High performance internal combustion engine

An internal combustion engine, high-performance technology, applied in the direction of valve details, valve driving devices, etc., can solve problems such as insufficient inflation, low speed, intake and exhaust cam profile plumpness coefficient decline, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

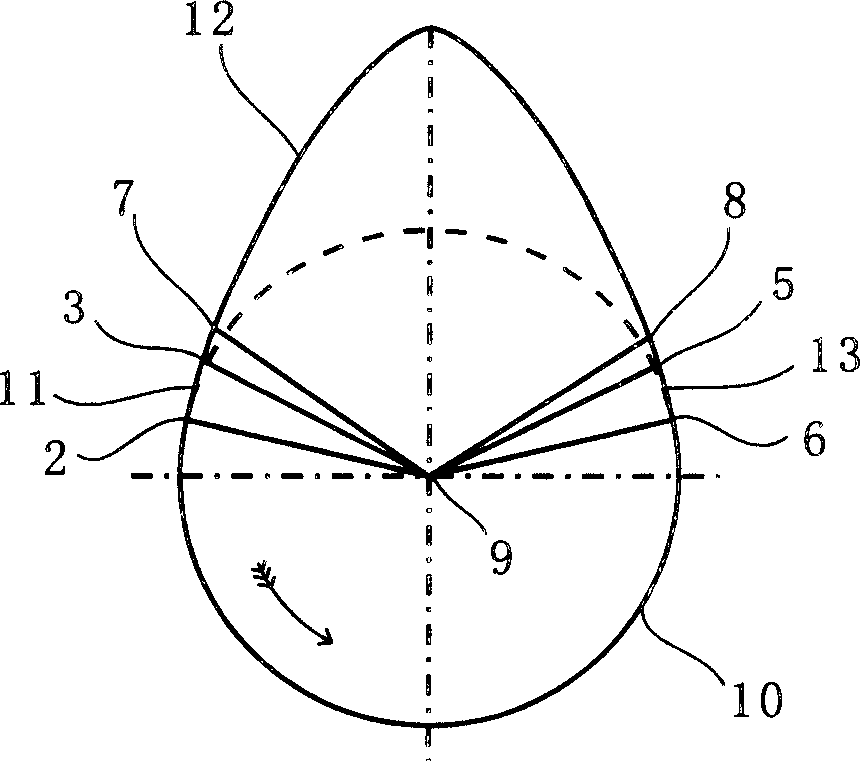

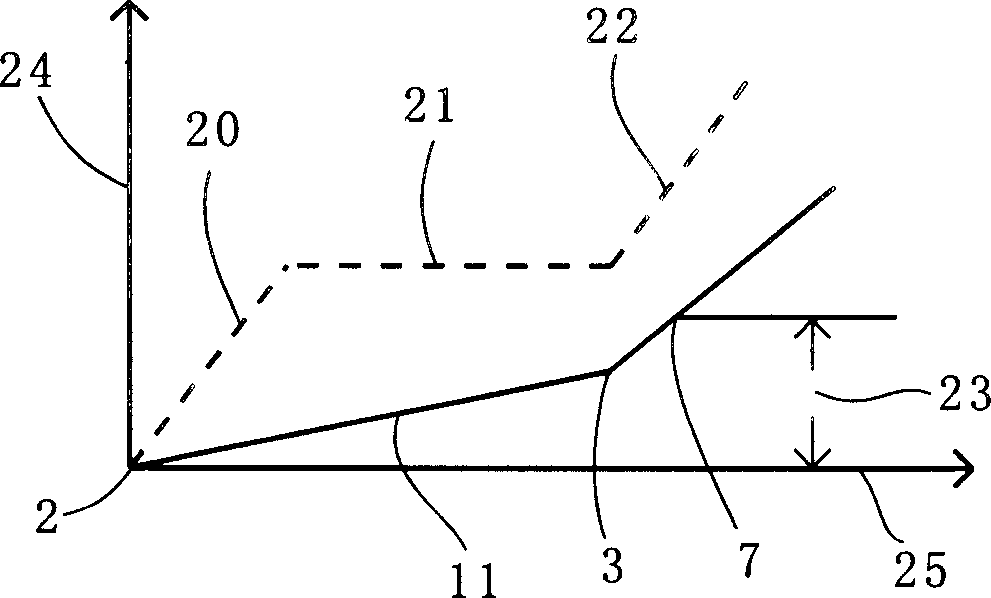

[0016] figure 1 It shows the schematic diagram of intake and exhaust cam profiles on the internal combustion engine camshaft of the present invention, point 9 in the figure is the center of the cam shaft, point 7 is to eliminate the valve clearance, point 8 is the beginning of the valve clearance, and points 6-2 are the base of the cam Circle 10, point 2-point 3 is the valve opening buffer section 11, point 3-point 5 is the working section 12, and point 5-point 6 is the valve closing buffer section 13. The figure shows that the end point 3 of its valve opening buffer section 11 is located before the valve clearance point 7 is eliminated in the cold state, and the starting point 5 of its valve closing buffer section 13 is located after the valve clearance point 8 begins to appear in the cold state.

[0017] The valve clearance is the clearance reserved during cold assembly, and the design of the buffer section in the traditional cam profile is also based on the valve clearance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com