Binder and file

A technology for file folders and utensils, which is applied in the field of file folders, can solve the problems of reduced storage efficiency, easy elastic deformation, and increase in the size of the file folder F, and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

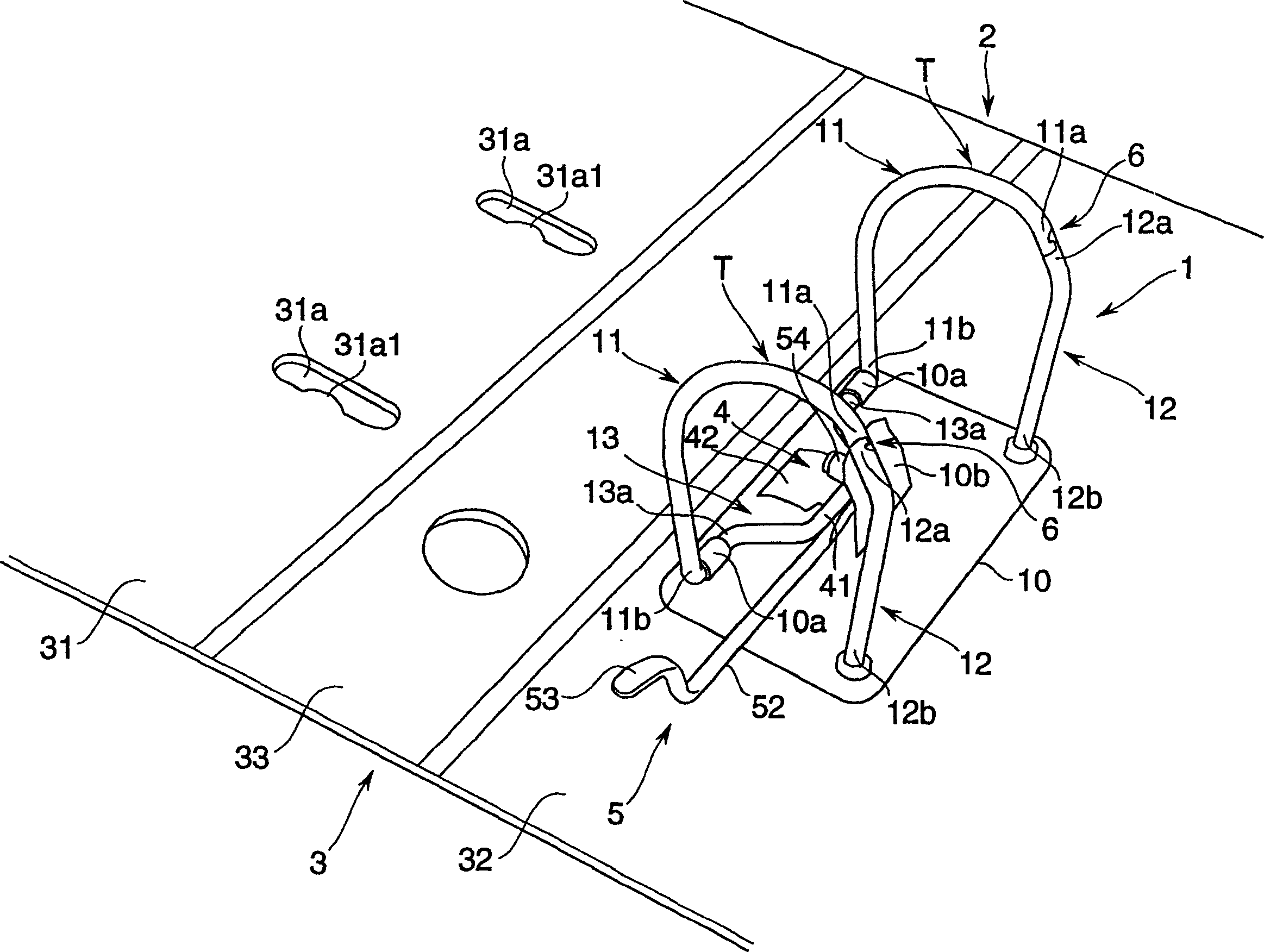

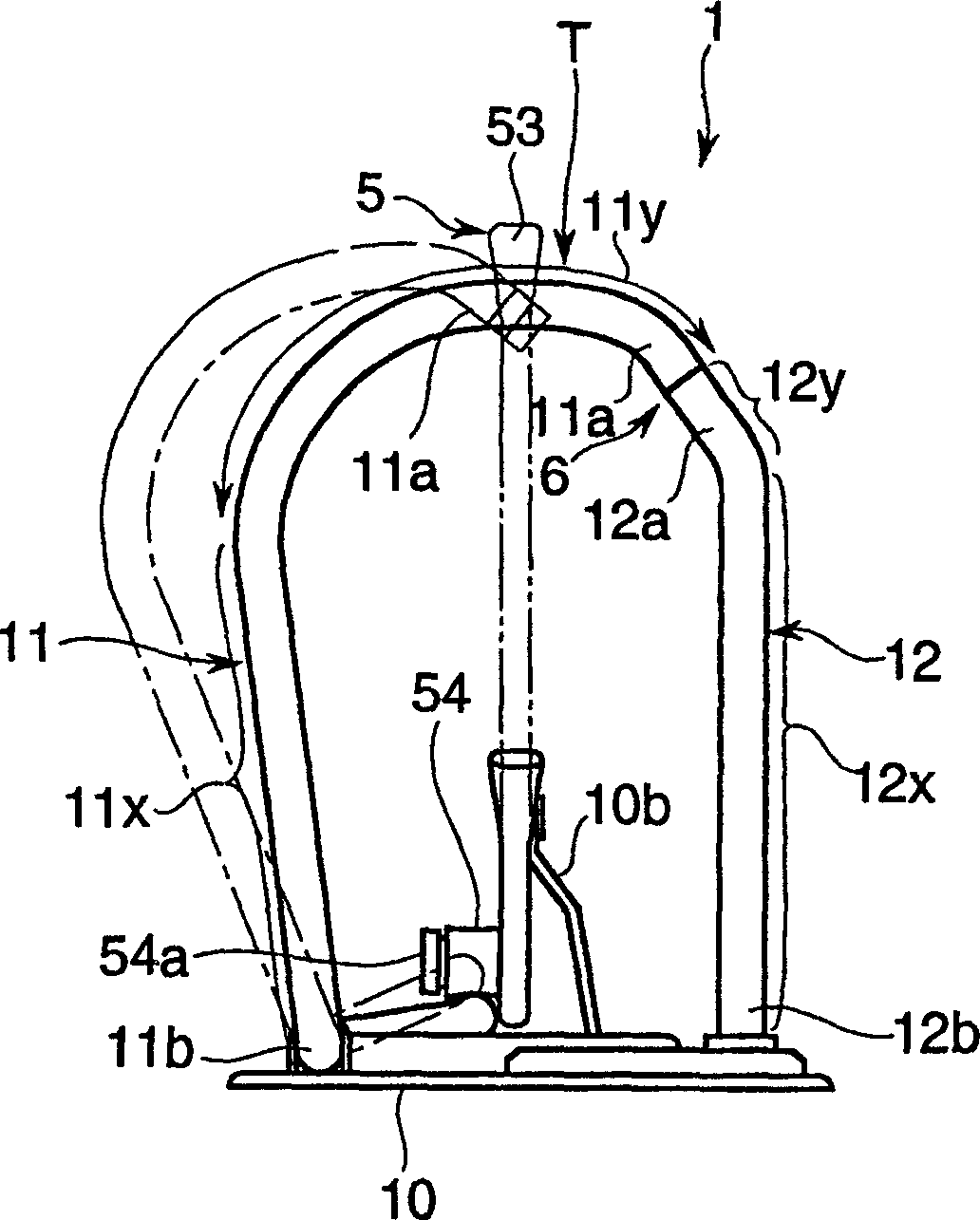

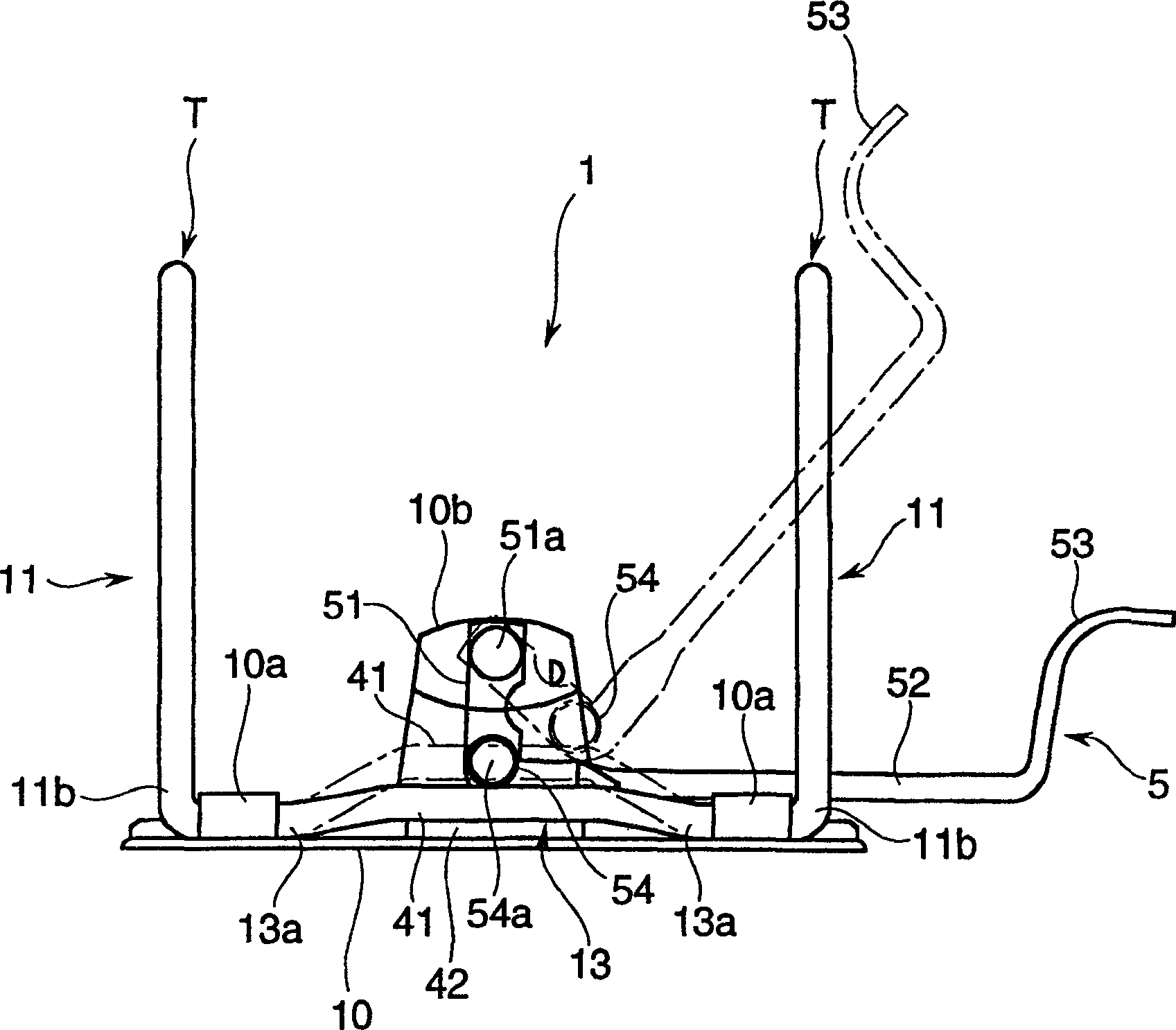

[0026] exist figure 1 In , a schematic perspective view of the main part of a file folder 2 equipped with a binding tool 1 is shown. Figure 2 to Figure 5In , the enlarged front view of the bookbinding tool 1 is shown, the left view is enlarged, the top view is enlarged, and the right view is enlarged. The folder 2 includes: a cover body 3 having a front cover 31 and a bottom cover 32 connected via a back cover 33 in the middle;

