Printing apparatus

A technology of printing device and supporting device, which is applied in the direction of printing, printing machine, rotary printing machine, etc., can solve the problem of stencil position deviation, etc., and achieve good support and restrain the effect of substrate inclination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

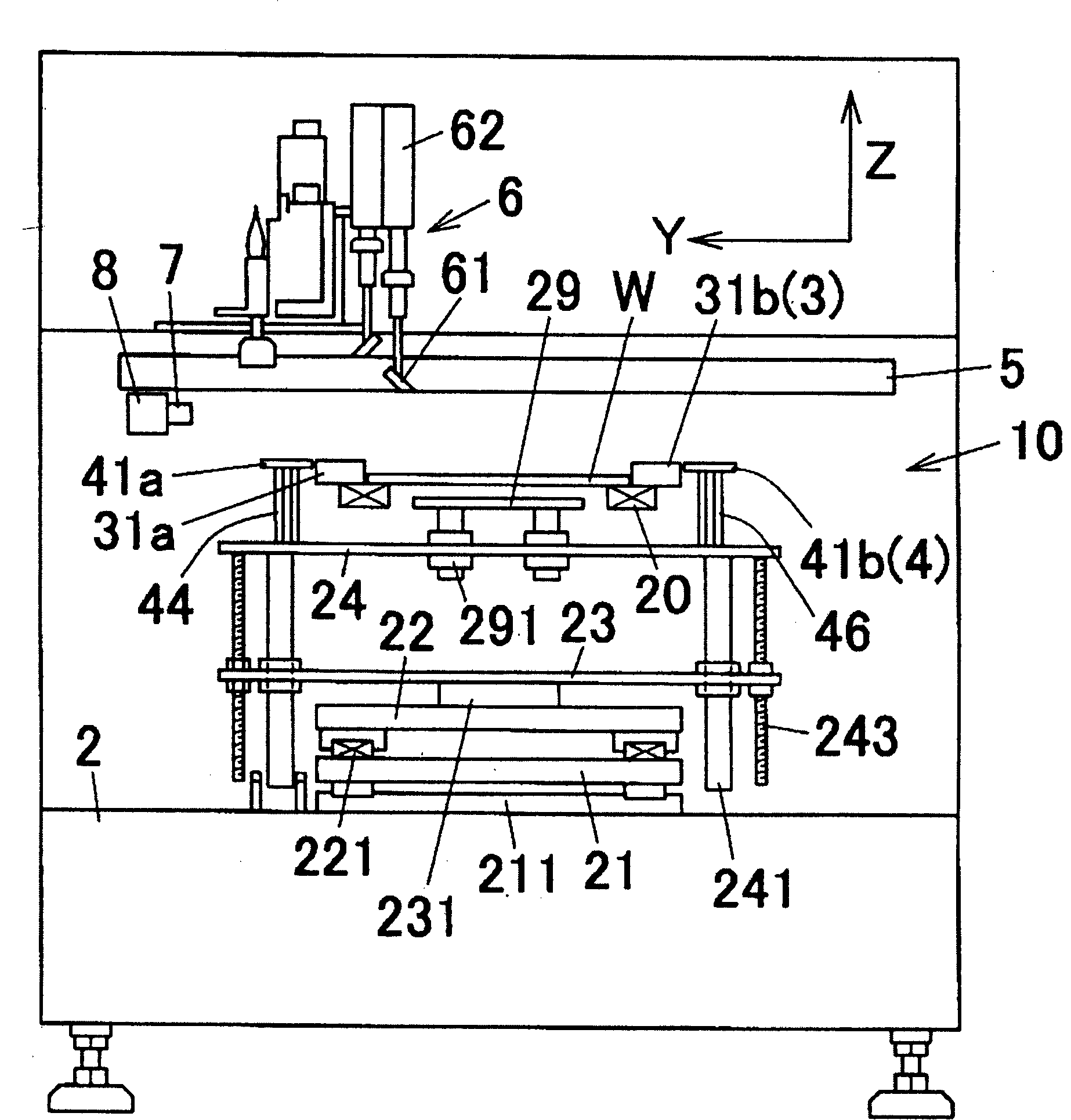

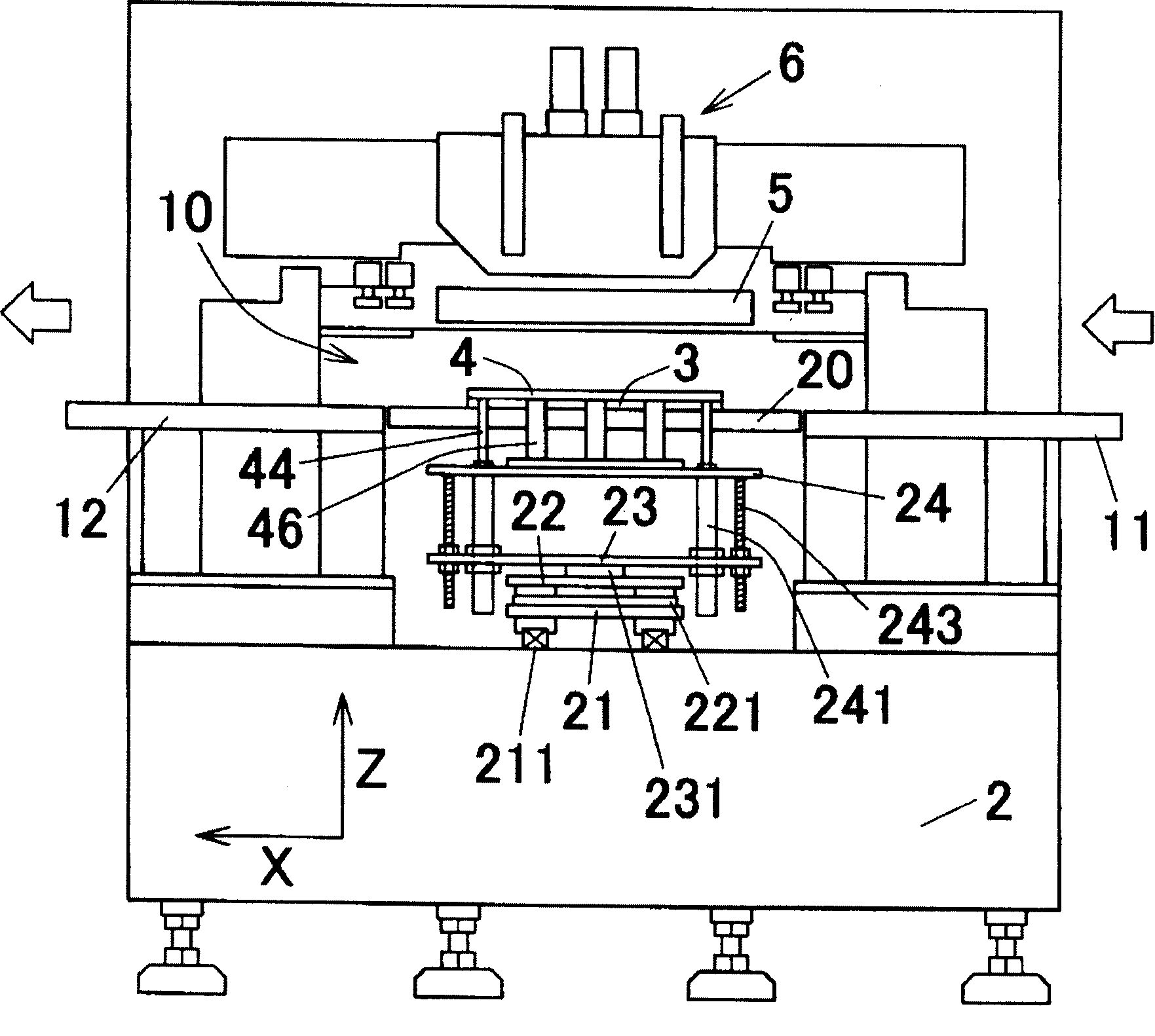

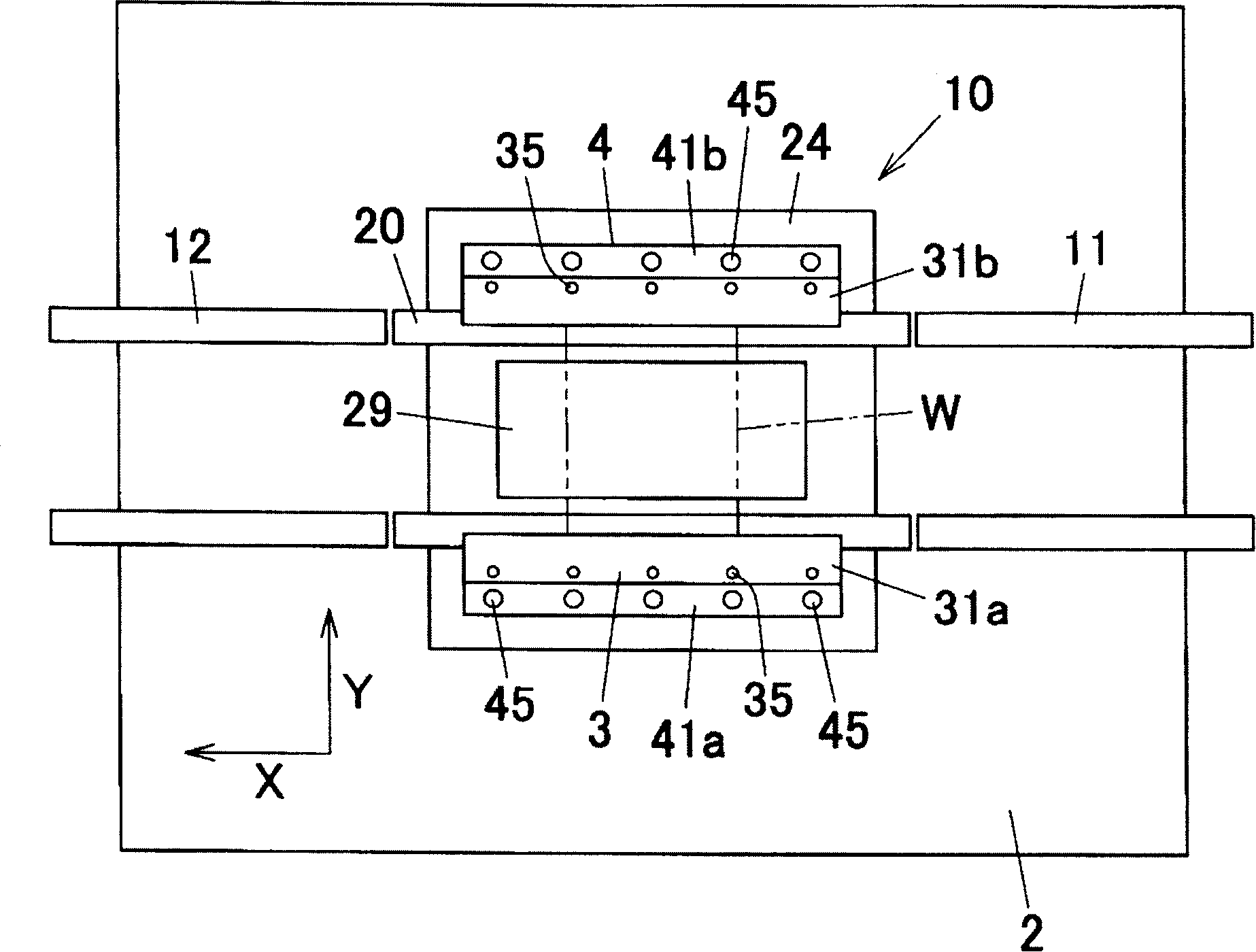

[0071] figure 1 is a side view of a screen printing device according to an embodiment of the present invention, figure 2 is the front view of the device, image 3 Fig. 4 is a top view of the device, and Fig. 4 is a perspective view of the main part of the device (printing station 10). As shown in these figures, a printing table 10 is provided on the base 2 of the screen printing apparatus, and on both sides of the printing table 10 , along the X-axis direction (conveyance direction), there are printed circuit boards for loading and unloading printed circuit boards W. The upstream side conveyor belt 11 and the downstream side conveyor belt 12 of the table 10 .

[0072] Moreover, the printing device includes: a clamp unit 3 for clamping the printed substrate W; a positioning unit 4 that engages with the upper surface of the substrate for positioning when clamping the substrate W; and a stencil holding unit arranged above the printing table 10 5 and the squeegee unit 6; as de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com