Method and structure for improving cathode current density of aluminium-electrolytic cell

An aluminum electrolytic cell and cathode current technology, which is applied in the field of cathode steel rods, can solve the problems of shortening the electrolytic cell, resistance difference, cathode electrochemical corrosion, etc., and achieve the effect of improving the current density distribution, weakening the peak value of the current density, and reducing the current component

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

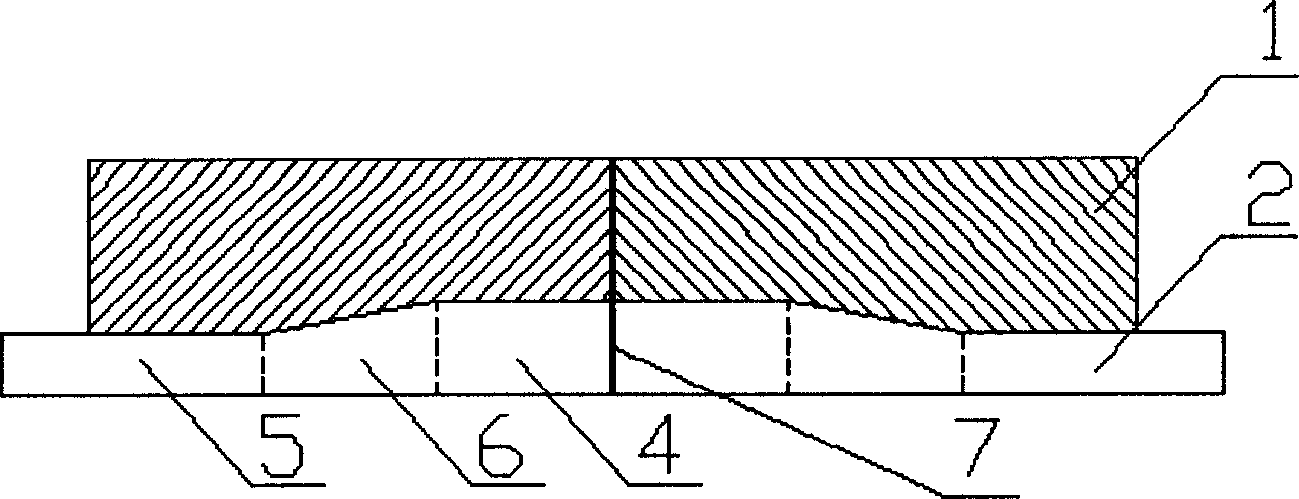

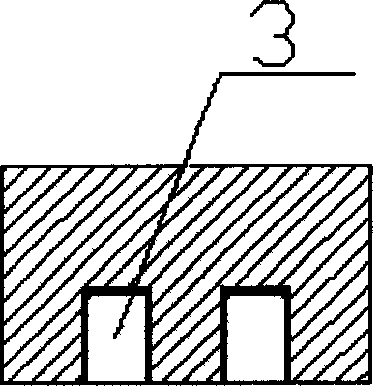

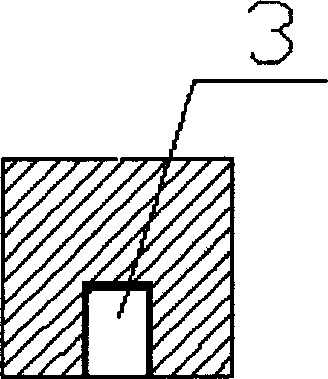

[0013] Embodiment of the present invention: when making, the cross section of steel bar (2) can be made into rectangle or circle, the middle section top of steel bar (2) is thickened, is made into large cross-section section (4), steel bar ( The two ends of 2) are made into a small section section (5) with a small section, and a slope-type variable section section (6) is made between the large section section (4) and the small section section (5), and the steel rod (2) The length ratio of the large section section (4), the small section section (5) and the variable section section (6) is 1:1:1, the lower part of the steel bar (2) is on the same straight line, and the large section section (4) The area ratio of the small section (5) is 1.3:1, so that the surface of the steel rod (2) transitions smoothly, and a steel rod groove (3) matching the shape of the steel rod (2) is processed in the cathode bottom block (1) ), steel bar groove (3) can be processed into rectangular double...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com