Patents

Literature

69 results about "Intratracheal pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Continuous calculation of intratracheal pressure in tracheally intubated patients. Rohrer's constant, [K.sub.2], as a factor of determining inspiratory resistance of common adult endotracheal tubes.

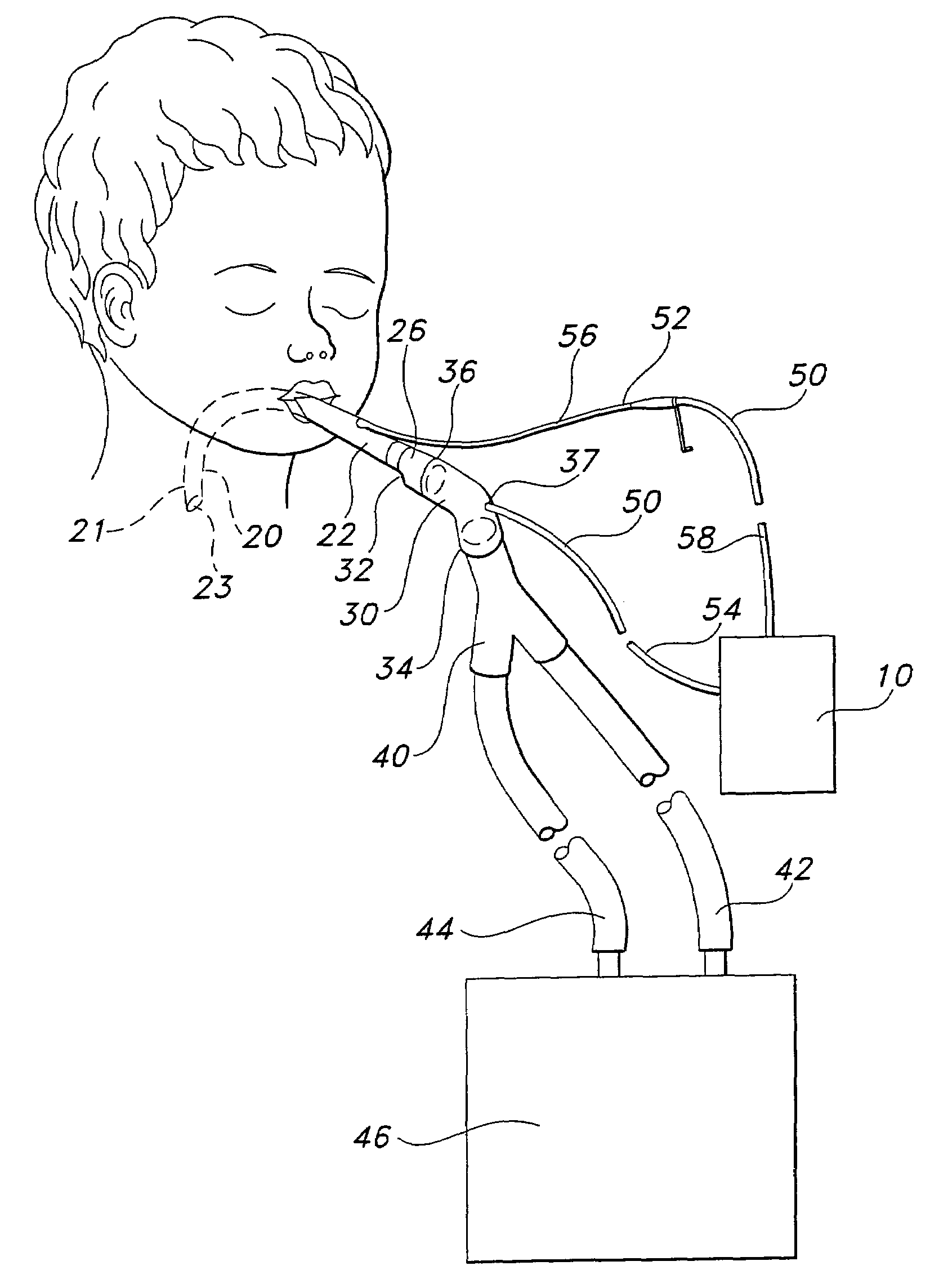

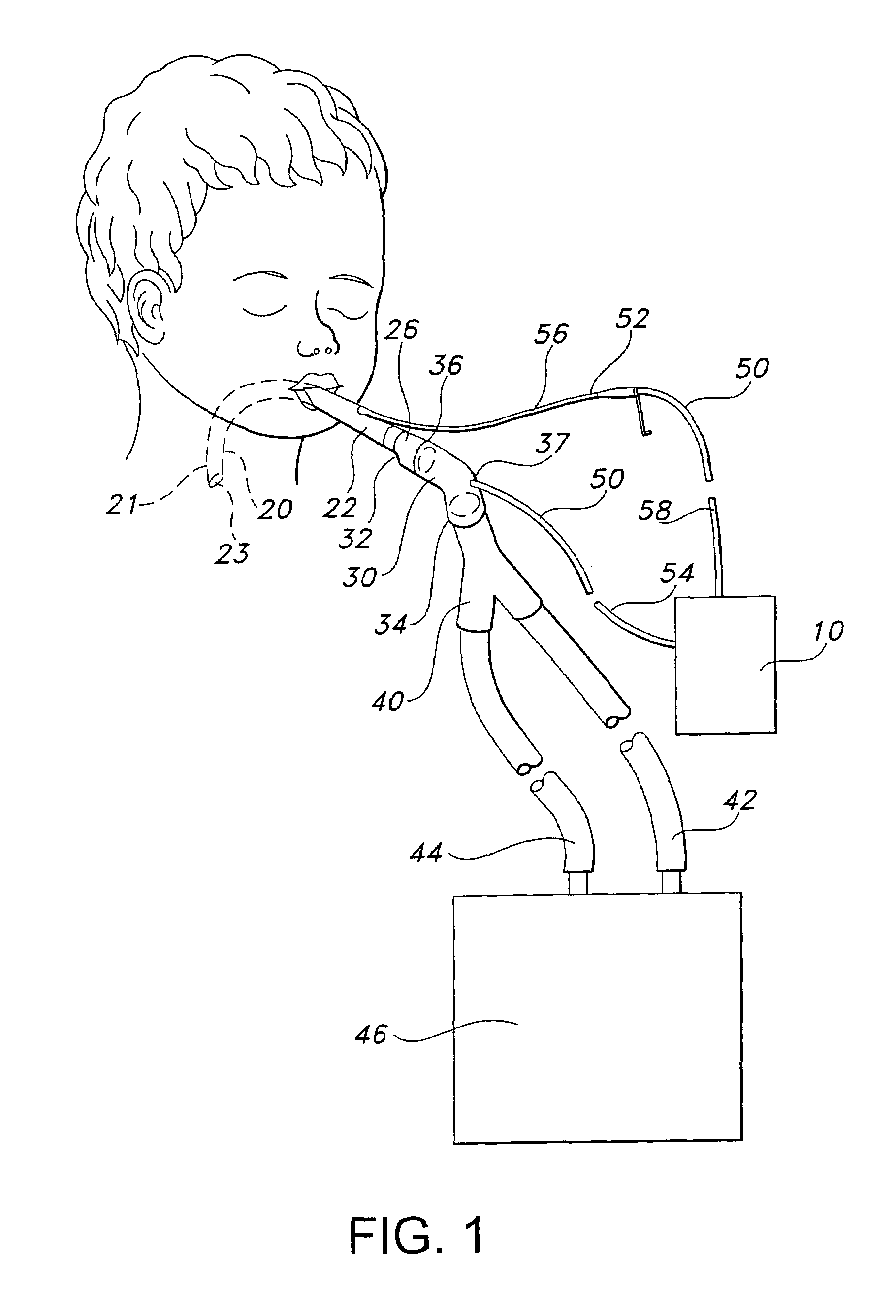

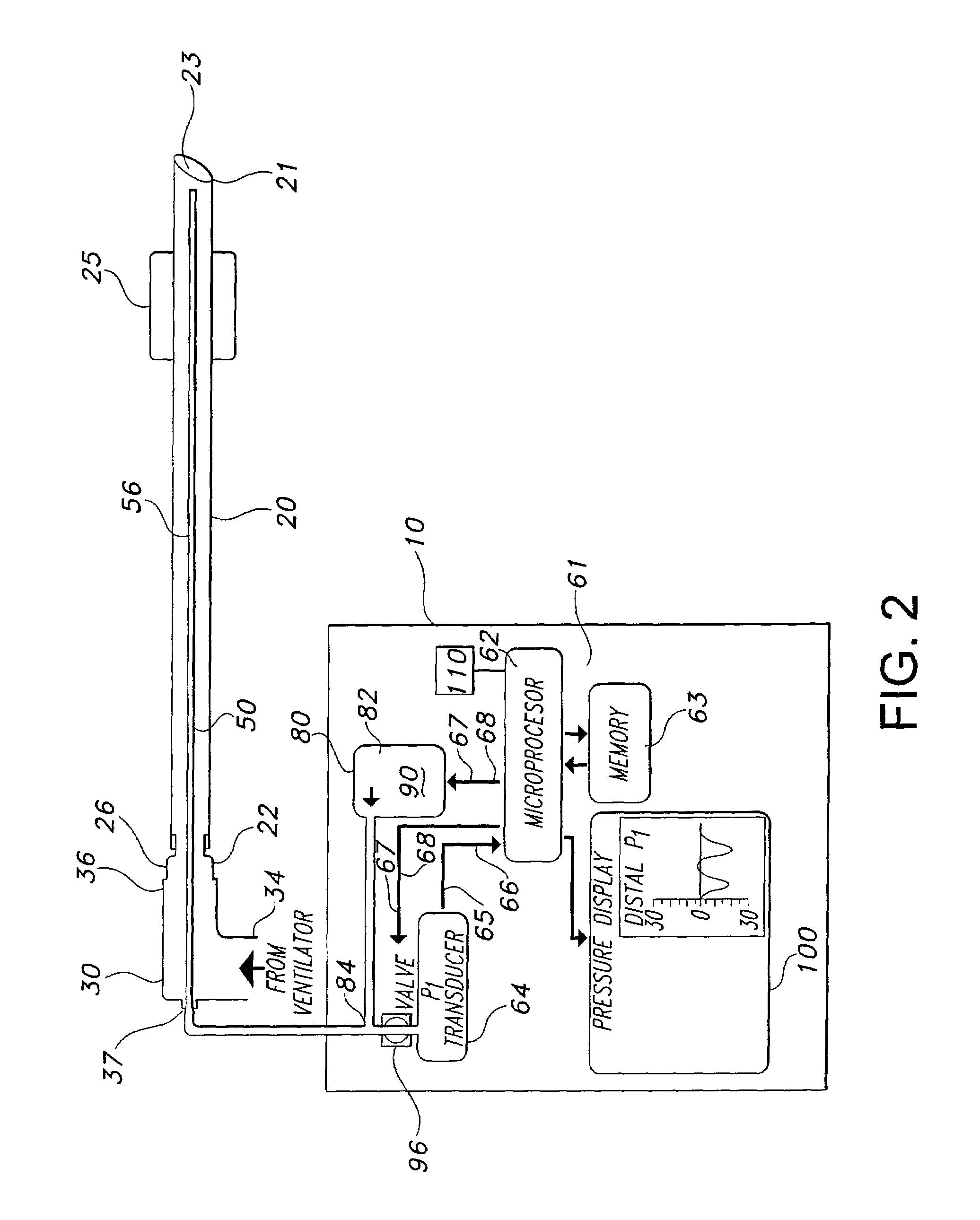

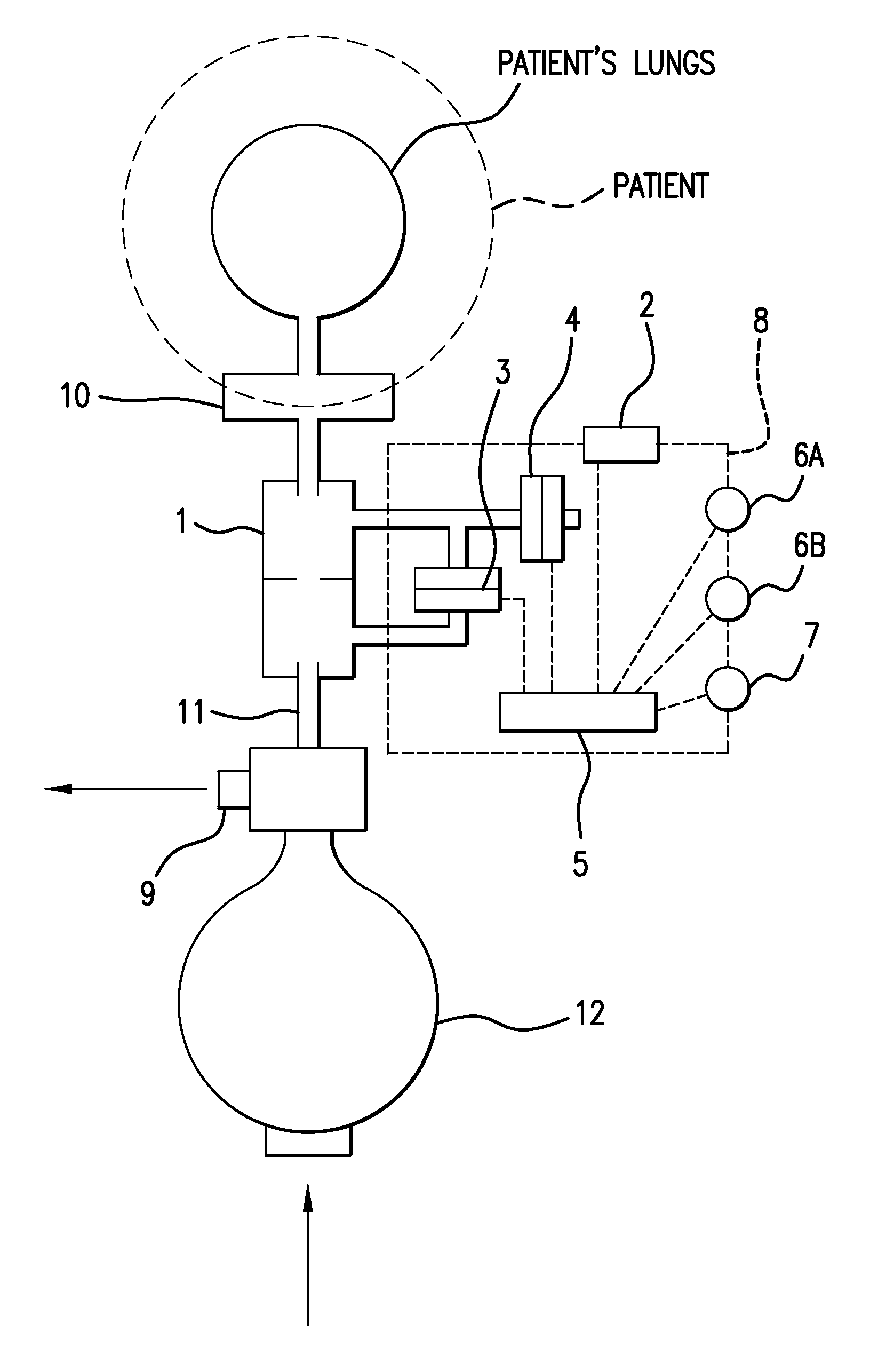

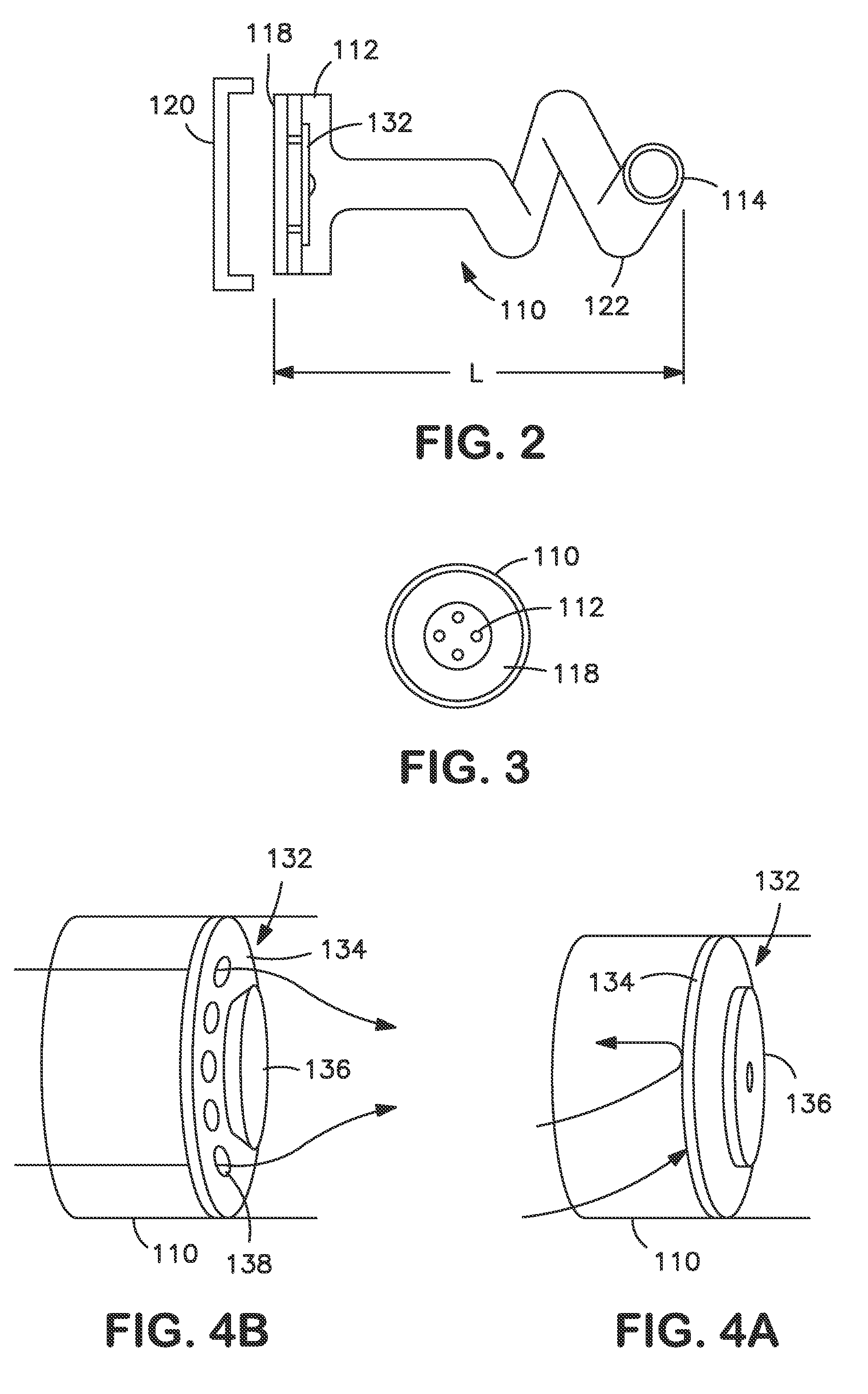

Endotracheal tube pressure monitoring system and method of controlling same

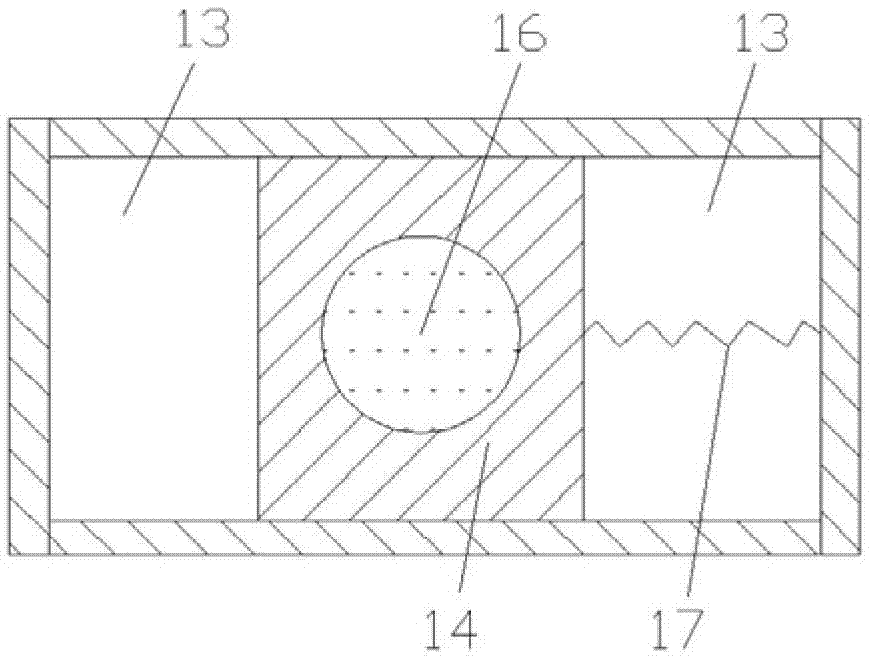

InactiveUS7051736B2High probability of blockageKeep openTracheal tubesOperating means/releasing devices for valvesLine tubingSubject matter

An endotracheal tube pressure monitoring system for an endotracheal tube having at least pressure sensor in communication with a major lumen of the endotracheal tube, and a pressure monitoring subsystem in operative communication with the pressure sensor. The system may also have at least one fluid pressure line in fluid communication with the major lumen and in operative communication with the pressure monitoring subsystem to monitor the pressure of fluid within each respective fluid pressure line, and a purging subsystem in fluid communication with the fluid pressure line. Each fluid pressure line that is in fluid communication with the purging subsystem being selectively purged by the purging subsystem when pressure monitoring subsystem determines the respective pressure line has become obstructed. Purging the fluid pressure line maintains the patency of the pressure line so that accurate pressure measurements within the endotracheal tube can be obtained for calculation of parameters in lung mechanics. It is emphasized that this abstract is provided to comply with the rules requiring an abstract which will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims. 37 C.F.R. §1.72(b).

