Annular back-flow vertical wind tunnel, and its back-flow method

A wind tunnel and ring-shaped technology, applied in the field of vertical wind tunnels, can solve problems such as difficult heat dissipation, high temperature of internal return air, and restricted use, so as to prevent serious separation, reduce energy loss, and fresh air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but it should be noted that these embodiments are only used to illustrate the solutions of the present invention, and should not limit the scope of the present invention thereto.

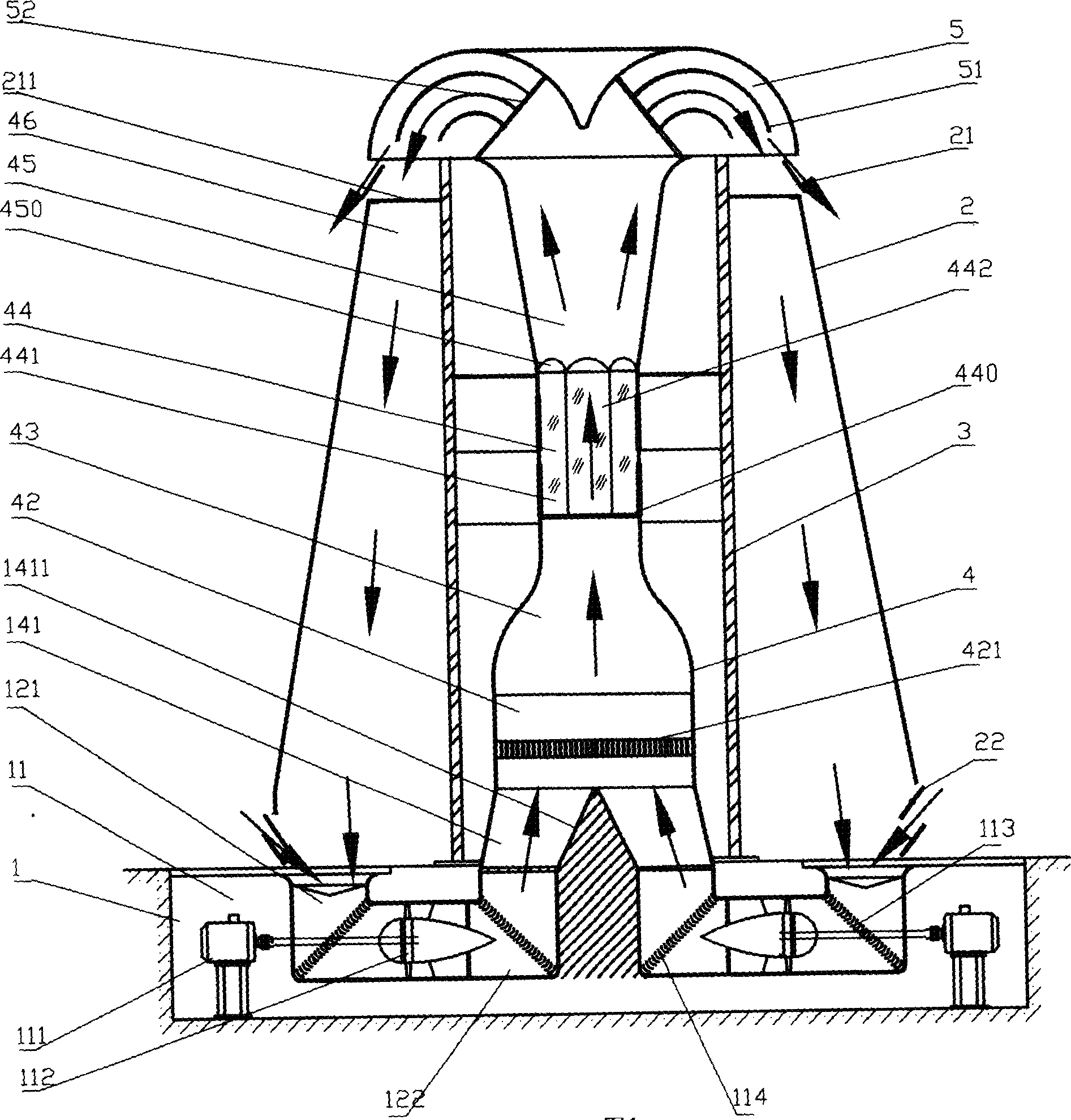

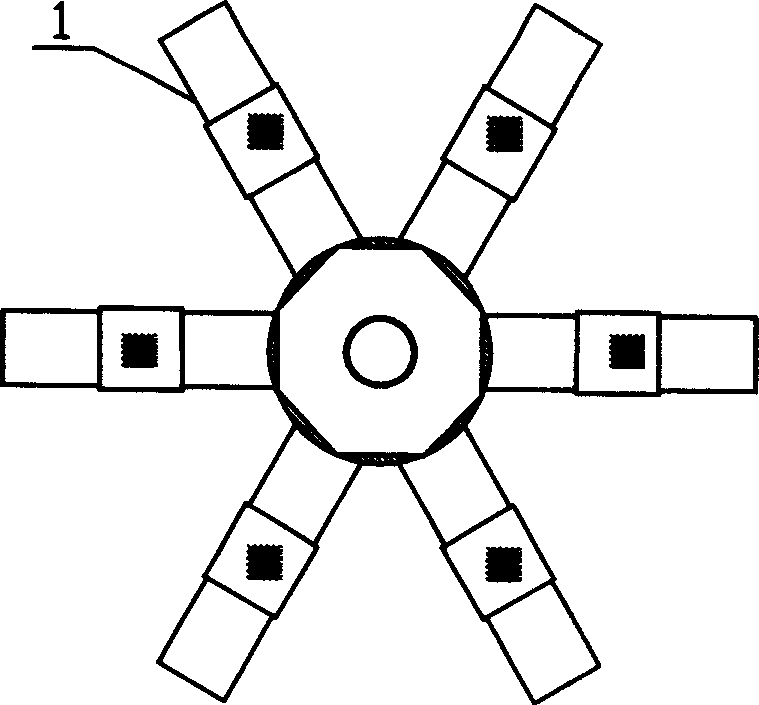

[0021] Such as figure 1 As shown, the annular backflow vertical wind tunnel of the present invention has the following parts: a lower power system 1 , a casing 2 , a bracket 3 , a working tunnel body 4 , and a backflow deflector 5 . The following describes the working principle of the system for these parts respectively.

[0022] In this embodiment, the power system of the present invention is different from the top-mounted power system of the existing wind tunnel, but the power system 1 is placed at the bottom of the entire vertical wind tunnel. Compared with the top-mounted power system, the advantage of this design is that Not only can the weight and vibration carried by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com