Safety cylinder of injector

A technology for safe injection and syringes, applied in the direction of syringes, hypodermic injection devices, infusion sets, etc., can solve the problems of danger, retraction and entry into the cylinder body 60, and insufficient tightness to avoid protruding or shrinking input effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

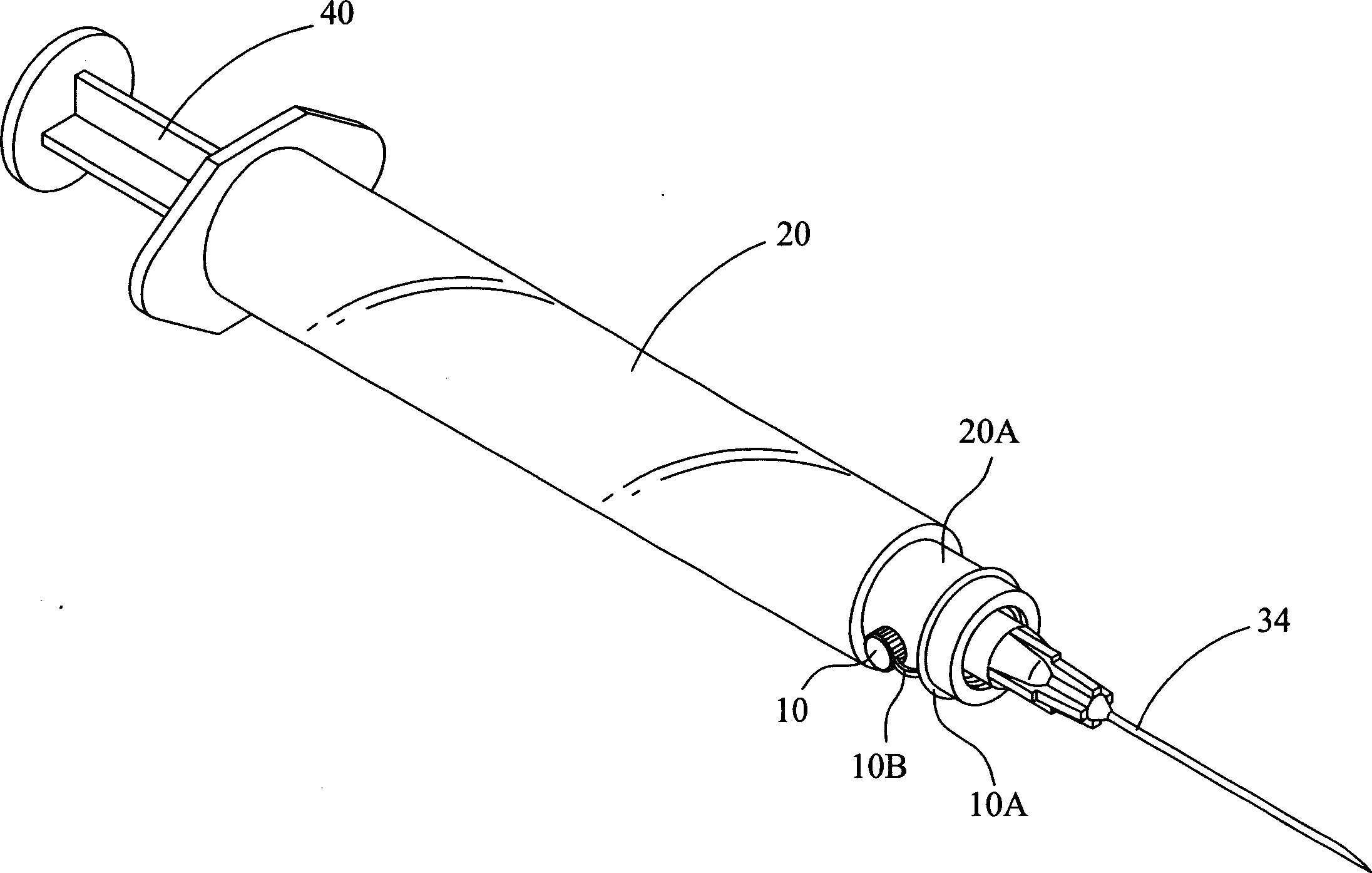

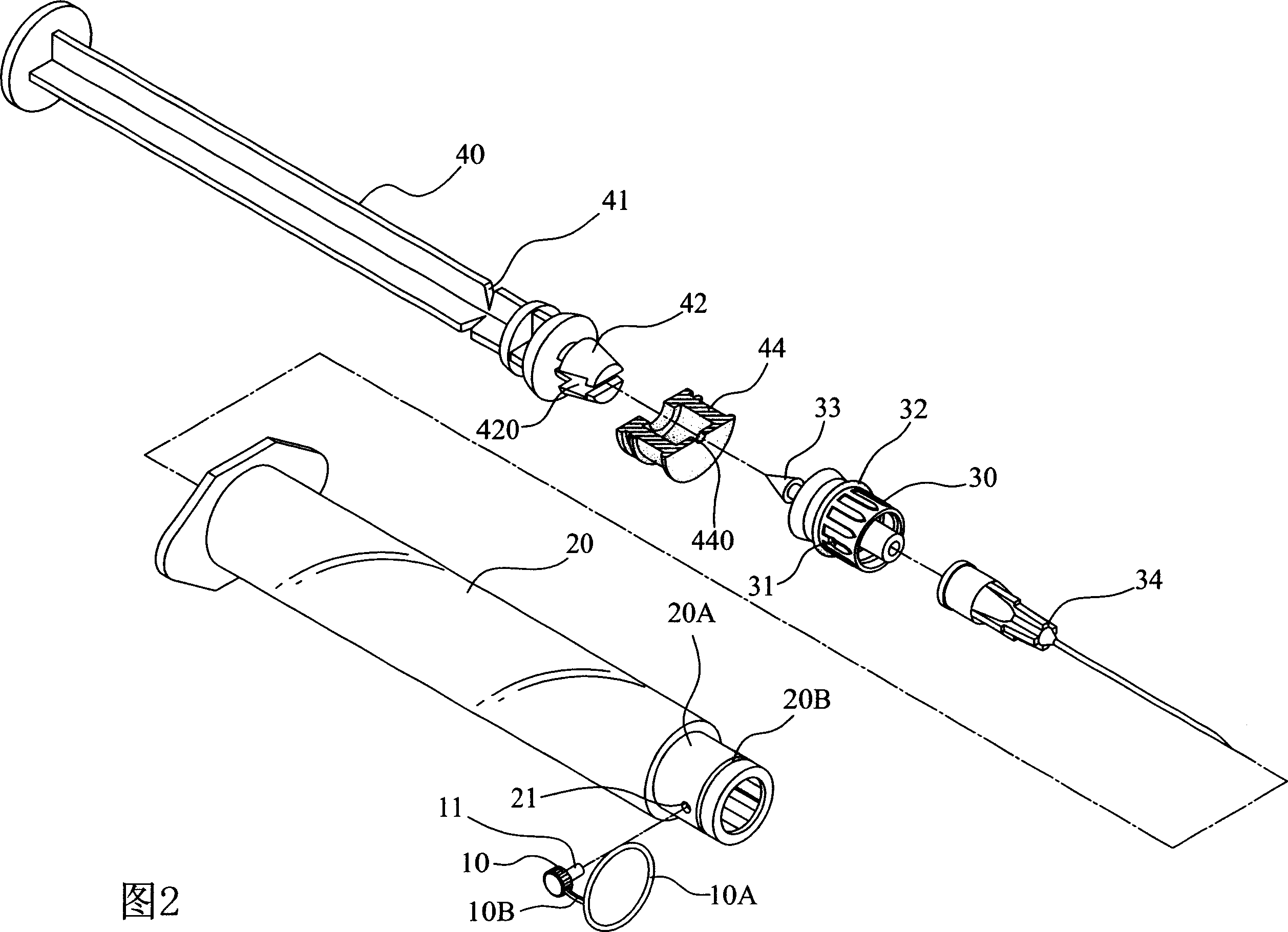

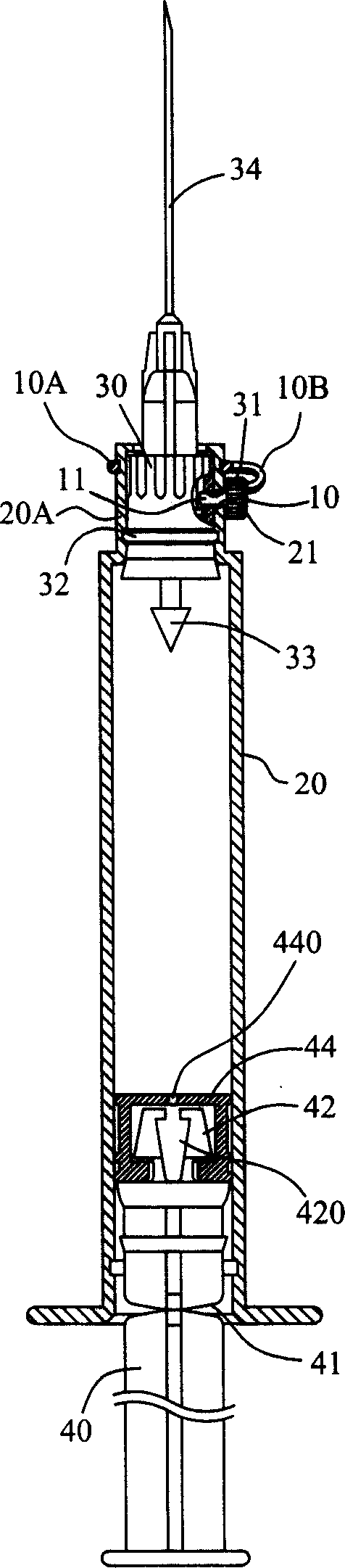

[0026] See first figure 1 , Figure 2 and image 3 As shown, it is a perspective view of a preferred embodiment of the present invention, a perspective exploded view and a schematic sectional view. The present invention is mainly provided with a hollow and elongated cylinder 20, and the front end of the cylinder 20 can accommodate a plunger 30. Set, and make the cylindrical body 20 opposite to the peripheral side of the end where the plunger 30 can be embedded, then a perforation 21 (as shown in Figure 2 ) is perforated, and the plunger 30 is embedded in the cylindrical body 20. At the position of the perforation 21, a positioning hole 31 corresponding to the size of the perforation is provided, and the outer side of the perforation 21 of the cylinder 20 is provided with a bolt positioning member with a connecting unit 10A socketed with the front end 20A of the cylinder 20 10. The positioning member 10 can be a positioning bolt with one end slightly larger than the positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com