Owner:UNIV OF FLORIDA

Indicating device for a ventilator

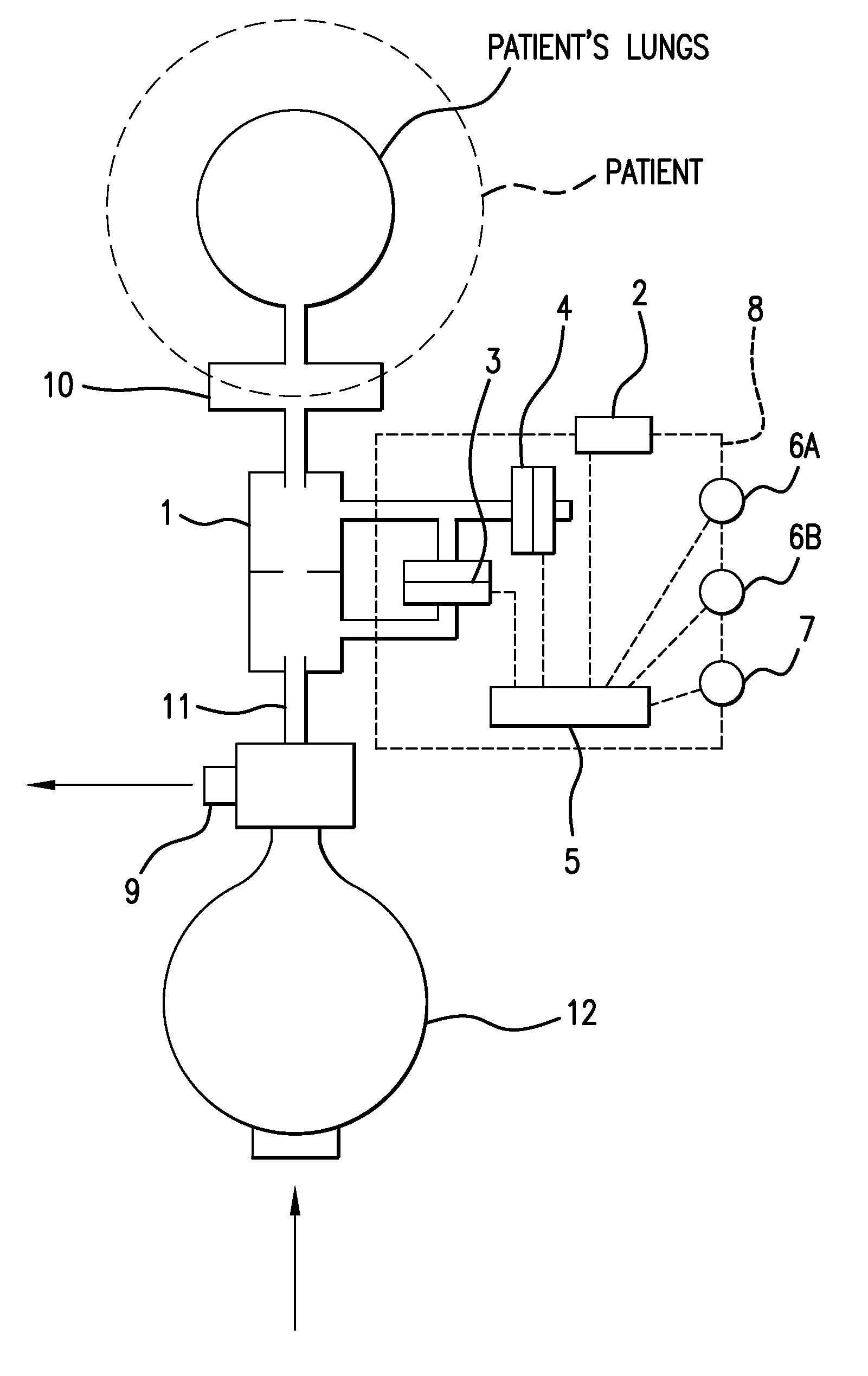

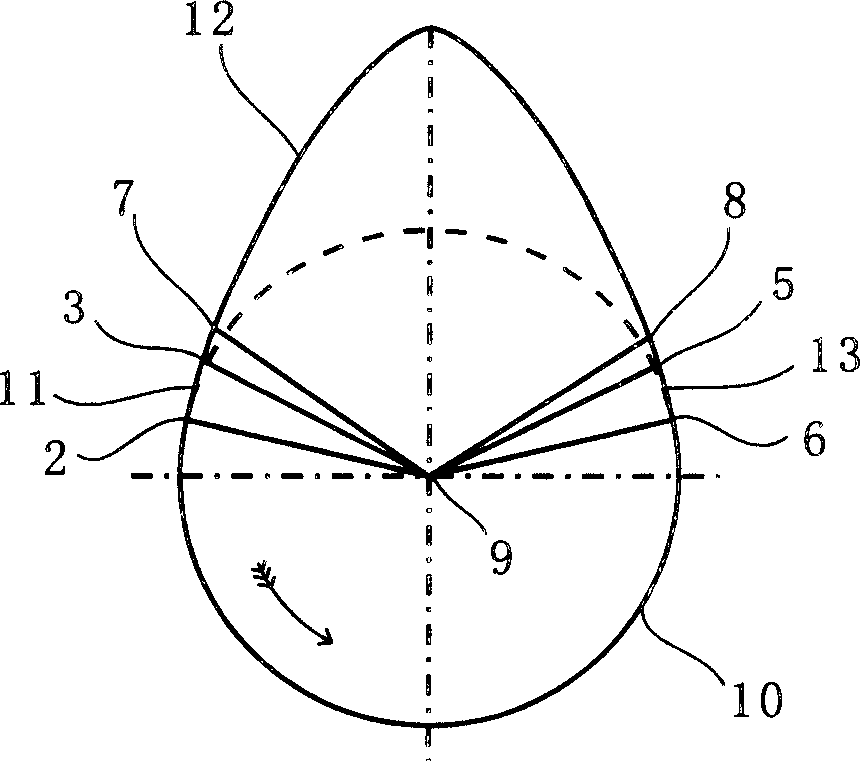

InactiveUS20080236585A1Reducing risk of deathImprove efficiencyRespiratorsMedical devicesTransducerEmergency medicine

An indicating device assists rescue personnel in administering cardiopulmonary resuscitation (CPR). A transducer measures the pressure drop in a flow tube attached to the patient, and this pressure drop is converted into a flow rate and volume. Another transducer measures the pressure in the flow tube at a point near the patient, the measured pressure being essentially the same as, or related to, the intratracheal pressure. Indicator lights show either red or green or yellow, when the flow rate, and / or the intratracheal pressure, are within or outside of a preferred range. The desired ranges can be adjusted according to the weight of the patient. The device provides immediate guidance for rescue personnel, by indicating whether the volume of gas received by the patient is appropriate, and whether intratracheal pressure is below or above a potentially lethal level. It also provides a prompt light to indicate the desirable rate at which to administer respirations, a rate based upon the measured values of the exhaled volume and the intratracheal pressure.

