Method and equipment for inspecting mounting accuracy of component

一种安装精度、检查方法的技术,应用在电气元件、电气元件等方向,能够解决夹具部件轮廓模糊、无法检测出部件安装位置等问题,达到清晰图像获取的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0082] Before continuing the description of the present invention, the same reference numerals are used for the same components in the drawings.

[0083] Hereinafter, embodiments of the present invention will be described in detail based on the drawings.

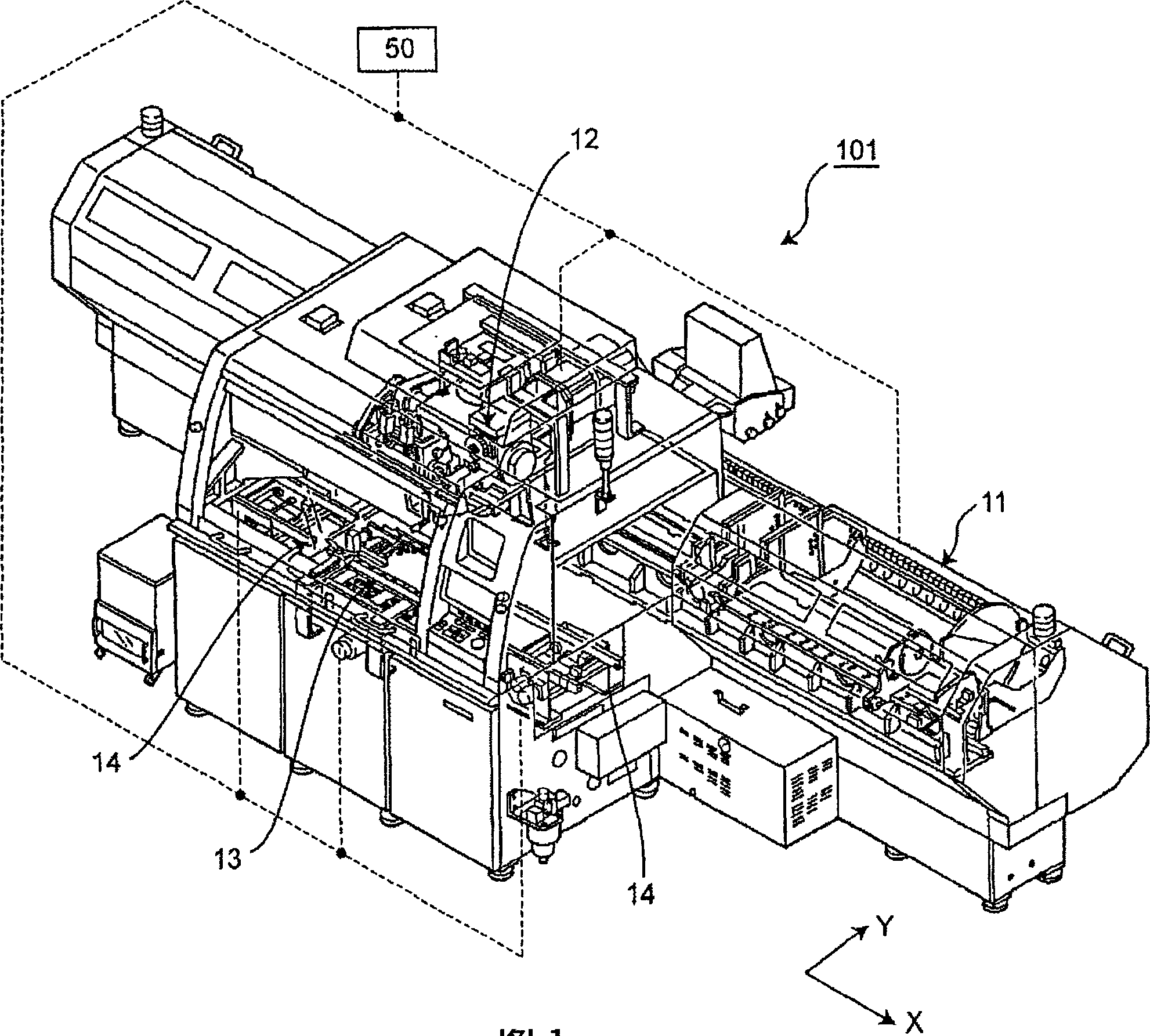

[0084] exist figure 1 3 is a perspective view showing an appearance of an electronic component mounting apparatus 101 as an example of a component mounting apparatus that performs inspection of component mounting accuracy according to Embodiment 1 of the present invention.

