Microgels in cross-linkable, organic media

A microgel, medium technology, used in the field of molded bodies or coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0161] Example 1: Hydroxyl-modified SBR gel in Desmophen 1150 (RFL 403A)

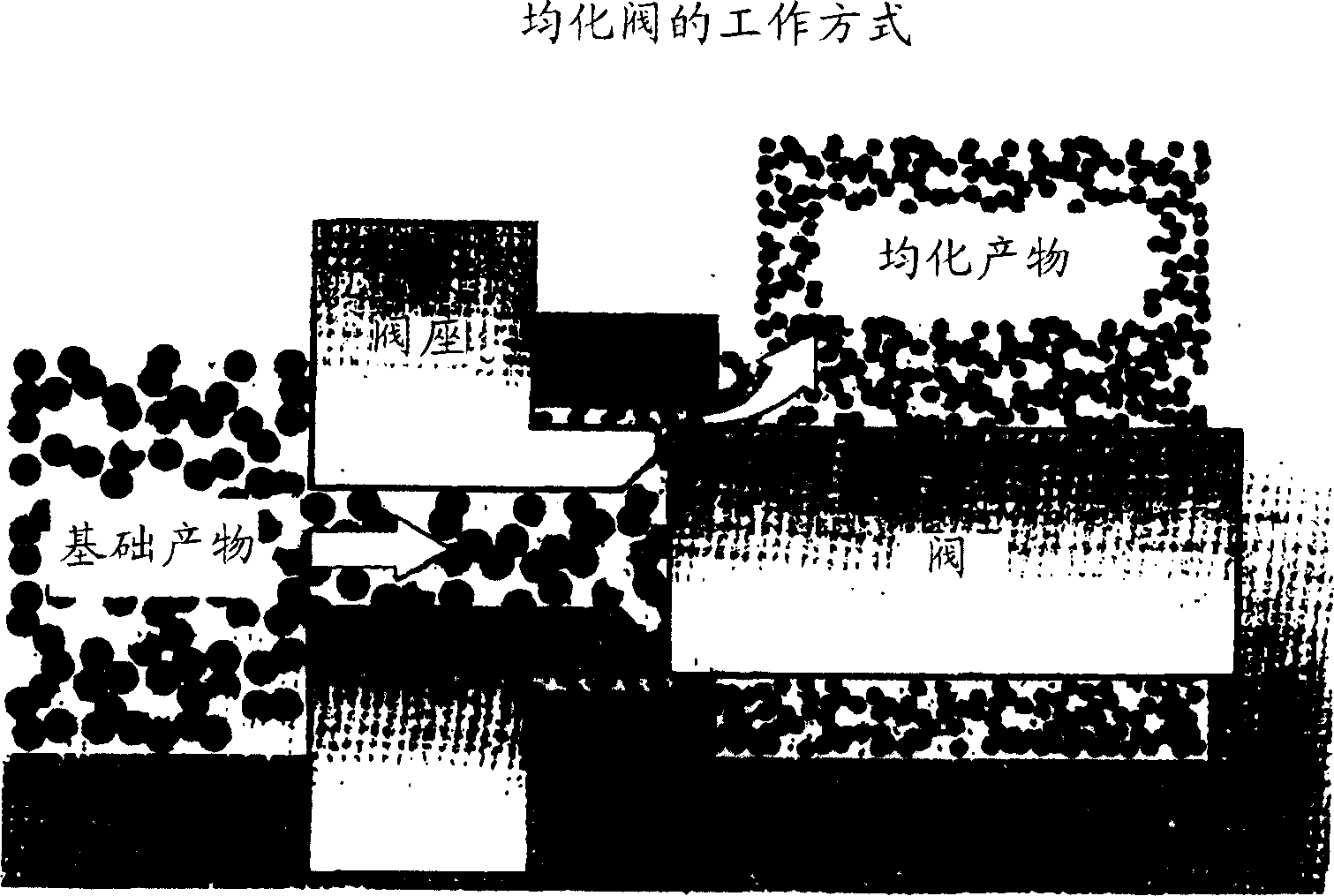

[0162] In the following examples, it is shown that using a homogenizer, applying a pressure of 900-1000 bar, and using a microgel based on hydroxyl-modified SBR, the microgel composition according to the present invention with a particle size of ≤220 nm can be prepared.

[0163] The composition of the microgel composition according to the present invention is shown in the following table:

[0164] 1.Desmophen 1150 79.7

[0165] 2.RFL 403A 20

[0166] 3.Tego Airex 980 0.3

[0167] Total 100

[0168] Desmophen 1150 is a branched polyol carrying ester and ether groups from Bayer AG for the preparation of viscoelastic coatings.

[0169] Tego Airex 980, an organically modified polysiloxane, is a degassing agent from Tego Chemie ServiceGmbH.

[0170] RFL 403A is a cross-linked, surface-modified SBR-based rubber gel from RheinChemie Rheinau GmbH.

[0171] RFL 403A is composed of 70% butadiene, 22wt% styrene, 5wt% ...

preparation Embodiment 1

[0173] Hydroxyl-modified SBR-based microgels are prepared by direct emulsion polymerization using the crosslinking monomer ethylene glycol dimethacrylate.

