Intelligent electrically controlled lock

An electronically controlled lock and intelligent technology, which is applied to building locks, non-mechanical transmission-operated locks, buildings, etc., can solve the problems of decreased safety protection performance, easy damage to the lock tongue, and failure to work normally.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

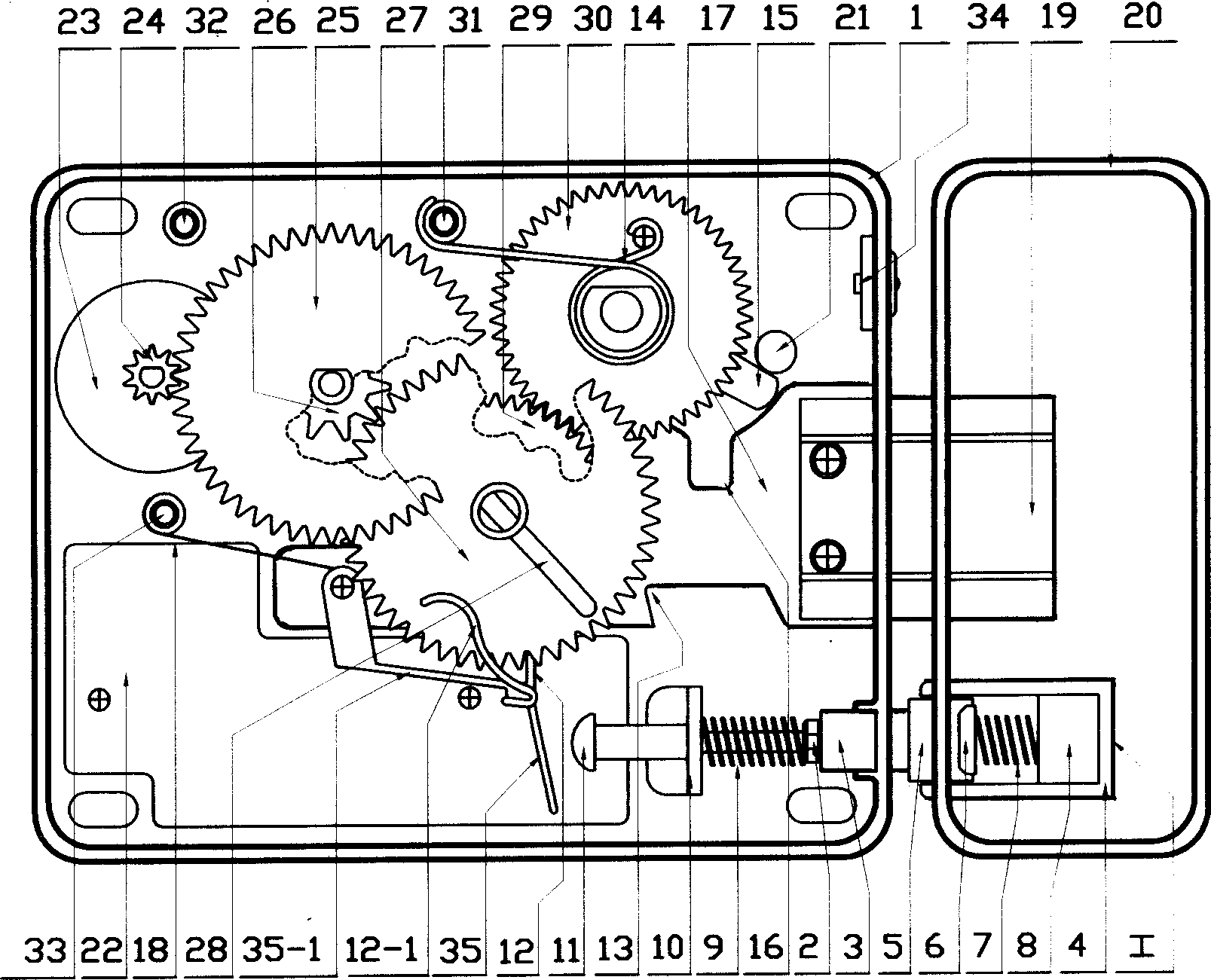

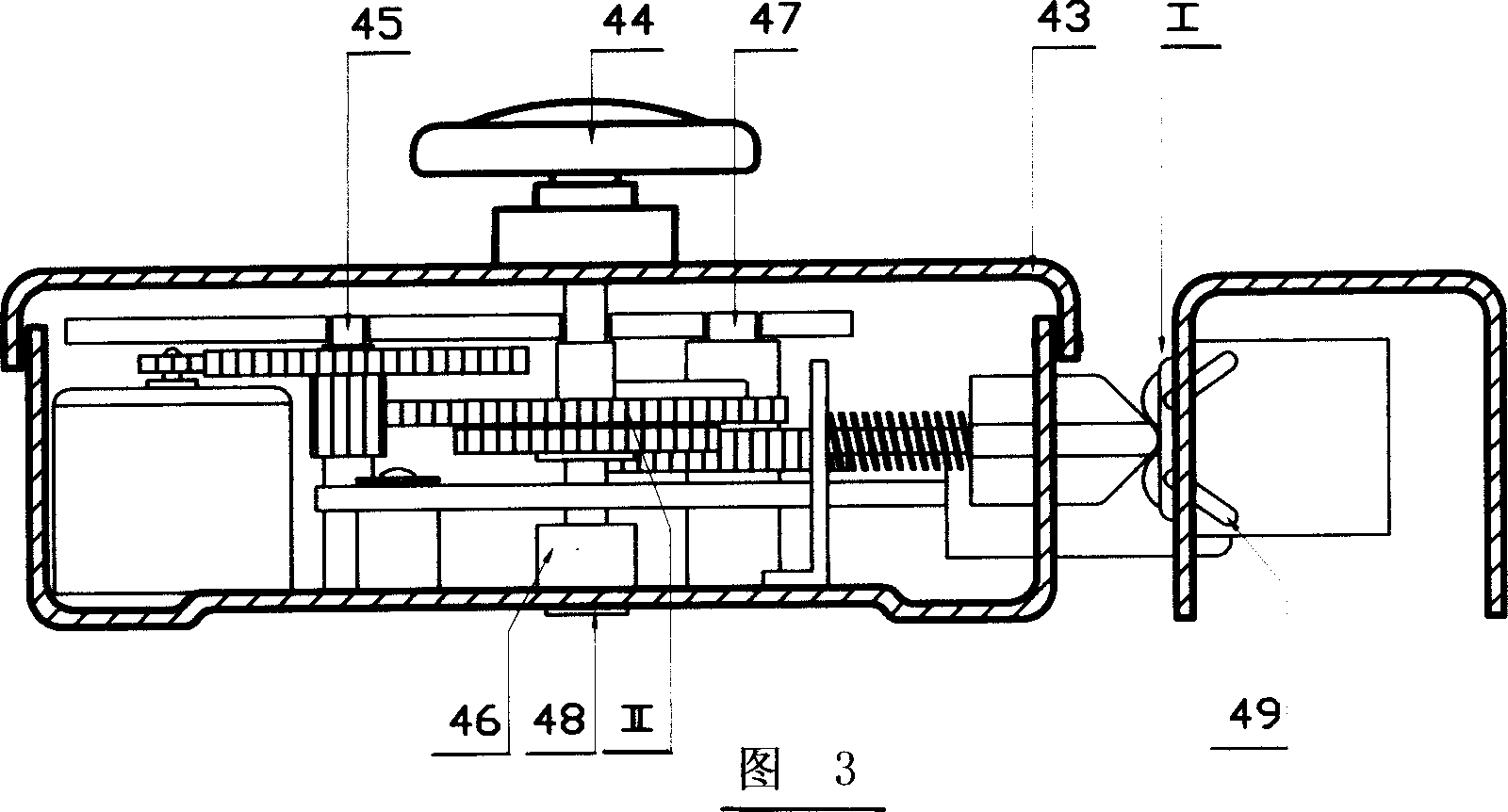

Embodiment Construction

[0031] The present invention can adopt two types of automatic adjusters, that is, two parallel adjuster rollers 5, the rollers 5 are closely attached to the adjuster roller tray 6, and the tray 6 is supported by a tray spring 7. There are two adjuster tray positioning plates 8 at both ends of the bracket 4, which are used to control the deflection (or motion) stroke of the adjuster roller tray 6; Two pairs of "eight" shaped oblique waist grooves 49 li on the support both sides. Another form has an in-line groove 51 on both sides of the "凵" type regulator bracket 4, and the roller is a regulator double conjoined roller 5-1, which is connected in the middle of the regulator double conjoined roller 5-1. A roller vertical shaft 50, the two ends of this vertical shaft 50 are inserted in the in-line groove 51 of " 凵 " shape adjuster support 4 both sides. The structures of these two forms of autoregulators are somewhat different, but the effect of autoregulation is the same. In add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com