Owner:CALDYNE

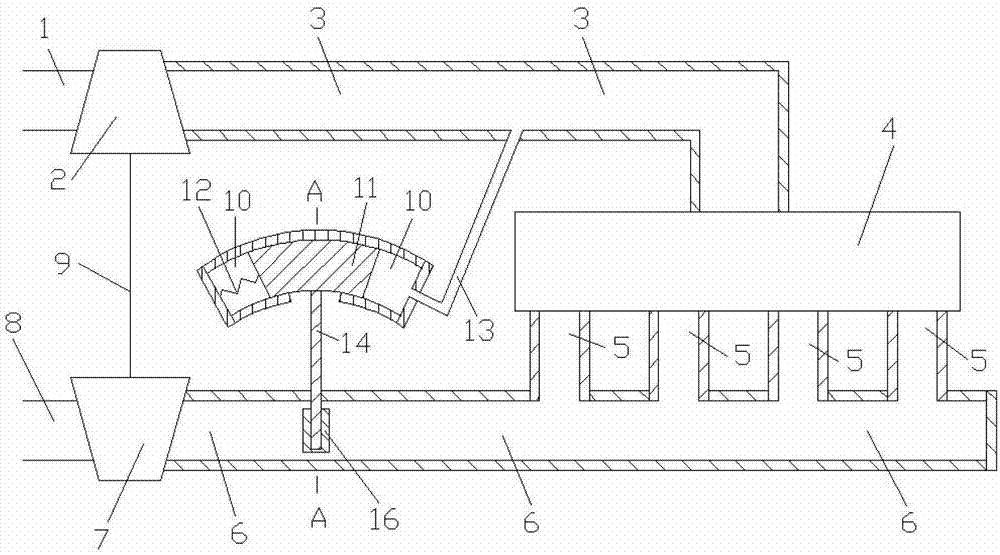

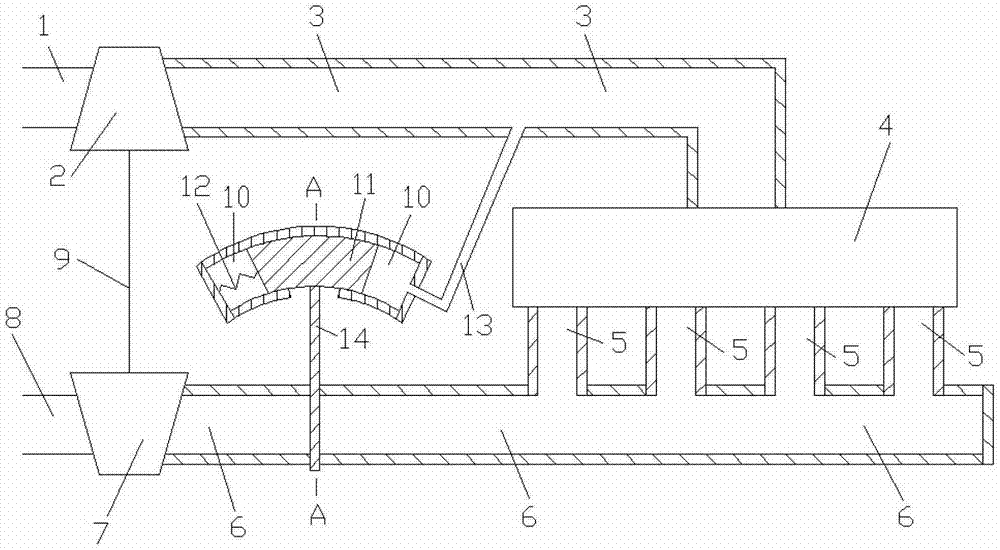

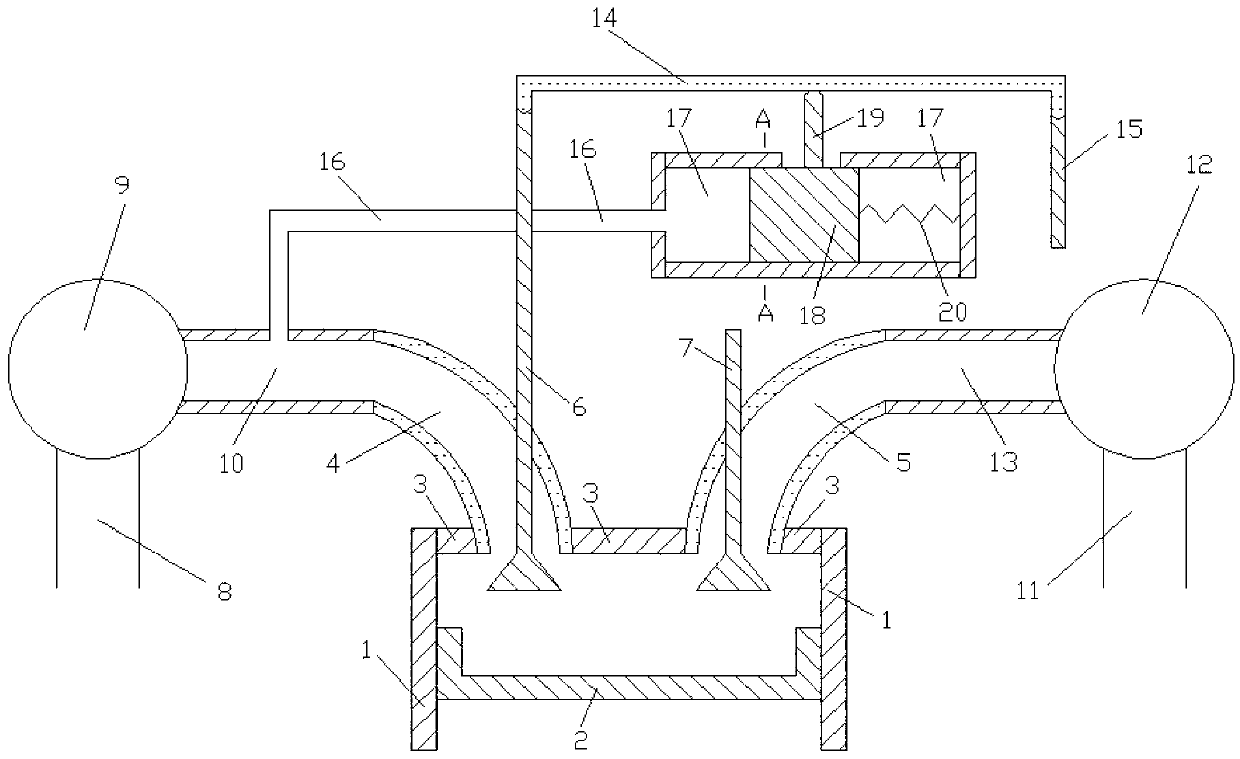

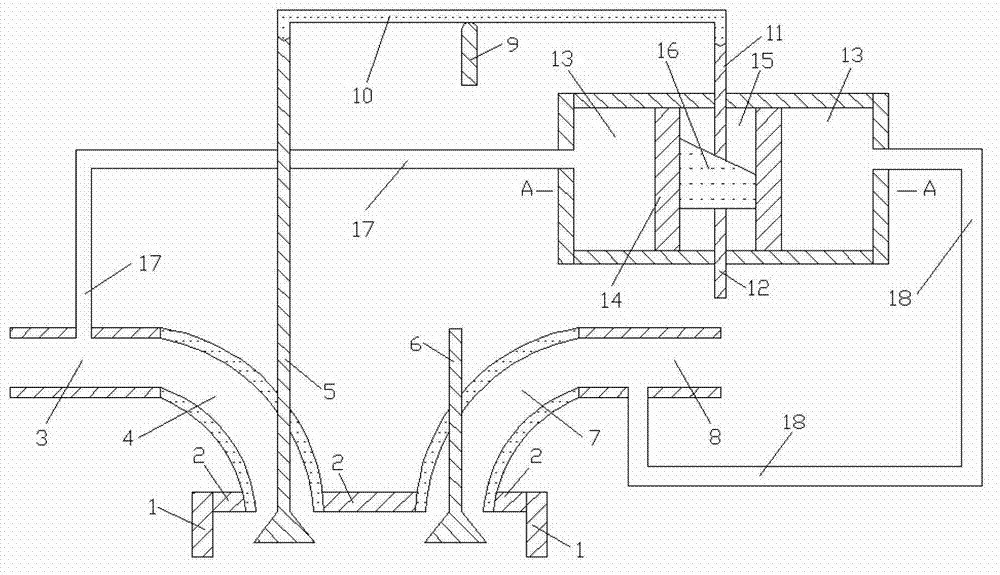

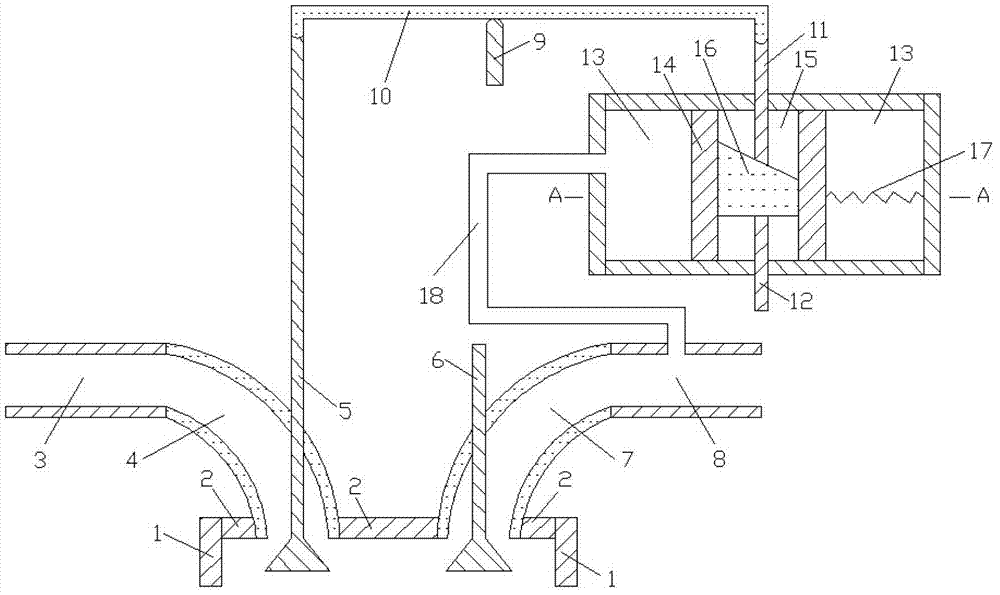

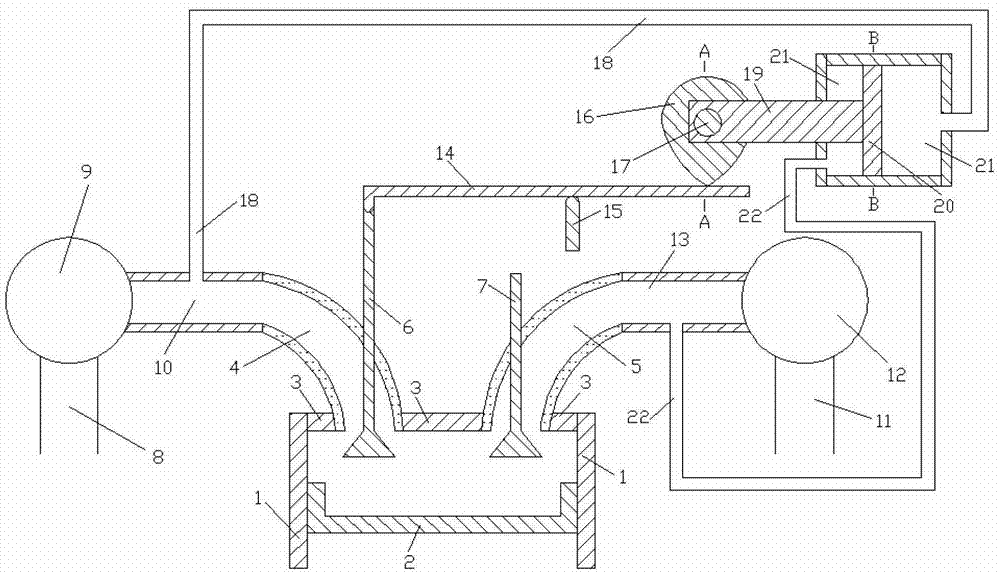

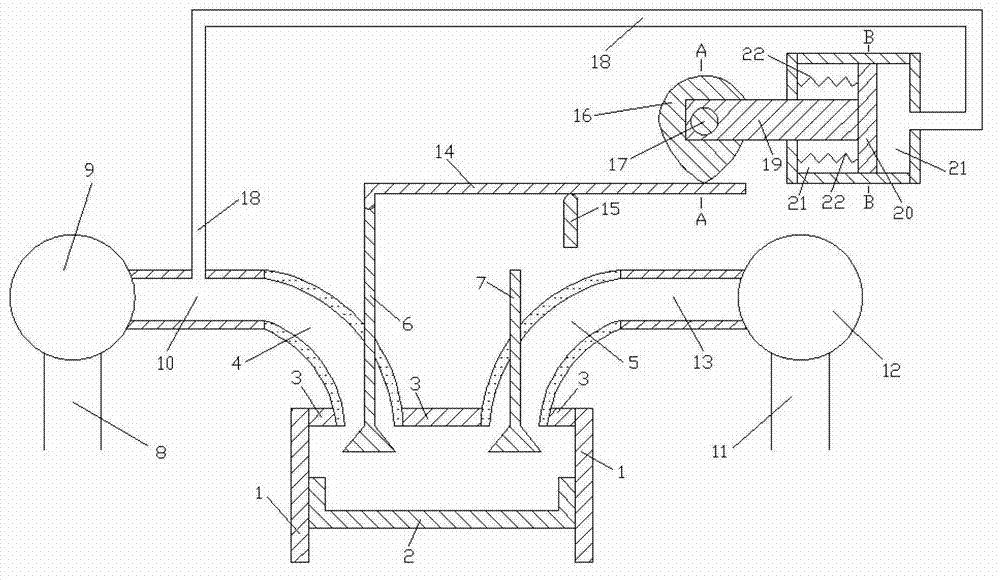

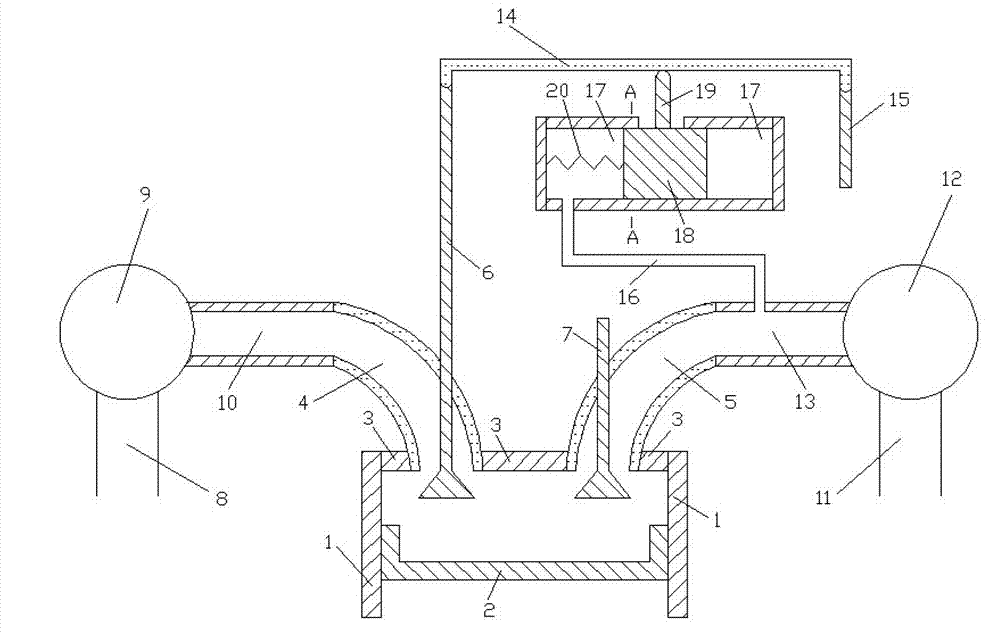

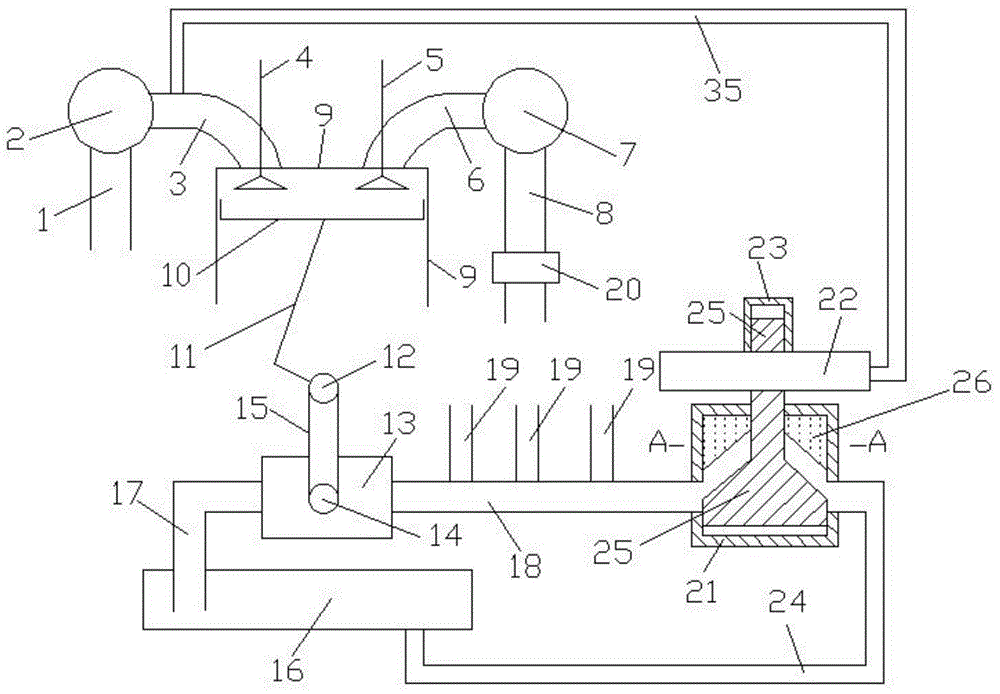

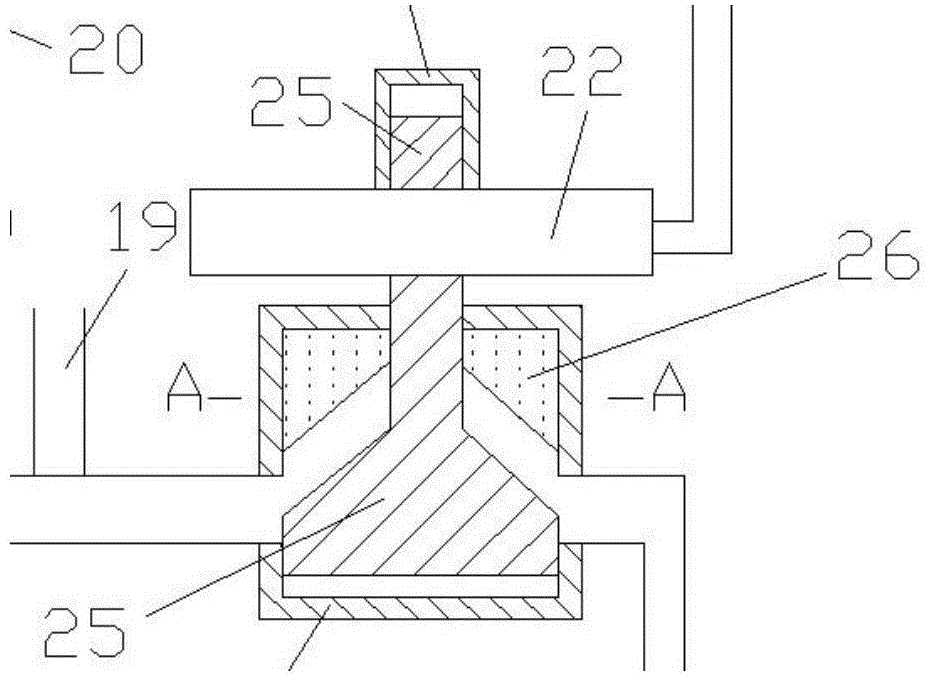

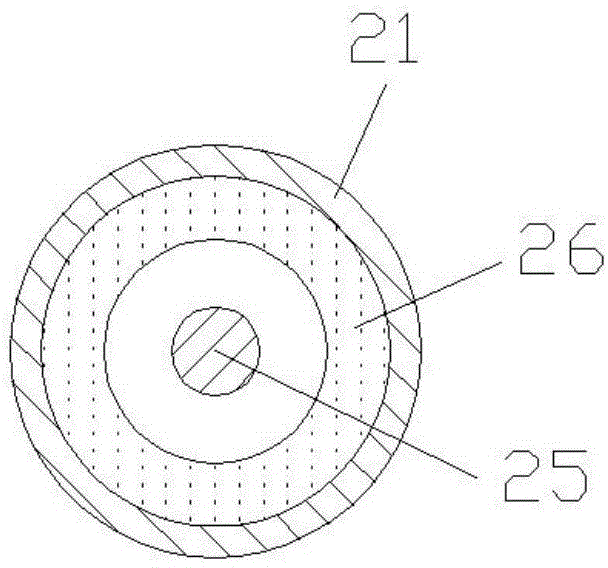

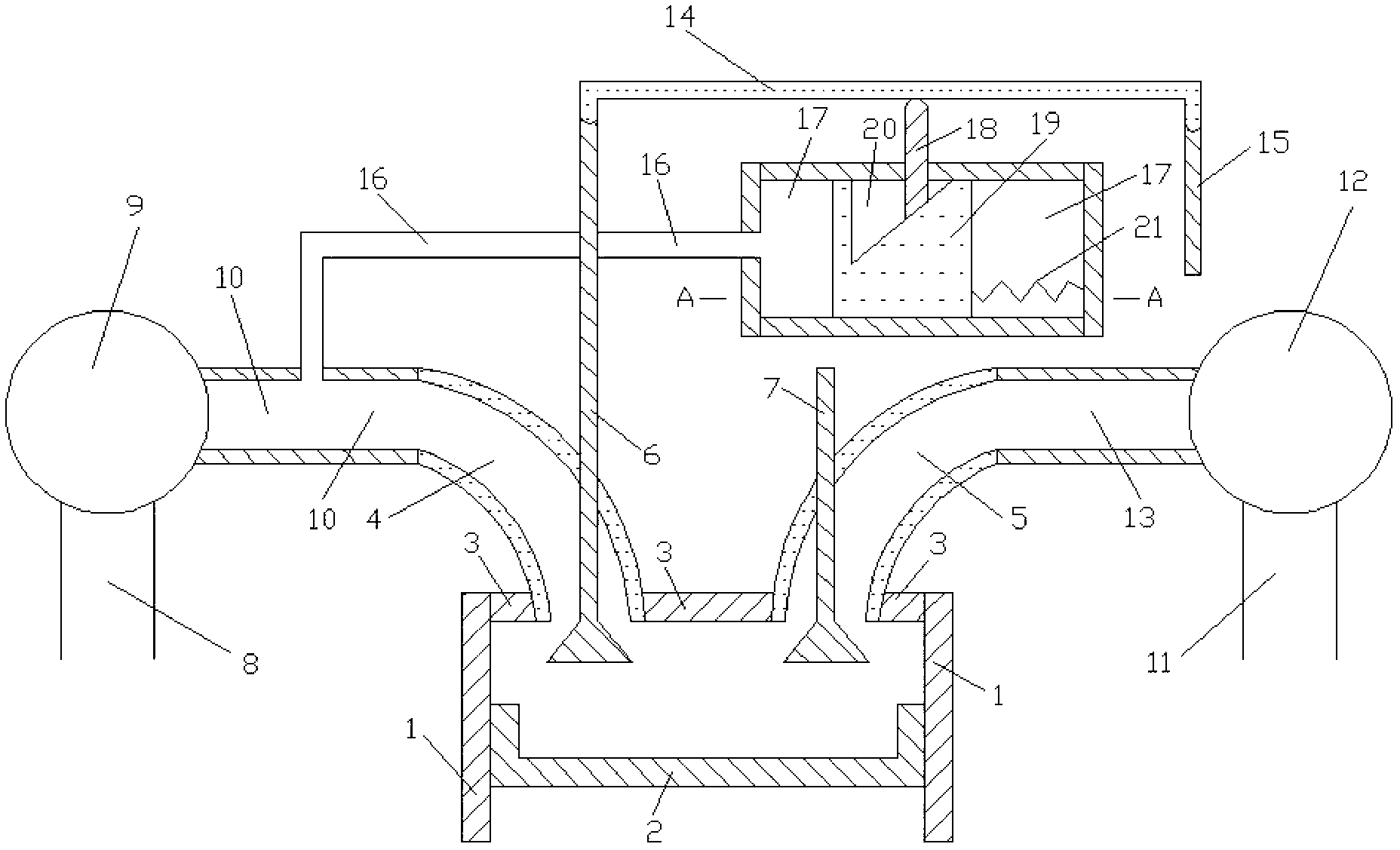

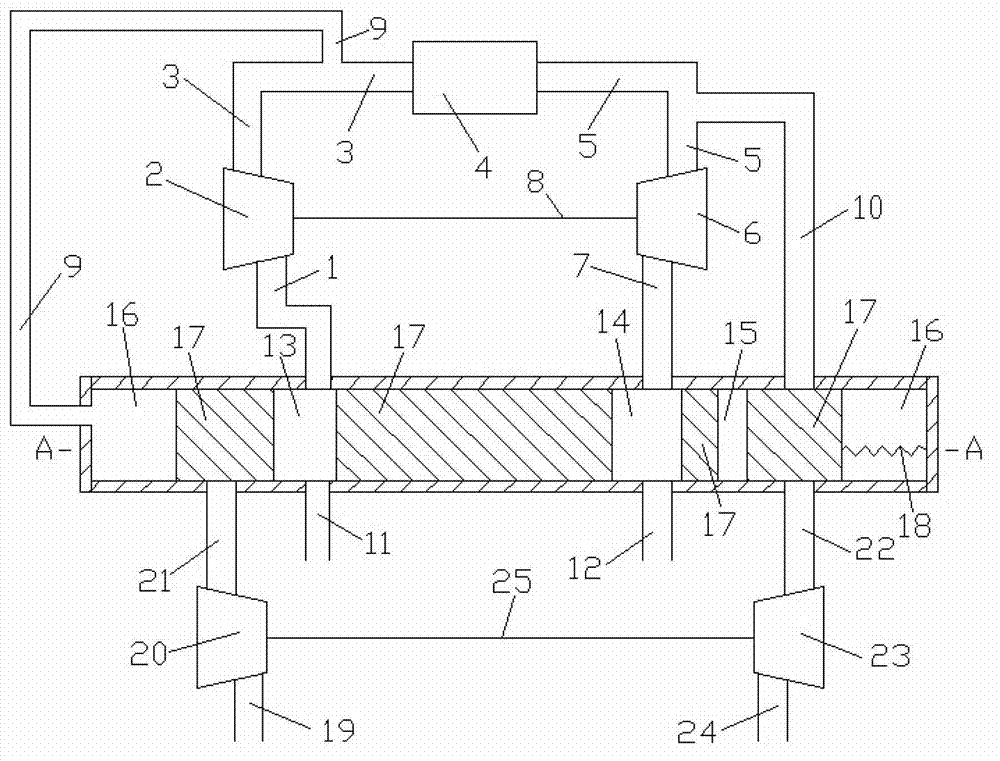

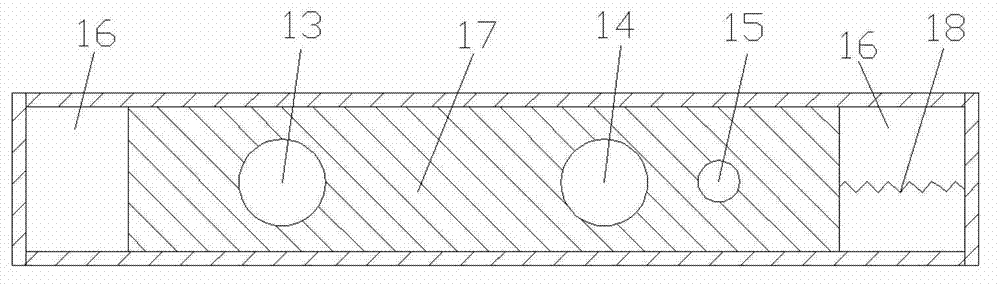

Variable air exhaust through flow area air inlet pressure control type adjusting device for turbocharged engine

InactiveCN103089409AConsidering both high and low speed conditionsReasonable designInternal combustion piston enginesInlet pressureAir compressor

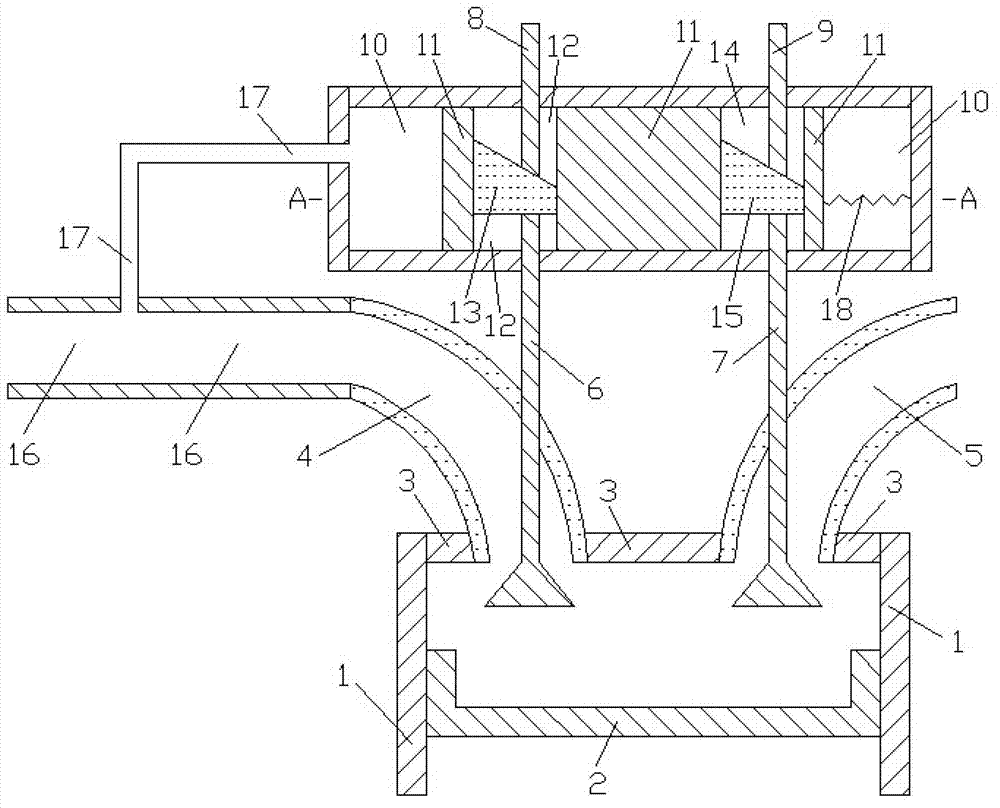

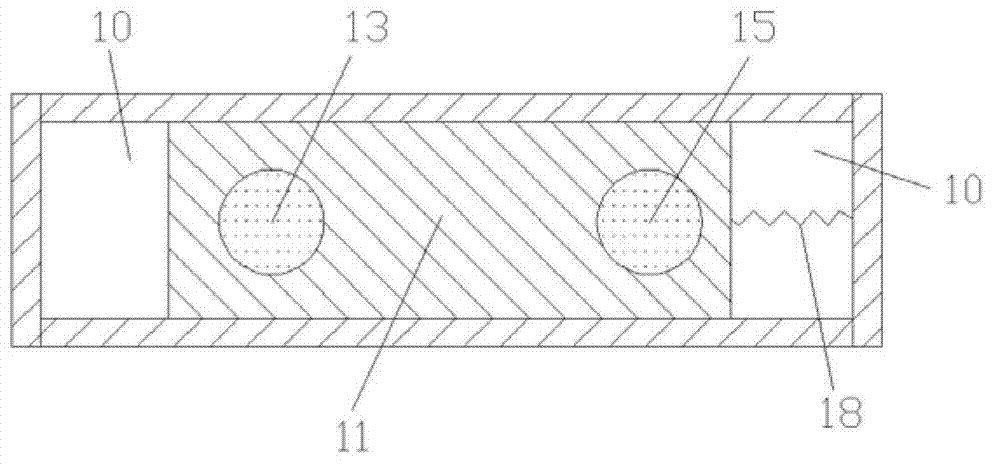

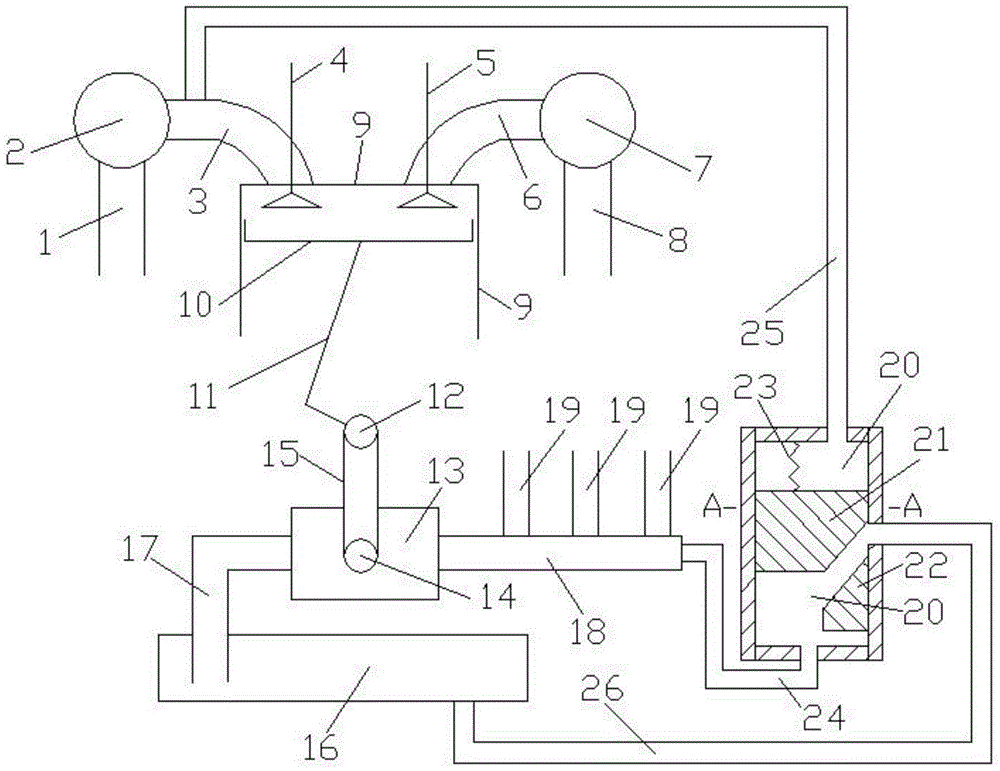

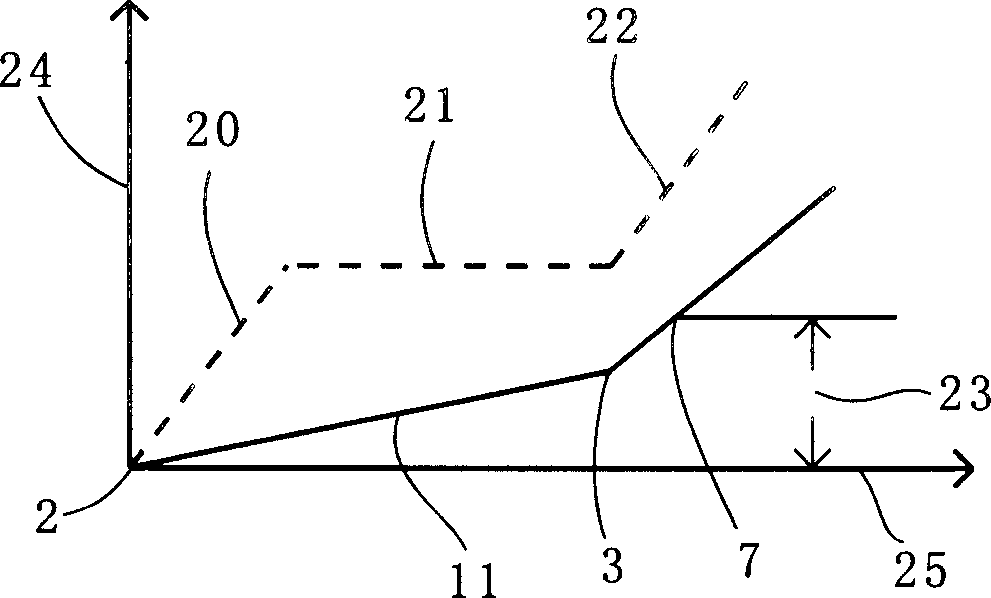

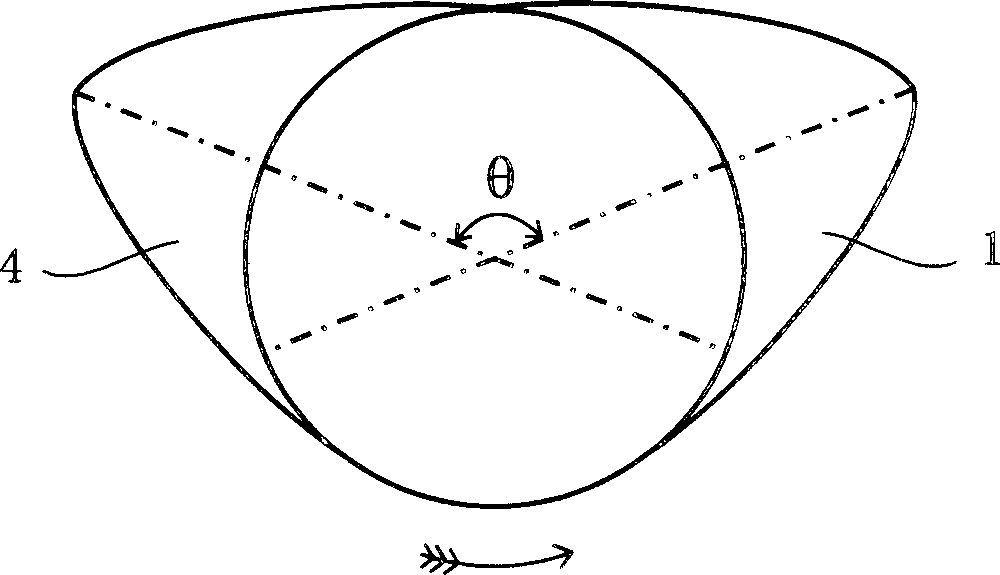

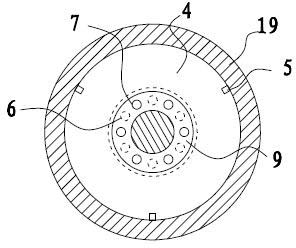

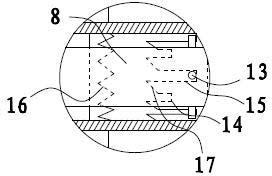

A variable air exhaust through flow area air inlet pressure control type adjusting device for a turbocharged engine belongs to the technical field of mechanical design and comprises an air compressor, an engine, a turbine, a volume cavity, a rotation body, a spring, a rotation rod, a rotation shaft and a rotation plate. The longitudinal sections of the volume cavity and the rotation body are both in arc shapes, the rotation plate is installed in an air exhaust pipe, the rotation plate and the rotation shaft are fixed together, the left wall of the rotation body is connected with the left wall of the volume cavity through the spring, and two ends of the connection pipe are respectively communicated with the right wall of the volume cavity and an air inlet pipe of the engine. When pressure in the air inlet pipe of the engine is high, the rotation body drives the rotation plate to rotate in a counterclockwise mode, pumping loss of the engine is small, and the whole performance is excellent. When pressure in the air inlet pipe of the engine is low, the rotation body drives the rotation plate to rotate in a clockwise mode, available energy in front of the turbine is more, air inlet pressure of the engine is high, and the whole performance is excellent. The variable air exhaust through flow area air inlet pressure control type adjusting device for the turbocharged engine is reasonable in design, simple in structure and suitable for a turbine single inlet turbocharged system.

