A vacuum adsorption platform based on deflector

A vacuum adsorption platform and deflector technology, which is applied in metal processing and other directions, can solve the problems of difficult specific processing, uneven adsorption force on the surface of the platform, and low overall permeability, and achieve low flow resistance, uniform adsorption force, and adsorption wide area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

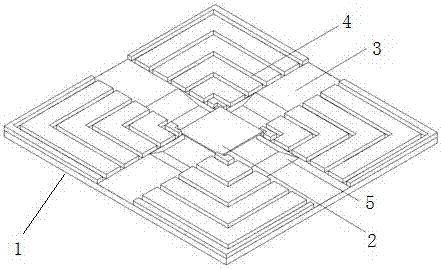

[0023] Such as figure 1 As shown, a deflector includes a base plate 1 and a baffle plate 2, and the baffle plate 2 is fixed on the base plate 1; the base plate 1 is provided with criss-cross airflow main passages 3, and its crossing point is located on the base plate 1 At the center, the baffle plate 2 is located above the intersection of the main air flow channel 3, and the base plate 1 is provided with an air exhaust port corresponding to the baffle plate 2, and a number of air flow branches 4 are also provided on the base plate 1, and the air flow branch The channel 4 communicates with the main air flow channel 3; the main air flow channel 3 is provided with a slope 5 with rounded chamfers near the baffle plate 2; 2 rounded corners.

[0024] When in use, the two airflow main passages 3 that cross horizontally and vertically around the baffle plate 2 gather the gas transported by the airflow branch 4, and send it to the exhaust port under the baffle plate 2 for extraction, ...

Embodiment 2

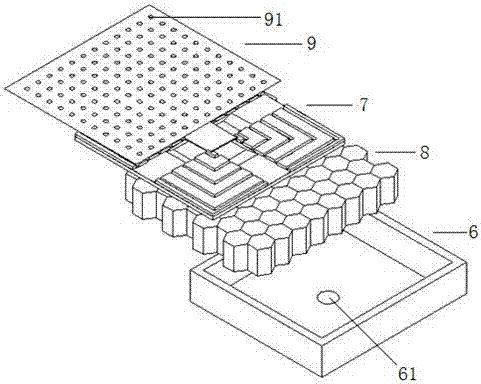

[0026] A vacuum adsorption platform is characterized in that it includes a base 6, a deflector 7, a honeycomb core 8 and a panel 9; the deflector 7 and the honeycomb core 8 are installed in the base 6, and the deflector 7 is located in the honeycomb above the core 8; the panel 9 is installed above the deflector 7; the base 6 is provided with a ventilation hole 61; the panel 9 is provided with a small hole 91.

[0027] The deflector includes a base plate 1 and a baffle plate 2, the baffle plate 2 is fixed on the base plate 1; the base plate 1 is provided with a vertical and horizontal air flow main channel 3, and its crossing point is located at the center of the base plate 1, and the The baffle plate 2 is located above the intersection of the main air flow channel 3, and the base plate 1 and the baffle plate 2 are provided with air outlets correspondingly. The base plate 1 is also provided with a number of air flow branch channels 4, and the air flow branch channels 4 are conne...

Embodiment 3

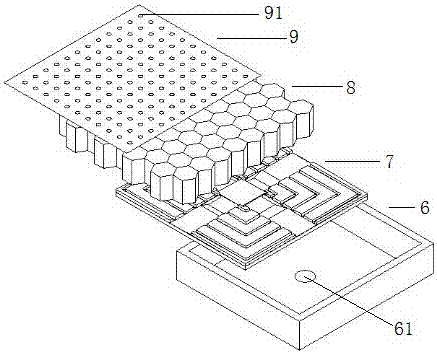

[0031] A vacuum adsorption platform is characterized in that it includes a base 6, a deflector 7, a honeycomb core 8 and a panel 9; the deflector 7 and the honeycomb core 8 are installed in the base 6, and the honeycomb core 8 is located in the guide above the board 7; the panel 9 is installed above the honeycomb core 8; the base 6 is provided with a ventilation hole 61; the panel 9 is provided with a small hole 91.

[0032] The deflector includes a base plate 1 and a baffle plate 2, the baffle plate 2 is fixed on the base plate 1; the base plate 1 is provided with a vertical and horizontal air flow main channel 3, and its crossing point is located at the center of the base plate 1, and the The baffle plate 2 is located above the intersection of the main air flow channel 3, and the base plate 1 and the baffle plate 2 are provided with air outlets correspondingly. The base plate 1 is also provided with a number of air flow branch channels 4, and the air flow branch channels 4 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com