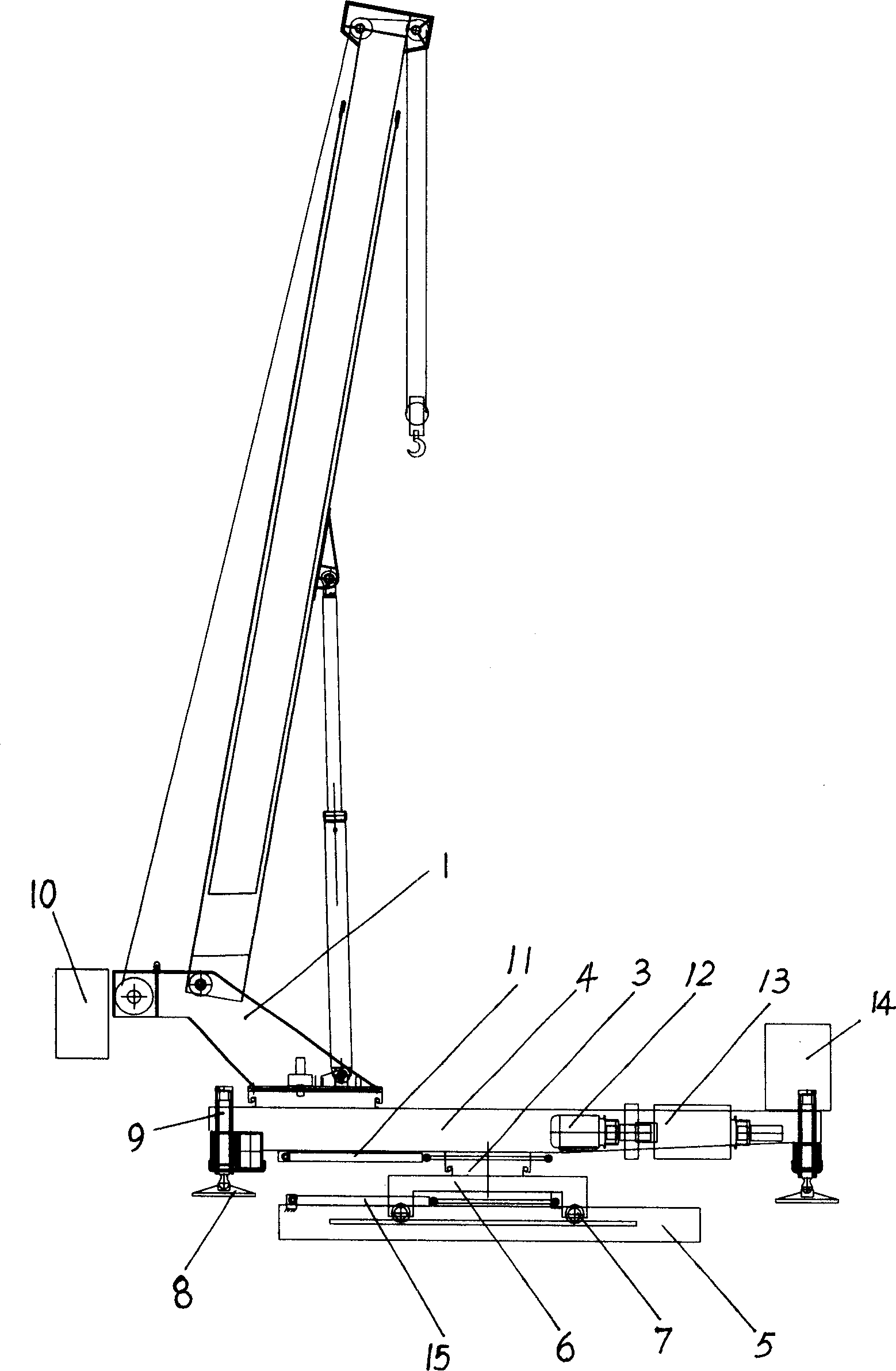

[0008] exist figure 1 , figure 2 Among them, the crane (1) of the present invention adopts an existing crane and is installed on the chassis of the present invention. The key to implementing the present invention is the structure and composition of the chassis. One embodiment is that the four legs (9) of the chassis platform (4) are connected with the platform (4) by a leg extension cylinder (2), and the two carrying rails (5) are respectively provided with a walking cylinder (15), and the platform (4) is provided with the double power drive unit of diesel engine power pump group (13) and electric motor power pump group (12), all the other are identical with the structure of existing walking chassis. Another kind of embodiment is that the two supporting legs at one end of the chassis platform (4) are connected with the platform (4) and the two supporting legs at the other end are fixed on the platform (4), and the rest The structure is the same as the previous embodiment. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com