Antimicrobial glass and glass ceramic surfaces

An anti-microbial, glass powder technology, used in biocides, animal repellents, plant growth regulators, etc., can solve the problems of insufficient fungicidal effect and no anti-microbial effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

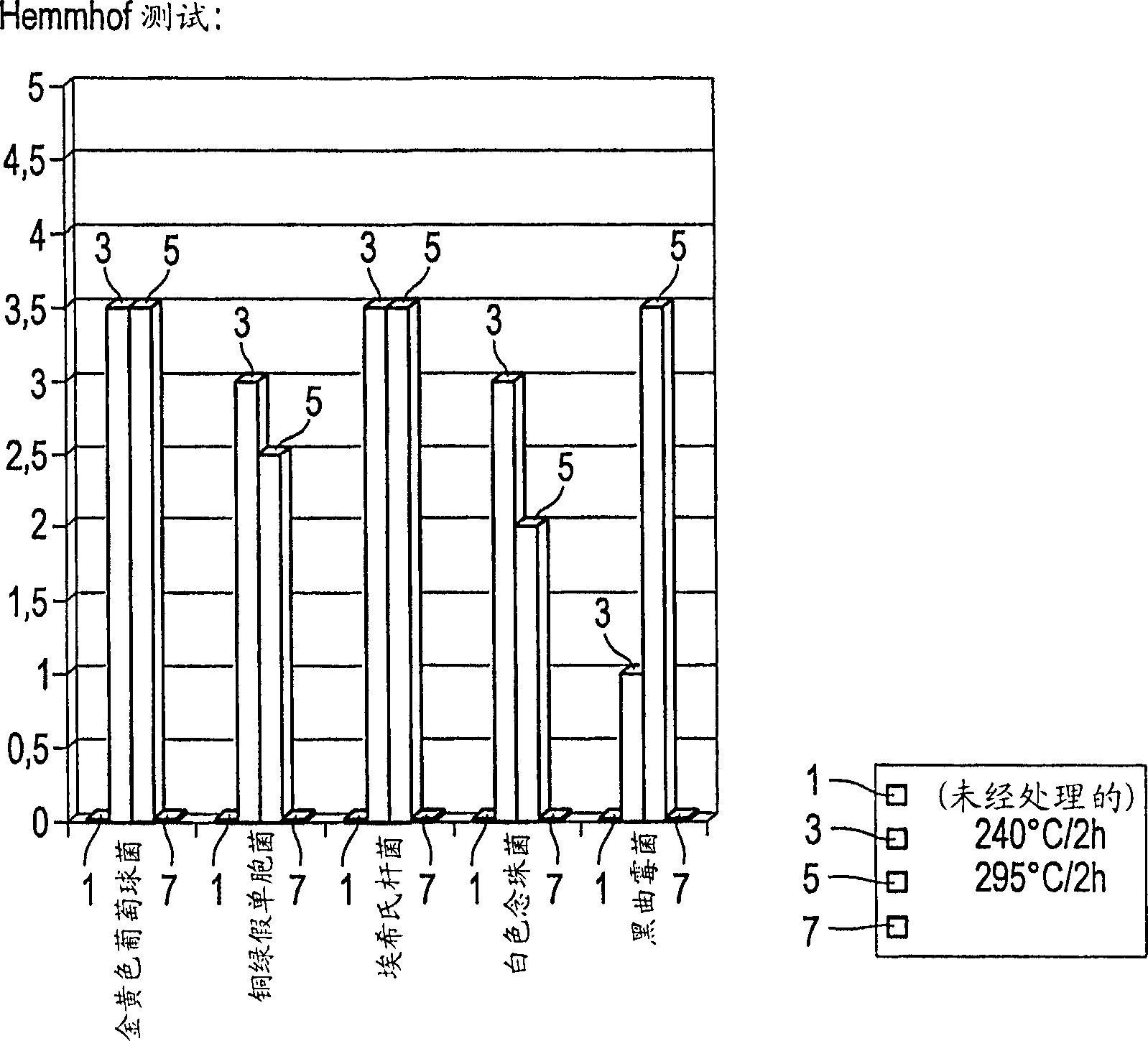

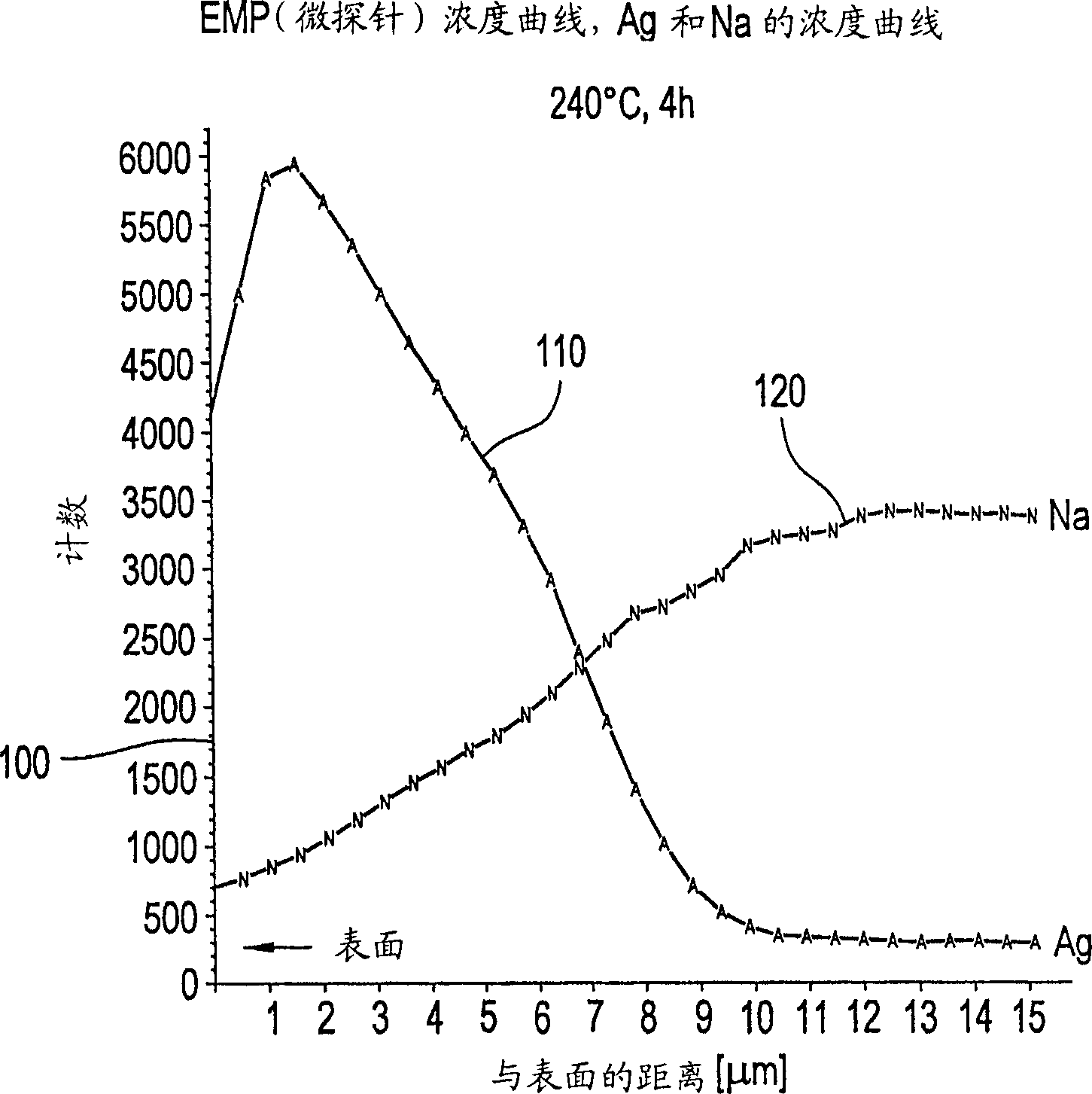

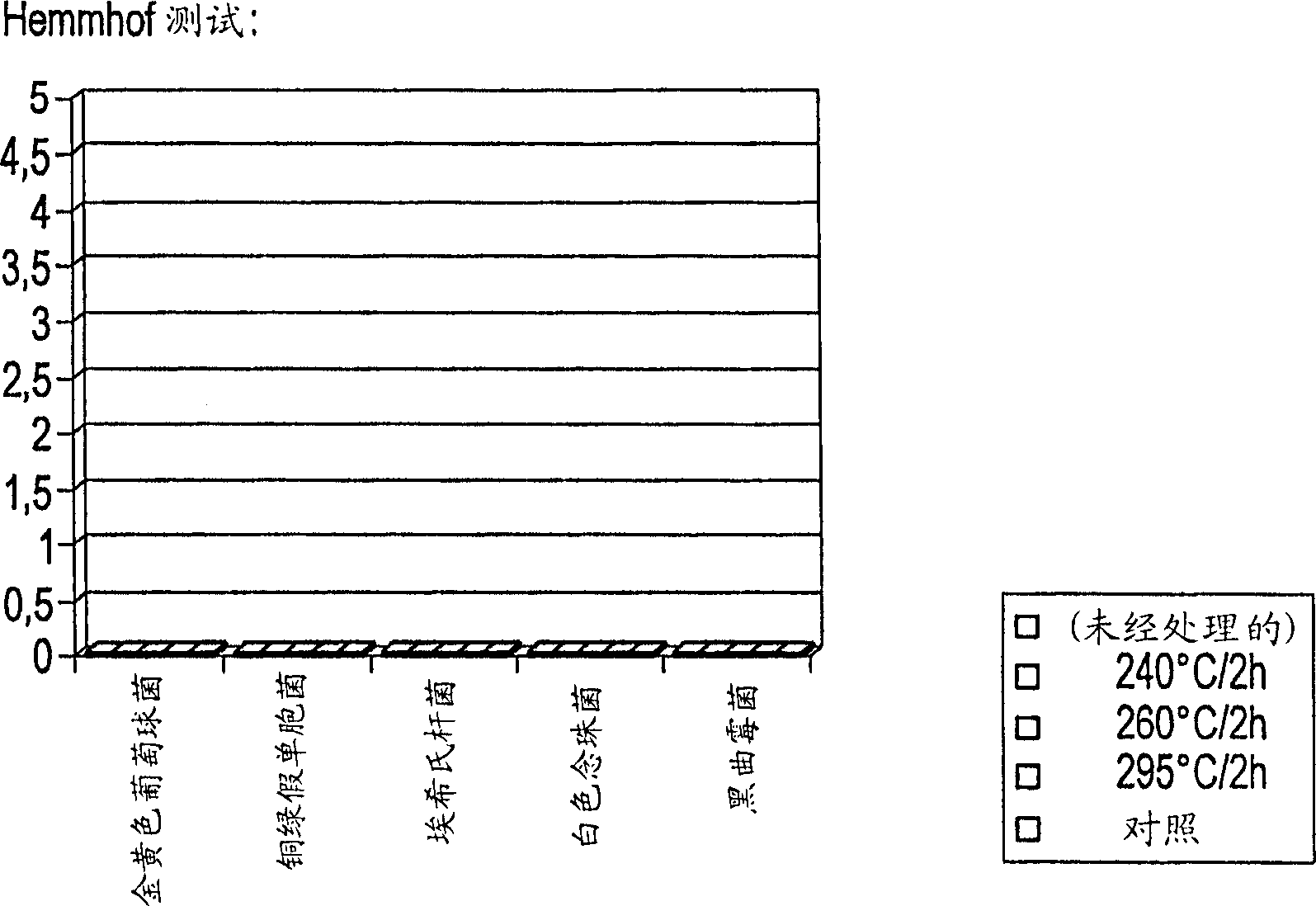

[0113]The present invention is described below based on examples.

[0114] In Table 1 are given examples of glass compositions which produce an antimicrobial surface by ion exchange in solution.

[0115] Example 1

SiO 2

71.2

al 2 o 3

0.35

CaO

9.6

MgO

4.0

Fe 2 o 3

0.1

Na 2 o

14.1

K 2 o

0.05

[0116] The glass given in Table 1 refers to a soda-lime glass which has the composition (% by weight) given in Table 1.

[0117] The glasses given in Table 1 have been ground once in an inert solution, ie in water. This glass powder was used as a control sample in terms of antimicrobial activity.

[0118] In order to demonstrate the increased antimicrobial effect due to the antimicrobial treatment according to the invention, the glasses of Table 1 were firstly ground in a zinc nitrate solution and in another configuration in a silver nitrate solution.

[0119] The developm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com