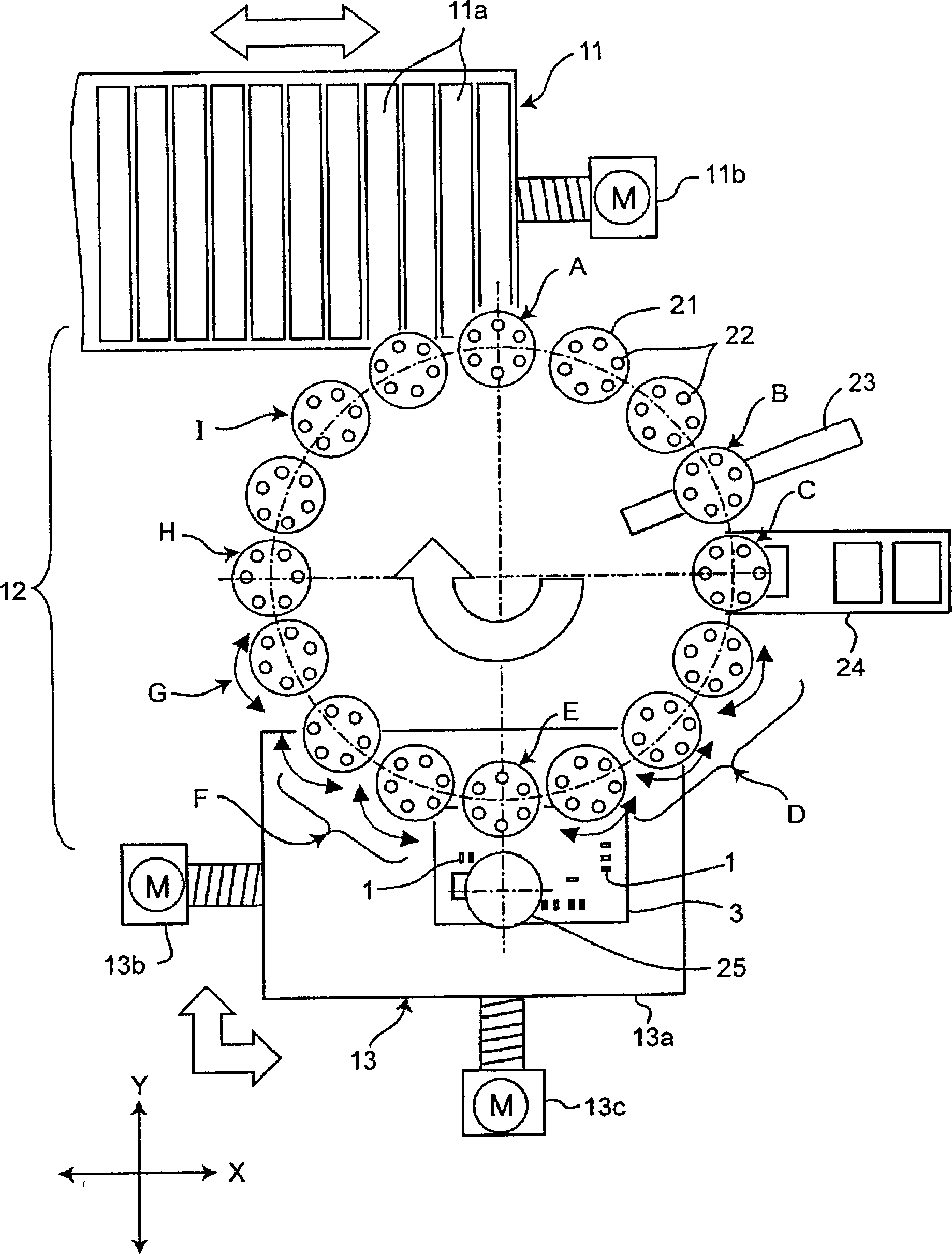

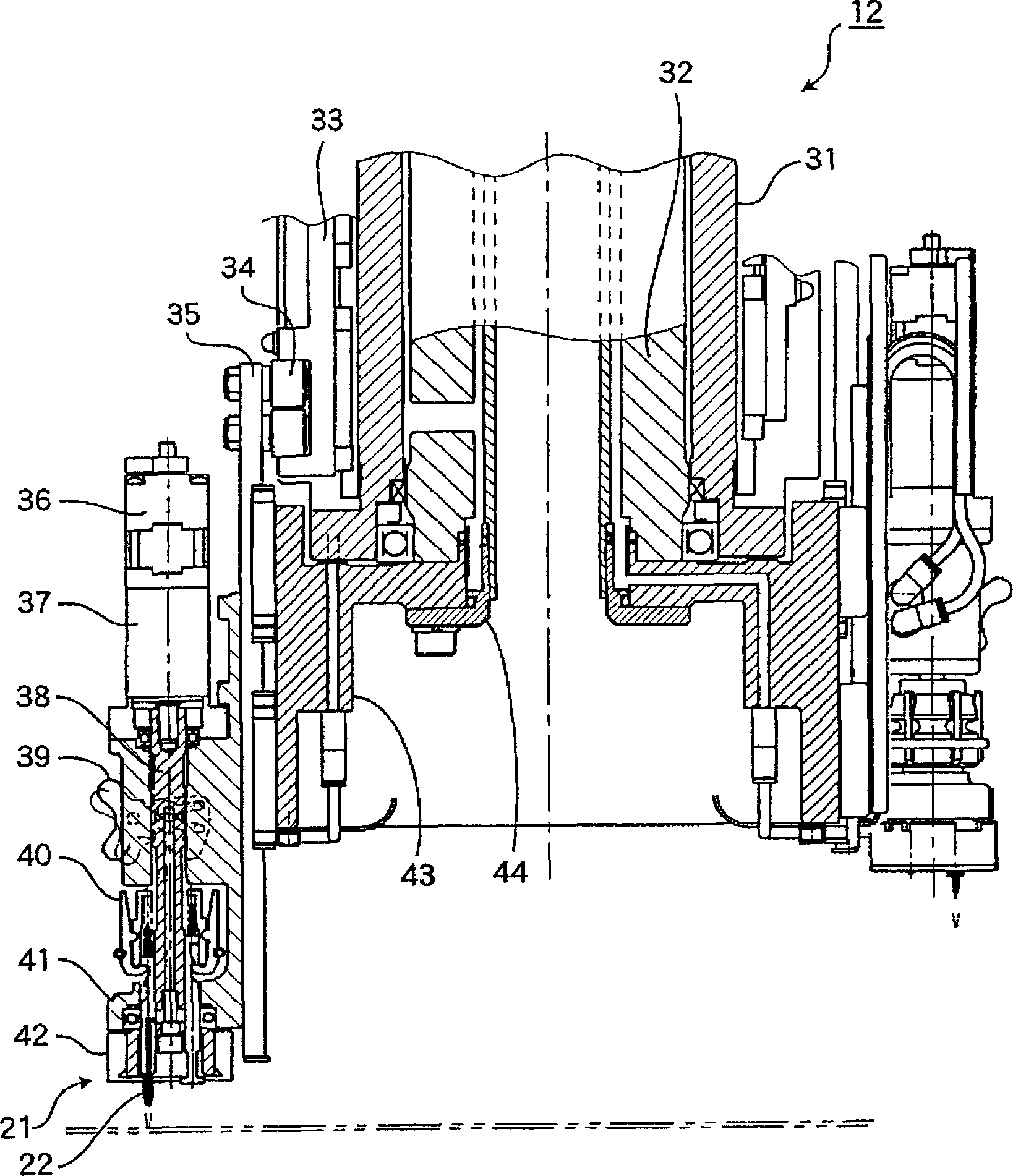

[0085] Such as figure 1 As shown, the electronic component mounting apparatus 101 is an apparatus for performing a component mounting operation for mounting a plurality of electronic components as an example of supplied components on a component mounting position on a substrate. The electronic component mounting apparatus 101 includes a component supply unit 11, a spindle device 12, an XY stage 13, and a substrate transfer device 14. The component supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com