Method for producing high voltage gas discharge lamp tube

A manufacturing method and high-pressure gas technology, applied in the manufacture of discharge tubes/lamps, gas discharge lamps, discharge lamps, etc., can solve problems such as accelerated corrosion of metal foil electrical conductors 6, production cost and efficiency problems, and difficulty in reaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

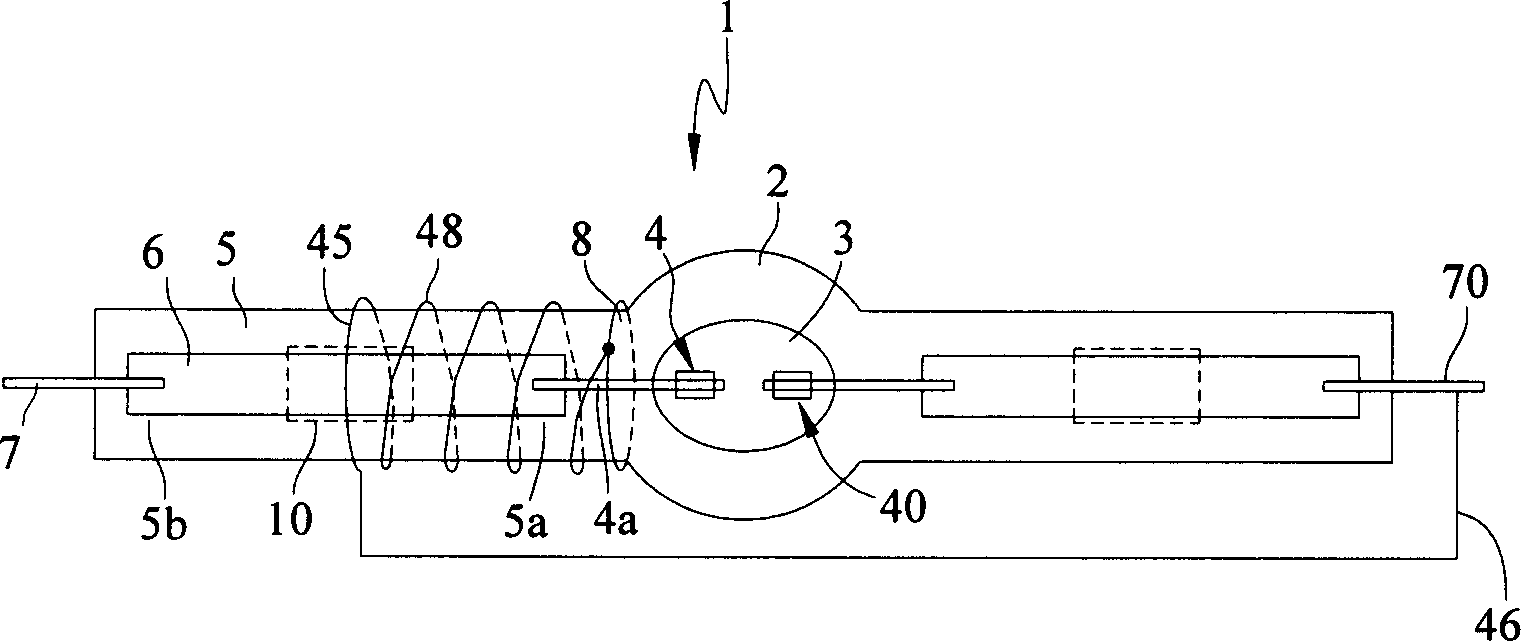

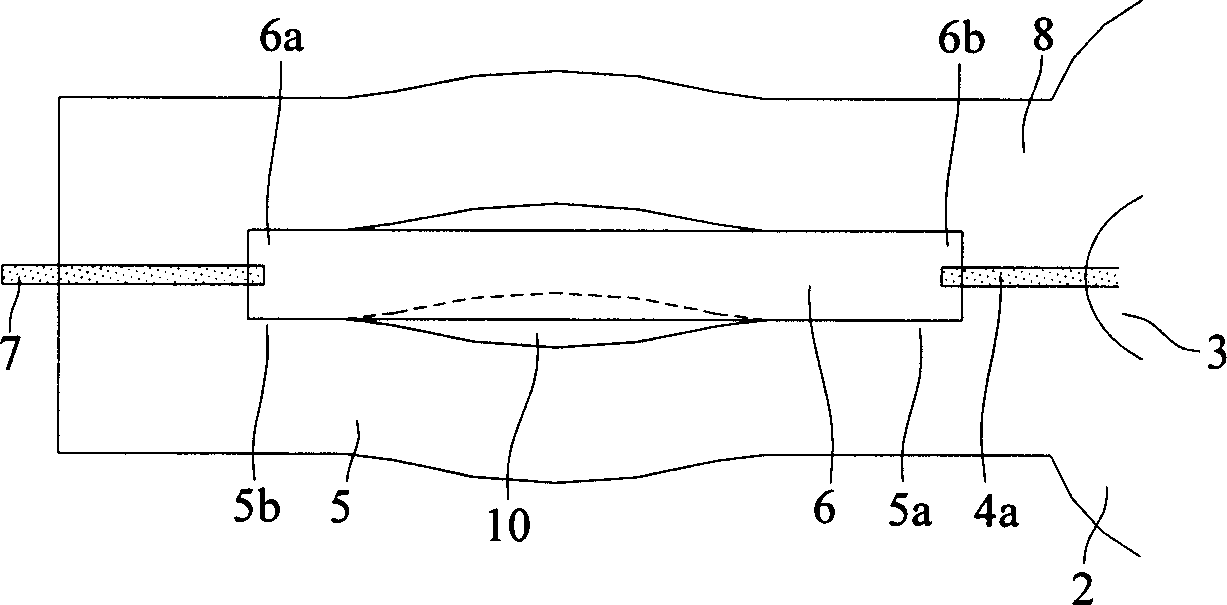

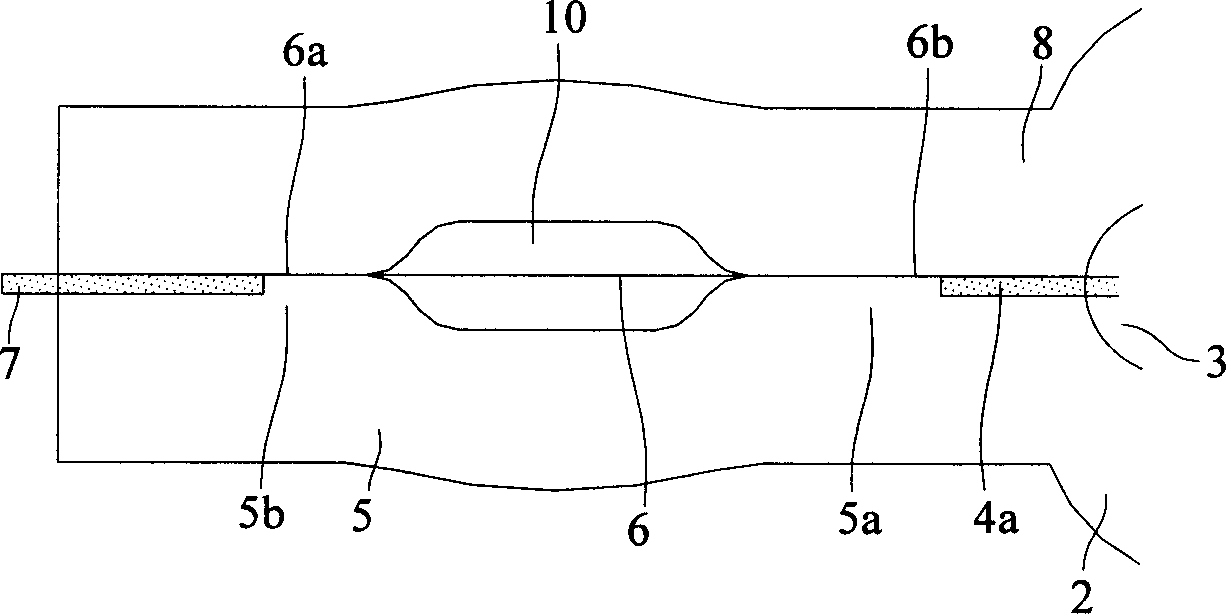

[0022] Regarding the characteristics and practice of the present invention, the preferred embodiments are described in detail below in conjunction with the accompanying drawings.

[0023] like image 3 As shown, the present invention proposes a manufacturing method of a high-pressure gas discharge lamp tube. The embodiment is that in the process of manufacturing the high-pressure gas discharge lamp tube 1, a light-emitting part 2 is sealed with the side extending on both sides of the light-emitting part 2. 5, due to the heat expansion and contraction effect of the metal foil 6, the electrode 4a, and the discharge lamp tube 1, a gap of width W is naturally formed between an adjacent metal foil 6 and a discharge space 3, and the gap is around the width The inner diameter space of the gap of the electrode 4a of d, using this naturally formed method, the gap filled with inert gas can be obtained without additional adjustment process, and because the gap communicates with the disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com