High-precision linear driver with arbitrary distance of run

A linear drive, arbitrary stroke technology, applied in the muscle field of humanoid robots, can solve the problems of small output torque, small output force, limited stroke, etc., and achieve the effect of increasing output force, large output force, and reliable clamping action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

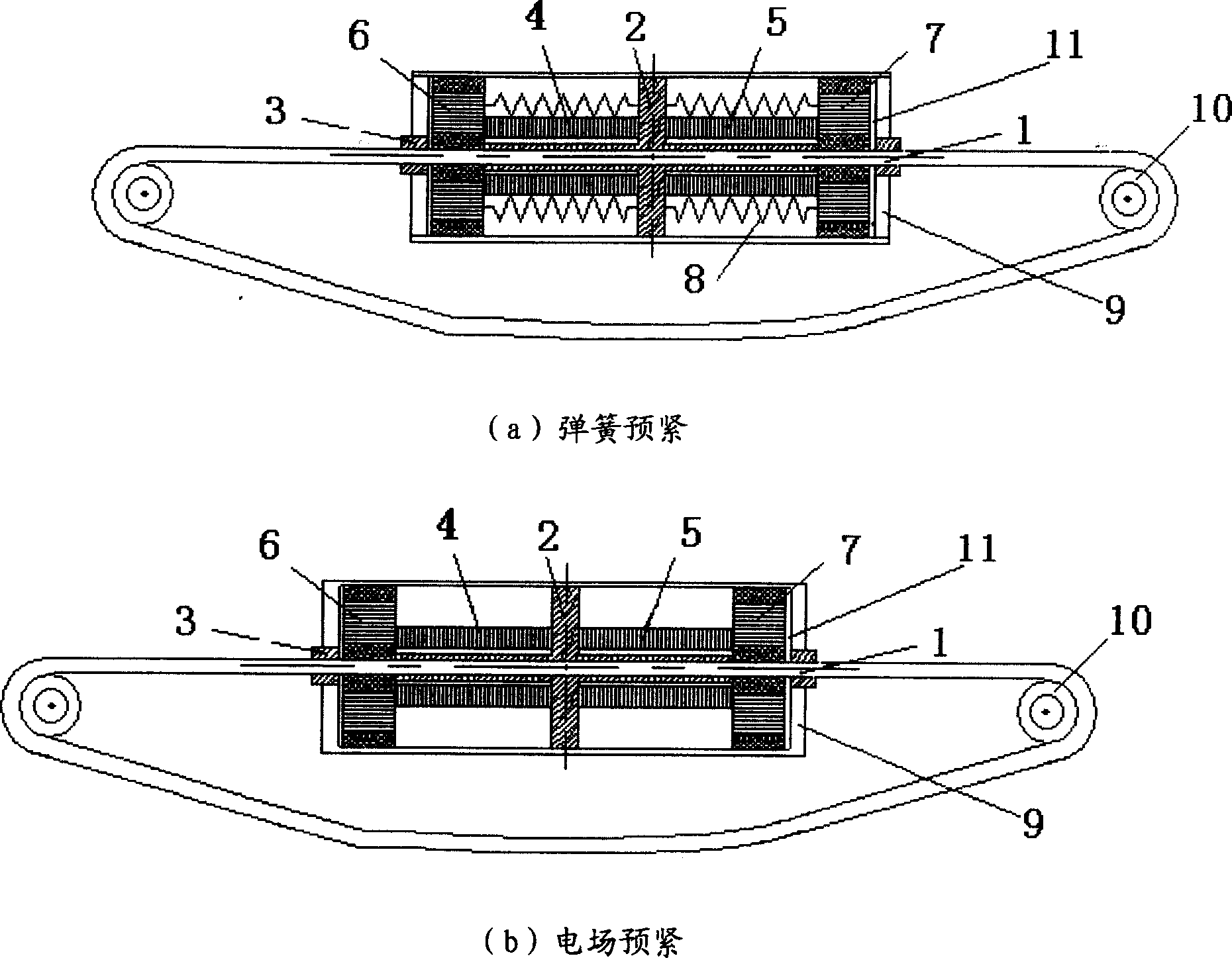

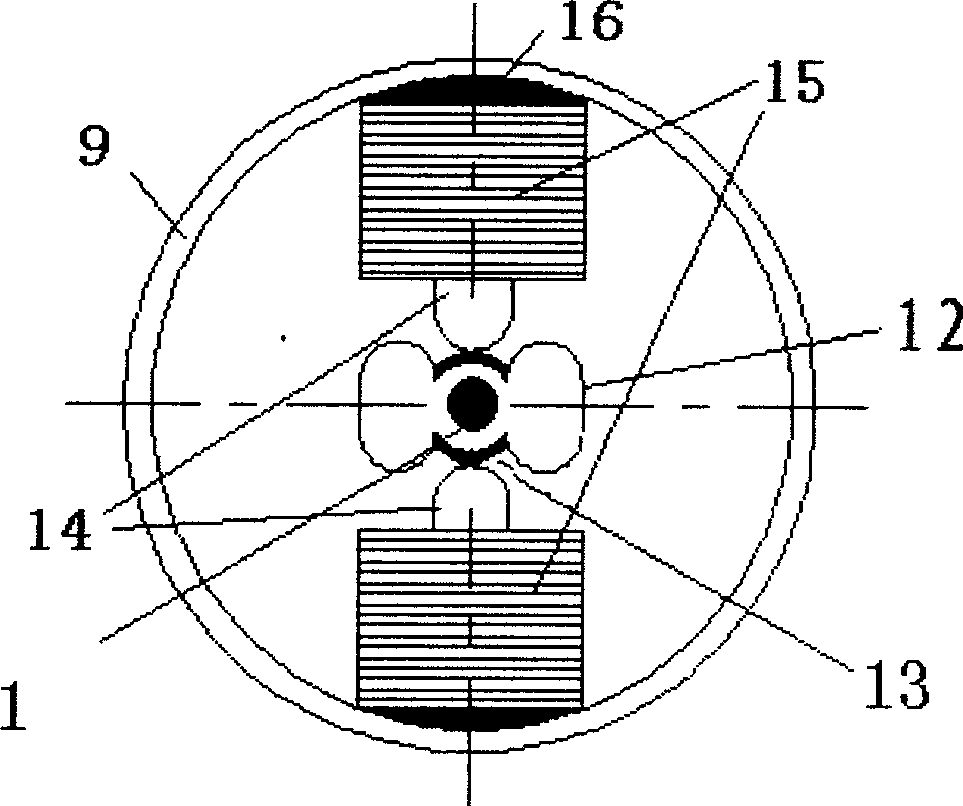

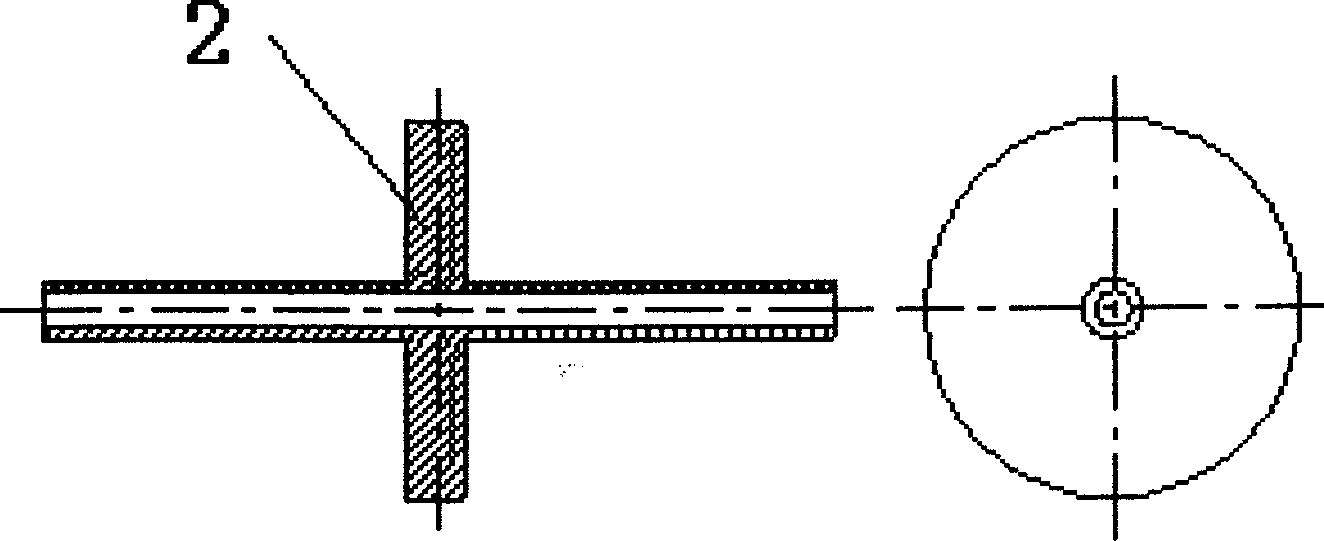

[0028] Such as figure 1 As shown in (a), it is mainly composed of a spring preloaded driver: a single-strand or multi-strand steel cable 1, the steel cable can be a fully enclosed ring or a line segment of a certain length; a guide support 2, a tubular guide part 3 ; The clamping mechanism includes a longitudinal telescopic clamping unit 6 and a longitudinal telescopic clamping unit 7; the axial telescopic mechanism includes a horizontal telescopic unit 4 and a horizontal telescopic unit 5. The clamping mechanism is fixedly connected with one end of the telescopic unit, and the other end of the telescopic unit is fixedly connected with the fixed part of the guide support 2 . The piezoelectric ceramic stack 15 in the clamping units 6 and 7 is prestressed by the spring 8, so that the piezoelectric ceramic stack 15 always works in a compressed state. 9 is the casing. 10 is the guide wheel of carrying steel cable, can install one or more guide wheels in the space, be installed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com