Device for manufacturing molded body

A technology for manufacturing devices and shaped bodies, applied in textiles and papermaking, etc., can solve the problems of water vapor explosion, inability to form small ridges, difficult positioning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, the present invention will be described according to its best embodiment with reference to the drawings.

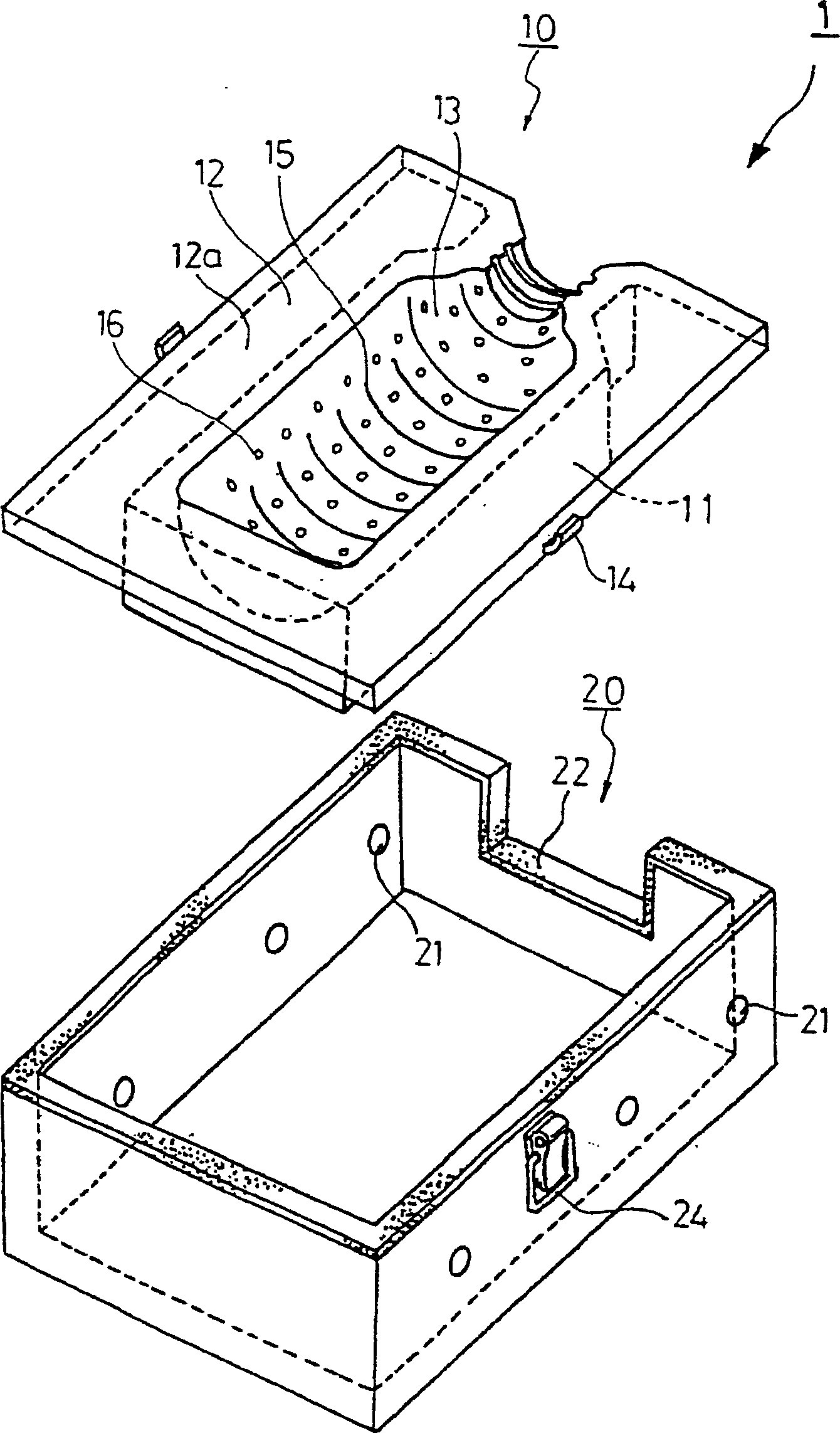

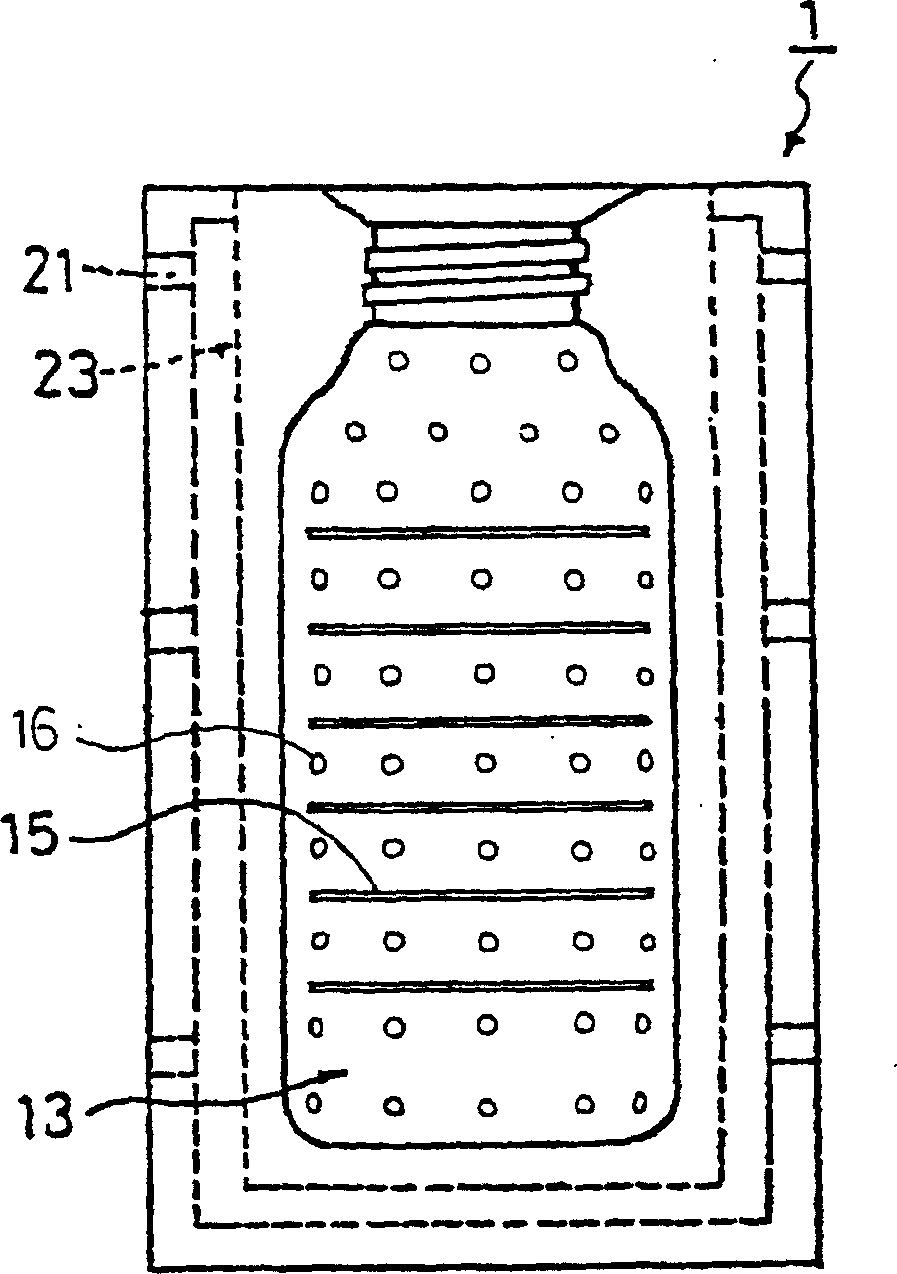