[0027] The binding tool 1 is equipped with a pair of first binding members 11, 11 on the base 10, and a pair of second binding members 12, 12 corresponding to these first binding members 11, 11. 1 The relative rotation of the binding member 11 and the second binding member 12, such as figure 2 etc., it becomes the structure which is closed or opened between the front-end|tip part 11a, 12a. In addition, this binding tool 1 is equipped with: an opening device 4, which applies force to the direction of opening between the front ends 11a, 12a of the...

no. 2 Embodiment approach

[0054] Figure 12 as well as Figure 13 The shown binding tool 101 of this embodiment basically has the same structure as the binding tool 1 of the above-mentioned first embodiment. Therefore, the same reference numerals are assigned to the same parts, and descriptions thereof will be omitted.

[0055] Therefore, in this binding tool 101, the shapes of the first and second binding members 111 and 112 are different from the shapes of the first and second binding members 11 and 12 constituting the binding tool 1 of the above-mentioned embodiment.

[0056] The first binding member 111 and the second binding member 112 are D-shaped members in a closed state. The first binding member 111 consists of an erecting area 111x that stands approximately vertically from the base 10 in the closed state, a bending area 111y that bends very slowly from the front end side of the erecting area 111x to the second binding member 112, and a The curved region 111y is configured with an extended ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com