Cold transfer making method

A manufacturing method and cold transfer technology, which are applied in the direction of transferring ink from originals, etc., can solve the problems of blurred patterns, falling off, uneven printing, etc., and achieve the advantages of simple operation, uniform pattern printing, and improved printing pattern quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

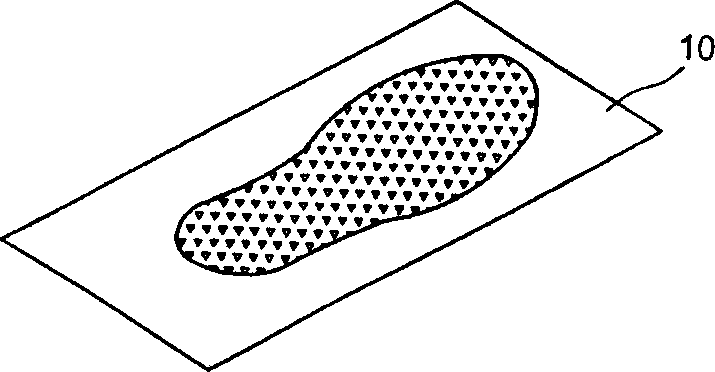

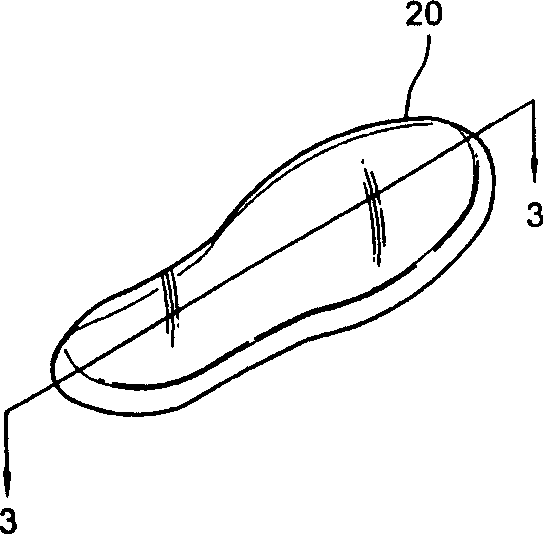

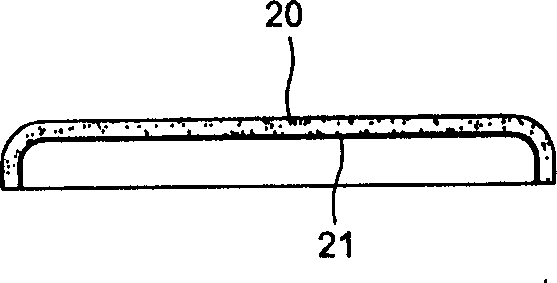

[0041] A kind of manufacturing method of cold transfer printing of the present invention, such as figure 1 , 2 , 3, mainly the printing pattern of the transfer film 10 is printed on the upper surface 21 of the transfer material 20 (sole), and contains a soft lower pressing member 31 (such as Figure 4 shown), a rigid upper pressure piece 32 (such as Figure 5 , 10 shown), a mold base 30 (such as Figure 6 shown) and a pressure frame 33 (such as Figure 8 As shown), the soft lower pressing part 31 can be positioned in the mold base 30, and the pressure frame 33 and the rigid upper pressing part 32 can be raised and lowered by a pneumatic mechanism. Above, the mold base 30 has a number of air holes 301, which are communicated with the suction pipe 302 for suction action. The upper part of the soft lower pressing part 31 is a convex surface, while the lower part of the rigid upper pressing part 32 is a concave surface;

[0042] The transfer process and method are as follows:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com