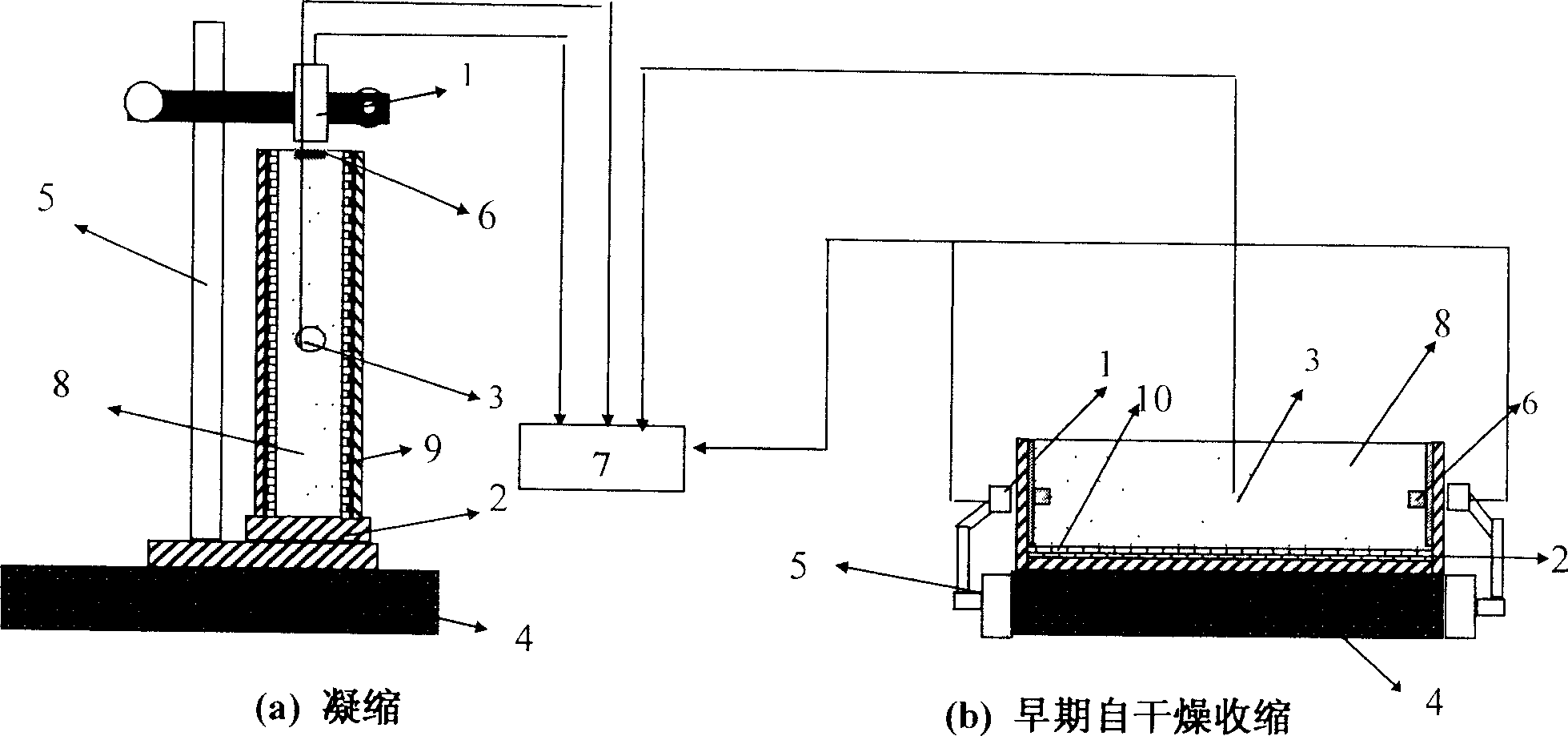

Method and apparatus for testing early self-deformation of concrete

A deformation test, concrete technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of concrete expansion, reduce self-shrinkage, etc., to achieve the effect of reducing constraints, avoiding constraints, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

