Fixed-type constant-velocity universal joint

A constant velocity universal joint, fixed technology, applied to elastic couplings, mechanical equipment, couplings, etc., can solve the problems of reduced strength of external joint components, increased load, and reduced wall thickness of external joint components. , to achieve the effect of large steering angle, small steering radius and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

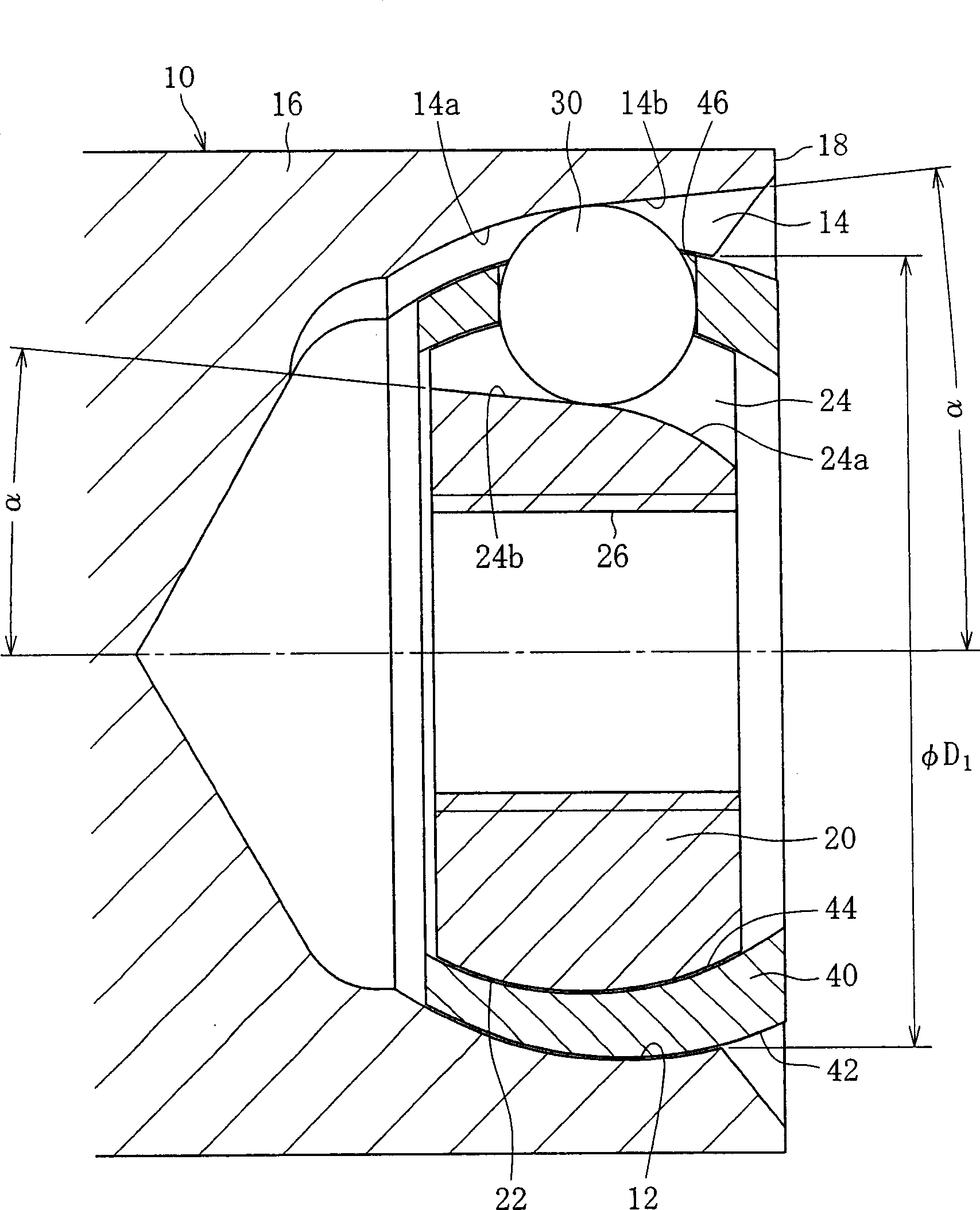

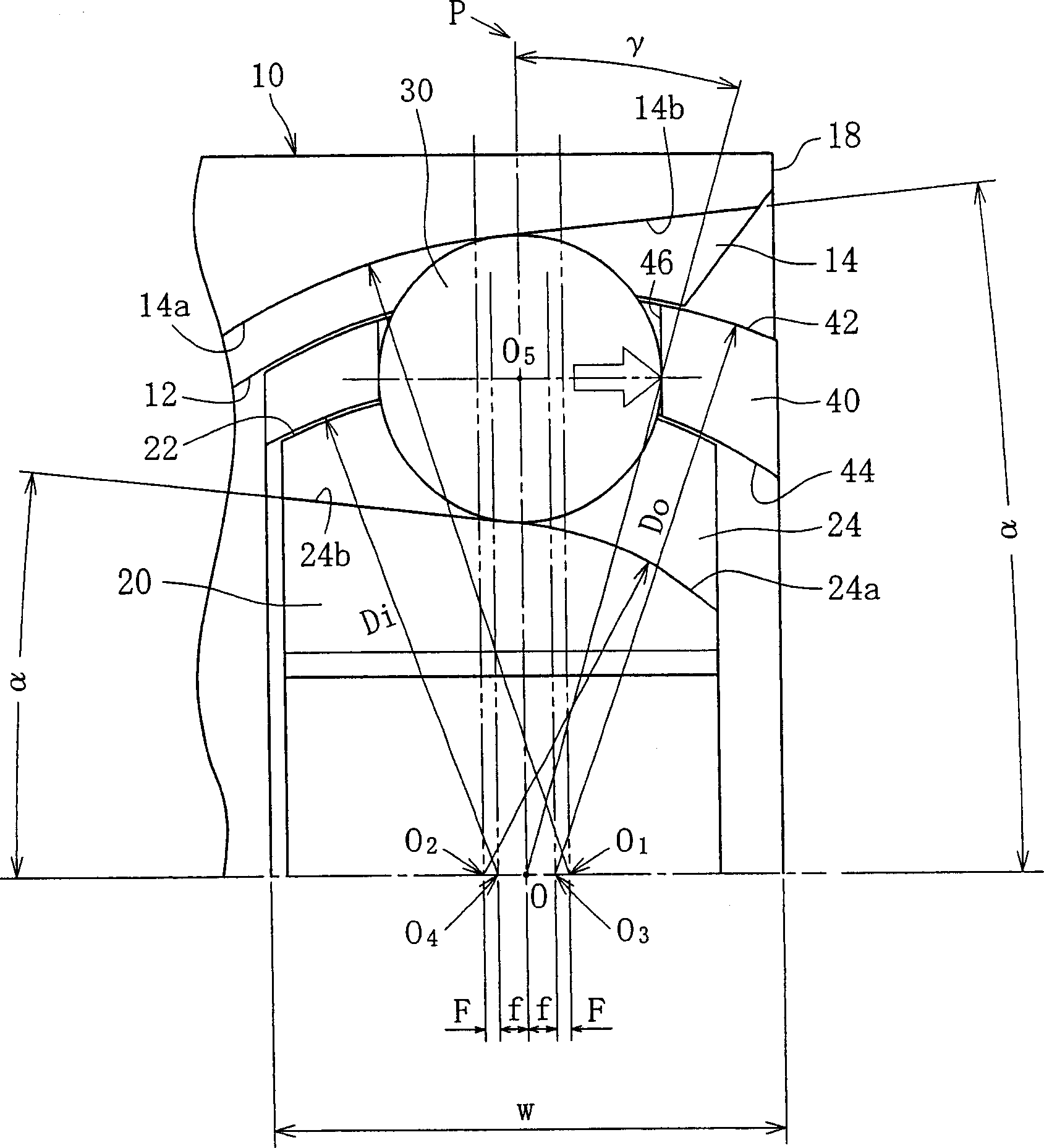

