Base plate for an electric power tool and method for producing the same

一种底板、金属板的技术,应用在制造工具、木材加工器具、金属加工设备等方向,能够解决底板昂贵、易于破裂、刚度高等问题,达到制造成本降低、节约潜能的效果

Inactive Publication Date: 2010-08-18

ROBERT BOSCH GMBH

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

But this base plate is expensive to manufacture because it has to be fitted with some mounting parts

As a third type, castings made of light metal-alloys are known, which have a high rigidity despite a very low weight

However, the manufacture of such base plates is associated with very high costs, since they have to be reworked

In addition, such castings are prone to cracking when subjected to shock loads

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

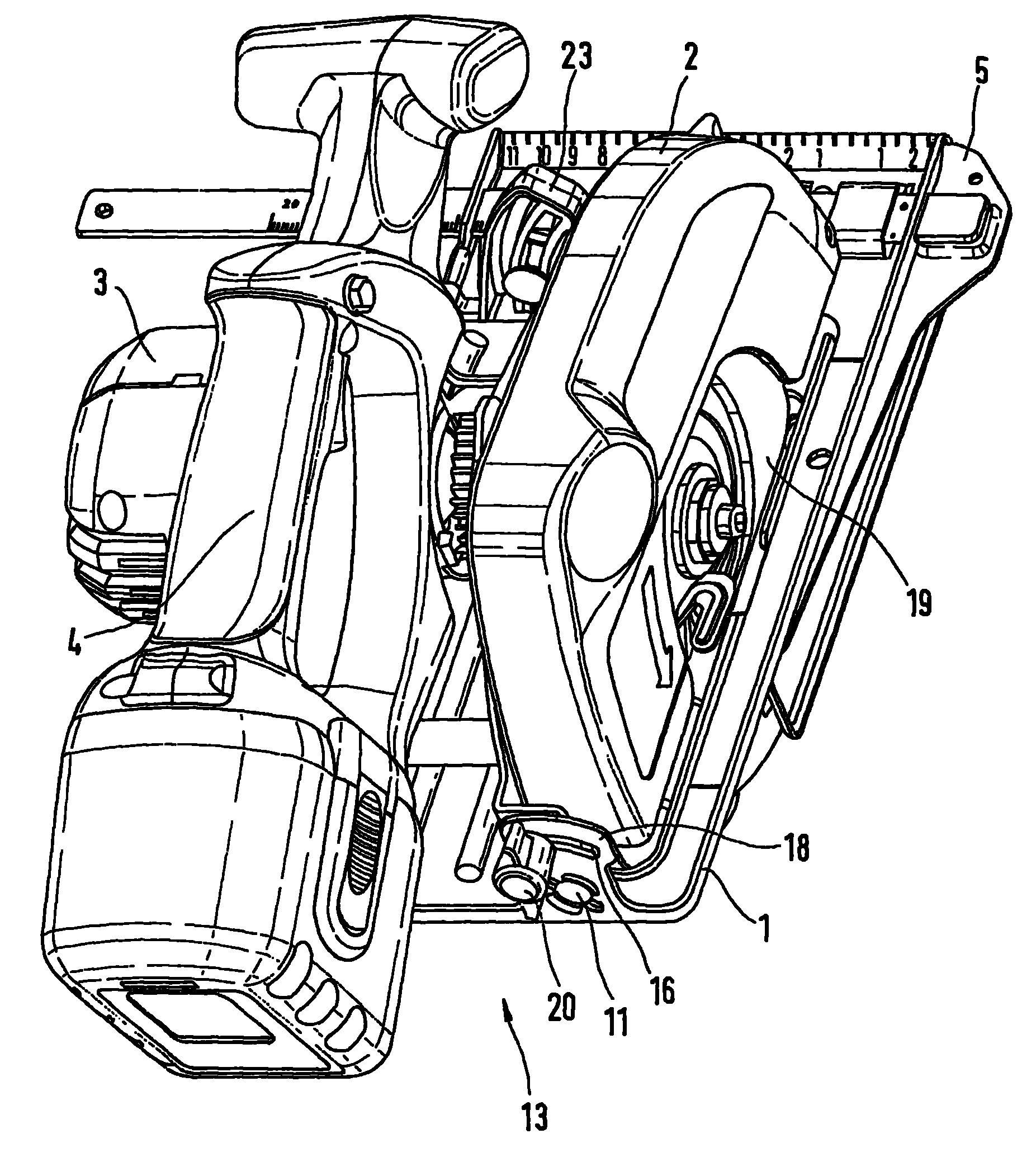

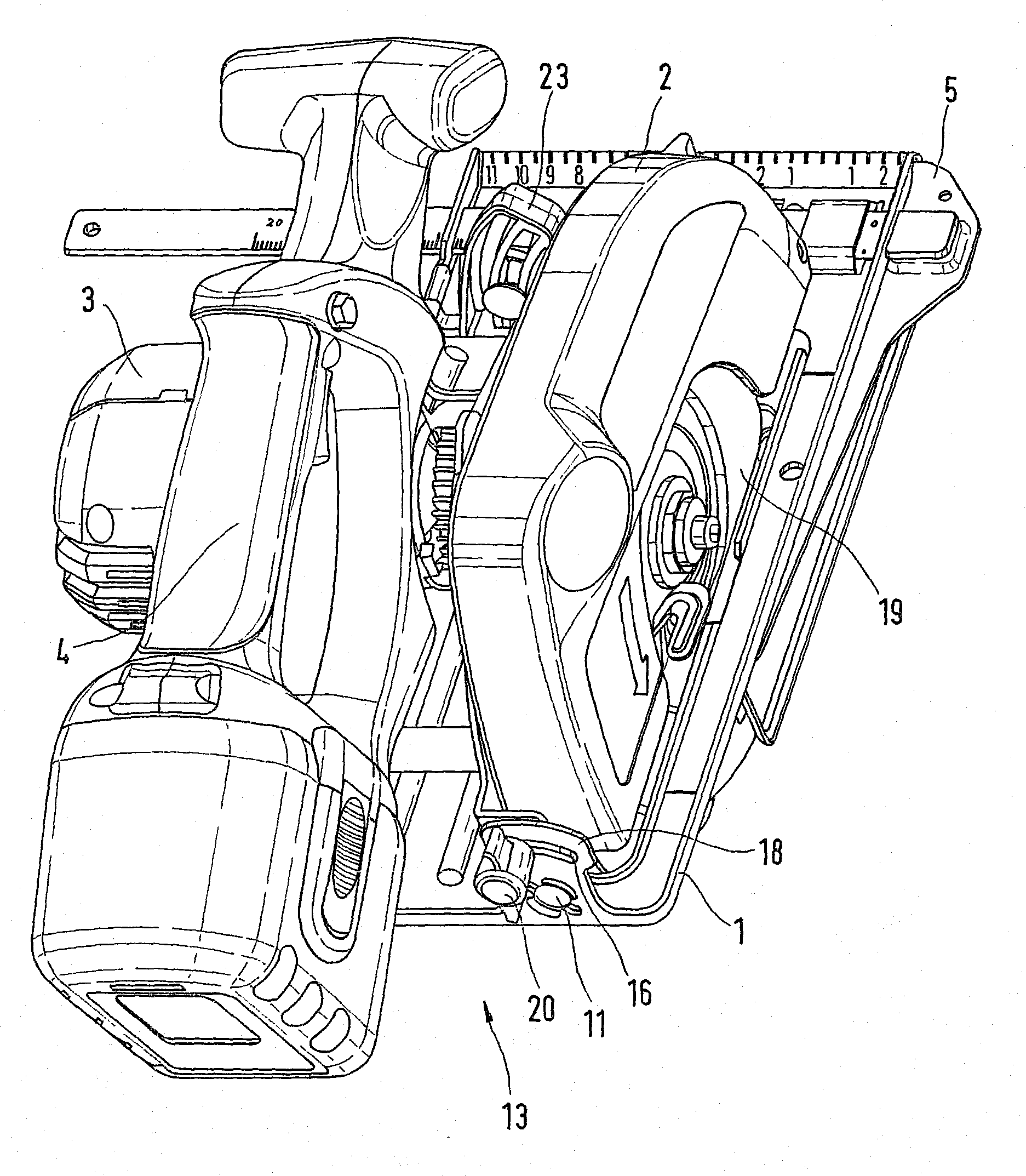

The invention relates to a base plate (1) for an electric power tool (13), especially for hand-held circular saws, compass saws and routers. Said base plate consists of sheet metal and comprises reinforcing elements projecting from the plane of the sheet metal, at least one of said elements being configured as a lateral stop (12), and connecting elements (14) projecting from the plane of the sheet metal for fastening the base plate (1) to the miter box (23). The aim of the invention is to provide a base plate that is less complex in production, has a lower weight and higher rigidity at a lower risk of fracture. For this purpose, the metal sheet consists of light metal and the entire base plate (1) is configured as a single piece. According to the invention, the base plate (1) of the aforementioned kind is produced by a combined cutting and bending method.

Description

technical field The invention relates to a base plate for an electric tool. Background technique Base plates for hand-operated circular saws, jigsaws, electric wall penetration machines and engraving machines are known, which base plates are designed as flat parts with a small overall height. They are used to guide power tools on a workpiece. In principle, there are three embodiments of the base plate. As a first type, base plates made of steel sheets as stamped-bent parts are known. They usually have some longitudinal ribs and a surrounding flange, which are used to increase rigidity, since the steel plate thickness is only between 1.5 and 2.5 mm. Such a component can be advantageously produced, since some of the technical functions, such as the abutment for a parallel stop or the center of rotation for angular adjustment, are realized by the component, which can be formed directly from sheet steel, without subsequent machining. In addition, warped base plates can also...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B27B9/02B23D47/02B23D51/02

CPCB27B9/02B23D51/02B23D47/02

Inventor 沃尔夫冈·富克斯海科·勒姆于尔根·盖林延斯·布卢姆

Owner ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com