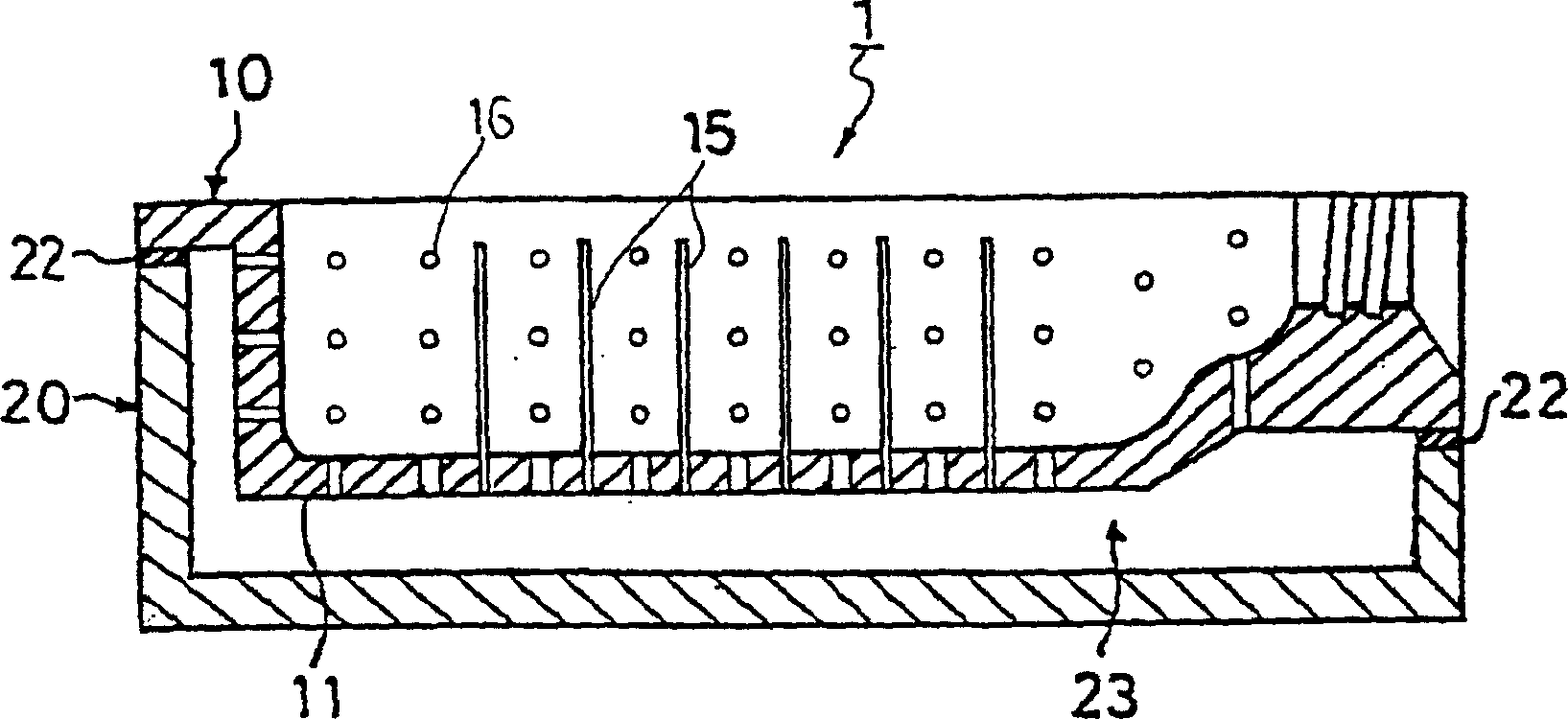

[0037] figure 1 It is an exploded perspective view of the first embodiment of the drying mold of the present invention, Figure 2A with Figure 2B Respectively represent the side view from its dividing plane figure 1 Front and side sectional views of the drying mold shown.

[0038]The drying mold 1 of this embodiment is used to dry a fiber laminate in a wet state obtained by a pulp molding method. The drying die 1 is composed of a fiber laminate housing portion (hereinafter simply referred to as the housing portion) 10 and a manifold portion 20 . The housing portion 10 has a cube-shaped block 11 and plate-shaped flanges 12 extending horizontally from three upper ends of the block 11 . On the upper surface of the block 11, a concave drying part 13 of a shape obtained by fitting with the longitudinal half of the fiber laminate in a wet state formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com