Method for manufacturing hand-knitting suspension rope and hand-knitting suspension rope

A manufacturing method and steel cable technology, which is applied in the manufacture of hand-woven slings and in the field of hand-woven slings, can solve the problems of the surface of the hand being cut, sharp, and difficult to pull out the steel cable 112, etc., so as to achieve safe use and high strength. full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, the present invention will be more specifically described based on preferred modes for implementing the present invention shown in the drawings.

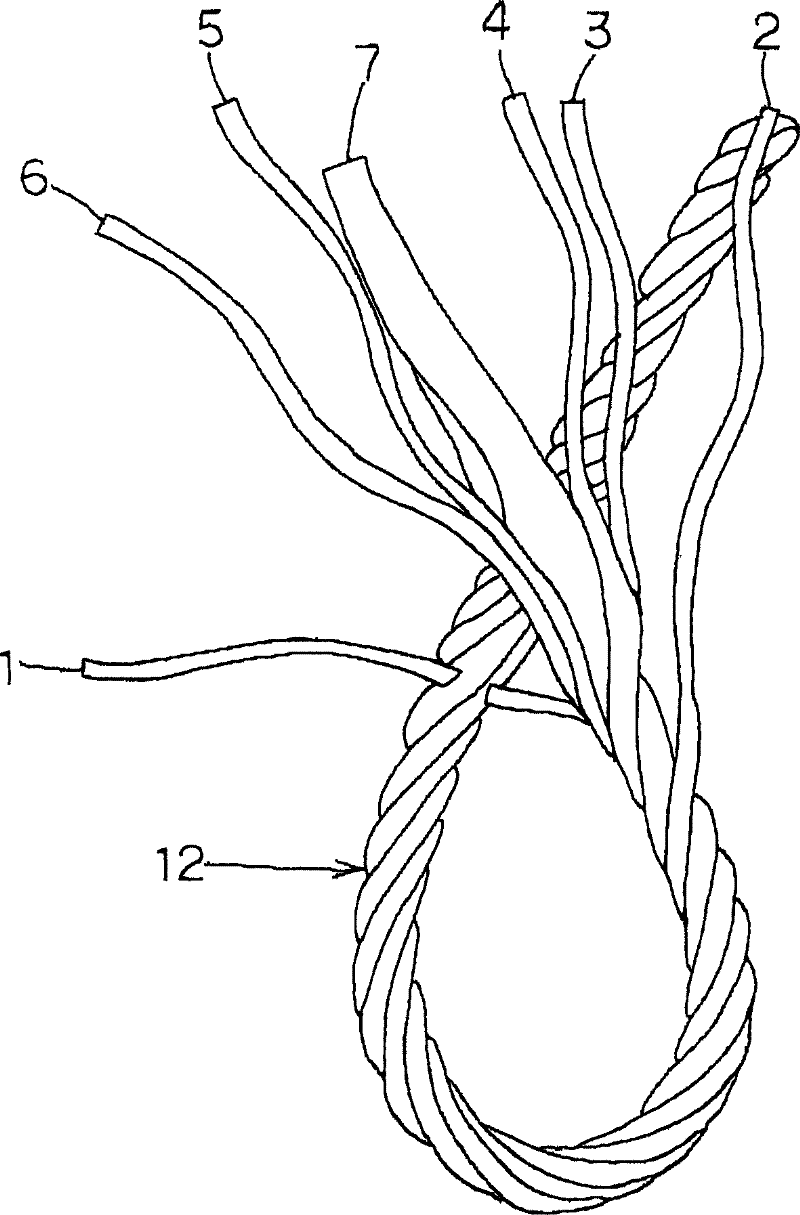

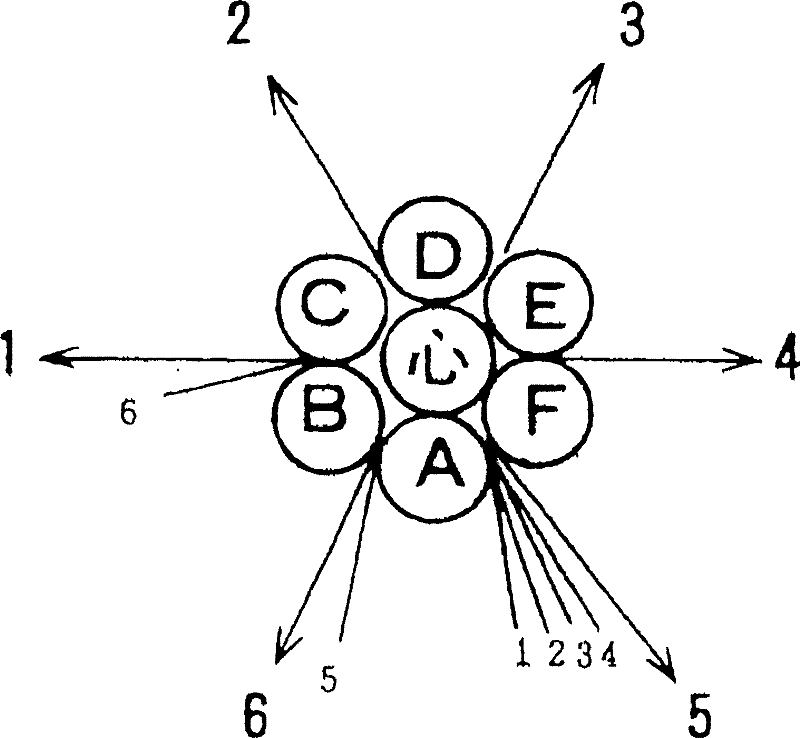

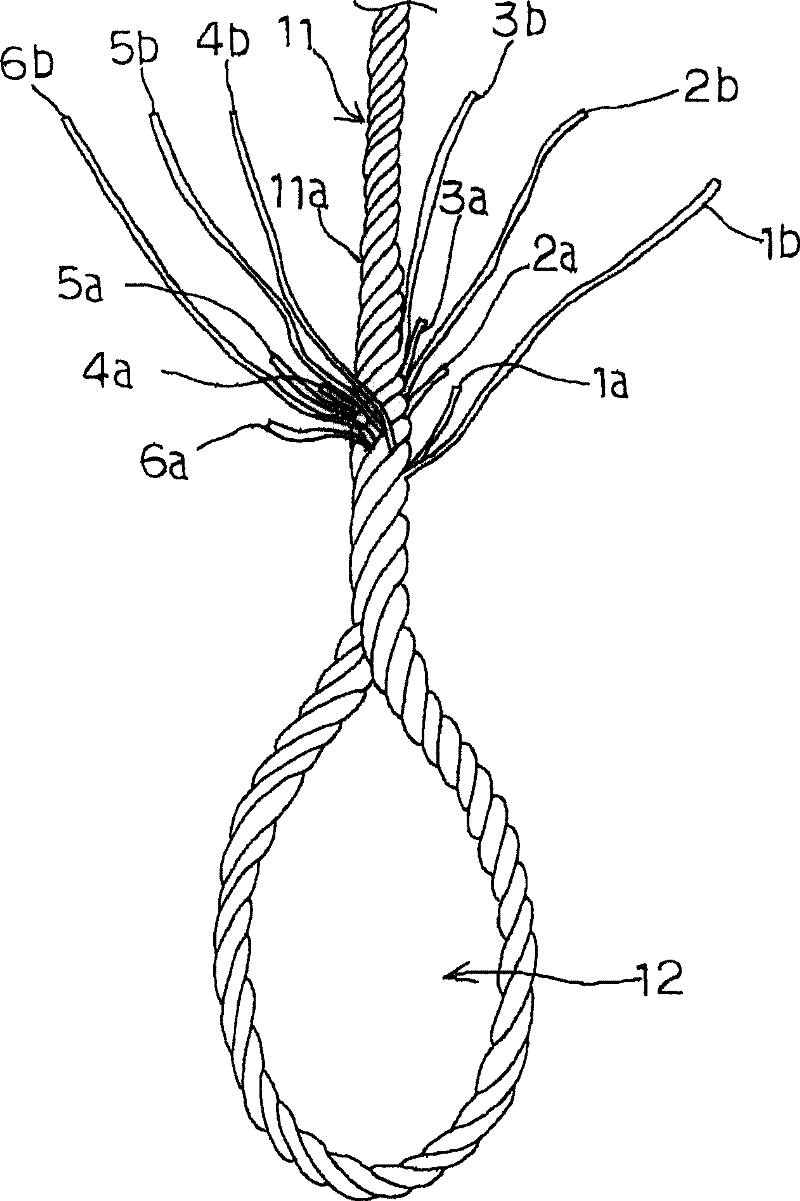

[0037] In the method of manufacturing hand-knitted slings from steel wires, known weaving methods such as roll-inserting, cage-inserting, etc. are used. Among them, the winding insertion method is a method in which the front end of the wire rope is decomposed in units of wire bundles, and the wire bundle is inserted between the wire bundles on the main wire of the wire rope, and is wound in the same direction as the direction in which the main wire is twisted. .

[0038] The insertion cage method is to decompose the front end of the steel cable into the unit of wire harness, insert the wire bundle between the wire bundles of the main wire of the steel cable, and wind it in the direction opposite to the direction of the twisted main wire.

[0039] Hereinafter, a method of manufacturing a hand-knitted sling accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com