Owner:SHANGHAI JIAO TONG UNIV

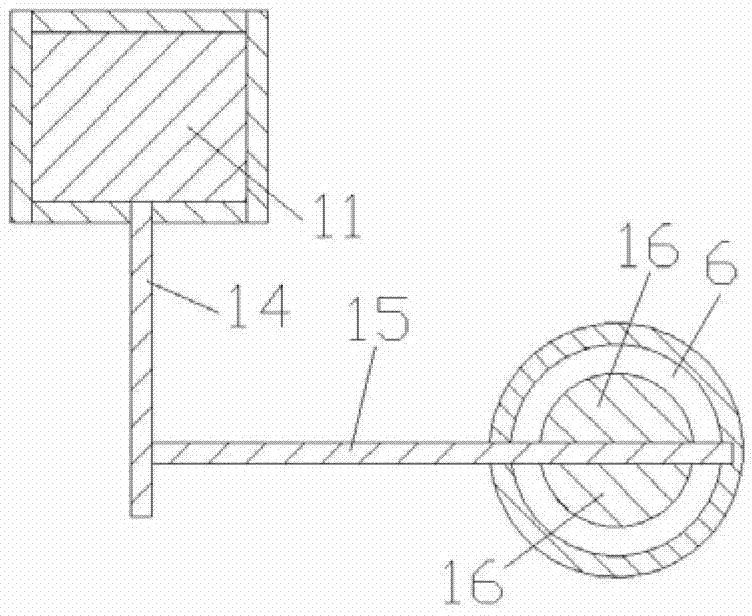

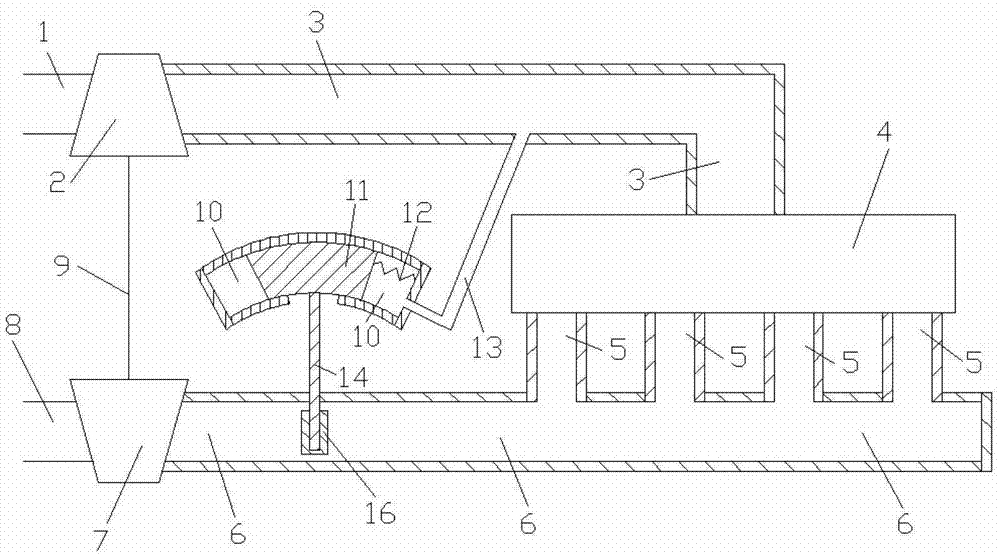

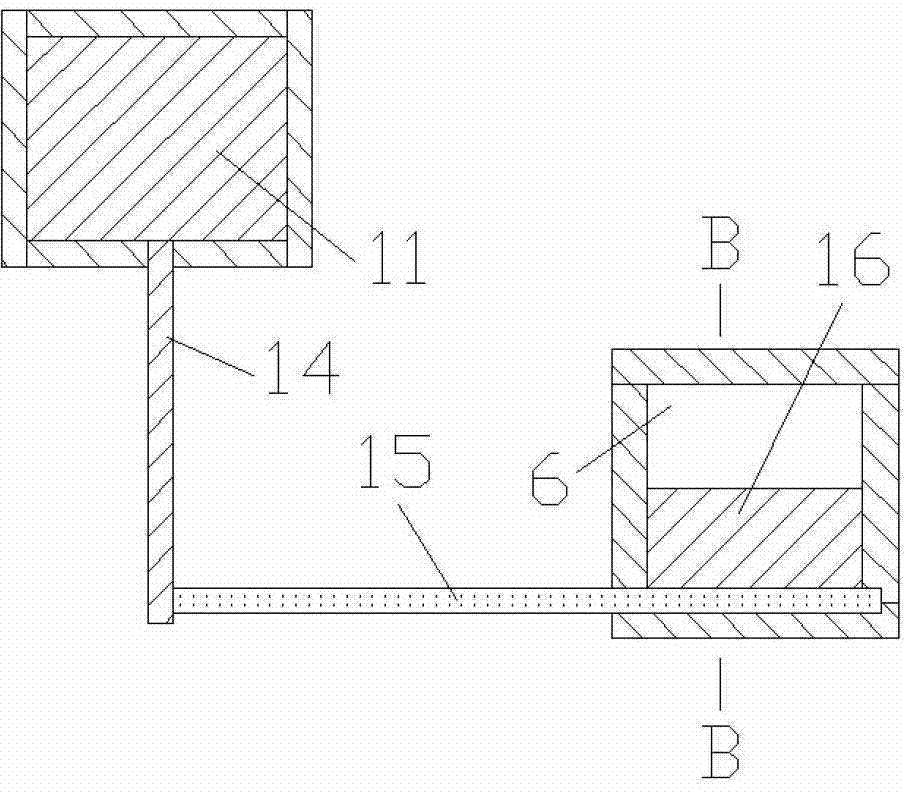

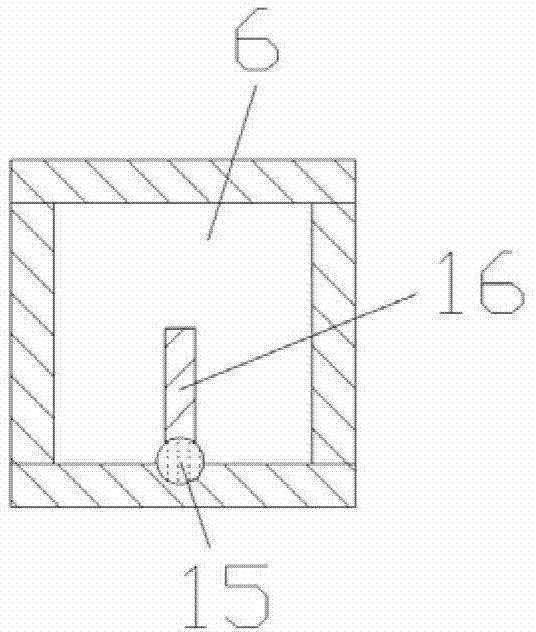

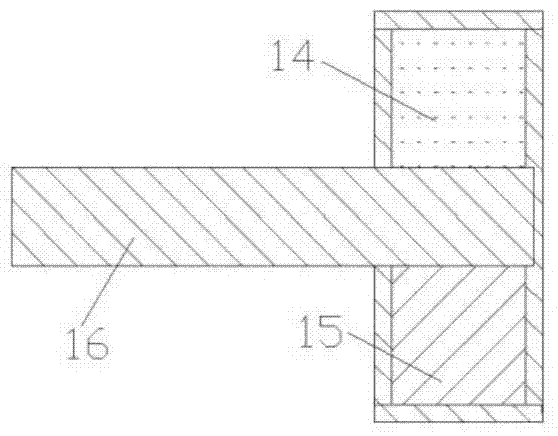

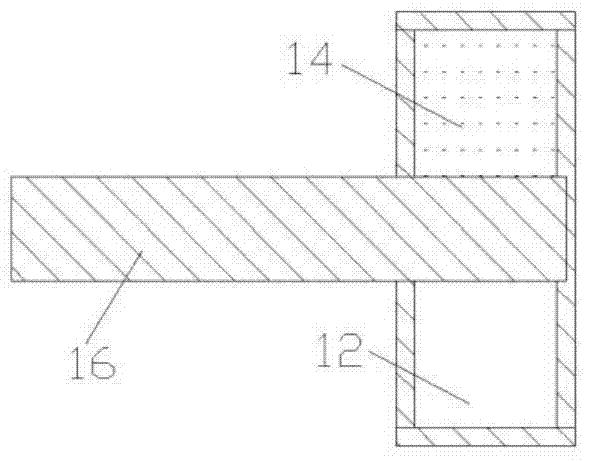

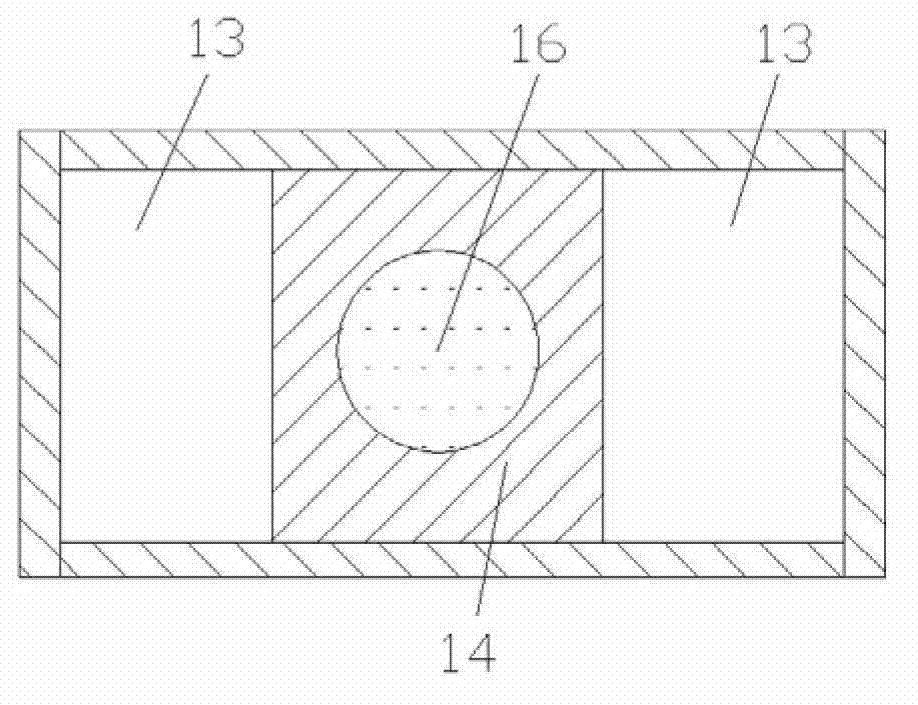

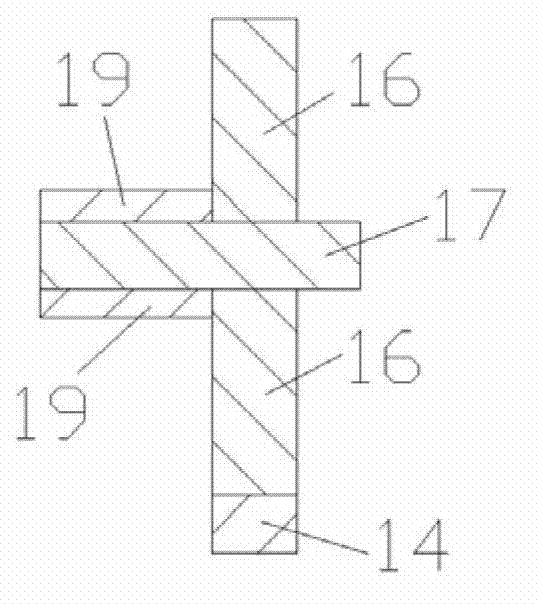

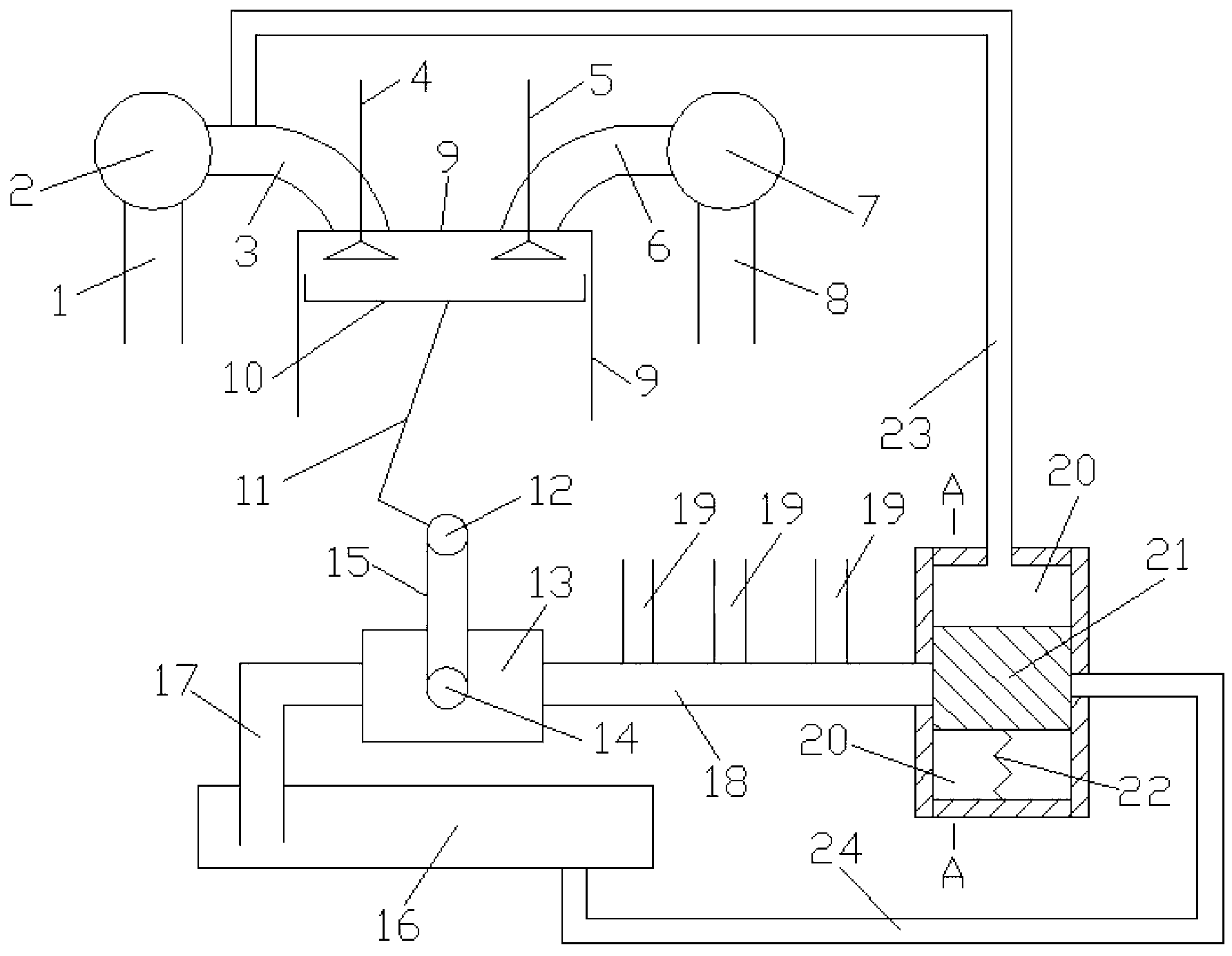

Rotation control type pipeline reducing rate variable device

ActiveCN103089410AConsidering both high and low speed conditionsReasonable designInternal combustion piston enginesGas compressorInlet pressure

A rotation control type pipeline reducing rate variable device belongs to the technical field of mechanical design and comprises an air compressor, an engine, an air exhaust pipe, a turbine, a volume cavity, a rotation body, a spring, a connection pipe, a rotation rod, a rotation shaft and a rotation plate. The longitudinal sections of the volume cavity and the rotation body are both in arc shapes, the rotation plate is installed in the air exhaust pipe, the rotation plate and the rotation shaft are fixed together, the left wall of the rotation body is connected with the left wall of the volume cavity through the spring, and two ends of the connection pipe are respectively communicated with the right wall of the volume cavity and the air exhaust pipe. When pressure in the air inlet pipe of the engine is high, the rotation body drives the rotation plate to rotate in a counterclockwise mode, pumping loss of the engine is small, and the whole performance is excellent. When pressure in the air inlet pipe of the engine is low, the rotation body drives the rotation plate to rotate in a clockwise mode, available energy in front of the turbine is more, air inlet pressure of the engine is high, and the whole performance is excellent. The rotation control type pipeline reducing rate variable device is reasonable in design, simple in structure and suitable for a turbine single inlet turbocharged system.

Owner:SUZHOU INTI AUTOMOTIVE TECH CO LTD

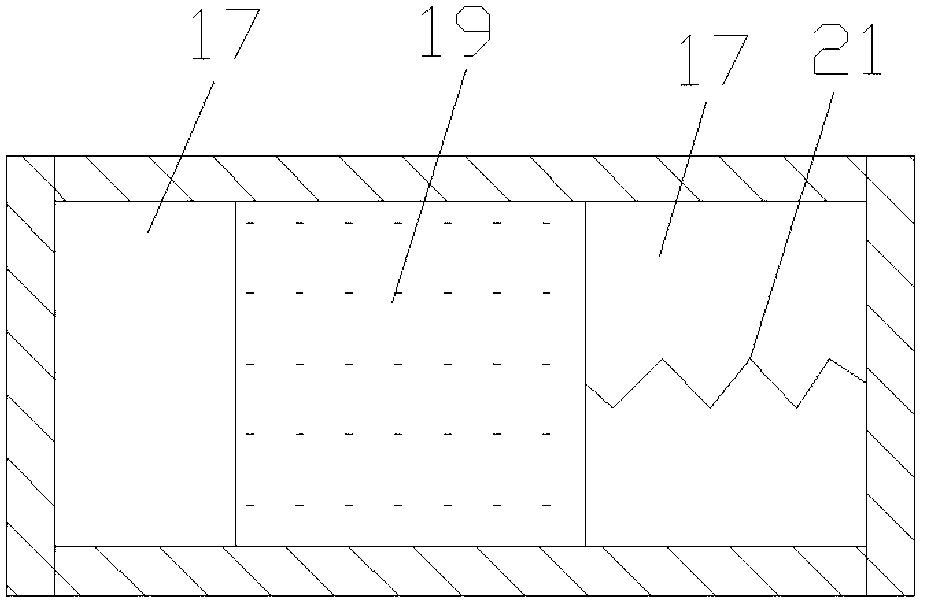

Square tube device with chain

InactiveCN103573389AConsidering both high and low speed conditionsReasonable designInternal combustion piston enginesThroatTurbine

The invention discloses a square tube device with a chain. The square tube device comprises capacity cavities, a rotating body, a clapboard, a rotating shaft, a rotating plate and the chain, wherein the longitudinal section of the capacity cavity is annular; the longitudinal section of the rotating body is arc; an exhaust pipe is a round pipe with a uniform section; one end of a first connecting pipe is communicated with the capacity cavity on the right of the clapboard and the other end is communicated with an air-inlet pipe of an engine; the two ends of a second connecting pipe are respectively communicated with the capacity cavity on the left of the clapboard and the exhaust pipe. When the pressure of the air-inlet pipe of the engine is higher than that in the exhaust pipe, the rotating body drives the rotating plate to rotate counterclockwise, and the area of the throat of the exhaust pipe is relatively large; when the pressure of the air-inlet pipe of the engine is lower than that in the exhaust pipe, the rotating body drives the rotating plate to rotate clockwise, and the area of the throat of the exhaust pipe is relatively small. The square tube device is reasonable in design, simple in structure and applicable to a turbo-charging system with one turbine inlet and a turbine which is laterally arranged.