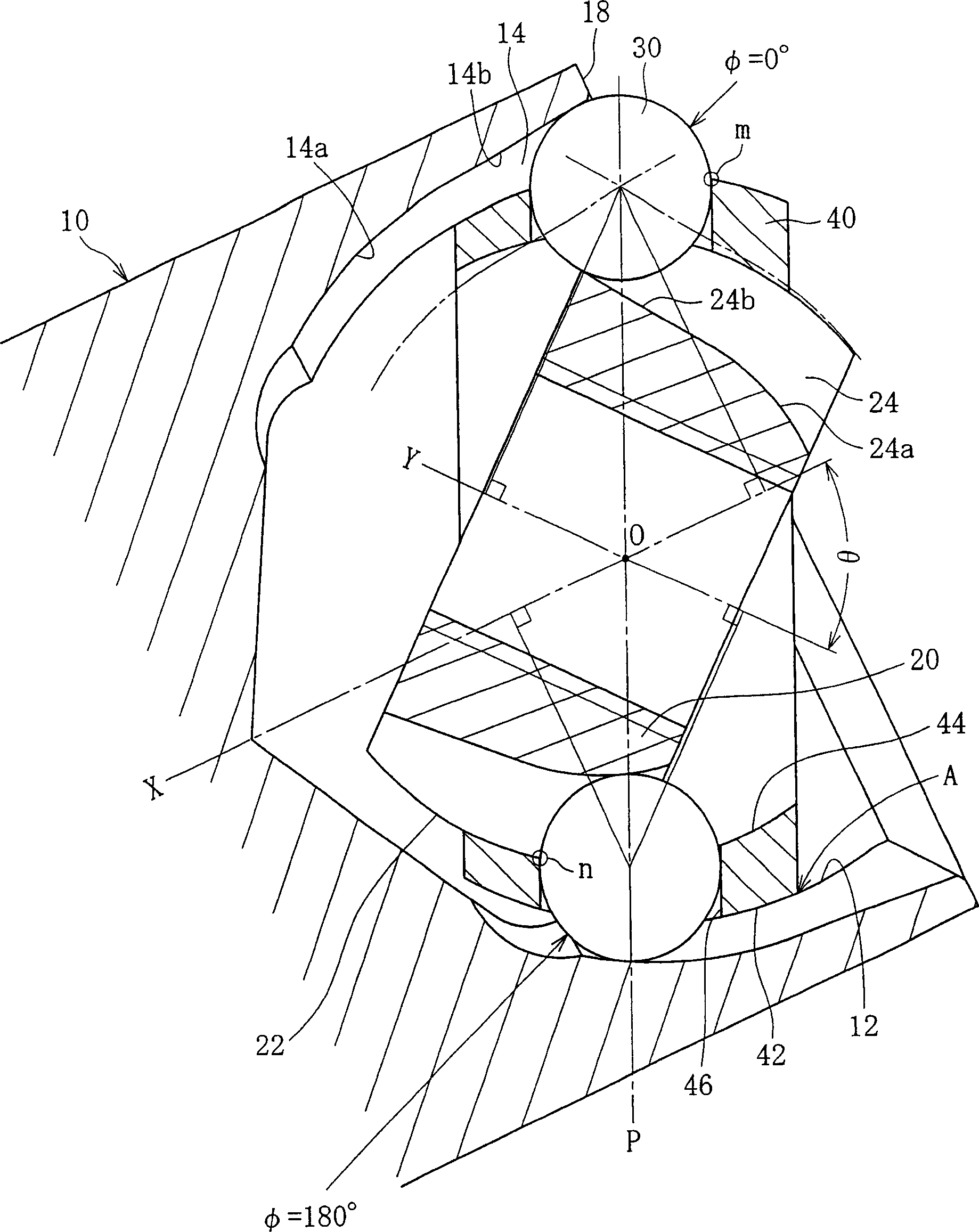

[0149] refer to figure 1 , The fixed constant velocity universal joint includes an outer ring 10 , an inner ring 20 , balls 30 and an isolation ring 20 . The fixed constant velocity universal joint connects the two shafts that need to be connected. For example, a driven shaft (not shown) is connected to the outer ring 10 and a driving shaft is connected to the outer ring so that torque is transmitted at a constant velocity from the driving shaft to the driven shaft when the two shafts are at an angle to each other. figure 1 Represent the state when the working angle θ formed by the rotating shaft X of the outer ring 10 and the rotating shaft Y of the inner ring 20 is 0°, and image 3 Indicates the state of the working angle θ at its maximum value.

[0150] The outer ring 10 as an outer joint member is composed of a mouth 16 and a stem (not shown) connected to the drive shaft in a torque-transmitting manner. Mouth 16 is essentially a cup with an open end and has a spherica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com