Plug and heating element assembly for a diffusing device for volatile substances

A technology of volatile substances and heating elements, applied in the field of plugs and heating element assemblies, can solve the problems of difficult assembly of automatic machine plugs, robots not knowing the relative position of heating elements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

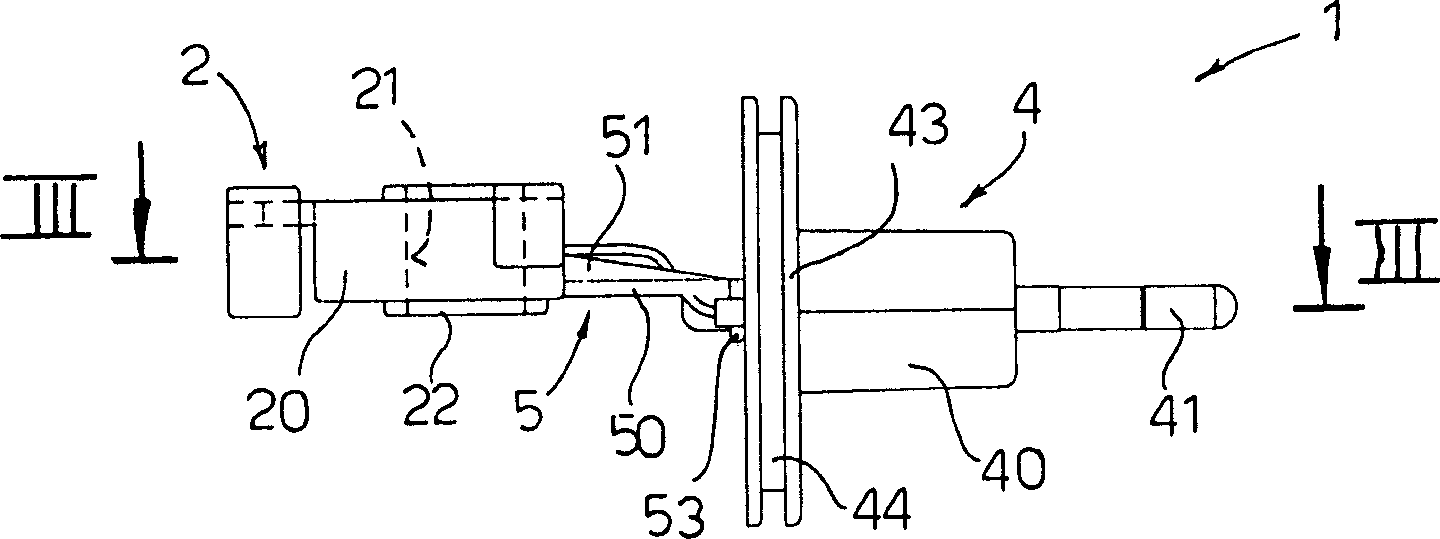

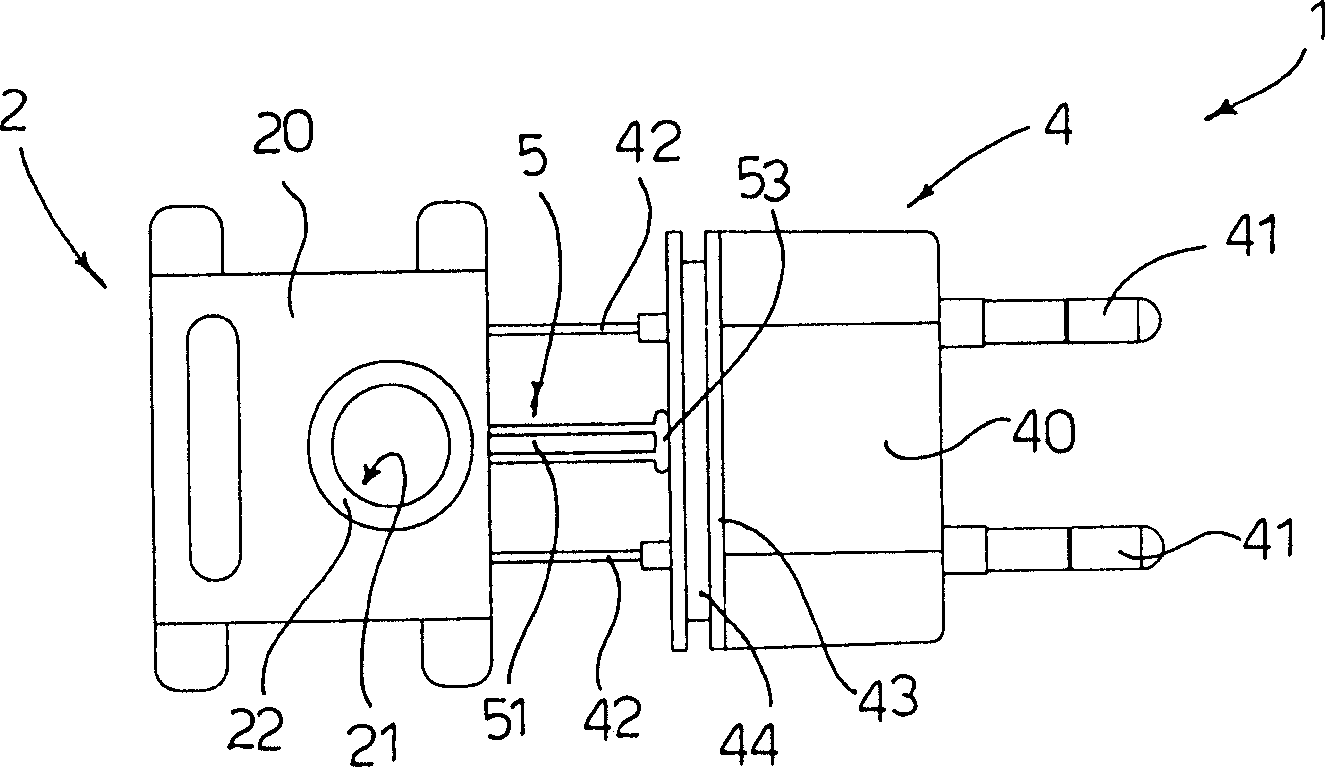

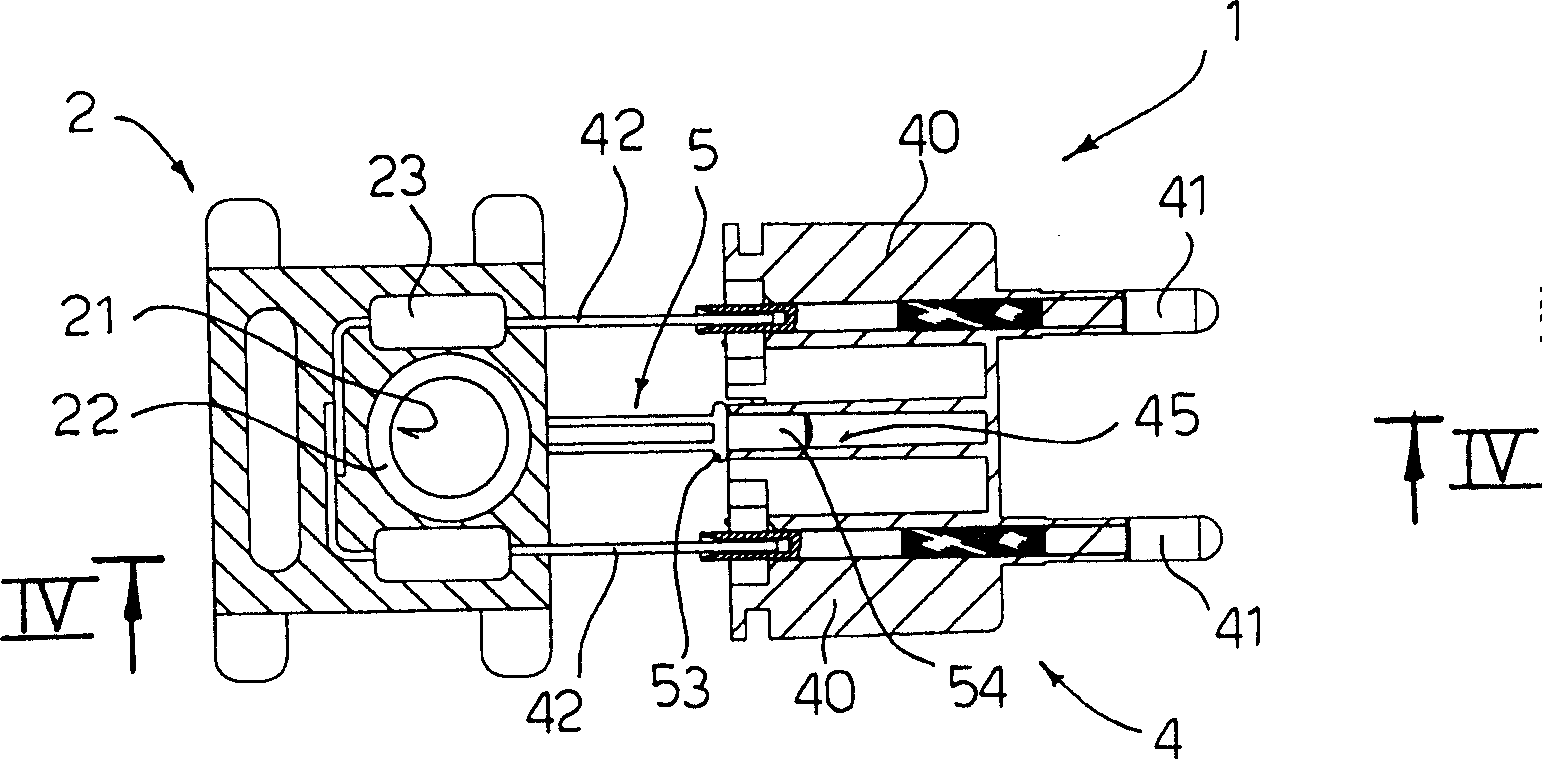

[0030] refer to Figure 1 to Figure 4 , describes a first embodiment of a plug and heating element assembly for a volatile substance diffusion device according to the present invention.

[0031] The assembly as a whole is indicated with reference numeral 1 , comprising a heating element 2 and a plug 4 .

[0032] The heating element 2 comprises a support or substrate 20, which may be made of plastic, ceramic material or other electrically insulating material having thermal resistance and thermal conductivity properties. The support 20 is shown in the shape of a parallelepiped, but could also be cylindrical or other shapes.

[0033] The support 20 of the heating element 2 comprises a cylindrical tang 22 which defines a circular hole 21 . A cylindrical siphon strip immersed in a volatile solution contained in a container shell (not shown) is inserted into the hole 21 of the heating element 2 .

[0034] Although specific reference is made to siphon strips, it is apparent that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com