Owner:SHANGHAI JIAO TONG UNIV

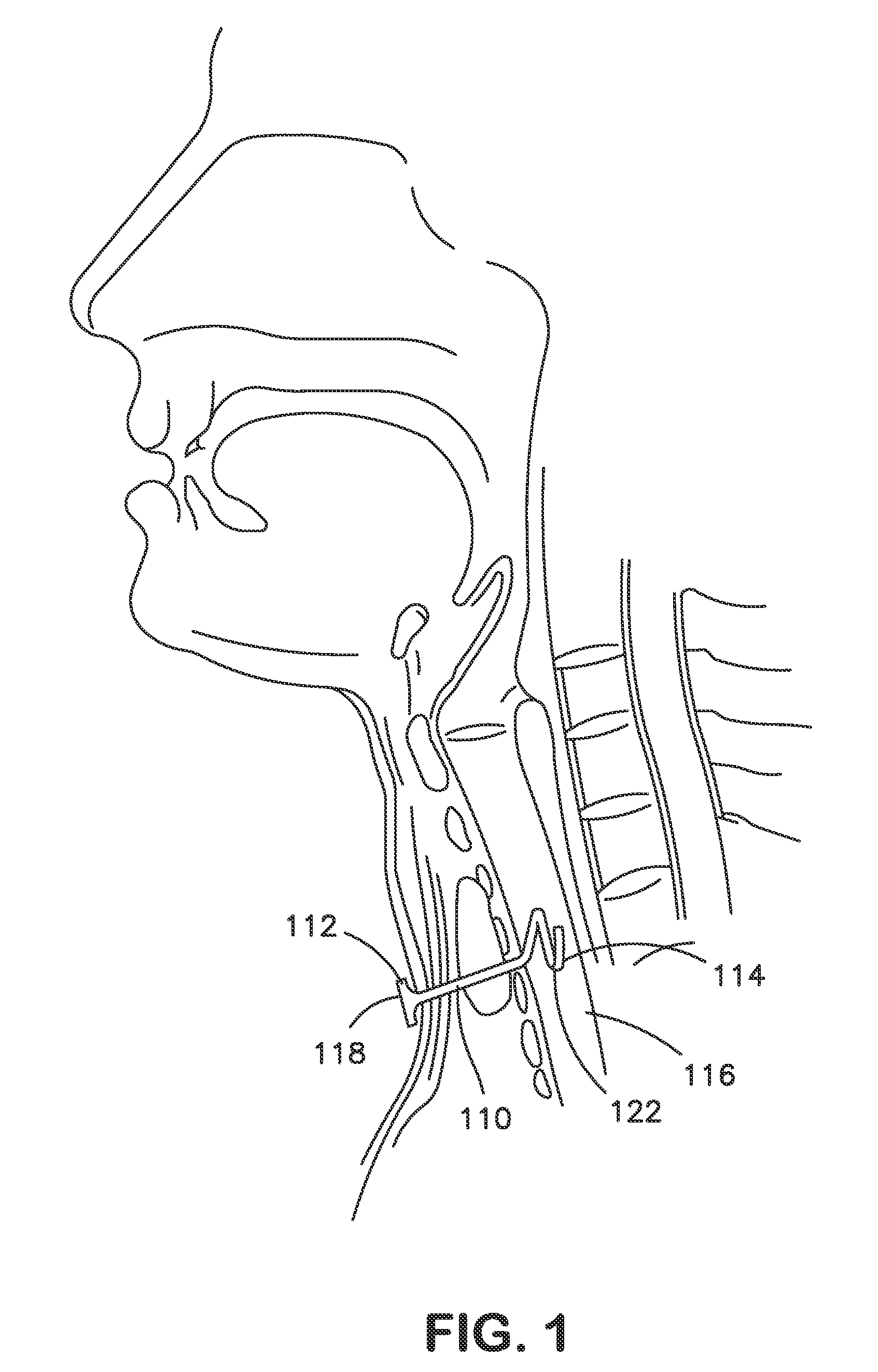

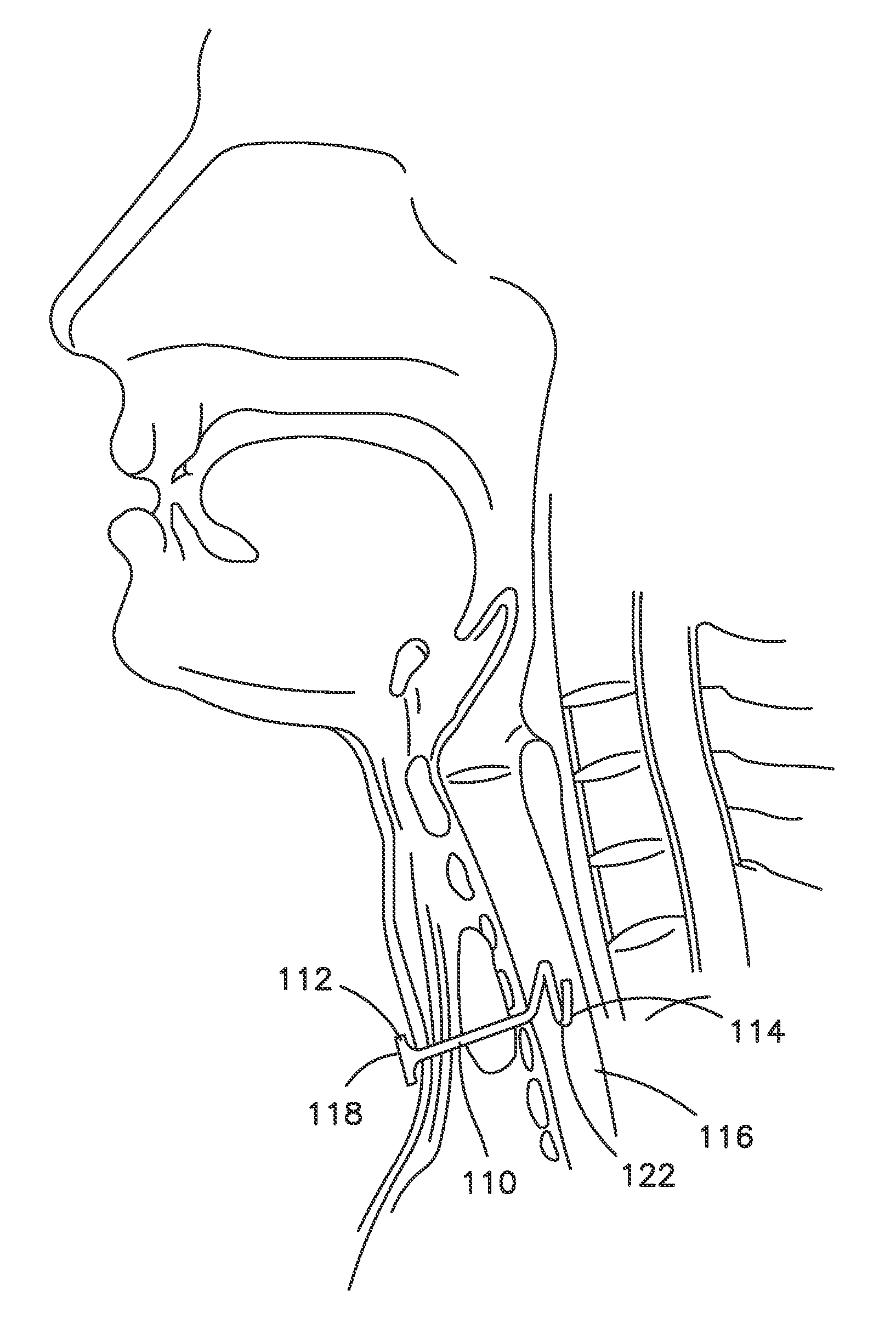

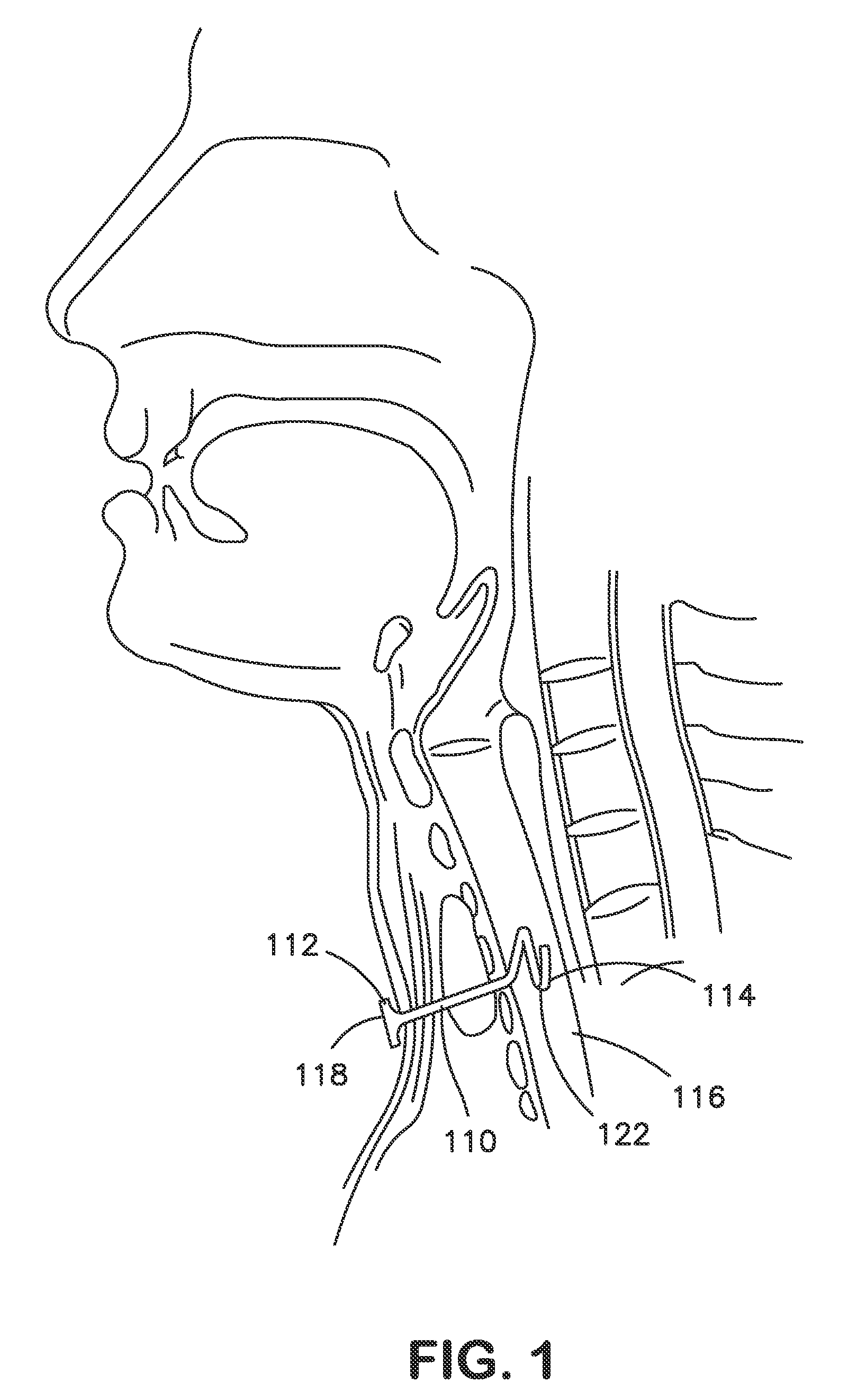

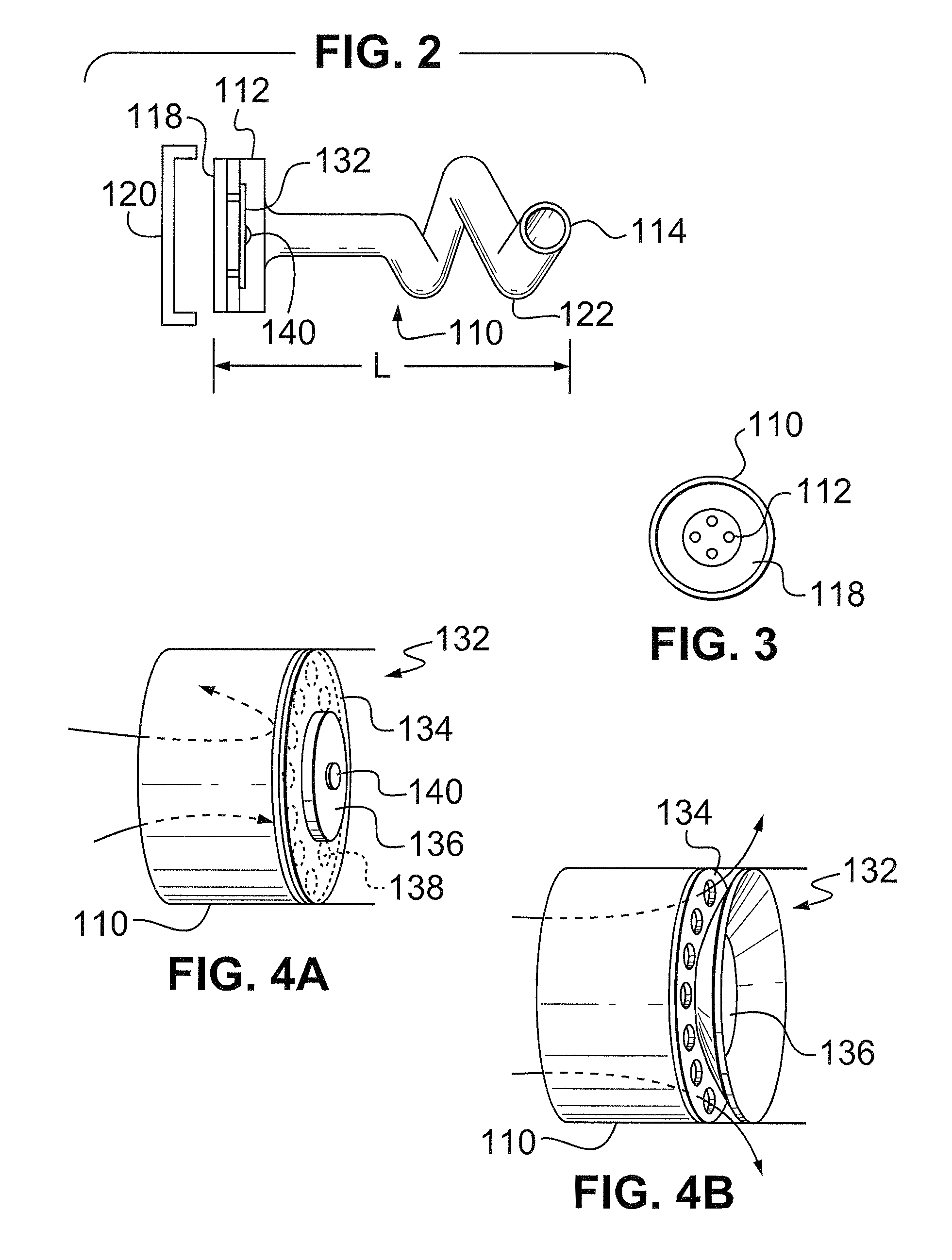

Tracheostomy Appliances and Methods for the Treatment of Sleep Apnea Syndromes

InactiveUS20080072912A1Prevent undersirable increaseAffects appearanceTracheal tubesSurgical needlesTreatment sleepAmbient pressure

Small tracheostomy appliances for use in treating Sleep Apnea Syndrome. The appliances are inserted in a tracheotomy incision, low on a patient's neck to equalize intra-tracheal pressure with ambient pressure under certain conditions to prevent undesirable increases in blood CO2 that could otherwise cause arousals from sleep.

Owner:SCOTT ELAINE D

Mechanical type lever proportion regulating mechanism

InactiveCN102926833AReasonable designSimple structureValve arrangementsMachines/enginesExhaust valveGas compressor

The invention relates to a mechanical type lever proportion regulating mechanism which belongs to the technical field of mechanical design. The mechanical type lever proportion regulating mechanism comprises an inlet valve, an exhaust valve, a gas compressor, a turbine, a lever, a tappet, a volume cavity, a movable body, a connecting pipe and a spring, wherein the movable body is arranged in the volume cavity and hermetically is contact with the inner wall surface of the volume cavity; the upper wall surface of the volume cavity is provided with a square hole; the lower end of a movable rod penetrates through the square hole positioned on the upper wall surface of the volume cavity to be fixedly connected together with the upper wall surface of the movable body, and the upper end of the movable rod is contact with the lever. When the pressure inside the air inlet pipe of an engine is higher, the movable body drives the movable rod to move towards right, and the stroke of the inlet valve is lengthened; when the pressure inside the air inlet pipe of the engine is lower, the movable body drives the movable rod to move towards left, and the stroke of the inlet valve is shortened. The mechanical type lever proportion regulating mechanism disclosed by the invention is reasonable in design, simple in structure and suitable for the valve stroke variable system of the engine.

Owner:SHANGHAI JIAO TONG UNIV

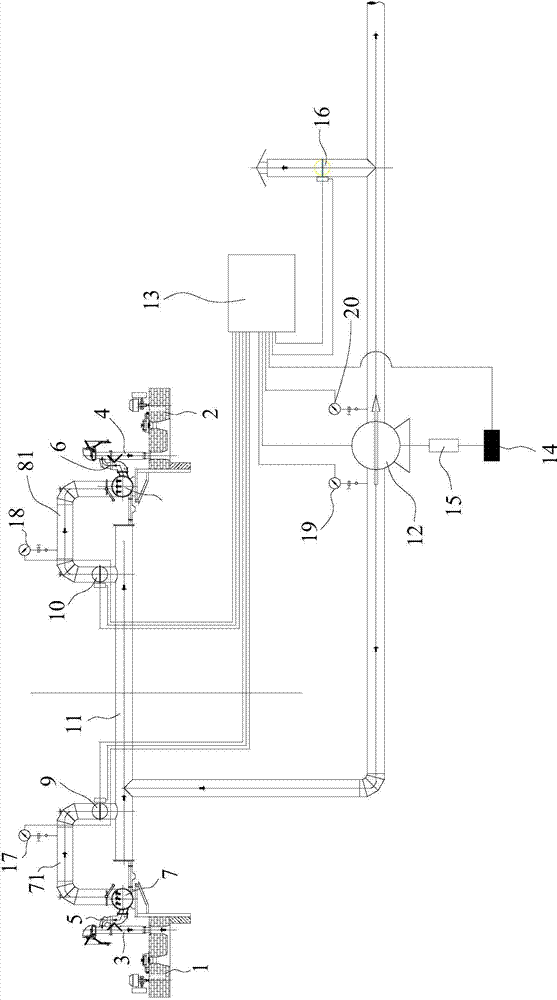

Pressure balance control method for coke oven gas collector

InactiveCN104498058APressure closed-loop controlStable pressureCoke oven safety devicesDistillation gas withdrawalLoop controlClosed loop

The invention provides a pressure balance control method for a coke oven gas collector. The method comprises the following steps: setting preset values for pressure of the gas collector in an industrial personal computer, an opening range of an electric butterfly valve on the gas collector and the rotating speed range of a blast blower; detecting information of the actual pressure in the gas collector, the opening of the electric butterfly valve on the gas collector and the rotating speed of the blast blower, and transferring the detected information into the industrial personal computer; comparing the detected actual pressure in the gas collector with the preset pressure value stored in the industrial personal computer, so as to change the opening of the electric butterfly valve; when the opening of the electric butterfly valve is the maximal value, if the actual pressure in the gas collector still is greater than the preset value, improving the rotating speed of the blast blower by virtue of the industrial personal computer; and when the opening of the electric butterfly valve is the minimal value, if the actual pressure in the gas collector still is smaller than the preset value, reducing the rotating speed of the blast blower by virtue of the industrial personal computer. According to the pressure balance control method for the coke oven gas collector provided by the invention, the electric butterfly valve and the blast blower are adjusted by virtue of the industrial personal computer, so that closed loop control on the pressure in the gas collector is achieved; and stable pressure in the gas collector can be ensured.

Owner:TAIYUAN HEAVY IND

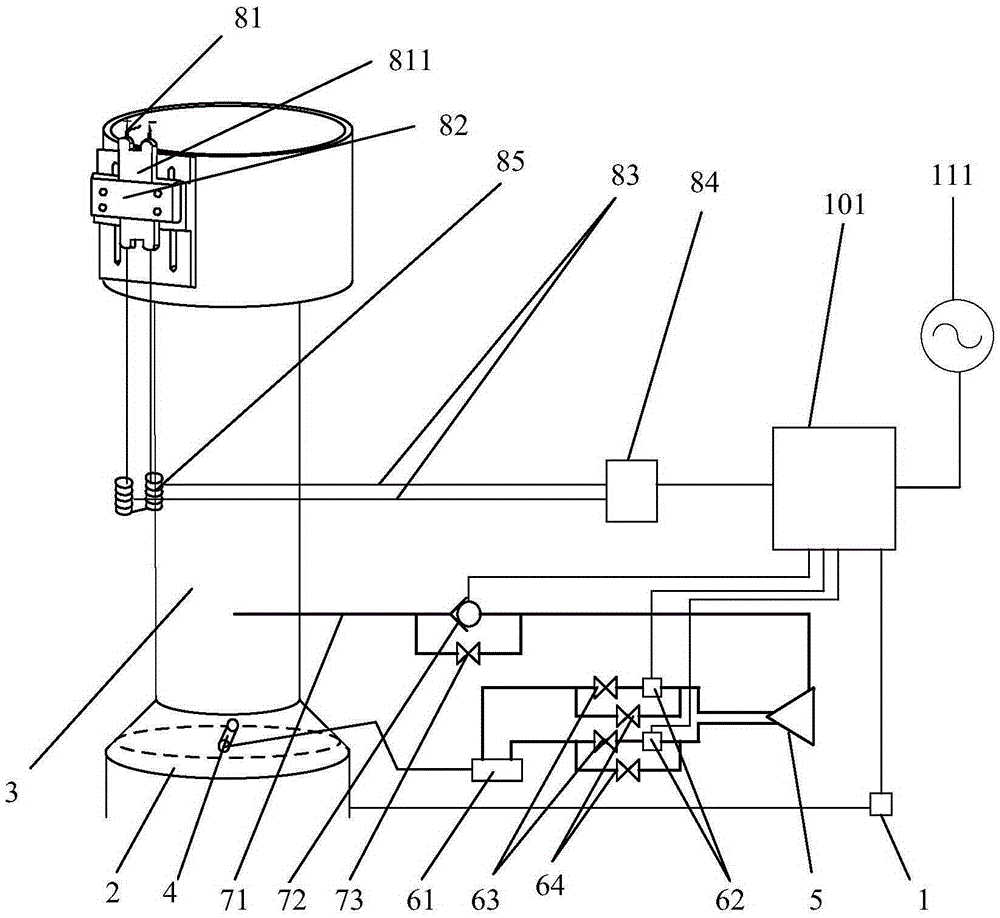

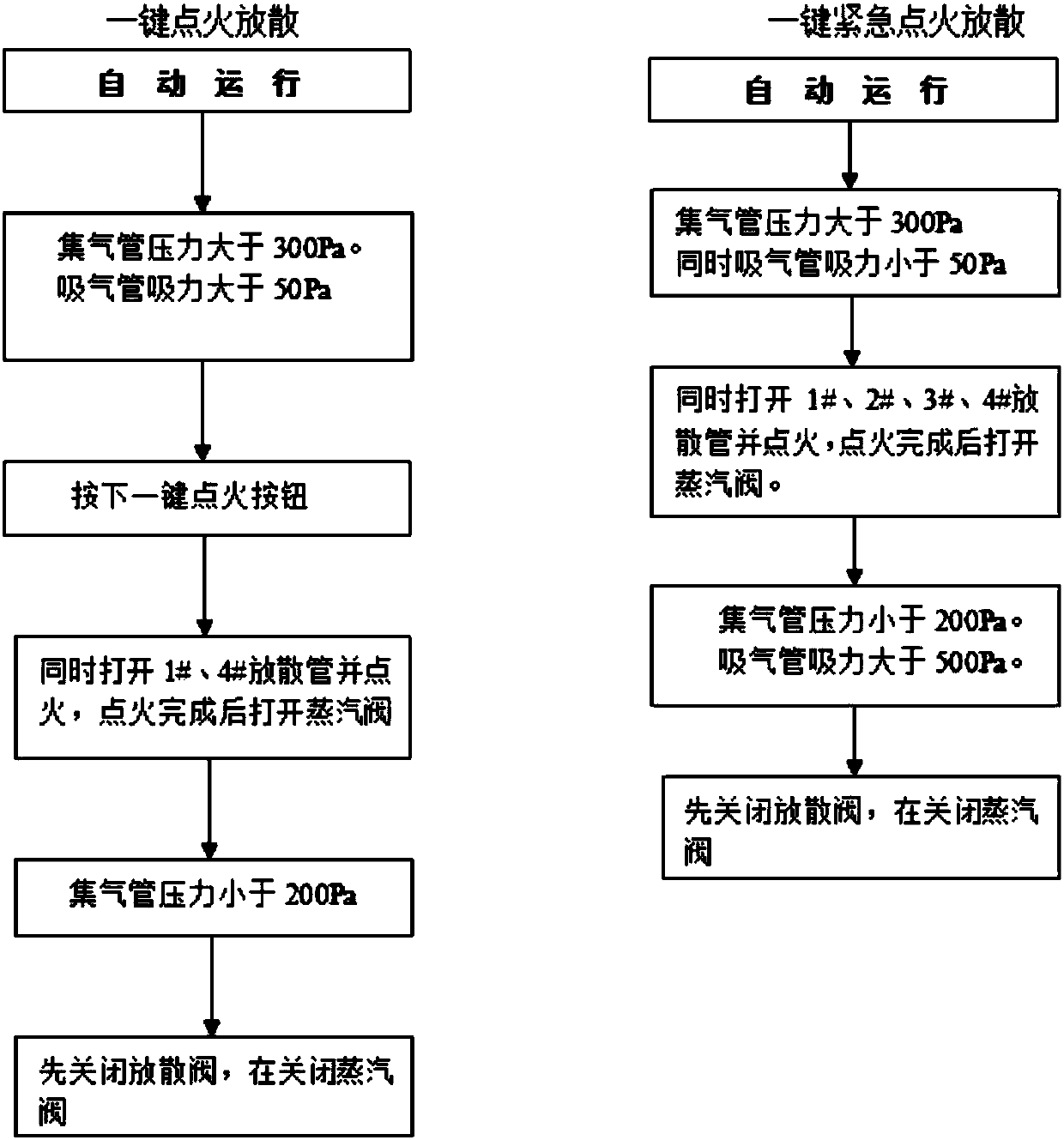

Automatic coke oven emission ignition control system and control method

ActiveCN105299659AGuaranteed stabilitySimple structureCoke oven safety devicesElectric spark ignitersCoke Oven EmissionEngineering

The invention discloses an automatic coke oven emission ignition control system and control method. The control system comprises an automatic emission device which is composed of a nitrogen source, an emission gas channel switch and a pneumatic air cylinder. When the pressure in a gas collecting pipe exceeds the preset upper pressure limit, nitrogen in the nitrogen source is convened to one gas inlet / outlet of the pneumatic air cylinder by controlling the emission gas channel switch, a flap valve is opened through the pneumatic air cylinder under the action of nitrogen pressure, and raw coal gas is emitted automatically. When the pressure of the gas collecting pipe is below the lower limit value, the nitrogen in the nitrogen source is convened to other gas inlet / outlet of the pneumatic air cylinder by controlling the emission gas channel switch, and the flap valve is closed. According to the automatic coke oven emission ignition control system and control method, the flap valve is opened and closed with the nitrogen as power, so that limiting to automatic emission due to insufficient electric energy of a reserve power source is eliminated. In addition, the automatic emission device is simple in structure and convenient to operate, so that the running stability of the whole automatic coke oven emission ignition control system is ensured.