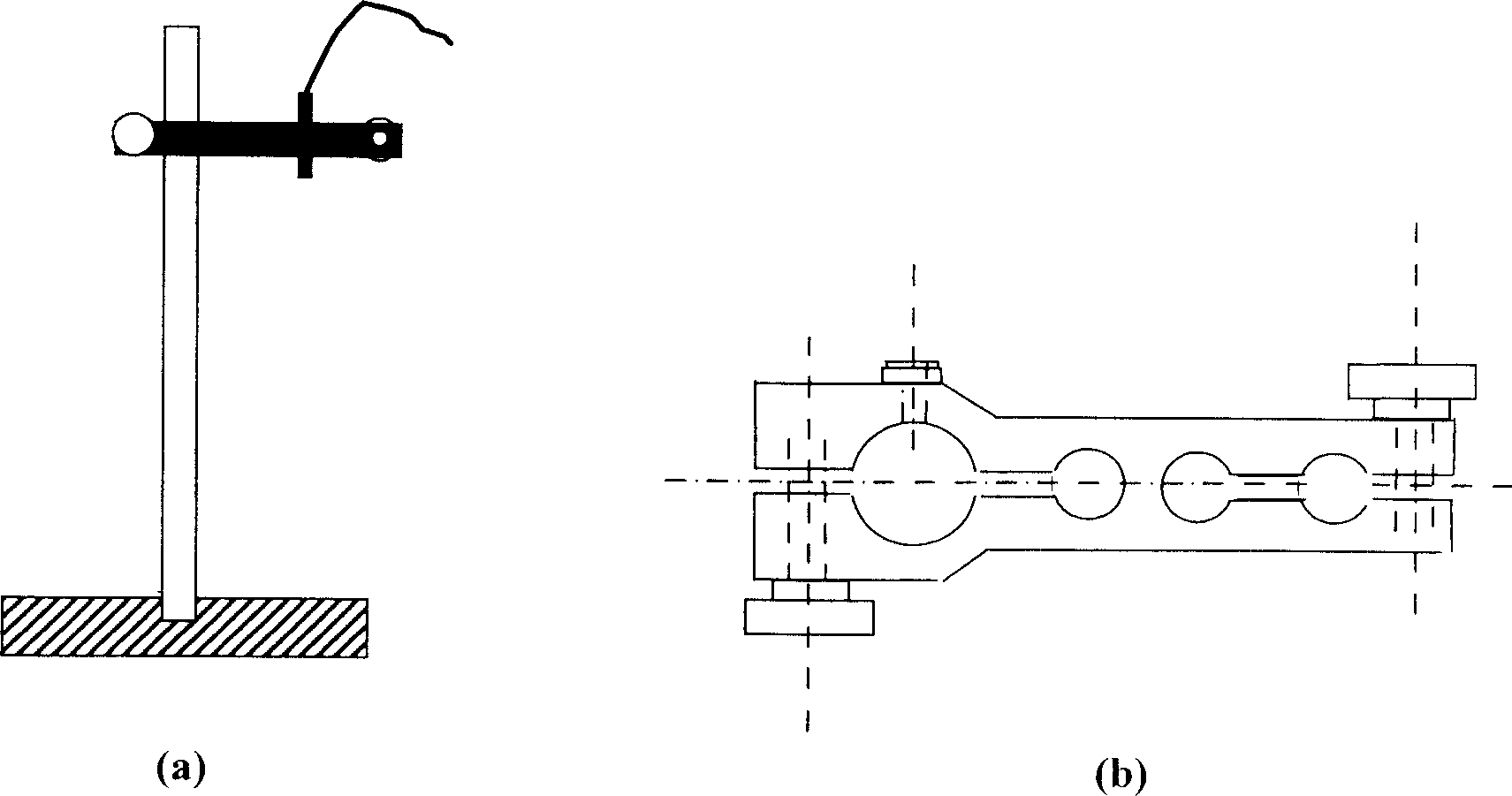

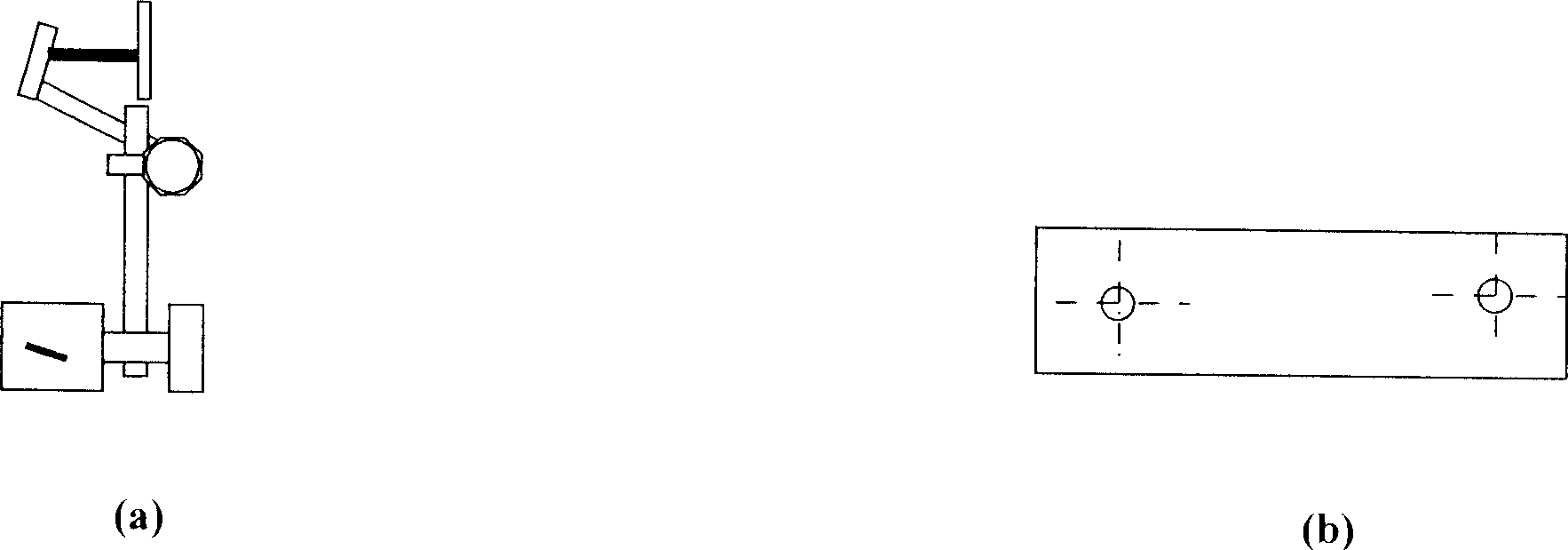

Method used

Image

Examples

Embodiment example 1

[0081] Concrete mix ratio (kg / m 3 ): cement-480, sand-676, gravel-1104, water-145, naphthalene superplasticizer-1.68

[0082] Initial setting time: 7.35h. A total of two tests A and B were tested. The early shrinkage results of the tested concrete are as follows: Figure 7 shown.

Embodiment example 2

[0084] Concrete mix ratio (kg / m 3 ): cement-470, sand-760, gravel-1140, water-150, polycarboxylate superplasticizer 0.94

[0085] Initial setting time: 7h, the early shrinkage of the tested concrete is as follows Figure 8 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com