[0174] 350 g of the sodium salt of long-chain alkyl sulfonic acid (368.4 g of Mersolat K30 / 95 from Bayer AG) and 27 g of the sodium salt of methylene bridged naphthalenesulfonic acid (Baykanol PQ from Bayer AG) were dissolved in 2.03kg of water was put into a 5L autoclave. The autoclave was evacuated three times and filled with nitrogen. Thereafter, 872 g butadiene, 274 g styrene, 69 g ethylene glycol dimethacrylate (90%), 38.5 g hydroxyethyl methacrylate (96%) were added. While stirring, the reaction mixture was heated to 30°C. Then metered in by 25g water, 180mg ethylenediaminetetraacetic acid (Merck-Schuchardt), 150mg ferrous (II) sulfate 7H 2 O, 400mg Rongalit C (Merck-Schuchardt) and 500mg trisodium phosphate 12H 2 O consists of an aqueous solution. The reaction is started by adding an aqueous solution of 350 mg p-menthan...

Embodiment 2

[0182] Example 2: Hydroxyl-modified SBR gel (RFL 403A) in Desmophen RC-PUR KE 8306

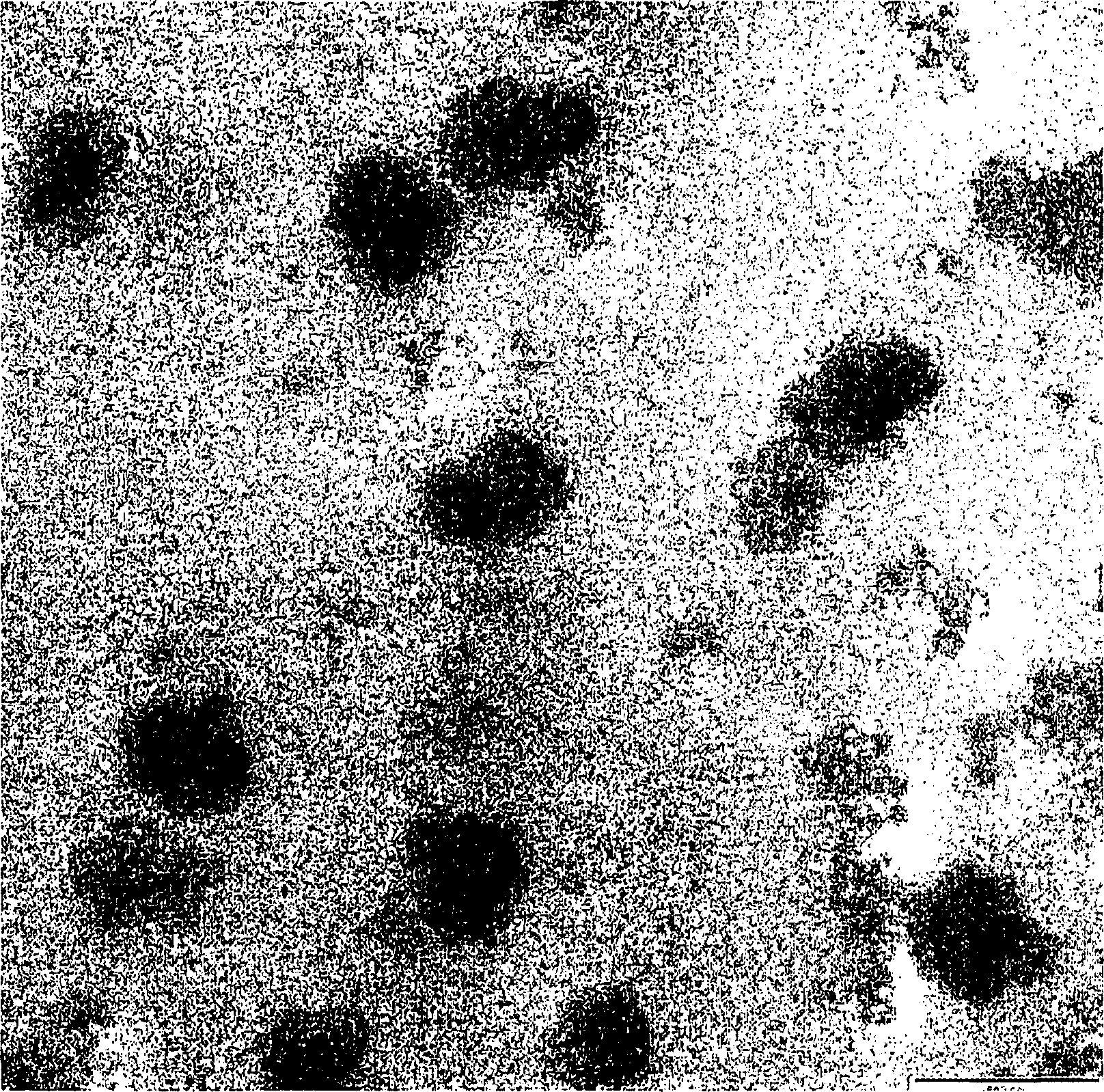

[0183] The following examples show that in the homogenizer, by applying a pressure of 900-1000 bar, the use of hydroxyl-modified SBR-based microgels can prepare particles with a particle size of mainly 50-500nm and an average particle size of about 250nm. The composition according to the invention of particles or agglomerates of particles.

[0184] The composition of the microgel paste is shown in the table below:

[0185] 1.RC-PUR KE8306 93.3

[0186] 2.Byk-LP X6331 0.2

[0187] 3.RFL 403A 6.5

[0188] Total 100

[0189] RC-PUR KE 8306 is an activated polyol blend from RheinChemie Rheinau GmbH for preparing PUR by a cold casting method.

[0190] The crosslinking component used was RC-DUR 120, an aromatic polyisocyanate from RheinChemie Rheinau GmbH.

[0191] Byk-LP X 6331 is a degassing agent for the PU system from Byk-Chemie GmbH.

[0192] RFL 403A is a cross-linked, surface-modified SBR-based r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com