Owner:SHANDONG IRON & STEEL CO LTD

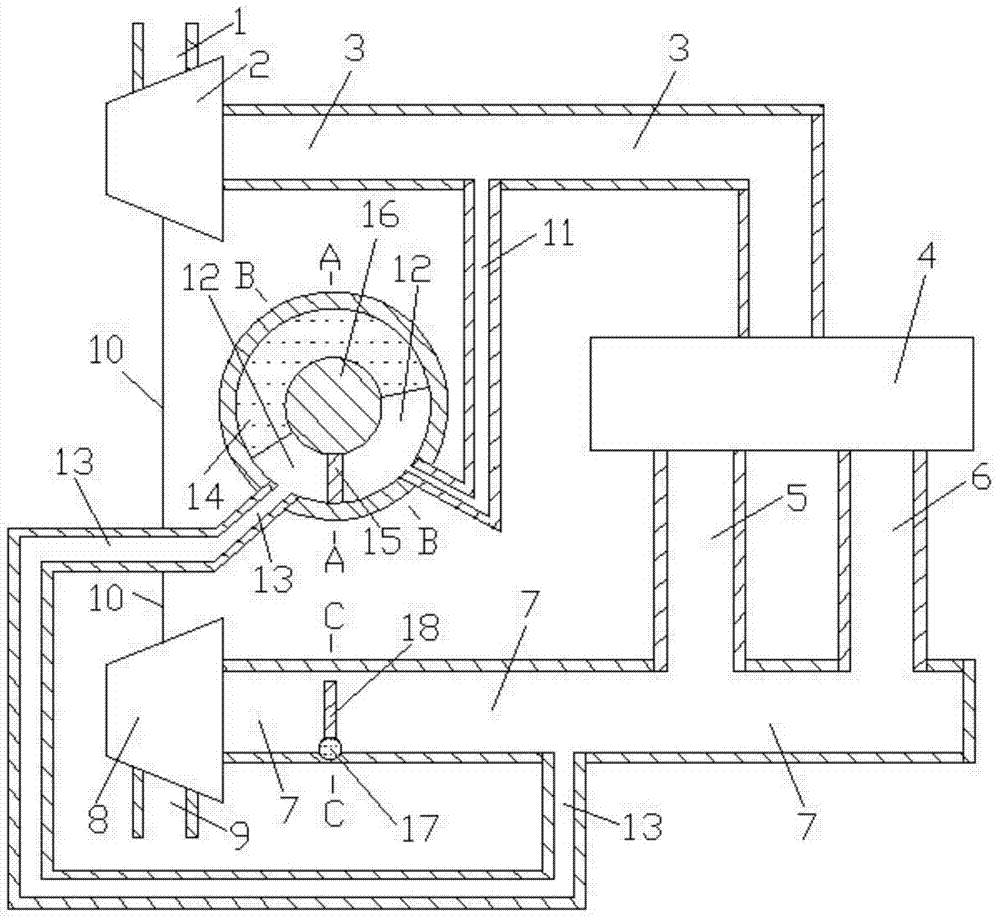

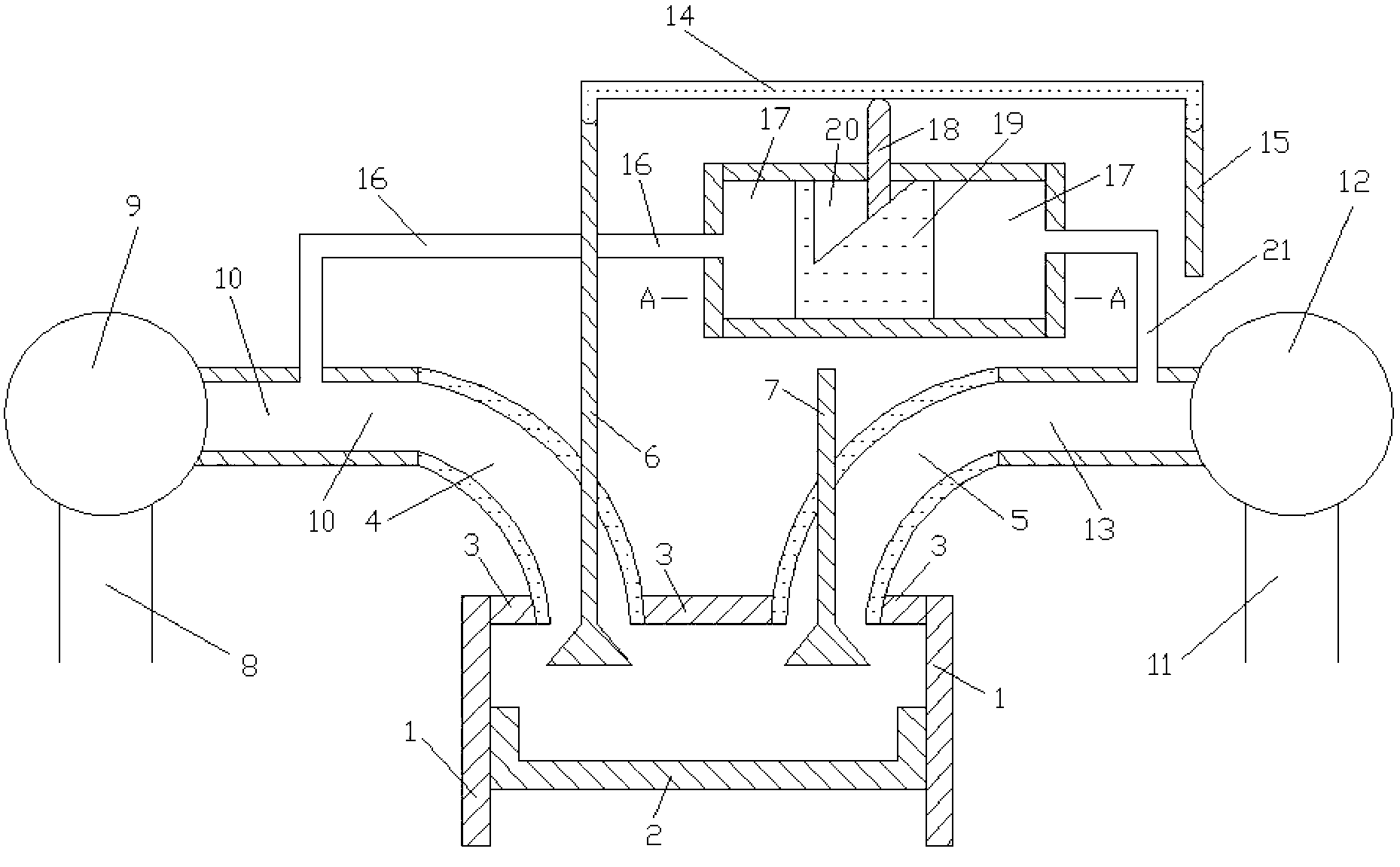

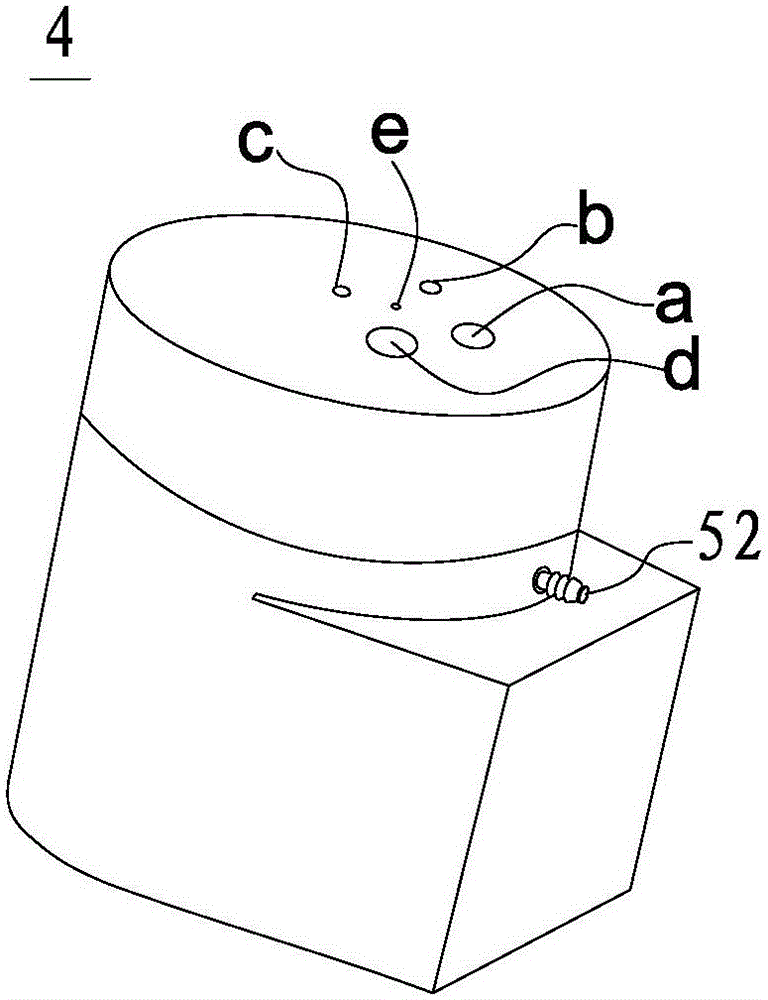

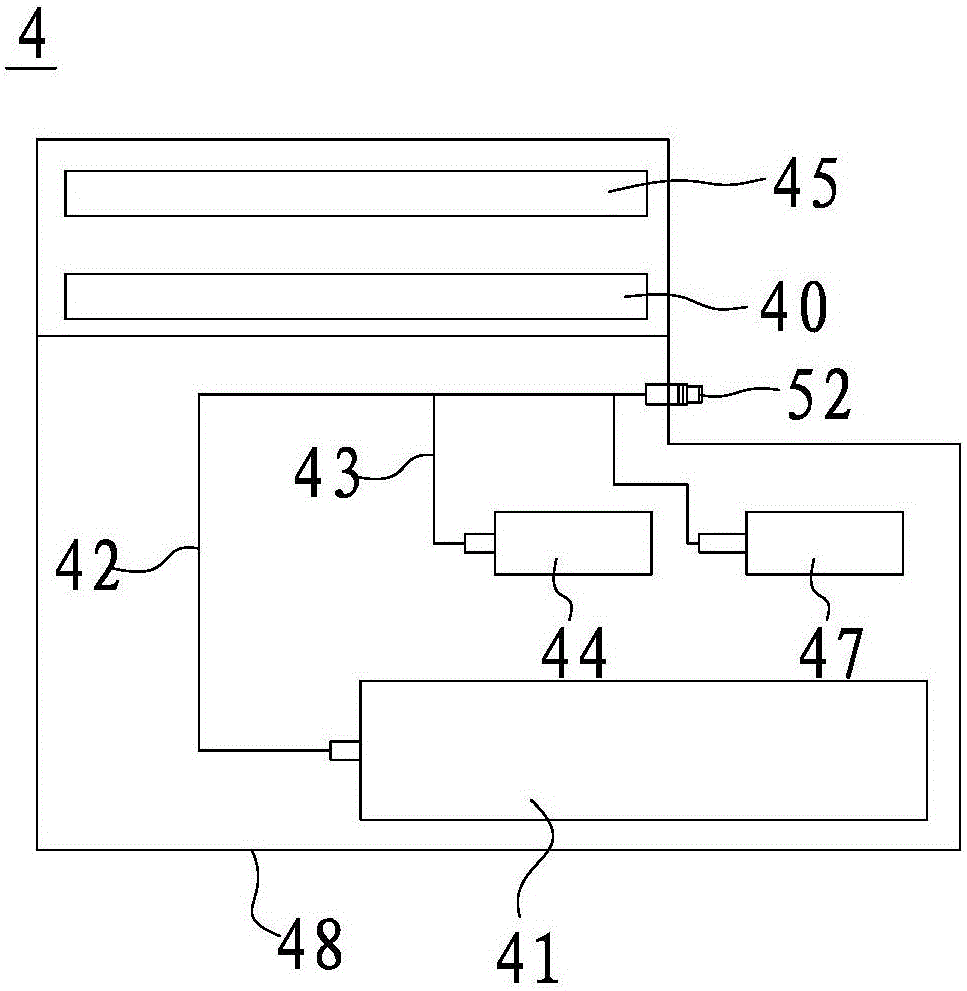

Air intake valve lift-variable system in air intake pressure regulating type

InactiveCN102808671AContinuously variableReasonable designValve arrangementsMachines/enginesExhaust valveCombustion

The invention discloses an air intake valve lift-variable system in an air intake pressure regulating type, belonging to the technical field of internal combustion engines. The system comprises an air intake channel, an air exhaust channel, an air intake valve lower section, an air exhaust valve, an air intake valve upper section, a capacity cavity, a movable body, a perforation pipe, a movable block, an air inlet pipe, a connecting pipe and a spring, wherein the movable body is mounted in the capacity cavity and is contacted with the inner wall face of the capacity cavity in a sealing manner; the perforation pipe perforates the upper wall face and the lower wall face of the movable body; the movable block is mounted in the perforation pipe and is contacted with the inner wall face of the perforation pipe in a sealing manner; the lower end face of the movable block is a plane; the upper end face of the movable block is an inclined face; two ends of the connecting pipe are communicated with the left wall faces of the air intake pipe and the capacity cavity; the right wall face of the movable body is connected with the right wall face of the capacity cavity through the spring; when pressure in the air intake pipe is relatively large, the movable body is moved to right; the air intake valve lift is increased; when the pressure in the air intake pipe is relatively small, the movable body is moved to left; the air intake valve lift is reduced; and the intake valve variable-lift system is characterized by reasonable design and simple structure and is suitable for engine valve lift-variable systems.

Owner:SHANGHAI JIAO TONG UNIV

Control device of internal combustion engine

InactiveCN1842646AFully understandElectrical controlCombustion enginesInternal pressureExternal combustion engine

A control device of an internal combustion engine, wherein a throttle valve passing air flow calculation expression for indicating a throttle valve passing air flow (mt) as the function of a downstream side intake tube inner pressure on the downstream side of a throttle valve and a cylinder intake air flow calculation expression for indicating a cylinder intake air flow (mc) as the function of the downstream side intake tube inner pressure calculates the downstream side intake tube inner pressure (Pm) and the cylinder intake air flow (mc) when the throttle valve passing air flow (mt) obtained by using the throttle valve passing air flow calculation expression agrees with the cylinder intake air flow (mc) obtained by using the cylinder intake air flow calculation expression as a downstream side intake tube inner pressure (Pmta) and a cylinder intake air flow (mcta) when the engine is stationarily operated under the operating conditions when the air flow (mt) agrees with the air flow (mc).

Owner:TOYOTA JIDOSHA KK

Tappet rod device with transverse moving type moving body

InactiveCN102966399AContinuously variableReasonable designMachines/enginesNon-mechanical valveExhaust valveInlet valve

A tappet rod device with a transverse moving type moving body in the technical field of mechanical design comprises a cylinder, a gas inlet pipe, a gas inlet valve, a gas exhaust valve, a gas exhaust pipe, an upright, a lever, a tappet, a volume chamber, a moving body, a through pipe, a moving block and a connecting pipe, wherein the through pipe penetrates through the upper wall surface and the lower wall surface of the moving body; the moving block is mounted in the through pipe and in sealed contact with the inner wall surface of the through pipe; the lower end surface of the moving block is a plane; the upper end surface of the moving block is an inclined surface; two ends of a first connecting pipe are respectively communicated with the gas inlet pipe and the left wall surface of the volume chamber; and two ends of a second connecting pipe are respectively communicated with the gas exhaust pipe and the right wall surface of the volume chamber. When the pressure in the gas inlet pipe is larger than the pressure in the gas exhaust pipe, the moving body moves to the right and the lift of the gas inlet valve is increased; and when the pressure in the gas inlet pipe is smaller than the pressure in the gas exhaust pipe, the moving body moves to the left and the lift of the gas inlet valve is reduced. The tappet rod device with the transverse moving type moving body, provided by the invention, has the advantages of reasonable design and simple structure and is suitable for systems with variable engine valve lifts.

Owner:SHANGHAI JIAO TONG UNIV

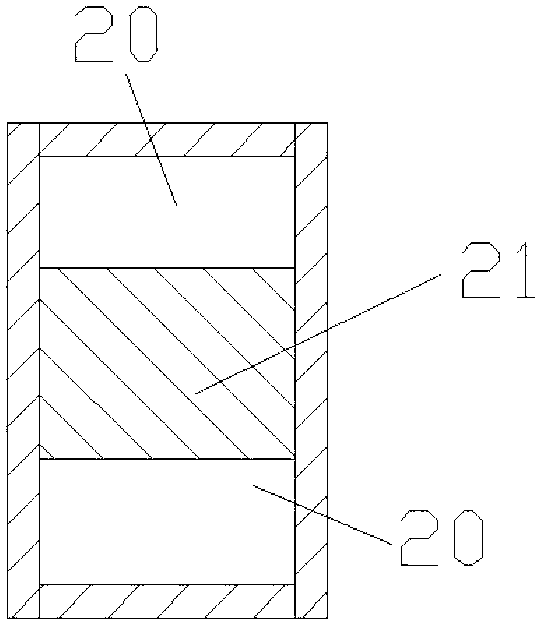

Differential pressure type valve lift control system

InactiveCN103233791AReasonable designSimple structureValve arrangementsMachines/enginesExhaust valveDifferential pressure

The invention relates to the technical field of machine design, in particular to a differential pressure type valve lift control system. The differential pressure type valve lift control system comprises an intake valve, an exhaust valve, an air compressor, a turbine, a lever, a tappet, a volume cavity, a movable body, a supporting rod and connecting pipes, wherein the movable body is mounted in the volume cavity and is in sealed contact with the inner wall of the volume cavity; a round hole is formed in the upper wall surface of the volume cavity; the lower end of the supporting rod penetrates the round hole in the upper wall surface of the volume cavity to be in contact with an inclined plane of a triangle groove; and the upper end of the supporting rod is in contact with the lever. When pressure in an air intake pipe of a motor is larger than that of an exhaust pipe of the motor, the supporting rod moves downward, the lift of the intake valve is enlarged; and when the pressure in the air intake pipe of the motor is smaller than that of the exhaust pipe of the motor, the supporting rod moves upward, and the lift of the intake valve is lessened. The differential pressure type valve lift control system is reasonable in design, simple in structure, and suitable for motor valve lift for changeable systems.

Owner:SHANGHAI JIAO TONG UNIV

Air intake/exhaust valve lift-variable system in air intake pressure regulating type

InactiveCN102808670AContinuously variableReasonable designValve arrangementsMachines/enginesCombustionExhaust valve

The invention discloses an air intake / exhaust valve lift-variable system in an air intake pressure regulating type, belonging to the technical field of internal combustion engines. The system comprises an air intake channel, an air exhaust channel, an air intake valve lower section, an air exhaust valve, an air intake valve upper section, a capacity cavity, a movable body, a perforation pipe, a movable block, an air inlet pipe, a connecting pipe and a spring, wherein the movable body is mounted in the capacity cavity and is contacted with the inner wall face of the capacity cavity in a sealing manner; the perforation pipe perforates the upper wall face and the lower wall face of the movable body; the movable block is mounted in the perforation pipe and is contacted with the inner wall face of the perforation pipe in a sealing manner; the lower end face of the movable block is a plane; the upper end face of the movable block is an inclined face; the air intake valve upper section passes through the upper wall face of the capacity cavity and is extended into the perforation pipe; the lower end face of the air intake door upper section is contacted with the upper end face of the movable block in a sealing manner; when pressure in the air intake pipe is relatively large, the movable body is moved to right; the air intake valve lift is increased; when the pressure in the air intake pipe is relatively small, the movable body is moved to left; the air intake valve lift is reduced; and the intake / exhaust valve variable-lift system is characterized by reasonable design and simple structure and is suitable for engine valve lift-variable systems.

Owner:SHANGHAI JIAO TONG UNIV

Inlet air pressure adjusting type oil discharging device

InactiveCN103603703AImprove mechanical efficiencyTaking into account the operating conditionsLubrication pressure controlElastic componentMechanical design

An inlet air pressure adjusting type oil discharging device in the technical field of mechanical design comprises an oil pump, a volume cavity, a movable body, a fixed body, an elastic component, a connecting pipe and an oil returning pipe. The movable body is arranged in the volume cavity and in contact with an inner wall face of the volume cavity in a sealing mode, the fixed body is arranged in the volume cavity and fixedly connected with the left wall face of the volume cavity, two ends of an oil inlet pipe are communicated with the rear end of a main oil channel and the lower wall face of the volume cavity, two ends of the oil returning pipe are communicated with the right wall face of the volume cavity and the lower wall face of an oil bottom casing, and the upper wall face of the movable body is connected with the upper wall face of the volume cavity through the elastic component. When pressure of the inside of the air inlet pipe of an engine is low, the movable body moves upwards, the main oil channel is communicated with the oil returning pipe, and the oil pressure of the main oil channel is reduced. When the pressure in an air inlet pipe of the engine is high, the movable body moves downwards, the main oil channel is separated from the oil returning pipe, and oil pressure of the main oil channel is increased. The inlet air pressure adjusting type oil discharging device is reasonable in design, simple in structure and suitable for the engine with a pressure increasing system.

Owner:SHANGHAI JIAO TONG UNIV

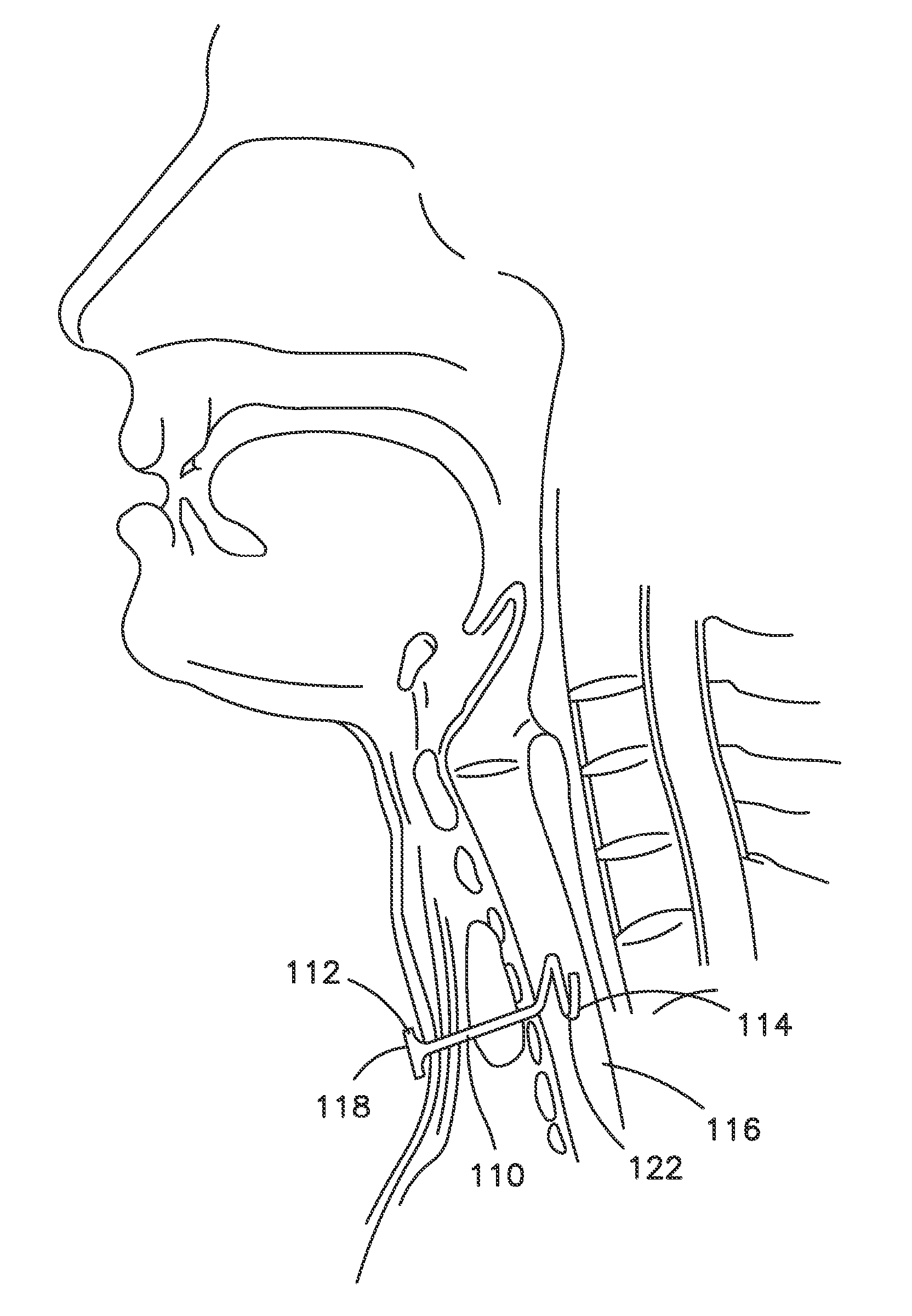

Tracheostomy appliances and methods for the treatment of sleep apnea syndromes

InactiveUS8800564B2Affects appearanceRespiratorsSurgical needlesAmbient pressureIntratracheal pressure

Small tracheostomy appliances for use in treating Sleep Apnea Syndrome. The appliances are inserted in a tracheotomy incision, low on a patient's neck to equalize intra-tracheal pressure with ambient pressure under certain conditions to prevent undesirable increases in blood CO2 that could otherwise cause arousals from sleep.

Owner:SCOTT ELAINE D

System for adjusting height of moving block type tappet rod

InactiveCN102966400AContinuously variableReasonable designMachines/enginesNon-mechanical valveExhaust valveInlet valve

A system for adjusting height of a moving block type tappet rod in the technical field of mechanical design comprises a cylinder, a gas inlet pipe, a gas inlet valve, a gas exhaust valve, a gas exhaust pipe, an upright, a lever, a tappet, a volume chamber, a moving body, a through pipe, a moving block, a connecting pipe and a spring, wherein the moving body is mounted in the volume chamber and in sealed contact with the inner wall surface of the volume chamber; the through pipe penetrates through the upper wall surface and the lower wall surface of the moving body; the moving block is mounted in the through pipe and in sealed contact with the inner wall surface of the through pipe; the lower end surface of the moving block is a plane; the upper end surface of the moving block is an inclined surface; the right wall surface of the moving body is connected with the right wall surface of the volume chamber through the spring; and two ends of the connecting pipe are respectively communicated with the gas exhaust pipe and the left wall surface of the volume chamber. When the pressure in the gas inlet pipe is larger, the moving body moves to the right and the lift of the gas inlet valve is increased; and when the pressure in the gas inlet pipe is smaller, the moving body moves to the left and the lift of the gas inlet valve is reduced. The system for adjusting the height of the moving block type tappet rod, provided by the invention, has the advantages of reasonable design and simple structure and is suitable for systems with variable engine valve lifts.

Owner:SHANGHAI JIAO TONG UNIV

High performance internal combustion engine

A high-performance internal-combustion engine comprises an air inlet and exhaust cam on the camshaft and a distributing phase. The contour of the air inlet and exhaust cam includes a base circle, air valve opening and closing buffer sections and a working section. In a cold state, the end of the air valve opening buffer section is set in front of the air valve clearance eliminating point and the initial point of the air valve closing buffer section is set at the back of the air valve clearance appearing point. Using the inventive structure can make the internal-combustion engine have simultaneously high-speed and low-speed superperformances.

Owner:晏家全

Pressure differential contact point moving system

InactiveCN102966397AReasonable designSimple structureMachines/enginesNon-mechanical valveExhaust valveInlet valve

The invention discloses a pressure differential contact point moving system, which belongs to the technical field of mechanical design. The pressure differential contact point moving system comprises an air inlet valve, an exhaust valve, an air compressor, a turbine, a lever, a tappet rod, a cam, a camshaft, a volume cavity, a moving body, a connecting pipe and a spring, wherein the moving body is arranged in the volume cavity, and is hermetically contacted with the inner wall surface of the volume cavity; an installation hole is formed in the left wall surface of the volume cavity; one end of a movable rod passes through the installation hole in the left wall surface of the volume cavity, and is fixedly connected together with the left wall surface of the moving body; and the other end of the movable rod is connected with the camshaft. When the pressure in an air inlet pipe of an engine is higher than the pressure in an exhaust pipe of the engine, the moving body is used for driving the movable rod to move leftwards, and the lift of the inlet valve is increased; and when the pressure in the air inlet pipe of the engine is lower than the pressure in the exhaust pipe of the engine, the moving body is used for driving the movable rod to move rightwards, and the lift of the air inlet valve is reduced. The pressure differential contact point moving system has the advantages of reasonable design, simple structure, and suitability for systems in which the lifts of engine air vales are variable.

Owner:SHANGHAI 01 POWER TECH

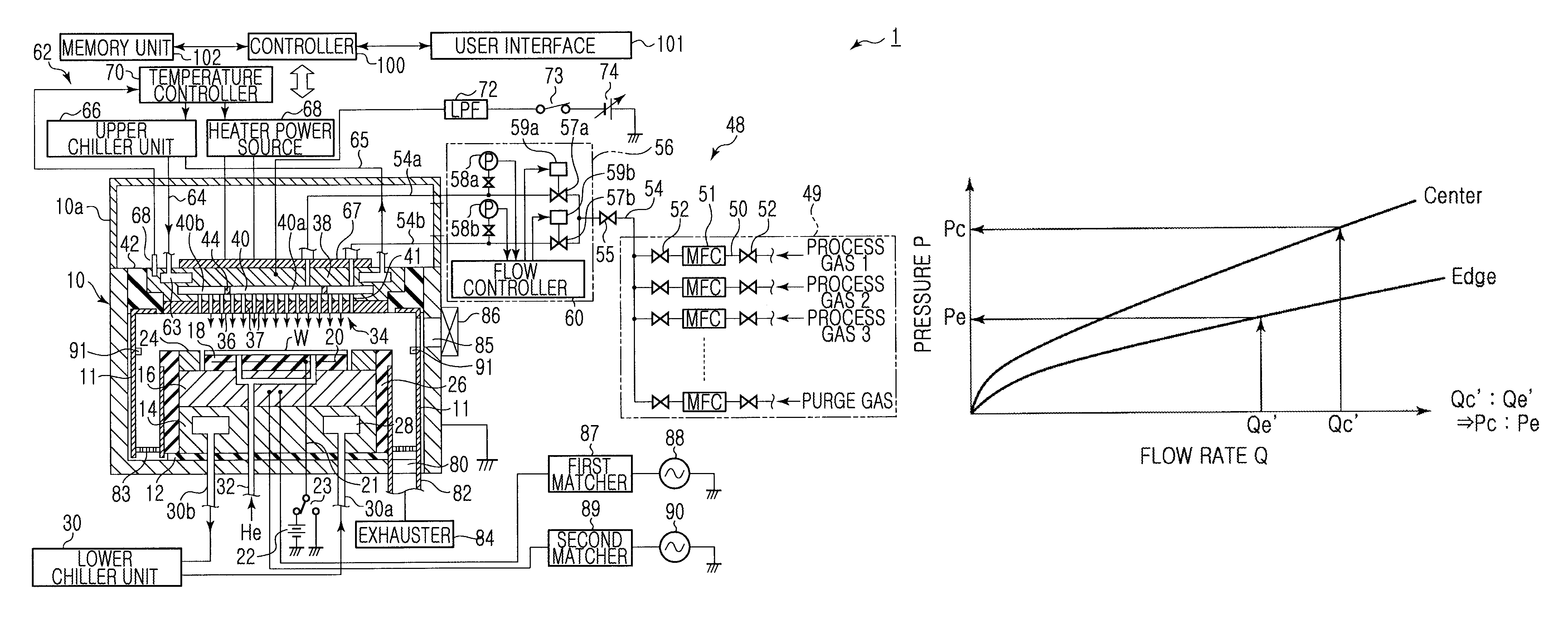

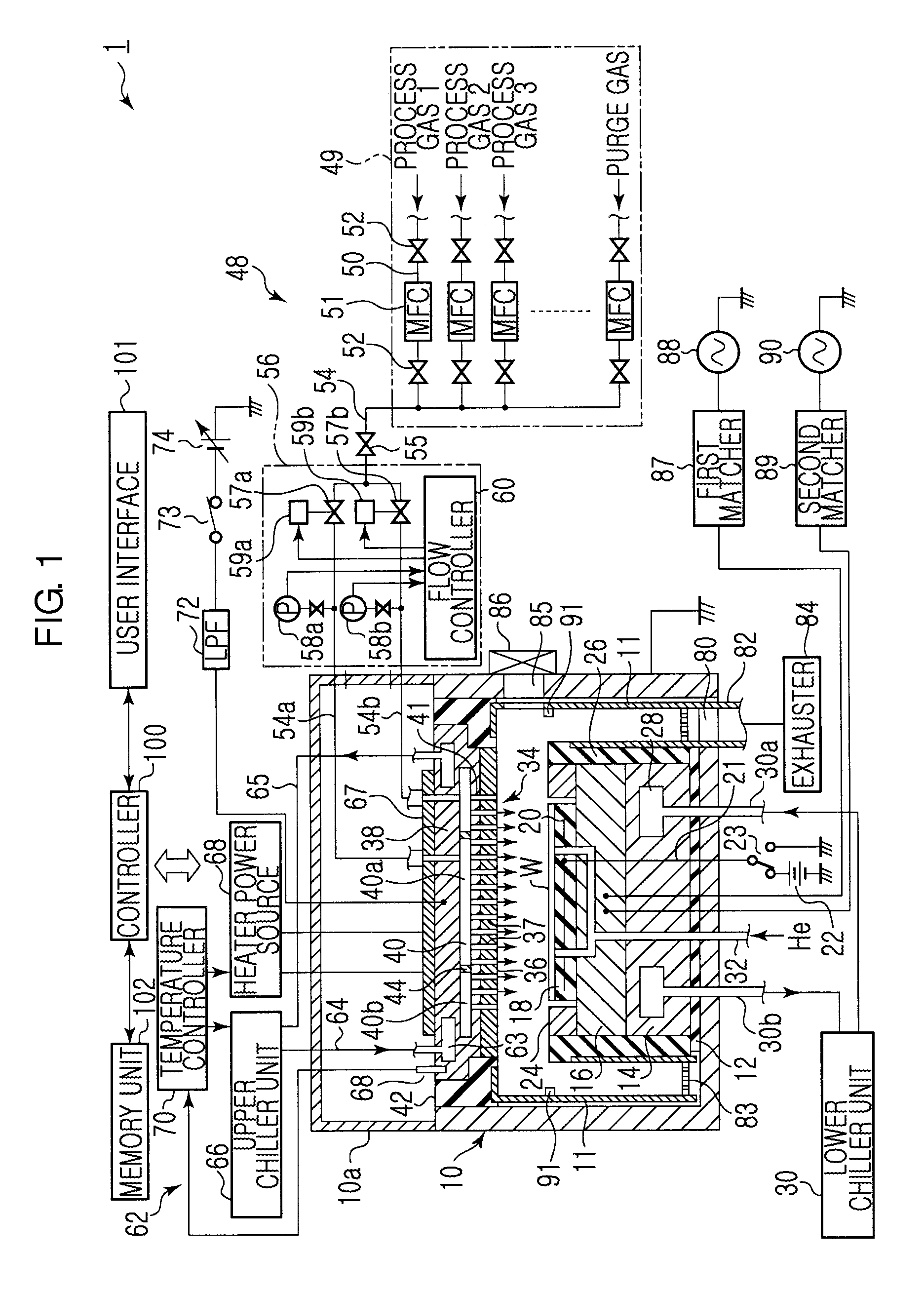

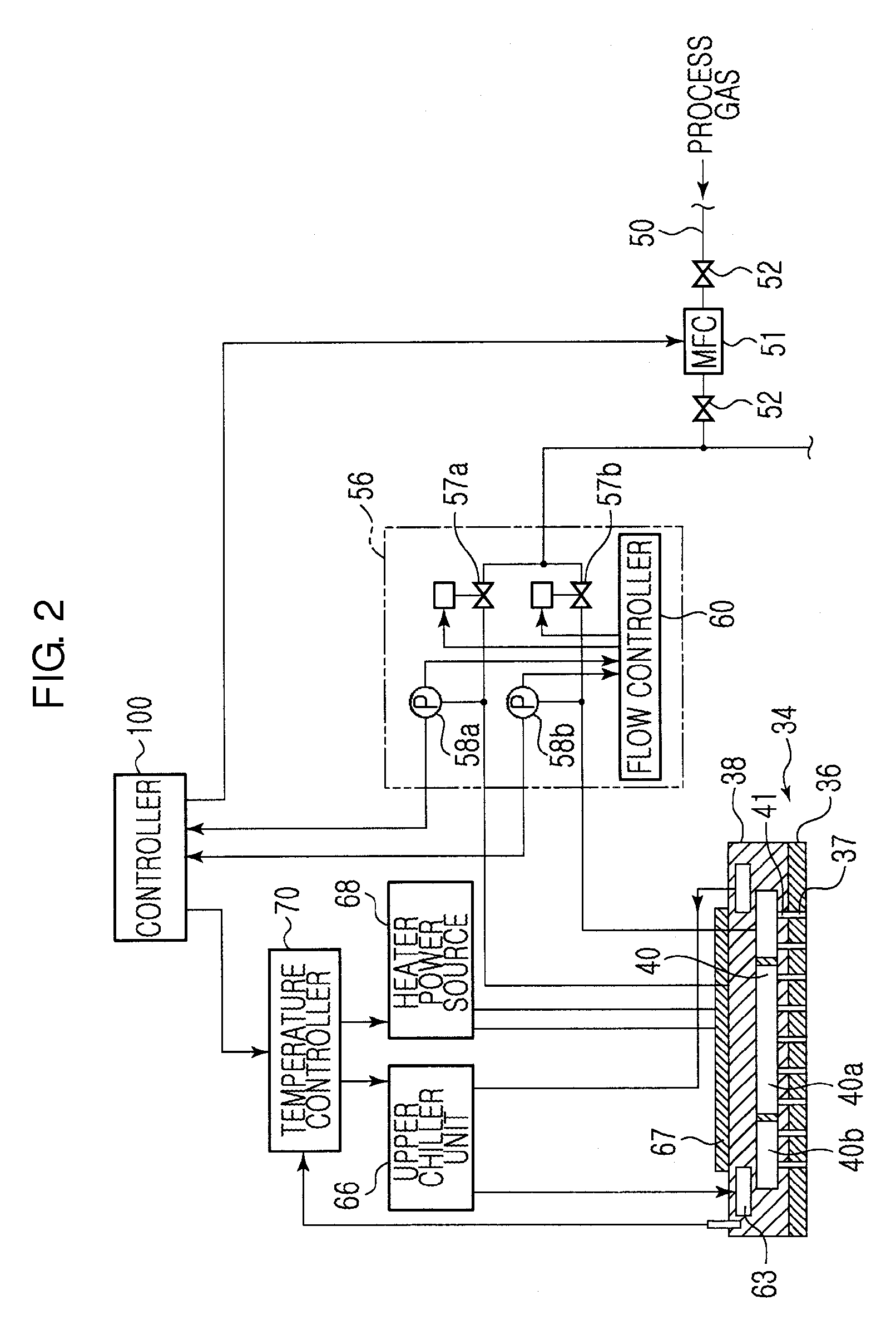

Plasma processing apparatus, plasma processing method, and non-transitory computer-readable medium

ActiveUS9396964B2Suppress mutationElectric discharge tubesSemiconductor/solid-state device manufacturingHigh frequency powerProcess engineering

A plasma processing apparatus includes: a process chamber which accommodates a substrate to be processed; a lower electrode disposed in the process chamber; an upper electrode including an electrode plate that is detachable and discharges a process gas inside the form of shower into the process chamber; a gas supply unit including a central pipe and a edge pipe for supplying the process gas to the upper electrode; a first high frequency power source which applies high frequency power for plasma generation to the lower electrode; pressure indicators which detect pressures inside gas supply pipes; and a controller which measures a degree of consumption of the electrode plate based on the pressures detected by the pressure indicators and calculates a variation in process rate resulting due to the consumption of the electrode plate to adjust process conditions to resolve the variation in process rate.

Owner:TOKYO ELECTRON LTD

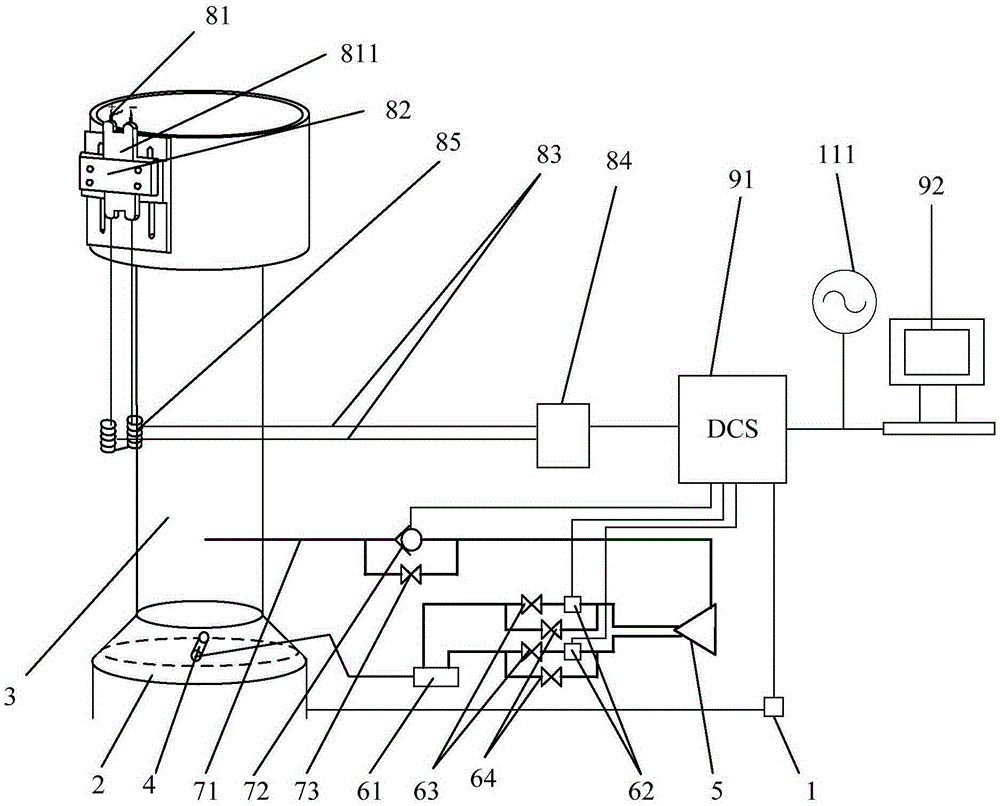

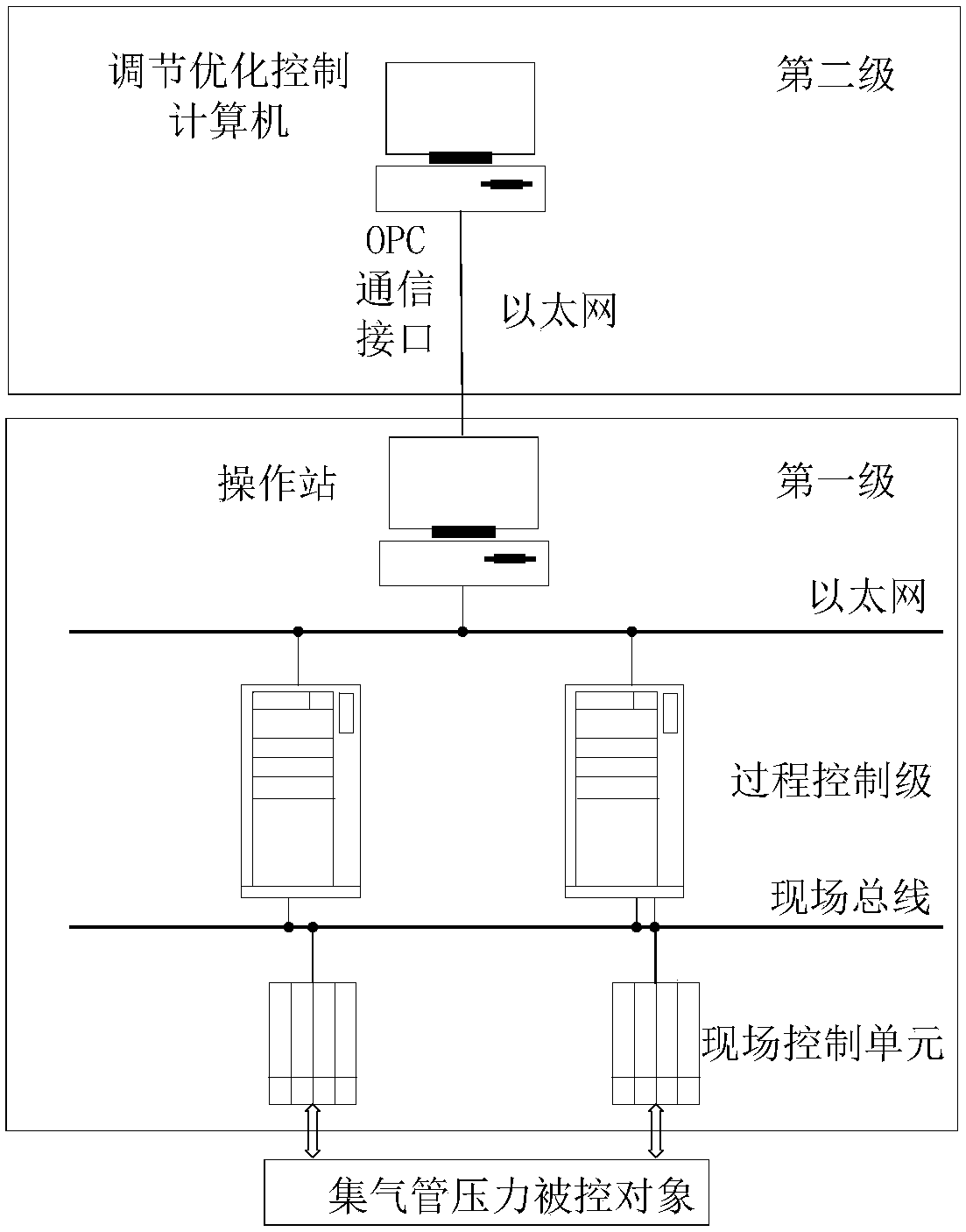

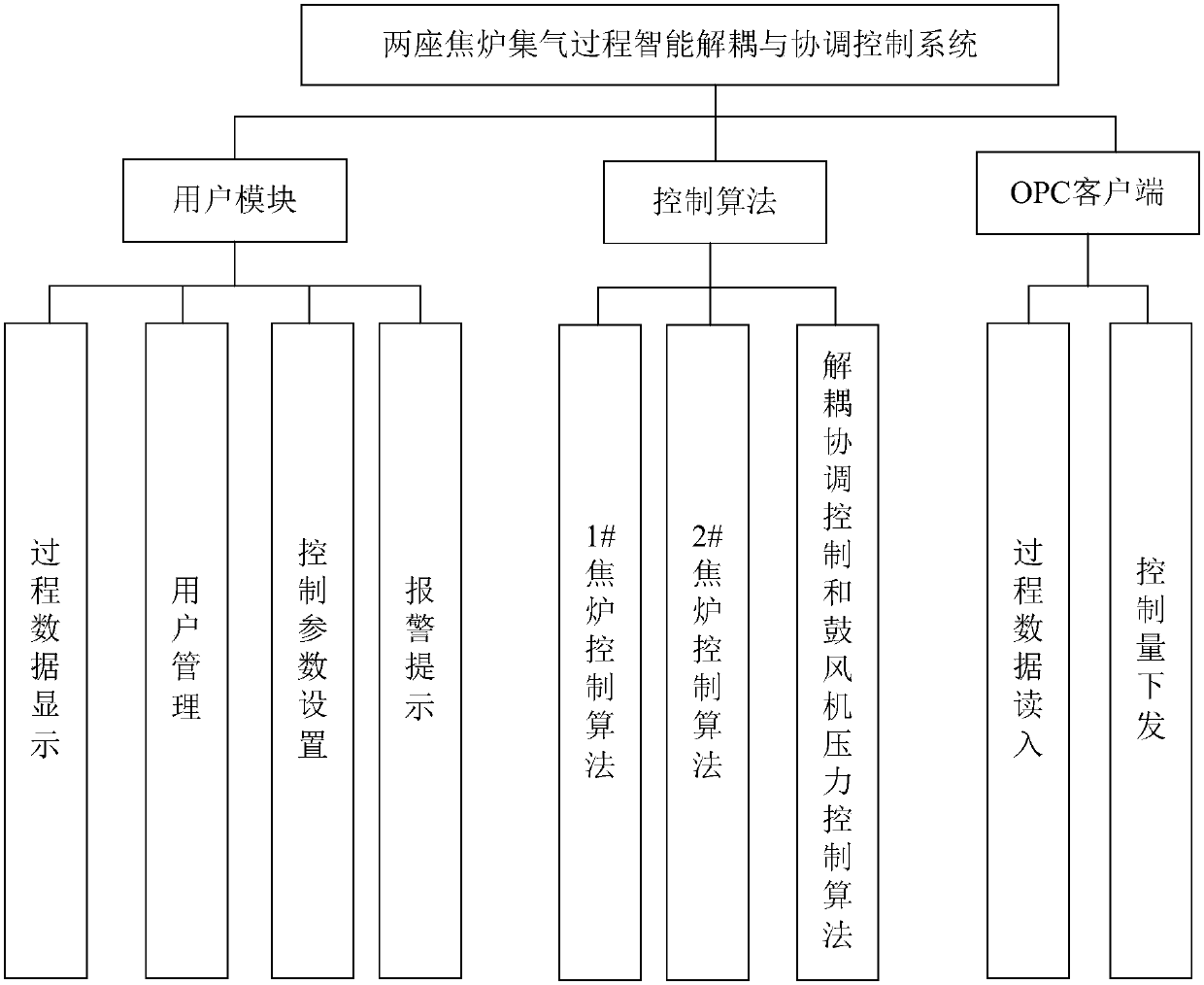

Pressure stabilizing automatic regulating system of coke oven gas collector and regulating method thereof

ActiveCN107903919ARelieve stressStable controlCoke oven safety devicesCharging devicesGas collecting tubeControl system

The invention discloses a pressure stabilizing automatic regulating system of a coke oven gas collector and a regulating method thereof, and can stably control a coke oven gas export system. The pressure stabilizing automatic regulating system comprises a coal charging section electric control valve used for regulating pressure in a coal charging section gas collecting tube, a communication valveused for regulating pressure in a large circulation pipe, a first-stage computer system and a second-stage computer system, wherein the first-stage computer system comprises a DCS control system, a field sensor and an actuating mechanism and is used for realizing field level distributed control; the second-stage computer system regulates the opening of the coal charging section electric control valve and the opening of the communication valve according to the pressure in the coal charging section gas collecting tube.

