In-situ cast hollow concrete slab

A cast-in-situ concrete and hollow slab technology, which is applied in the field of cast-in-place concrete hollow slabs, can solve the problems such as damage of cavity formwork components, poor overall strength and rigidity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

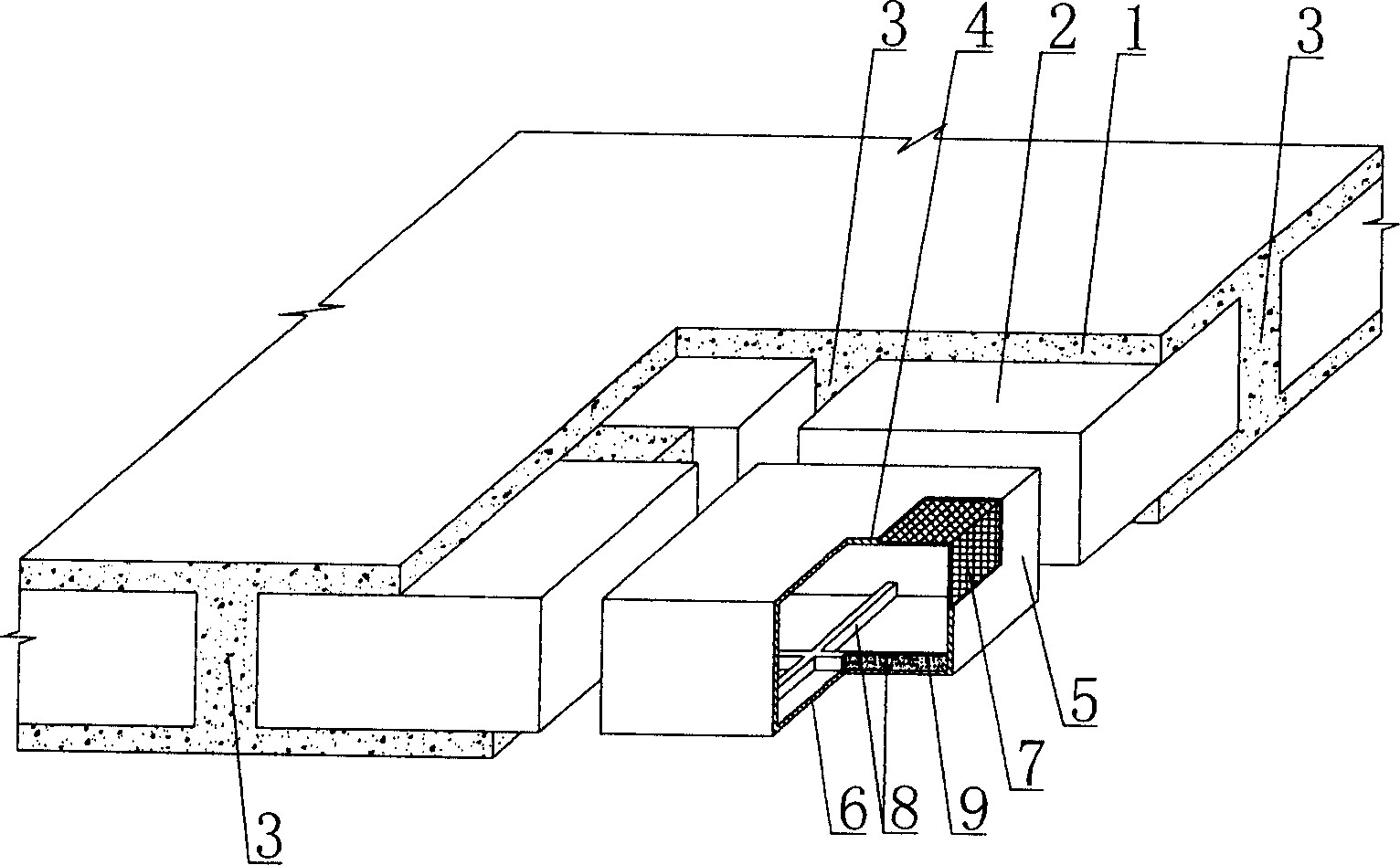

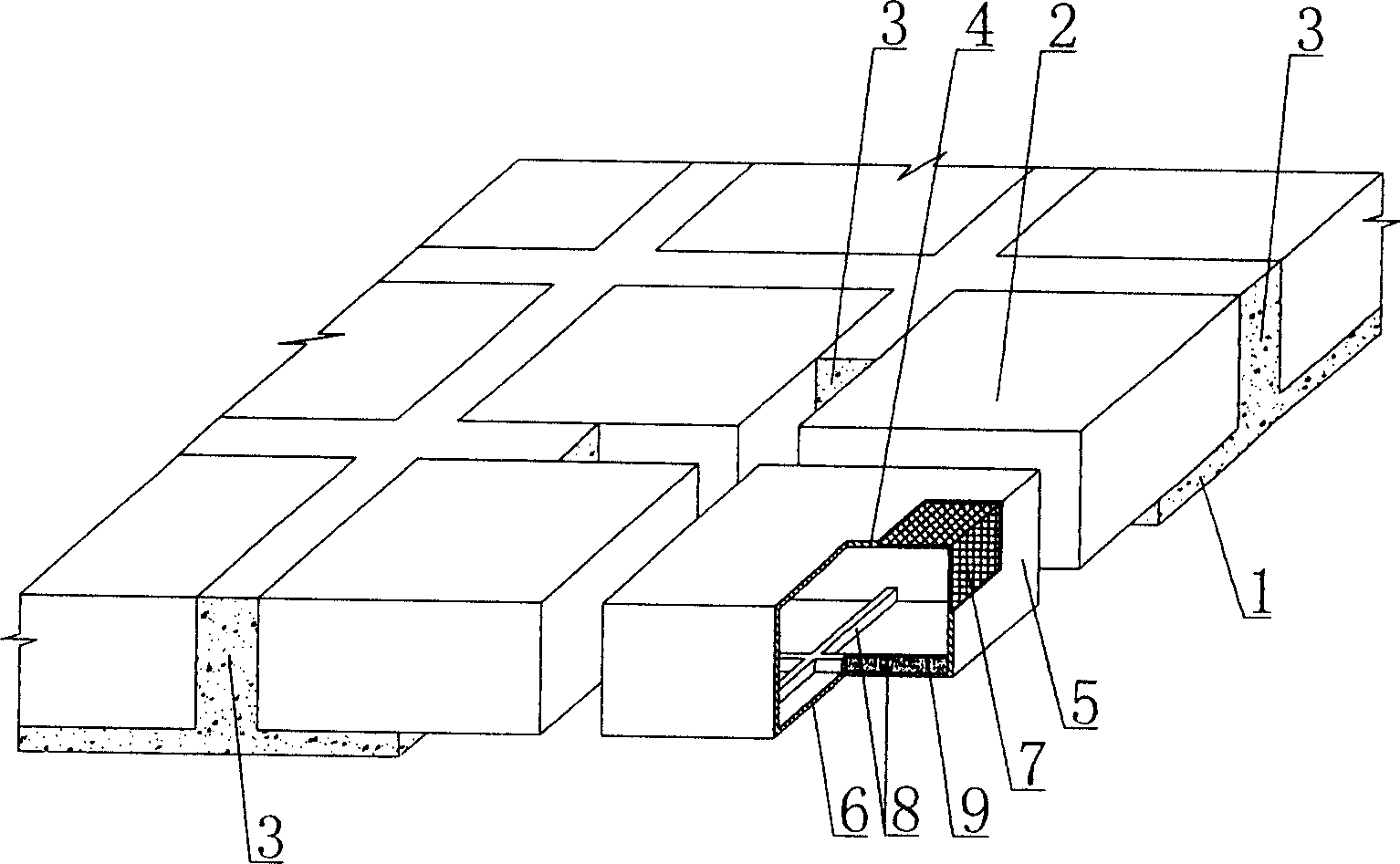

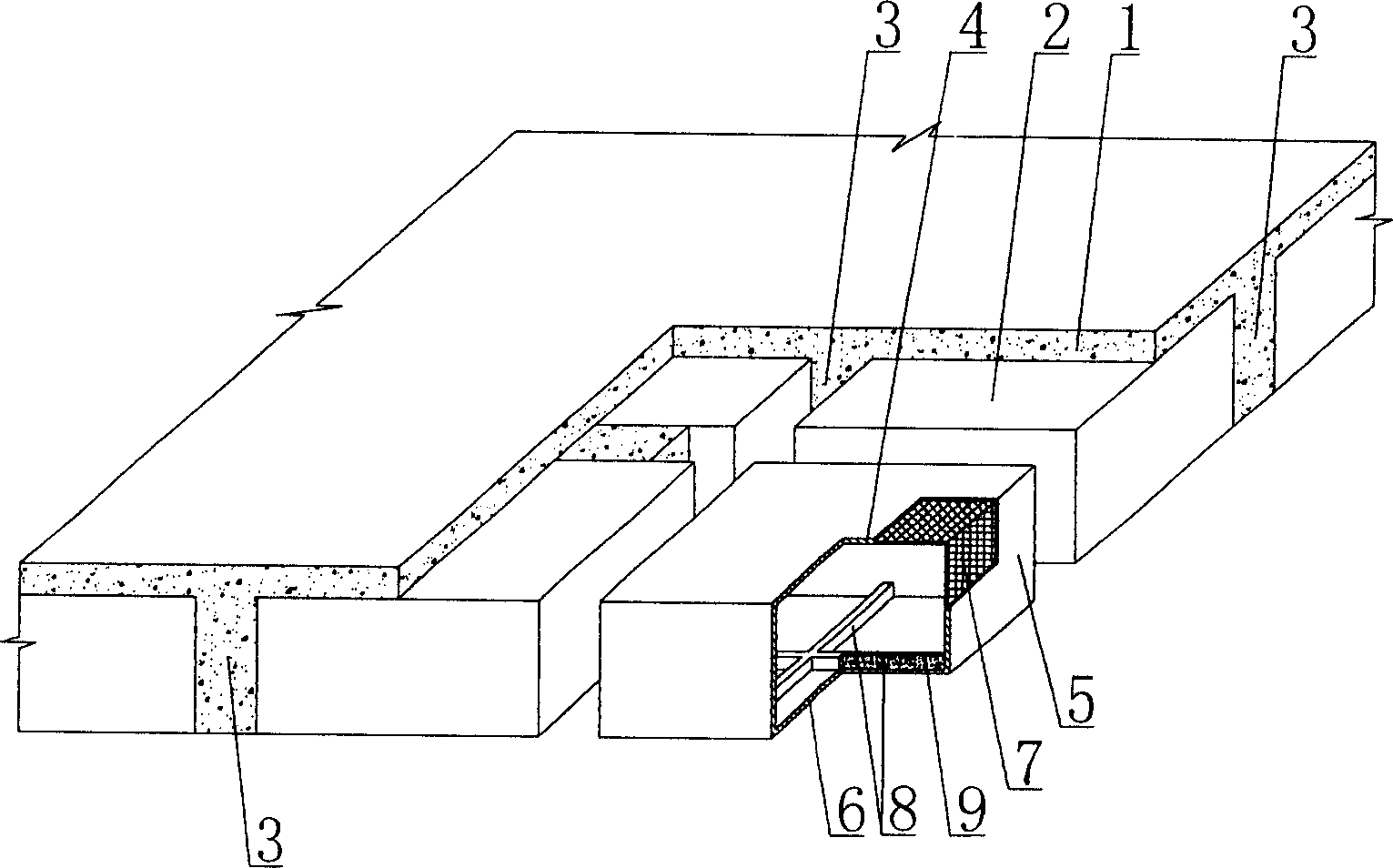

[0059] The present invention will be further described below in conjunction with the drawings and embodiments.

[0060] The present invention, as shown in the drawings, includes reinforced concrete 1, a formwork member 2, which is wrapped in reinforced concrete 1, and formwork members 2 are arranged alternately, with cast-in-situ reinforced concrete ribs 3 between them, and the formwork The component 2 includes an upper plate 4, a surrounding side wall 5, and a lower bottom 6. The upper plate 4, the surrounding side walls 5, and the lower bottom 6 form a polyhedral mold shell member 2. The upper plate 4, the surrounding side walls 5, and the lower bottom 6 contain Reinforcement 7, characterized in that the said formwork member 2 is provided with a reinforcement 8 which is a prefabricated reinforcement 9 or a stiffening rib plate 10, and the prefabricated reinforcement 9 or the stiffening rib plate 10 is superimposed and fixed in The wet slurry of the mold shell member 2 is hardene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com