Method of driving plasma display panel (PDP)

A plasma and display panel technology, applied in static indicators, general control systems, instruments, etc., to solve problems such as unstable discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be fully described with reference to the accompanying drawings, in which exemplary embodiments of the invention are shown.

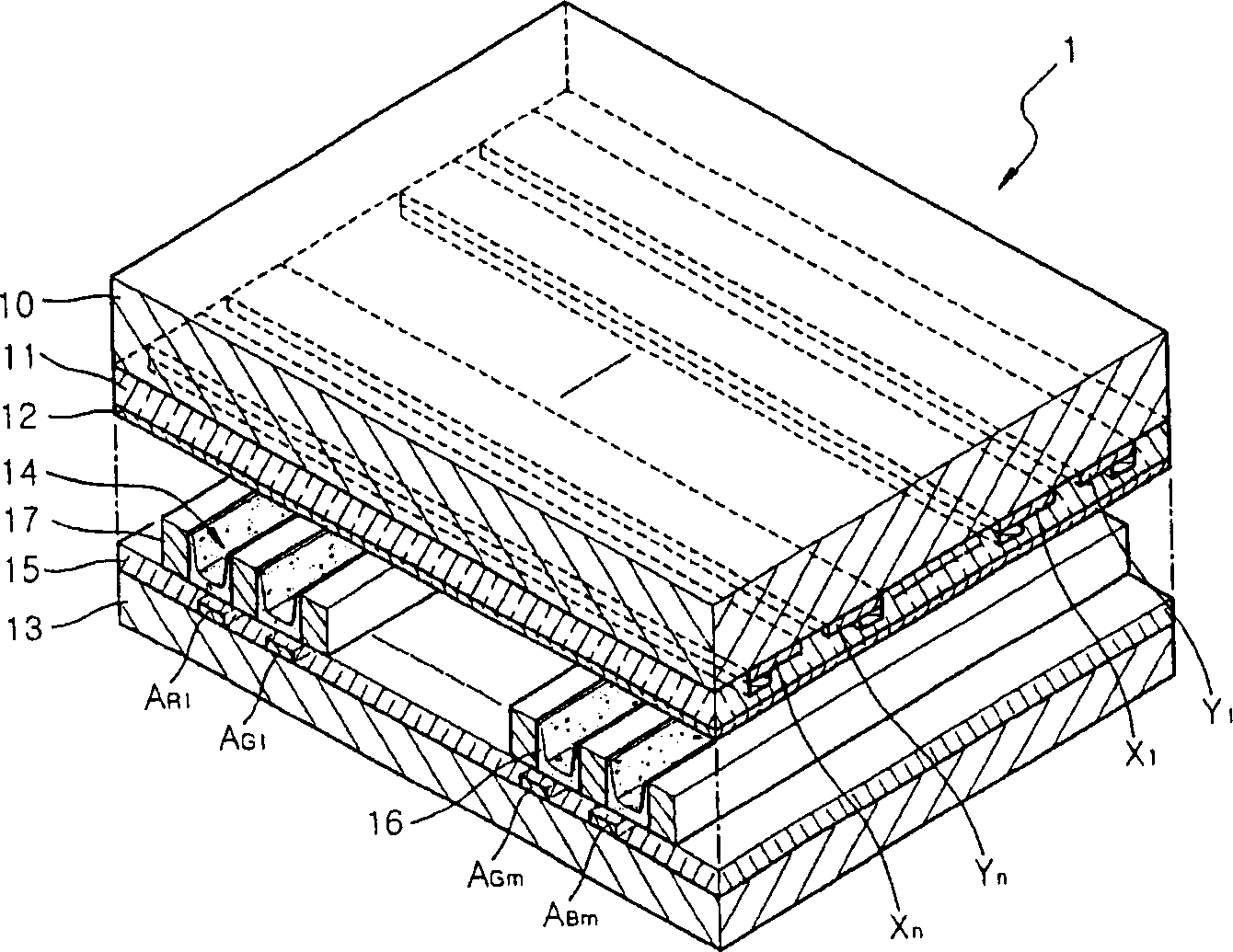

[0034] figure 1 is a perspective view of a 3-electrode surface discharge PDP 1 to which a PDP driving method according to an embodiment of the present invention is applied.

[0035] refer to figure 1 , address electrode A R1 ,...,A Bm , upper and lower insulating layers 11 and 15, Y electrode Y 1 ,...,Y n , X electrode X 1 ,...,X n , a fluorescent material layer 16, barrier ribs 17, and a MgO layer 12 as a protective layer are formed between the front and rear glass substrates 10 and 13 of the surface discharge PDP 1.

[0036] Address electrodes A are formed on the upper surface of the rear glass substrate 13 in a predetermined pattern. R1 ,...,A Bm . The lower insulating layer 15 covers the address electrodes A R1 ,...,A Bm . Isolation rib 17 and address electrode A R1 ,...,A Bm formed in parallel on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com