Temperature control electric connector for liquid heater

A technology of temperature controller and heating device, applied in the direction of temperature control, electric heating device, connecting device parts, etc., can solve the problems of aging, short circuit, prone to electric shock, etc., and achieve the effect of stable performance and convenient installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

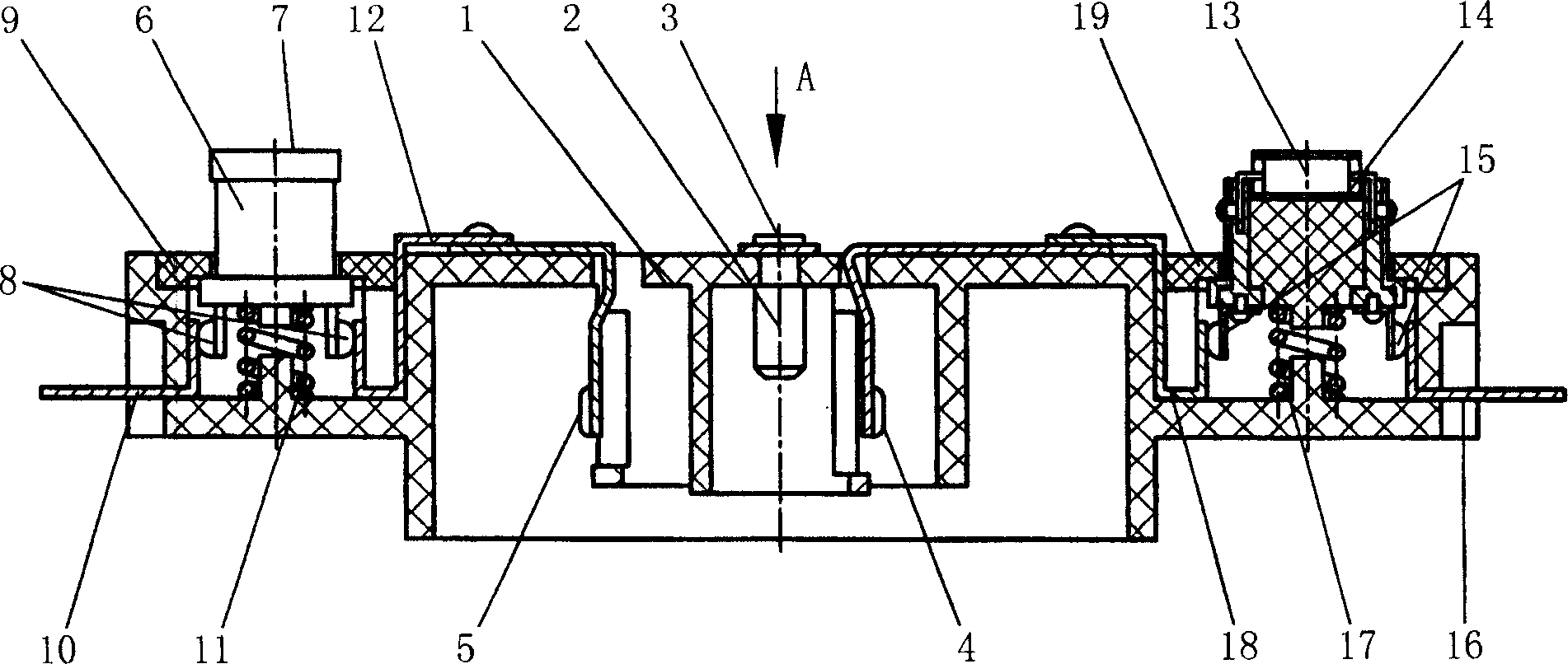

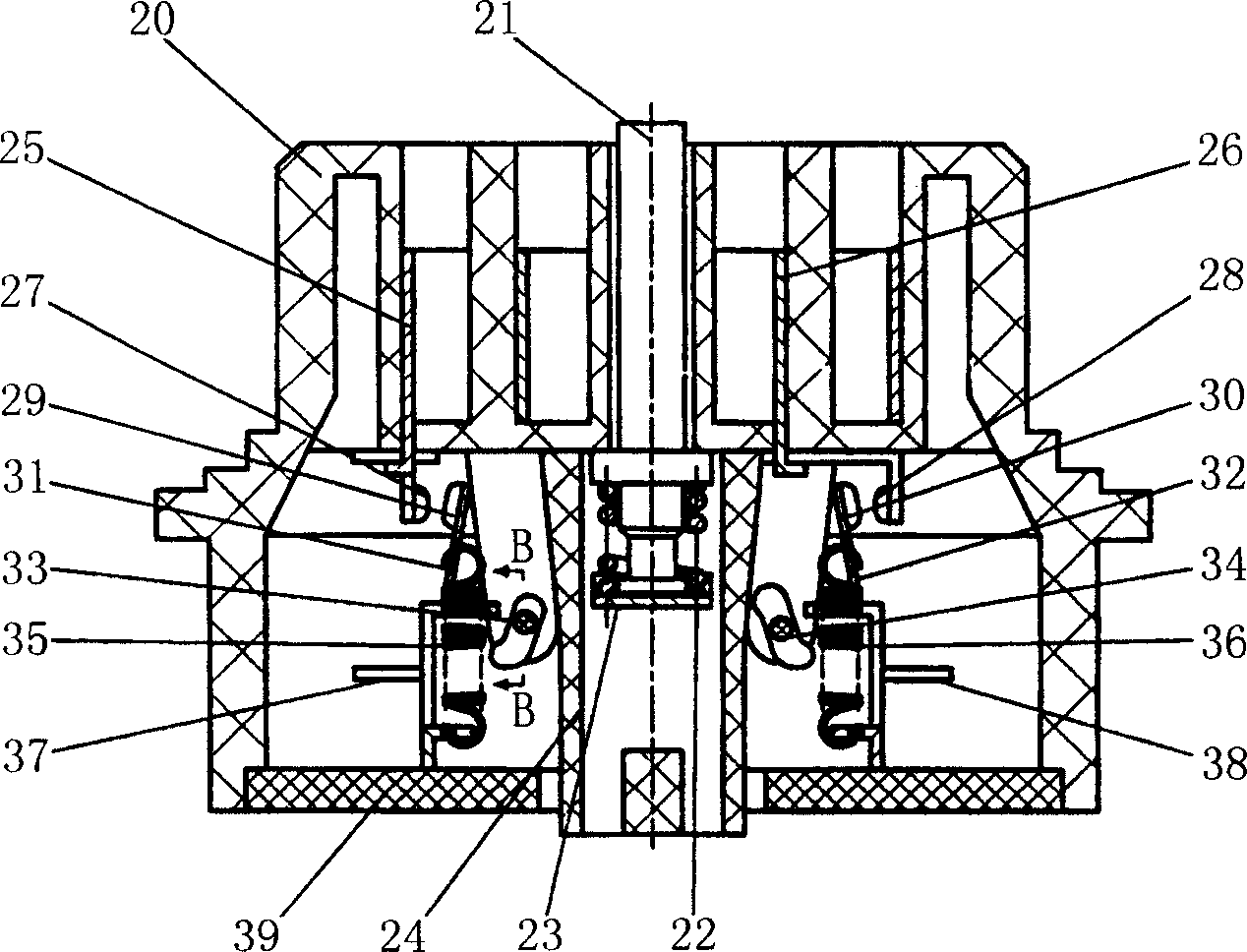

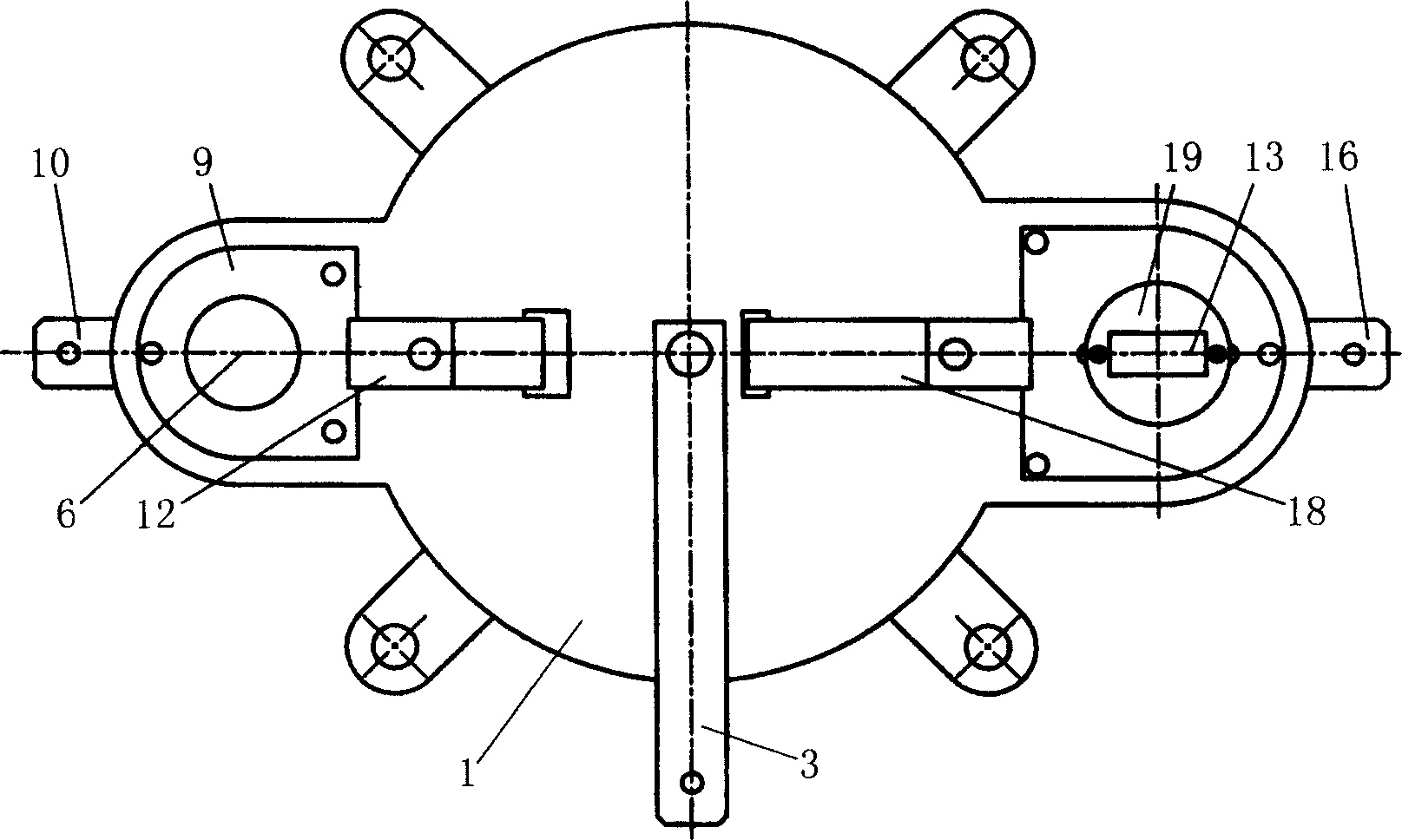

[0019] In the following, the present invention will be further described through embodiments with reference to the drawings.

[0020] Reference attached figure 1 Attached Figure 7 , The temperature control electrical connector of a liquid heating device of the present invention includes an upper coupler and a lower coupler, wherein the upper coupler housing 1 and the lower coupler housing 20 are made of flame-retardant reinforced PA6 plastic; The sides of the upper coupler housing 1 are respectively provided with a temperature controller 6 and a metal thermal fuse 13, a metal heat conducting surface 7 is provided on the top of the temperature controller 6, and a contact 8 is provided on the bottom of the temperature controller 6. The compression spring 11 and the upper external insert 10 are provided with a gland 9 in the middle of the temperature controller 6; a gland 19 and a sliding bracket 14 are arranged in the middle of the metal fuse 13, and the bottom of the metal fuse 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com