Owner:攀钢集团西昌钢钒有限公司

Inlet pressure control type camshaft device

InactiveCN102953777AReasonable designSimple structureValve arrangementsMachines/enginesExhaust valveGas compressor

The invention relates to an inlet pressure control type camshaft device in the technical field of machine design. The inlet pressure control type camshaft device comprises an inlet valve, an exhaust valve, a gas compressor, a turbine, a lever, a lifter, a cam, a camshaft, a volume cavity, a moving body, a connecting pipe and a spring, wherein the moving body is mounted in the volume cavity and in hermetical contact with the inner wall surface of the volume cavity, a mounting hole is formed in the left wall surface of the volume cavity, one end of a moving rod penetrates through the mounting hole in the left wall surface of the volume cavity and then is fixedly connected with the left wall surface of the moving body, and the other end of the moving rod is connected with the camshaft. When the pressure in an inlet pipe of an engine is high, the moving body can drive the moving rod to move left and then the lift of the inlet valve is increased; and when the pressure in the inlet pipe of the engine is low, the moving body can drive the moving rod to move right, and the lift of the inlet valve is decreased. The inlet pressure control type camshaft device disclosed by the invention has the advantages of reasonable design and simple structure and is suitable for valve lift variable systems of the engines.

Owner:SHANGHAI JIAO TONG UNIV

Engine air filter blockage reminding device

ActiveCN102678399AReliable reminder signalThe overall structure is simple and reliableAir cleaners for fuelInternal pressureAir filter

The invention relates to an engine air filter blockage reminding device. The engine air filter blockage reminding device solves the problem that at present, after an air filter is blocked, a negative-pressure condition inside an air inlet pipe is unstable, so that an existing alarm device cannot work normally. The engine air filter blockage reminding device comprises a shell, an outer cavity and an inner cavity communicated with an air inlet pipe of an engine are disposed in the shell, and a partition board is arranged between the inner cavity and the outer cavity. The inner cavity is isolated from the outer cavity at an initial position, and the outer cavity is communicated with the external; when the partition board is driven by change of pressure to move to a reminding position, the inner cavity is communicated with the outer cavity, and the outer cavity is isolated from the external. The reminding device is driven to act due to the change of the inner pressure of the air inlet pipe and cannot move along with further change of the inner pressure of the air inlet pipe after the single action, and a reliable reminding signal is provided. In addition, pressure of the outer cavity is converted by means of switching air pressure channels, electronic equipment or other complicated clamping fixing devices are omitted, and the engine air filter blockage reminding device is simple and reliable in structure.

Owner:ZHEJIANG MARINE DEV RES INST

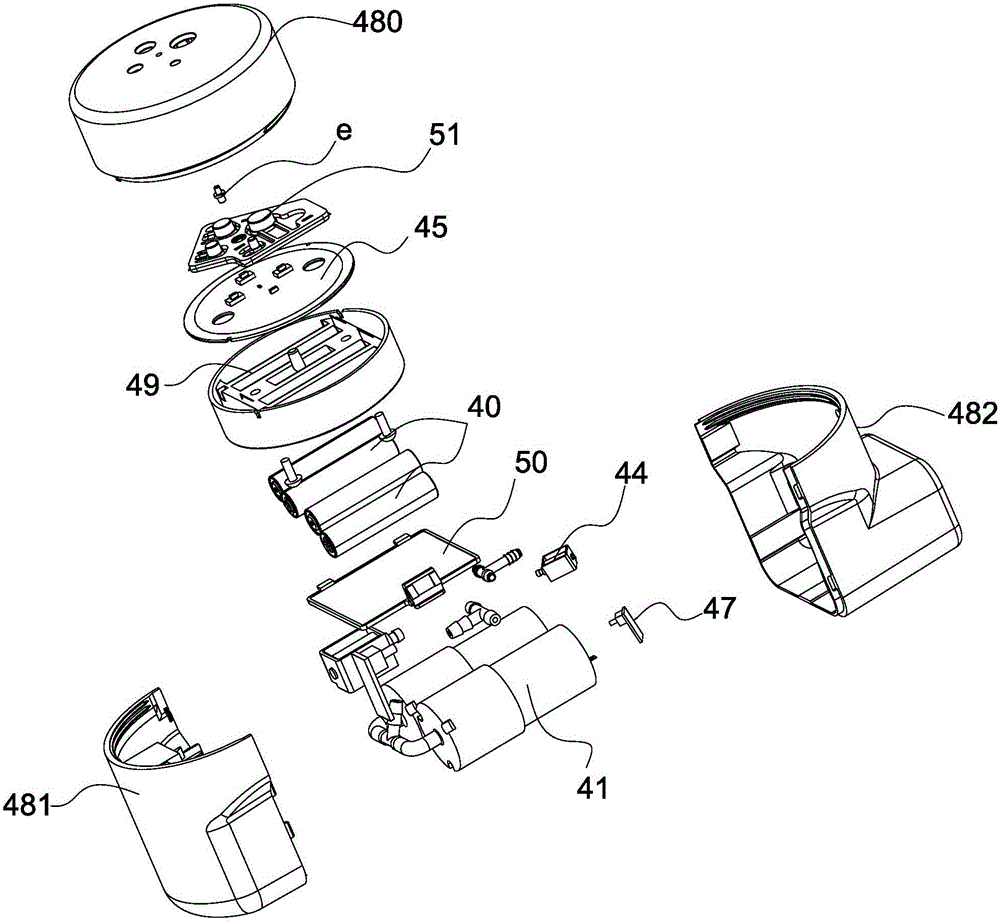

Auxiliary device for inflation product

InactiveCN105134571AHeight adjustableAdjust hardnessPump controlPump installationsKey pressingWireless control

The invention relates to an auxiliary device for an inflation product. The auxiliary device for the inflation product comprises a power source, an electronic pump, a gas guide pipe, an exhaust pipe communicated with the gas guide pipe, an electromagnetic valve arranged on the exhaust pipe, a controller used for controlling the electronic pump to work and the electromagnetic valve to open and close, operation keys connected with the controller, a wireless control chip connected with the controller and a pressure sensor used for detecting the pressure in the inflation product or the gas guide pipe. The pressure sensor is connected with the controller and transmits detected pressure signals to the controller. The auxiliary device has the inflation state and the deflation state, when the auxiliary device is in the inflation state, the electromagnetic valve is closed, the electronic pump supplies gas, and the gas flows into the inflation product through the gas guide pipe; and when the auxiliary device is in the deflation state, the electromagnetic valve is opened, and the gas in the inflation product is exhausted through the gas guide pipe via the exhaust pipe. By the adoption of the auxiliary device, on one hand, the inflation and deflation functions are achieved, and on the other hand, the auxiliary device can be controlled through the keys and can be remotely controlled through a wireless data terminal as well.

Owner:虞冀 +1

Engine oil pressure adjusting device of main oil gallery

InactiveCN103321710ATaking into account the operating conditionsReasonable designLubrication pressure controlMachine designIntratracheal pressure

An engine oil pressure adjusting device of a main oil gallery belongs to the technical field of machine designs and comprises an engine inlet air pipe, an engine oil pump, an oil pan, a volume cavity, a moving body, an elastic part, a connecting pipe and an oil return pipe, wherein the moving body is arranged inside the volume cavity and in contact with the inner wall surface of the volume cavity in a seal mode, the back end of the main oil gallery is communicated with the left wall surface of the volume cavity, two ends of the connecting pipe are communicated with the upper wall surface of the volume cavity and the engine air inlet pipe respectively, two ends of the oil return pipe are communicated with the right wall surface of the volume cavity and the lower wall surface of the oil pan, and the lower wall surface of the moving body is connected with the lower wall surface of the volume cavity through the elastic part. When pressure in the engine air inlet pipe is relatively low, the moving body moves upwards, the main oil gallery is communicated with the oil return pipe, and the engine oil pressure of the main oil gallery is reduced; when the pressure in the engine air inlet pipe is relatively high, the moving body moves downwards, the main oil gallery is separated from the oil return pipe, and the engine oil pressure of the main oil gallery is increased. The engine oil pressure adjusting device of the main oil gallery is reasonable in design, simple in structure and applicable to engines with supercharging systems.

Owner:SHANGHAI JIAO TONG UNIV

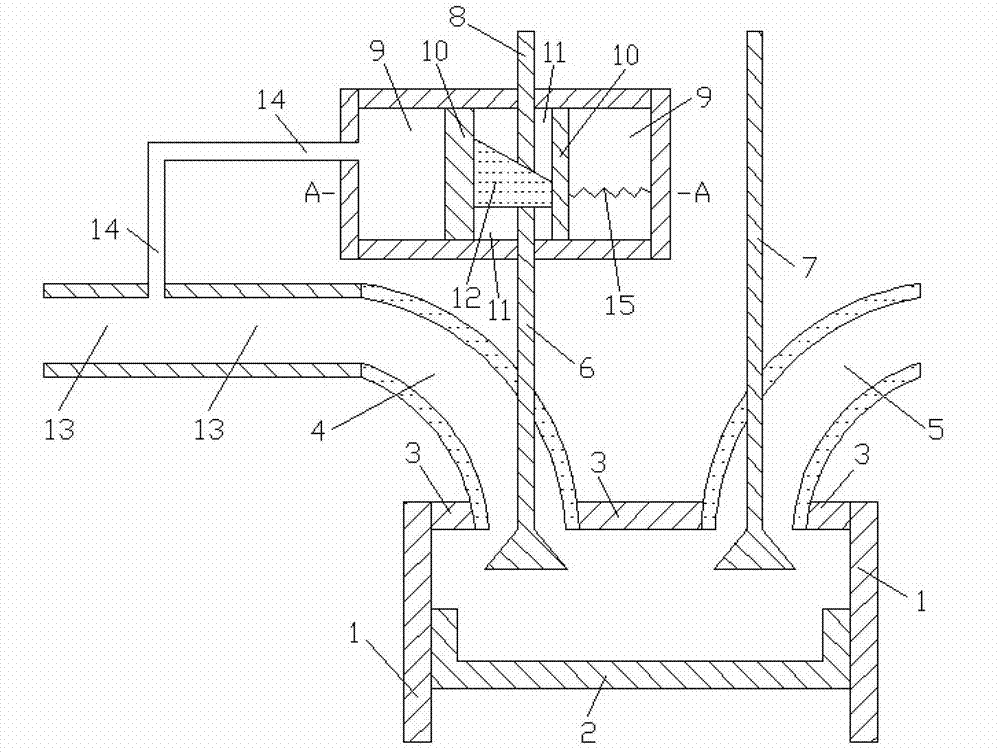

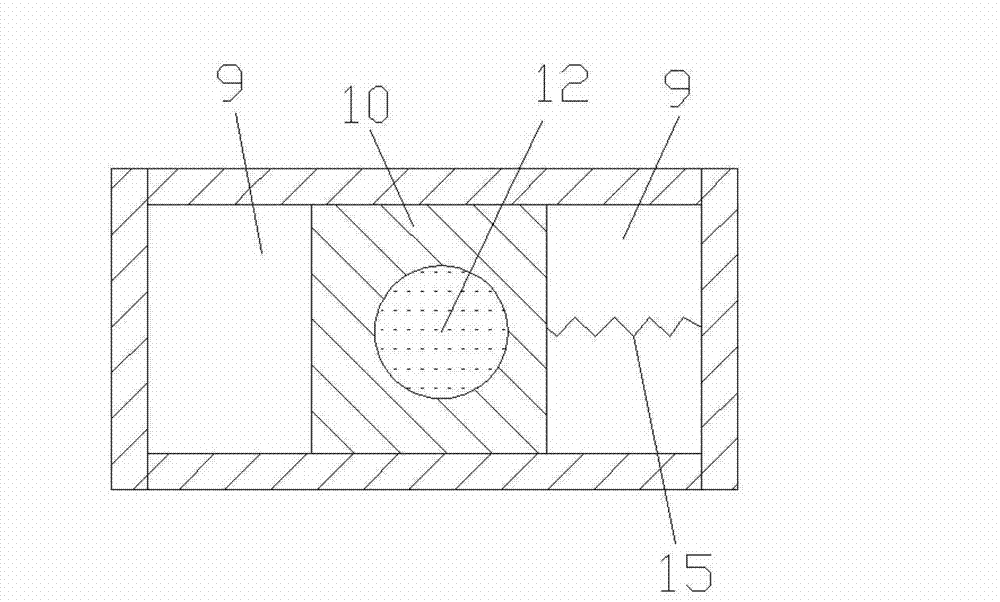

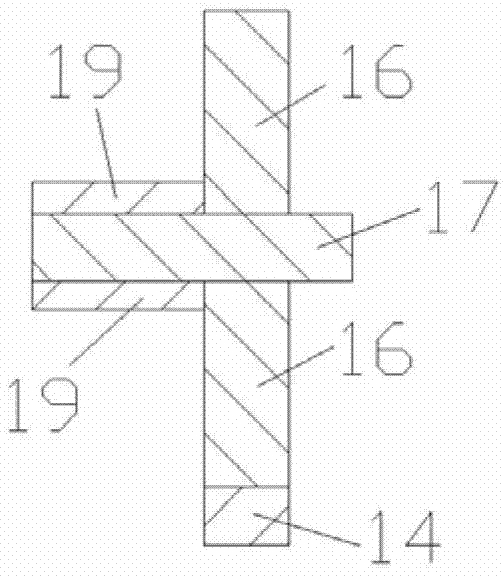

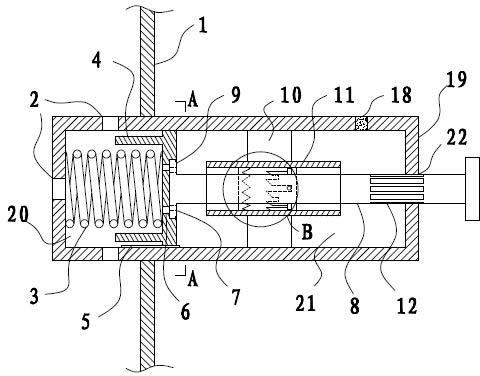

Lever regulation type lift variable system

InactiveCN102953779AReasonable designSimple structureMachines/enginesNon-mechanical valveIntratracheal pressureEngineering

The invention relates to a lever regulation type lift variable system in the technical field of machine design. The lever regulation type lift variable system comprises an inlet valve, an exhaust valve, a gas compressor, a turbine, a lever, a lifter, a volume cavity, a moving body, a connecting pipe and a spring, wherein the moving body is mounted in the volume cavity and in hermetical contact with the inner wall surface of the volume cavity, a square hole is formed in the upper wall surface of the volume cavity, the lower end of a moving rod penetrates through the square hole in the upper wall surface of the volume cavity and then is fixedly connected with the upper wall surface of the moving body, and the upper end of the moving rod is in contact with the lever. When the pressure in an inlet pipe of an engine is high, the moving body can drive the moving rod to move right and then the lift of the inlet valve is increased; and when the pressure in the inlet pipe is low, the moving body can drive the moving rod to move left, and the lift of the inlet valve is decreased. The lever regulation type lift variable system disclosed by the invention has the advantages of reasonable design and simple structure and is suitable for valve lift variable systems of the engines.

Owner:SHANGHAI JIAO TONG UNIV

Internal transportation machinery flow division device

InactiveCN104895644ATaking into account the operating conditionsReasonable designLubrication pressure controlLubricationIntratracheal pressure

The invention relates to the mechanical design technical field, particularly to an internal transportation machinery flow division device. The internal transportation machinery flow division device comprises control chambers, a valve body, a filling body, a fixing body, penetrating pipes, a spring, a rotating block, a rotating plate, a connecting plate, a rotating shaft and a connecting pipe; the lower section of the valve body is in a conical shape; the middle section of the valve body is provided with four ribs; the upper section of the valve body is provided with external threads; the first penetrating pipe and he second penetrating pipe are arranged on the fixing body; the area of the cross section of the first penetrating pipe is smaller than that of the cross section of the second penetrating pipe; one end of the connecting pipe is communicated with an internal chamber body of the second control chamber; the other end of the connecting pipe is communicated with an intake pipe of an engine. When the pressure in the intake pipe of the engine is high, the valve body moves upward, a main oil channel and an oil return pipe are partitioned, and the pressure of the engine oil of the main oil channel is increased. When the pressure in the intake pipe of the engine is low, the valve body moves downward, the main oil channel is communicated with the oil return pipe, and the pressure of the engine oil of the main oil channel is reduced. The internal transportation machinery flow division device is reasonable in design, simple in structure and suitable for the optimized design of mechanical lubrication systems.

Owner:高雅

Valve adjusting mechanism with groove structure

InactiveCN103233794AReasonable designSimple structureValve arrangementsMachines/enginesExhaust valveInlet valve

The invention discloses a valve adjusting mechanism with a groove structure, and belongs to technical field of mechanical design. The valve adjusting mechanism comprises an inlet valve, an exhaust valve, a compressor, a turbine, a lever, a tappet, a volume cavity, a moving body, a fulcrum bar and a connecting pipe, wherein the moving body is mounted in the volume cavity and is in contact with the inner wall surface of the volume cavity hermetically; a round hole is formed in the upper wall surface of the volume cavity; the lower end of the fulcrum bar passes through the round hole in the upper wall surface of the volume cavity and then is in contact with the inclined plane of a triangular groove; and the upper end of the fulcrum bar is in contact with the lever. When the pressure in an air inlet pipe of an engine is higher, the fulcrum bar is moved downwards, and the inlet valve lift becomes high; and when the pressure in the air inlet pipe of the engine is lower, the fulcrum bar is moved upwards, the inlet valve lift becomes low. The valve adjusting mechanism is reasonable in design, simple in structure, and suitable for engine valve stroke variable system.

Owner:SHANGHAI JIAO TONG UNIV

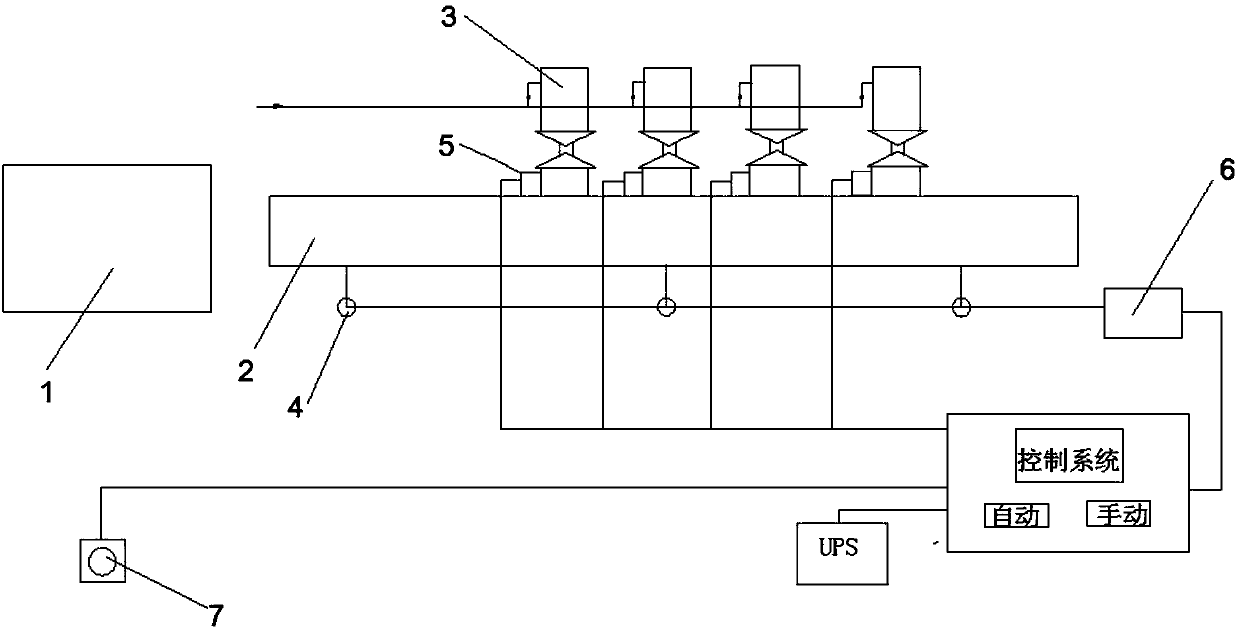

Diffusion system and diffusion method for coke oven raw gas emergency ignition

PendingCN107641517ARelease automatically stopsCoke oven safety devicesEnergy inputDiffusion methodsSolenoid valve

The invention discloses a diffusion system and a diffusion method for coke oven raw gas emergency ignition. The diffusion system is provided with a coal tower, at least two diffusion pipes, a solenoidvalve, a pressure gage, a button and an UPS (Uninterrupted Power Supply), wherein the coal tower is provided with a gas collection pipe; the diffusion pipes are communicated with the gas collection pipe; the solenoid valve is arranged on the connection part of the diffusion pipes and the gas collection pipe; the pressure gage is arranged on the gas collection pipe and is capable of detecting pressure in the gas collection pipe; the button is connected with the solenoid valve through a circuit and controls the solenoid valve to be switched on and off; the UPS (Uninterrupted Power Supply) is connected with the solenoid valve through a circuit to provide uninterrupted power for the diffusion system, a situation that operation can not be carried out due to outage is avoided, the raw gas of the gas collection pie can be timely and quickly diffused, and a normal working condition is recovered in time according to a working condition so as to stabilize the pressure of the gas collection pipeand lower potential safety hazards.

Owner:MAANSHAN IRON & STEEL CO LTD

Air inlet pressure adjusting type parallel connection boost system

InactiveCN103089399AReduce lossesReasonable designInternal combustion piston enginesInlet pressureEngineering

An air inlet pressure adjusting type parallel connection boost system belongs to the technical field of mechanical design and comprises an air compressor, an engine, a turbine, connection pipes, through pipes, a volume cavity, a movable body and a spring. The movable body is installed in the volume cavity and is in sealing contact with the inner wall of the volume cavity, a first through pipe, a second through pipe and a third through pipe all penetrate through the upper wall and the lower wall of the movable body, two ends of a first connection pipe are respectively communicated with an air inlet pipe of the engine and the left wall of the volume cavity, and the right wall of the movable body is connected with the right wall of the volume cavity through the spring. When pressure in the air inlet pipe of the engine is high, the movable body moves towards right, and two boosters can be in parallel connection to work. When pressure in the air inlet pipe of the engine is low, the movable body moves towards left, and only a first booster works. The air inlet pressure adjusting type parallel connection boost system is reasonable in design, simple in control strategies and suitable for turbine boost systems with the number of the turbines different.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com