Novel cleaning technique for production of high-quality sugar

A high-quality, clean technology, applied in the beet sugar process and sugar cane field, can solve the problems of high cost and difference, achieve the effect of improving quality, reducing cost and increasing flux through the membrane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

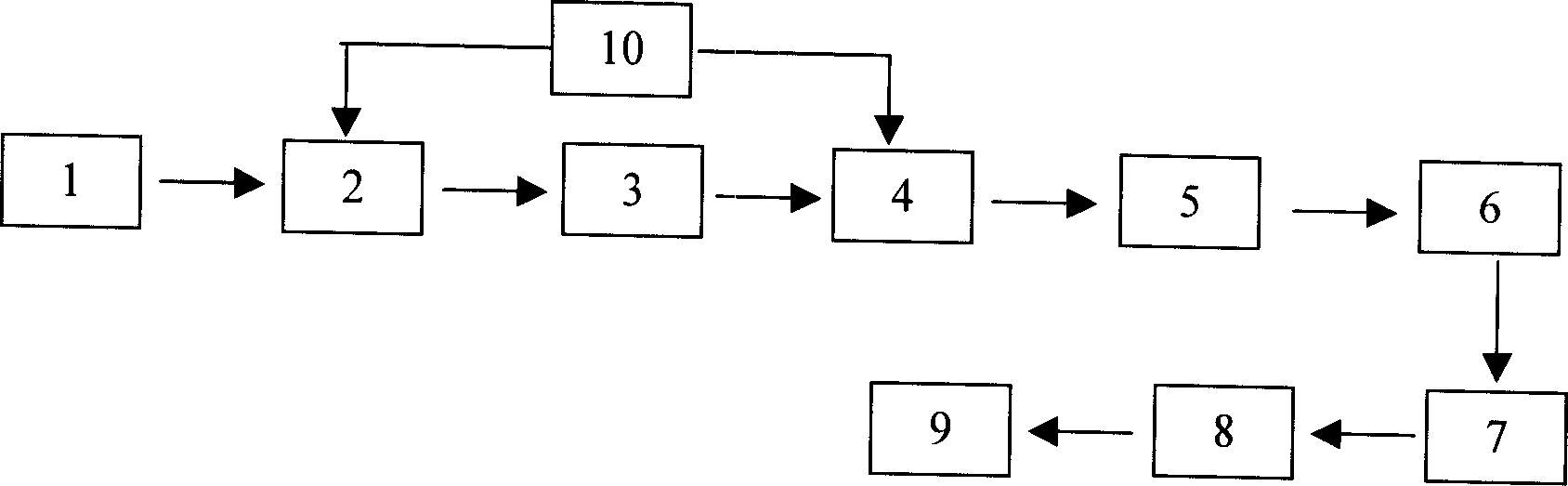

Method used

Image

Examples

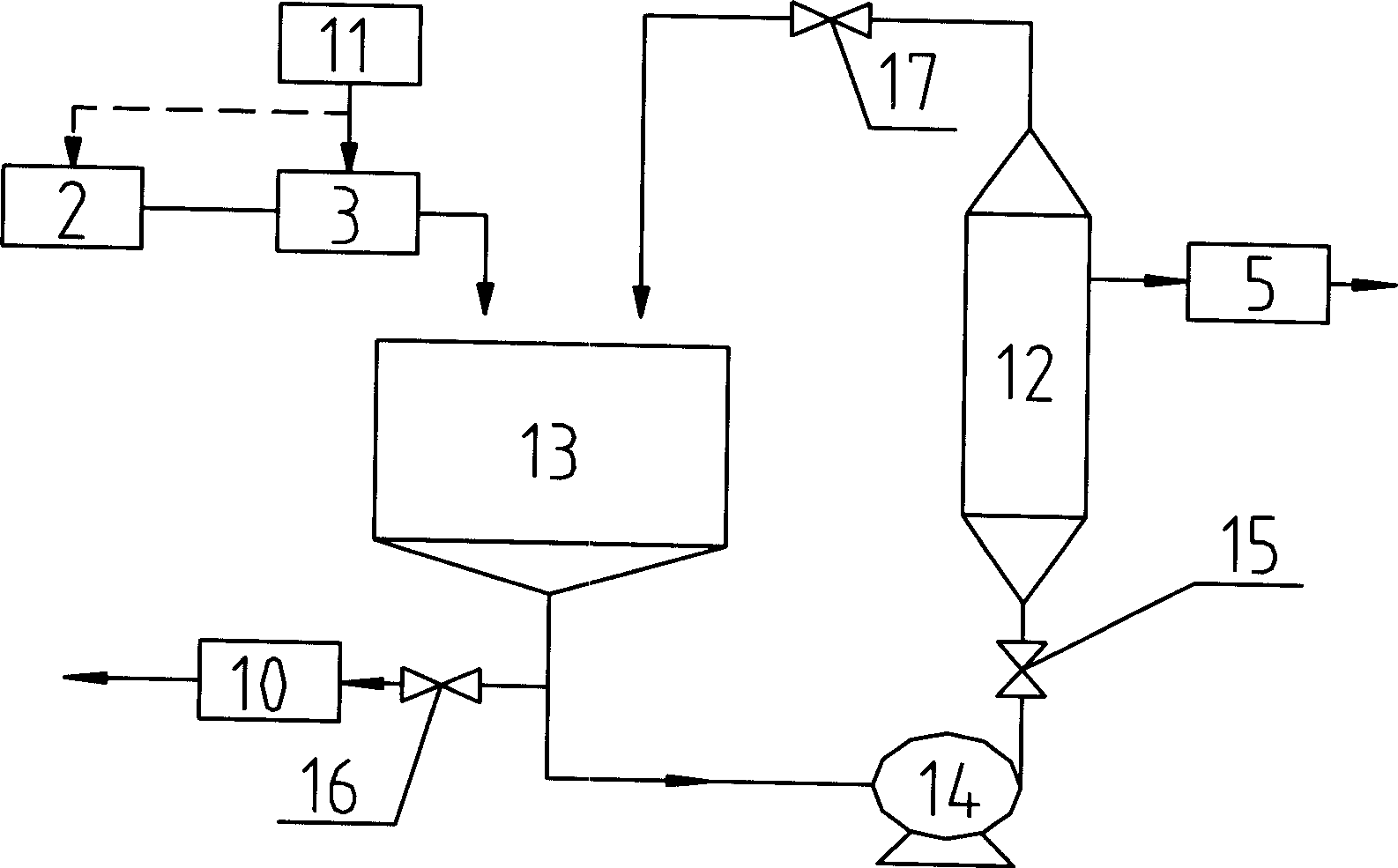

Embodiment 1

[0014] The ratio of amylase to sugarcane or sugar beet clear juice or the juice of the initial filtration (2) is 0.05ppm, the temperature of the clear juice is 100°C, and the pure clear juice is obtained by filtering with a membrane device (4) of a ceramic membrane.

Embodiment 2

[0016] The ratio of adding amylase to sugarcane or sugar beet clear juice or the juice of initial filtration (2) is 5ppm, the temperature of the clear juice is 80°C, and the pure clear juice is obtained by filtering with a membrane device (4) of a ceramic membrane.

Embodiment 3

[0018] The ratio of adding amylase to sugarcane or sugar beet clear juice or the juice of initial filtration (2) is 5ppm, the temperature of the clear juice is 60°C, and the pure clear juice is obtained by filtering with a membrane device (4) of a ceramic membrane.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap