High-haze conductive film and preparation method thereof

A conductive film, high haze technology, used in the manufacture of cables/conductors, conductive layers on insulating carriers, circuits, etc., can solve the problems of uneven surface conductivity, low production yield, low transparency, etc., and achieve convenient operation. , The effect of stable electrical conductivity and high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This embodiment provides a method for preparing a polyimide composite film with high light transmittance and high haze, comprising the following steps:

[0043] 1) Preparation of brown-yellow polyimidic acid solution: Dissolve 0.02mol of HFBAPP in 8.7g of DMF under a nitrogen atmosphere, stir evenly on a stirring table, then add 0.02mol of ODPA to it, at a temperature of 20-30°C Stir for more than 12 hours to obtain a yellow-brown polyimidic acid solution;

[0044] 2) Centrifuge to obtain PS microspheres: take a certain amount of PS microsphere dispersion system (the diameter of PS microspheres is 2 μm, the dispersion system is water, and the mass fraction of PS microspheres is 5%), and centrifuge at 10000rpm in a centrifuge to obtain a centrifuged product. The centrifuged product is dispersed in DMF, centrifuged again at 10,000 rpm, and the centrifuged product is PS microspheres;

[0045] 3) Coating of conductive silver nanowires: Dilute the aqueous dispersion of silver...

Embodiment 2

[0048] A flexible polyimide conductive film with high haze silver nanowires was prepared according to the method of Example 1, except that the diameter of the silver nanowires in step 3) was 20 nm, and other conditions were the same as in Example 1.

[0049] Using the above conditions, the square resistance of the silver wire electrode prepared in step 3) is 11Ω / □, thus, the square resistance of the prepared flexible polyimide conductive film with high haze nano-silver wire is 11Ω / □. It shows that silver wires with a diameter of 20nm are also suitable for this kind of flexible polyimide conductive film with high haze nano-silver wires.

Embodiment 3

[0051] According to the method of Example 1, a flexible polyimide conductive film with high haze nano-silver wires was prepared, except that the amount of PS microspheres in step 4) was changed to 15 mg, and other conditions were the same as in Example 1.

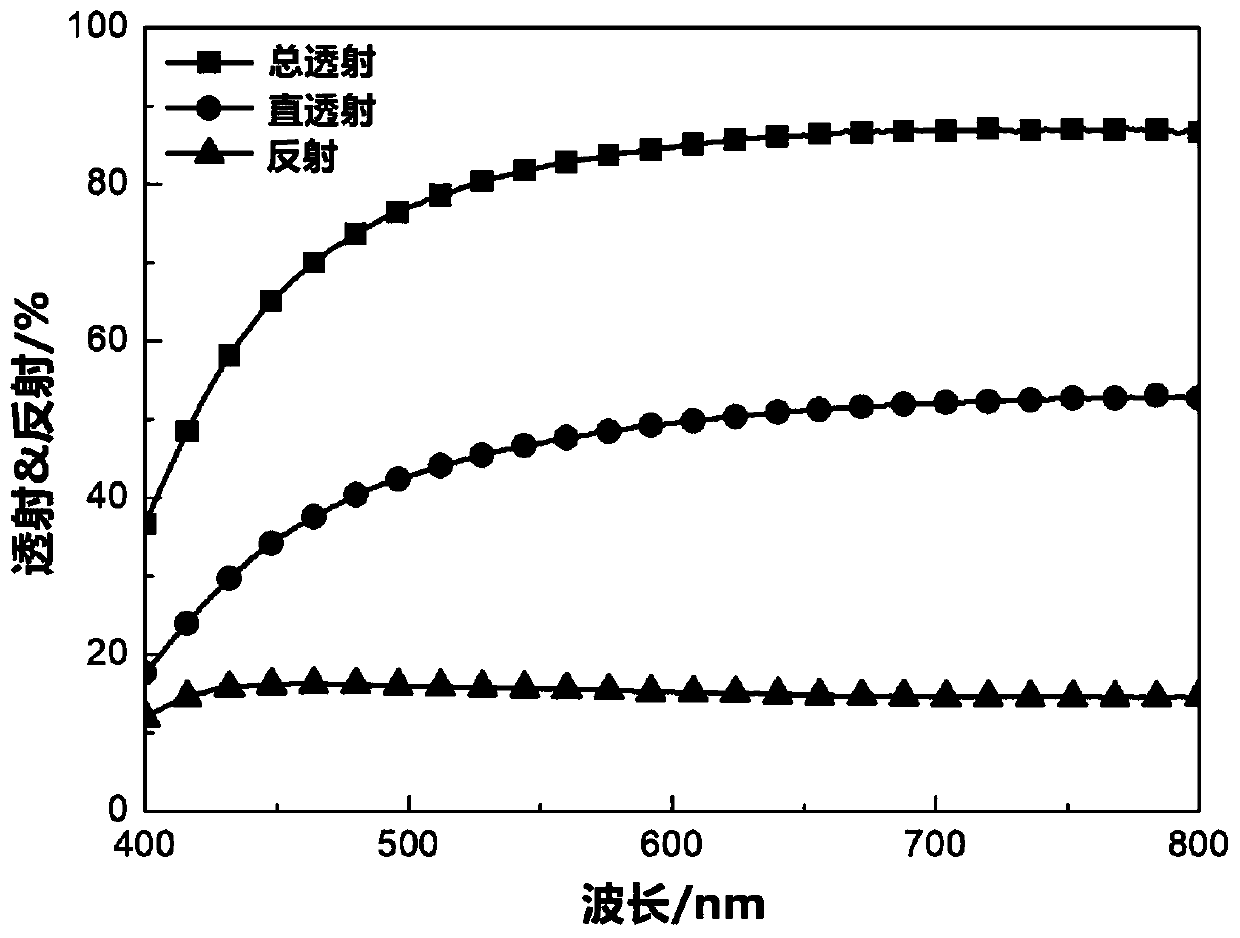

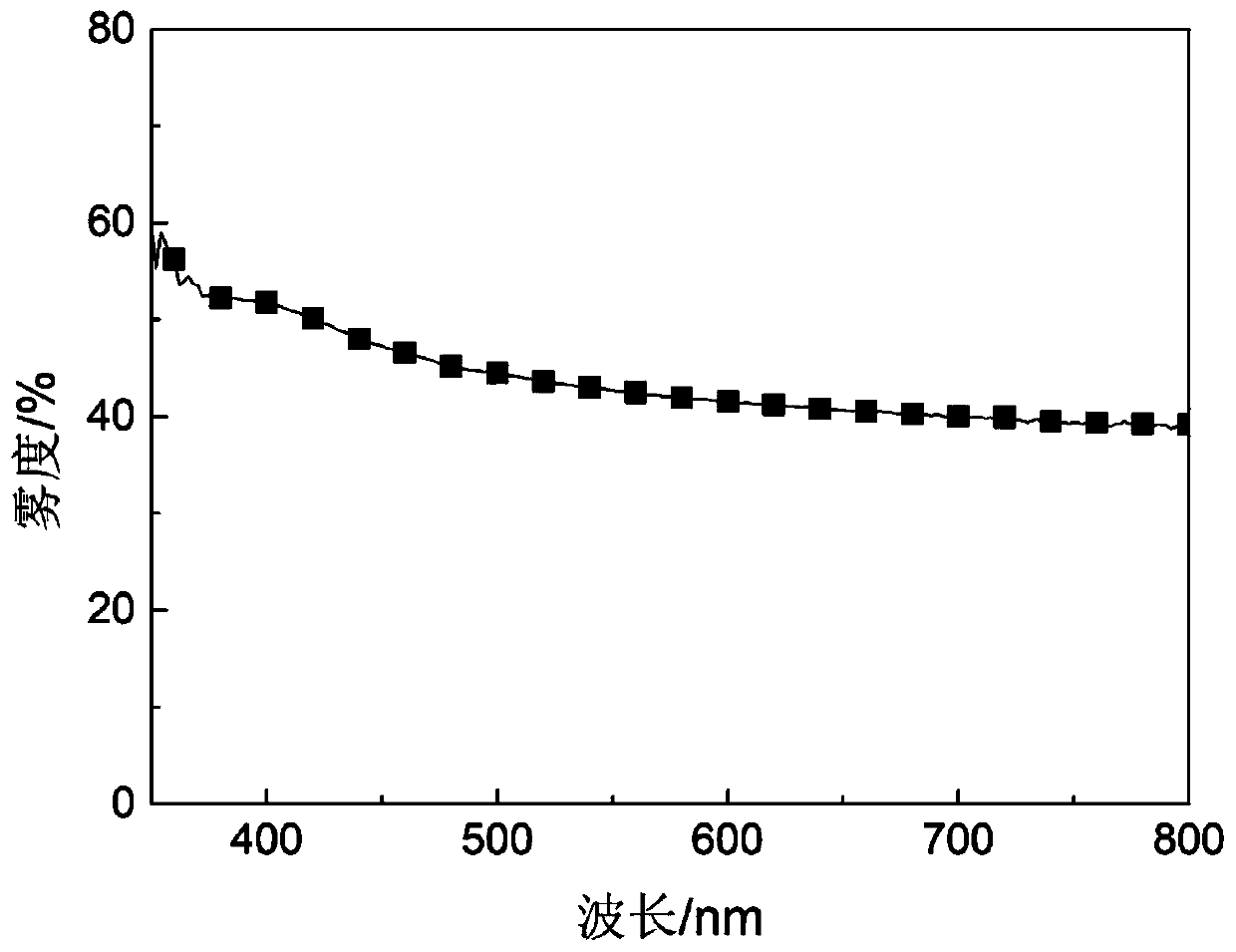

[0052] Using the above conditions, the square resistance of the flexible polyimide conductive film with high haze silver nanowires in this embodiment is 10Ω / □, the highest transmittance in the visible light region is 83.0%, and the haze can reach up to 54%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com