Optical disk drive focusing apparatus

A technology for optical disc drives, actuators, applied in packaging, head configuration/installation, recording/reproducing by optical methods, etc., which can solve problems such as performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

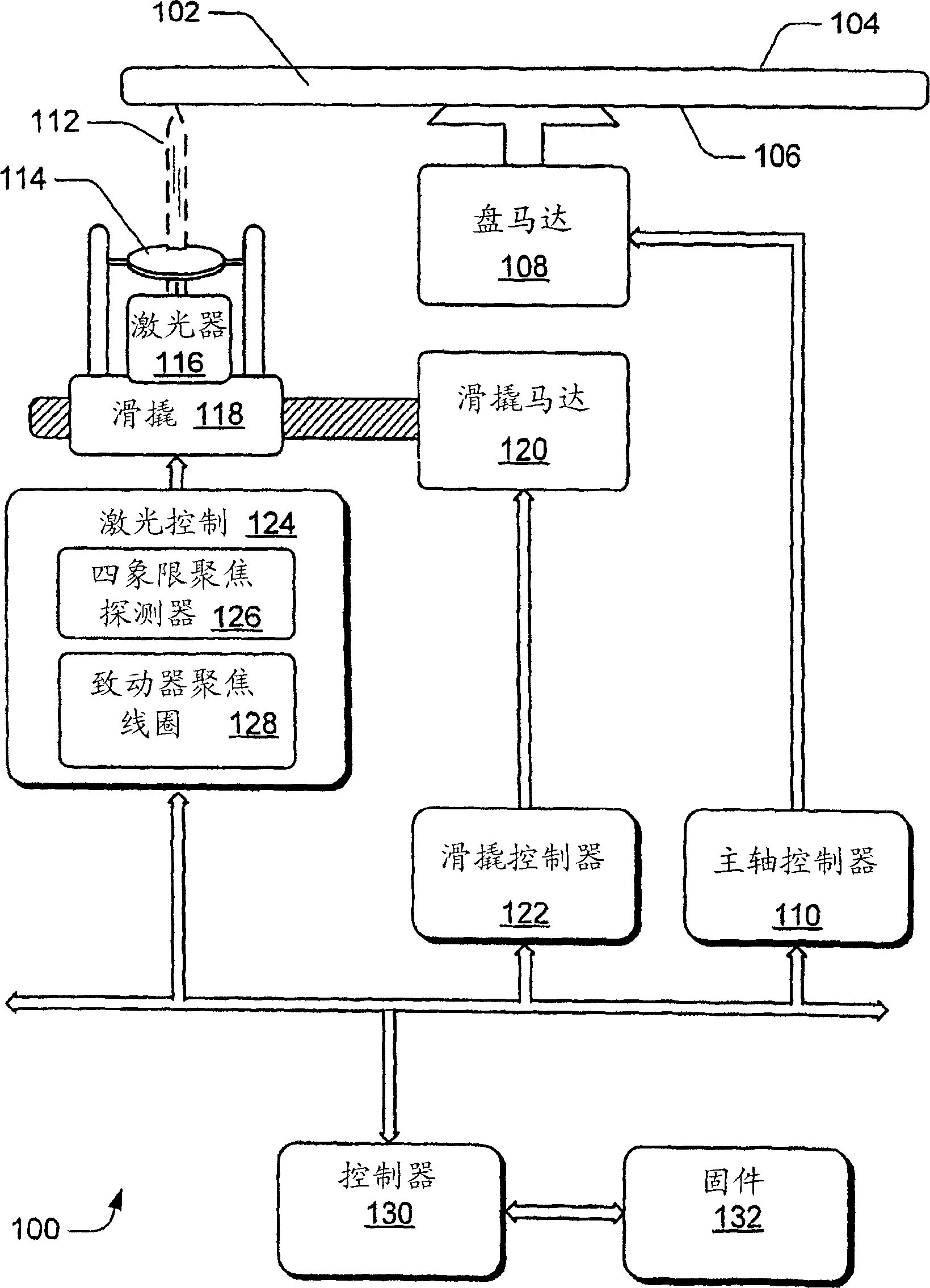

[0017] figure 1 A general schematic diagram of a typical disk drive and controller system 100 is shown. A disc 102 with an information side 104 is oriented to position a label side 106 for labeling. The disk is rotated by a disk or spindle motor 108 which is controlled by a spindle controller 110 . The laser beam 112 reaches the coated surface of the label side 106 of the disc 102 after passing through an optical system, such as a lens 114 . Laser 116 is carried by sled 118, and sled motor 120 moves the sled in a radial direction. In a typical application, sled motor 120 under the direction of sled controller 122 advances sled 118 carrying laser 116 in incremental steps from the radially inner edge of the label area to the radially outer edge of the label area.

[0018] Laser controller 124 controls the operation of laser 116 and associated tracking coils and detectors. exist figure 1 In the example of , the four-quadrant focusing detector 126 typically contains four dete...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap