Thin film transistor and its forming method

A technology of thin film transistors and semiconductors, applied in transistors, semiconductor/solid-state device manufacturing, optics, etc., to achieve the best resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

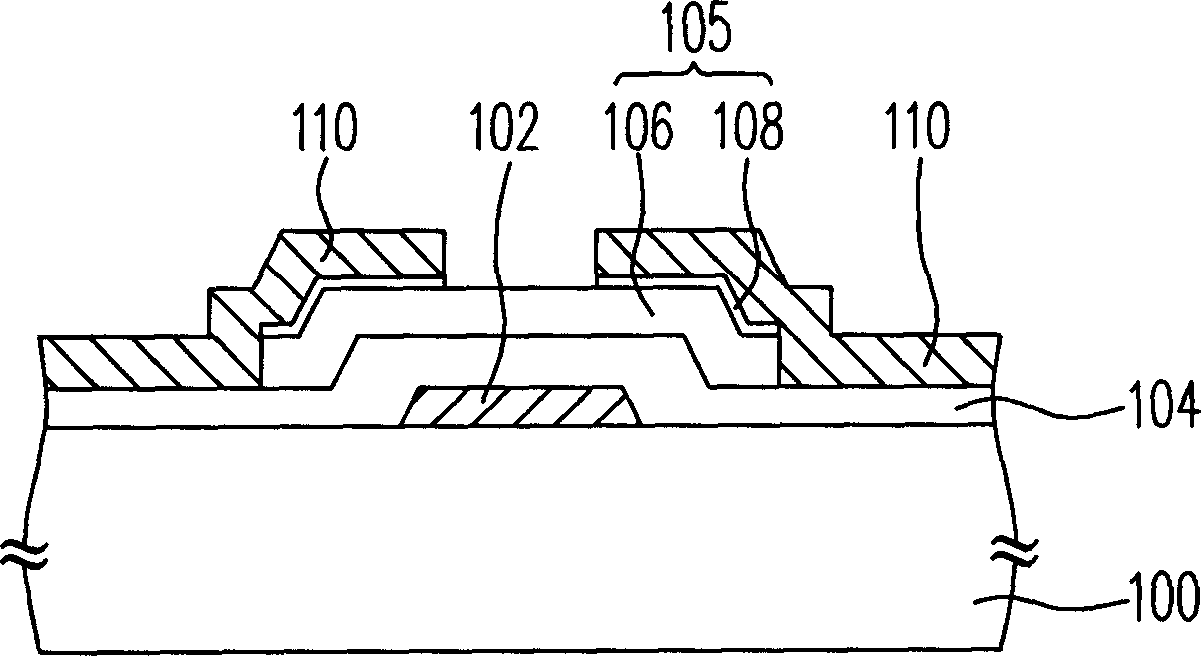

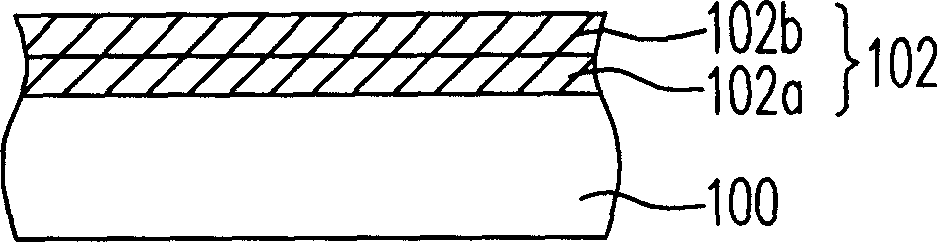

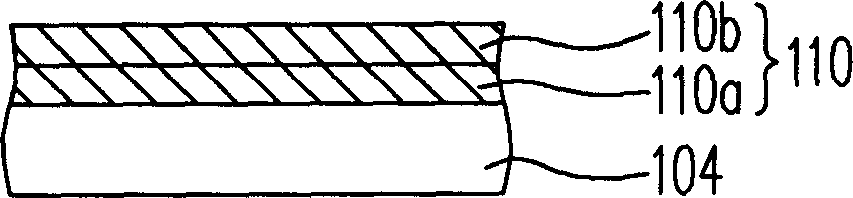

[0034] figure 1 It is a schematic cross-sectional view of a thin film transistor according to a preferred embodiment of the present invention. Please refer to figure 1 , the thin film transistor includes a gate 102 , a gate insulating layer 104 , a semiconductor layer 105 and a source / drain 110 . The gate 102 is disposed on the substrate 100 , and the gate insulating layer 104 is disposed on the substrate 100 to cover the gate 102 . The gate insulating layer 104 is made of, for example, a silicon oxide layer, a silicon nitride layer, or a combination layer of a silicon oxide layer and a silicon nitride layer. The semiconductor layer 105 is disposed on the gate insulating layer 104 above the gate 102 . The source / drain 110 is disposed on the semiconductor layer 105 . In this embodiment, the semiconductor layer 105 includes, for example, a channel layer 106 formed on the gate insulating layer 104 and an ohmic contact layer 108 formed between the channel layer 106 and the sou...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap