Flat panel display and assembling method thereof

A flat-panel display and assembly method technology, which is applied in the direction of instruments, lighting devices, optics, etc., can solve problems such as offset, complicated assembly steps, and display panel assembly tolerance screens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

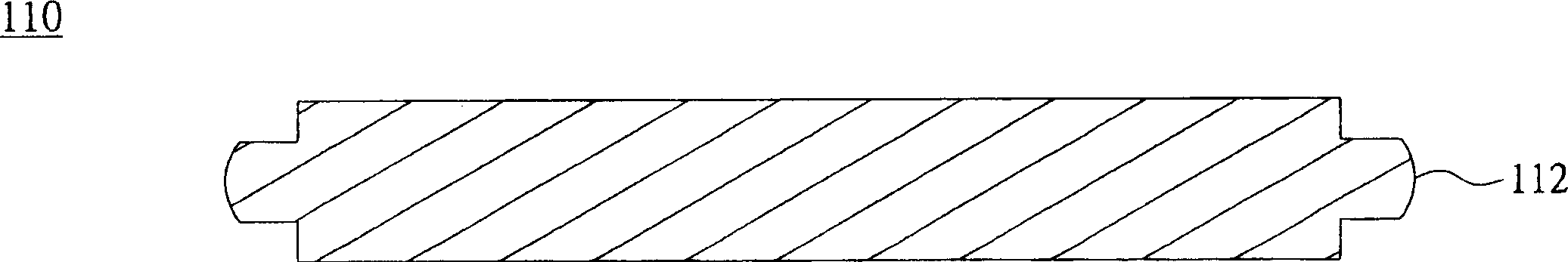

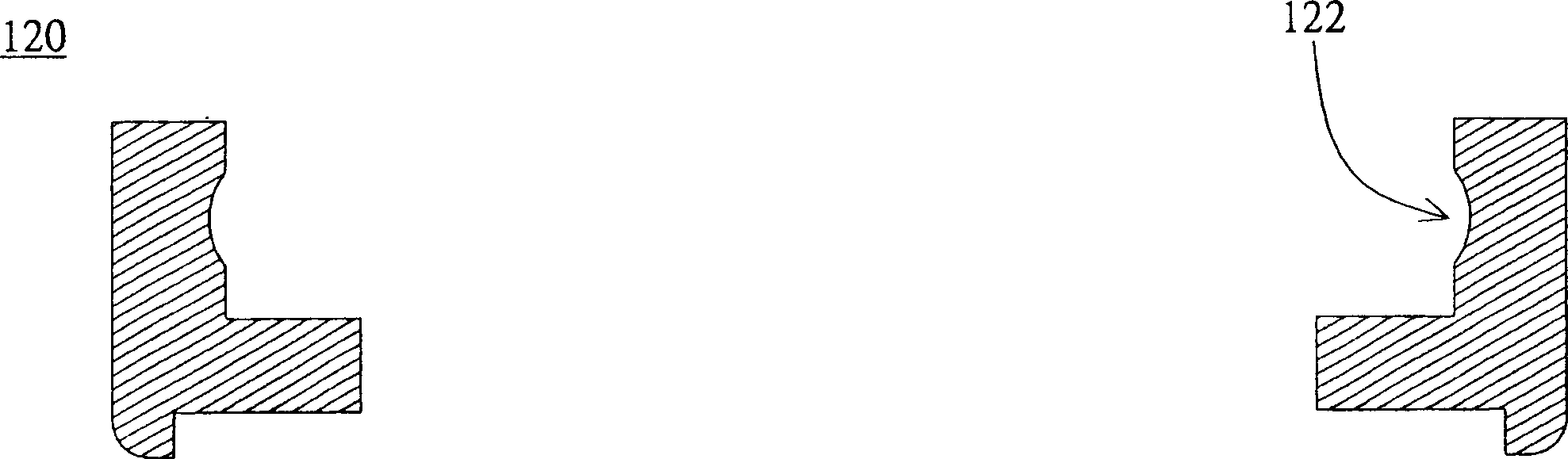

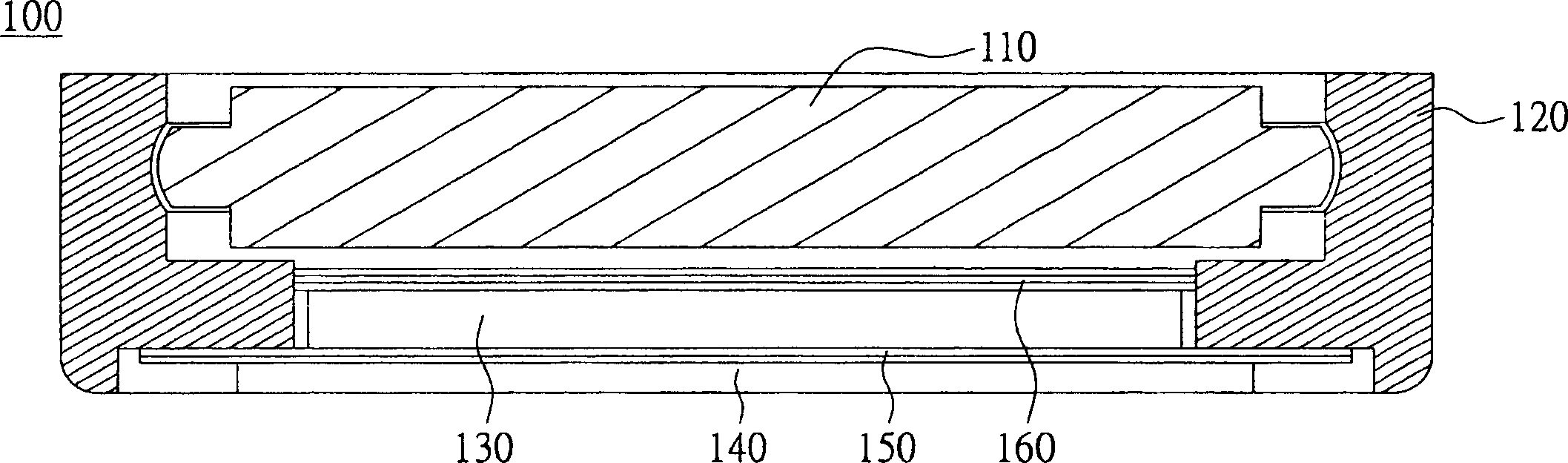

[0023] Please also refer to figure 1 and figure 2 , which respectively show a schematic diagram of a display panel and a schematic frame of a flat-panel display according to a preferred embodiment of the present invention. The outer edge of the display panel 110 has a first joint portion 112 , and the inner edge of the frame 120 has a second joint portion 122 . In this embodiment, the first joint portion 112 is a convex portion, such as a rounded corner; the second joint portion 122 is a concave portion, such as a circular groove whose shape is complementary to that of the first joint portion 112 , so that the display panel 110 can be fixed on the frame 120 . The shapes of the first combining portion 112 and the second combining portion 122 can interfere with each other, so that the display panel 110 can be more stably fixed on the frame 120 . Please refer to image 3 , which shows figure 1 display panel and figure 2 Schematic diagram of a flat-panel display after comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com